ASTM D246-95e1

(Test Method)Standard Test Method for Distillation of Creosote and Creosote-Coal Tar Solutions

Standard Test Method for Distillation of Creosote and Creosote-Coal Tar Solutions

SCOPE

1.1 This test method covers a procedure for the distillation of creosote and creosote-coal tar solution. Test Methods D38 covers the sampling of wood preservatives prior to testing.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

e1

Designation: D 246 – 95 Highway Transportation Officials Standard

AASHTO No. T 62

Standard Test Method for

Distillation of Creosote and Creosote-Coal Tar Solutions

This standard is issued under the fixed designation D 246; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—An editorial correction was made in 5.8 in March 1998.

1. Scope 4. Significance and Use

1.1 This test method covers a procedure for the distillation 4.1 Creosote quality is defined by the boiling ranges of its

of creosote and creosote-coal tar solution. Test Methods D 38 distillation fractions. The boiling limits of the fractions as

covers the sampling of wood preservatives prior to testing. determined by this test method must conform to the limits

1.2 This standard does not purport to address all of the established by Specifications D 390 and D 391 to qualify the

safety concerns, if any, associated with its use. It is the creosote as an acceptable preservative for its intended appli-

responsibility of the user of this standard to establish appro- cation.

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Flask—Distillation flask, 300 mL, specified as Type II,

2. Referenced Documents

Class 2 in Specification E 1405.

2.1 ASTM Standards: 5.2 Condenser Tube—A tapered glass condenser, as shown

D 38 Test Methods for Sampling Wood Preservatives Prior in Fig. 1 and Fig. 2, conforming to the following dimensions:

to Testing

Diameter of small end, outside 12.5 6 1.5 mm

Diameter of large end, outside 28.5 6 3.0 mm

D 370 Test Method for Dehydration of Oil-Type Preserva-

Length 360 64mm

tives

Length of tapered part 100 65mm

D 390 Specification for Coal-Tar Creosote for the Preserva-

5.3 Source of Heat—A source of heat consisting of a bunsen

tive Treatment of Piles, Poles, and Timbers for Marine,

or Meker type gas burner or an electric heater. The electric

Land, and Fresh Water Use

2 heater shall have an output variable to 600 or to 750 W and

D 391 Specification for Creosote-Coal Tar Solution

removable upper and lower refractories as illustrated in Fig. 3.

E 1 Specification for ASTM Thermometers

4 The temperature of the heater shall be controlled by a variable

E 1404 Specification for Laboratory Glass Conical Flasks

transformer or rheostate suitable for the voltage used, and shall

E 1405 Specification for Laboratory Glass Distillation

4 be fitted with a clamp for mounting on a vertical support rod.

Flasks

5.4 Flask Shield for Flame Distillation—A stainless steel

3. Summary of Test Method shield, fitted with mica windows and lined with ⁄8-in. heat-

resistant ceramic board, with two-part cover made from ⁄4-in.“

3.1 A 100-g sample is distilled at a controlled rate in a

Transite” board of the forms and dimensions shown in Fig. 4.

300-mL flask. The weights of distillate fractions at a series of

5.5 Flask Shield for Electric-Heater Distillation—A stain-

specified temperatures and of residue at the maximum specified

less steel shield fitted with mica windows and cover of the

temperature are determined. The residue and distillates may be

same construction and dimensions as those for flame distilla-

tested by appropriate procedures.

tion (5.4), except for the height of the shield. See Fig. 5.

5.6 Gauze—Two sheets of 16-mesh wire gauze made with

This test method is under the jurisdiction of ASTM Committee D-7 on Wood

0.51-mm (0.02-in.) diameter Nichrome wire and 125 to 152

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

mm in diameter or square.

Products.

5.7 Burner Chimney for Flame Distillation—A cylindrical

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as D 246 – 26 T. Last previous edition D 246 – 95.

metal chimney approximately 100 mm high, 95 to 105 mm in

This test method is identical in substance with the Standard Method of

diameter, and having a peephole 25 mm in diameter centered

Distillation which is part of the American Wood-Preservers’ Association Standard

about 32 mm below the ring support, used to protect the flame

Methods for Analysis of Creosote and Oil-Type Preservatives (A1). Acknowledg-

ment is made to the American Wood Preservers’ Association for its development of

the subject matter covered in this test method.

Annual Book of ASTM Standards, Vol 04.10.

3 5

Annual Book of ASTM Standards, Vol 14.03. The “Precision” Ful-Kontrol 750-W heater with built-in variable transformer

Annual Book of ASTM Standards, Vol 14.02. control has been found satisfactory. This heater is available for 115 V, 50/60 Hz only.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 246

FIG. 1 Apparatus Assembly for Flame Distillation

FIG. 2 Apparatus Assembly for Electric-Heater Distillation

FIG. 3 Upper Part of Electric Heater

from air currents. The top of the shield should be flanged to 5.8 Receivers—Standard 125-mL conical flasks, specified

permit its being suspended from the ring support. as Type I, Class 1 in Specification E 1404.

D 246

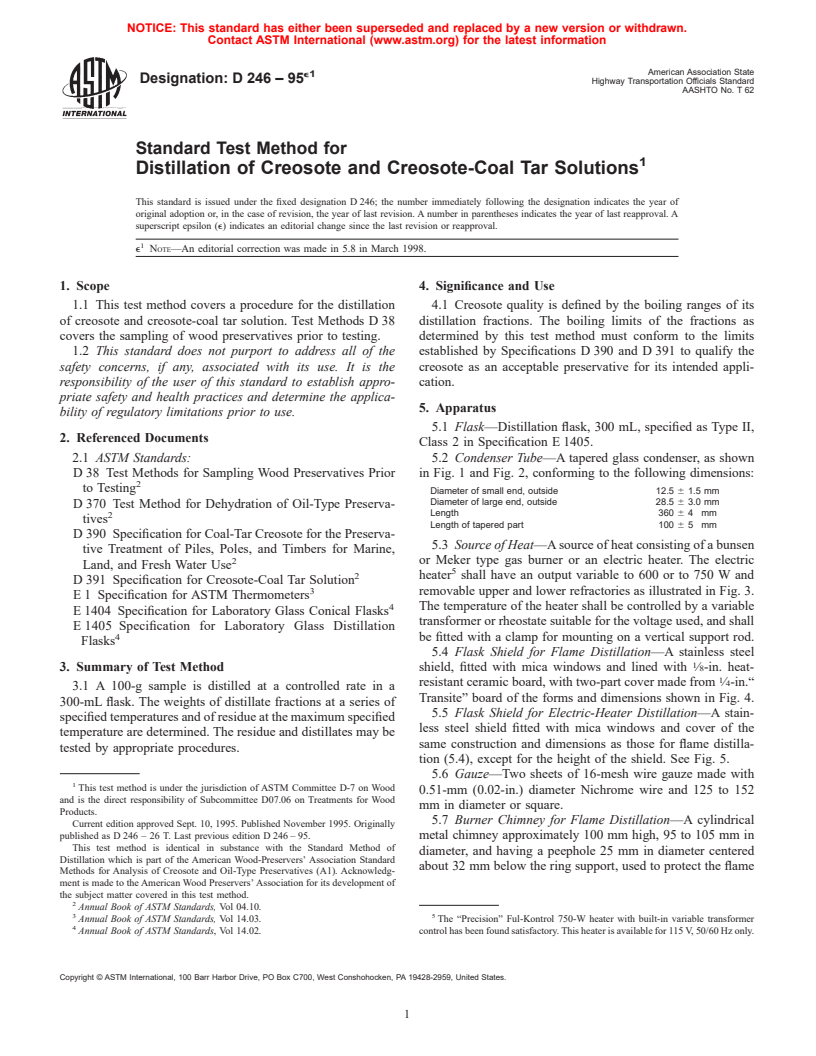

NOTE 1—Flanged open-end cylinder made of 22-gage stainless steel with ⁄8-in. heat-resistant ceramic board lining.

NOTE 2—Two mica windows are provided at right angles to the end slot.

FIG. 4 Shield and Cover for Flame Distillation

7. Dehydration of Sample

7.1 If not more than 3.0 % of water is present, the sample

may be tested without previous dehydration. If the water

content exceeds 3.0 %, dehydrate a representative portion of

the sample before distillation, in accordance with Test Method

D 370. In case of dispute the determination shall be carried out

on a dehydrated sample.

8. Apparatus Assembly

8.1 Assemble the apparatus as described in 8.1.1-8.1.3 and

as shown in Fig. 2 and Fig. 3.

8.1.1 Suspend the burner chimney by its flange from the

support ring, place the specified two sheets of wire gauze on

the burner chimney, and place the flask shield on the upper

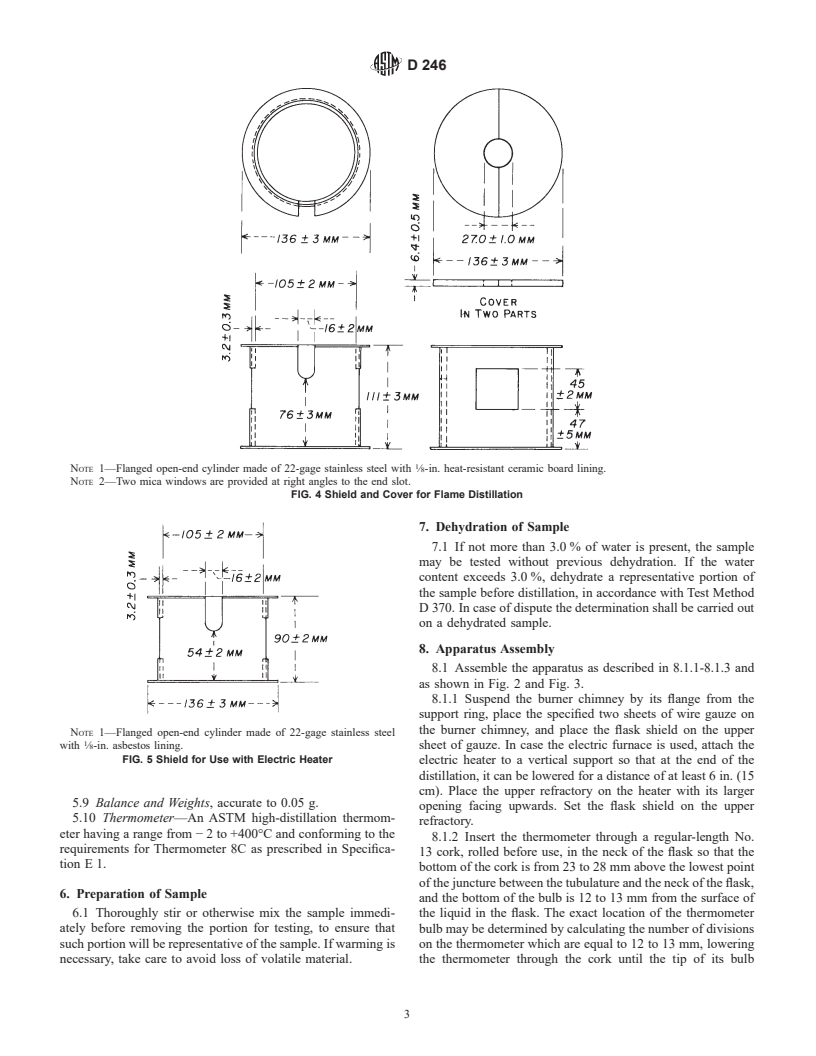

NOTE 1—Flanged open-end cylinder made of 22-gage stainless steel

with ⁄8-in. asbestos lining. sheet of gauze. In case the electric furnace is used, attach the

FIG. 5 Shield for Use with Electric Heater

electric heater to a vertical support so that at the end of the

distillation, it can be lowered for a distance of at least 6 in. (15

cm). Place the upper refractory on the heater with its larger

5.9 Balance and Weights, accurate to 0.05 g.

opening facing upwards. Set the flask shield on the upper

5.10 Thermometer—An ASTM high-distillation thermom-

refractory.

eter having a range from − 2 to +400°C and conforming to the

8.1.2 Insert the thermometer through a regular-length No.

requirements for Thermometer 8C as prescribed in Specifica-

13 cork, rolled before use, in the neck of the flask so that the

tion E 1.

bottom of the cork is from 23 to 28 mm above the lowest point

of the juncture between the tubulature and the neck of the flask,

6. Preparation of Sample

and the bottom of the bulb is 12 to 13 mm from the surface of

6.1 Thoroughly stir or otherwise mix the sample immedi- the liquid in the flask. The exact location of the thermometer

ately before removing the portion for testing, to ensure that bulb may be determined by calculating the number of divisions

such portion will be representative of the sample. If warming is on the thermometer which are equal to 12 to 13 mm, lowering

necessary, take care to avoid loss of volatile material. the thermometer through the cork until the tip of its bulb

D 246

TABLE 1 Adjustment of Distillation Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.