ASTM D8223-19

(Practice)Standard Practice for Evaluation of Fire-Retardant Treated Laminated Veneer Lumber

Standard Practice for Evaluation of Fire-Retardant Treated Laminated Veneer Lumber

SIGNIFICANCE AND USE

5.1 Design values obtained from 4.2 are permitted for use in design where the end-use temperature does not exceed 38 °C (100 °F).

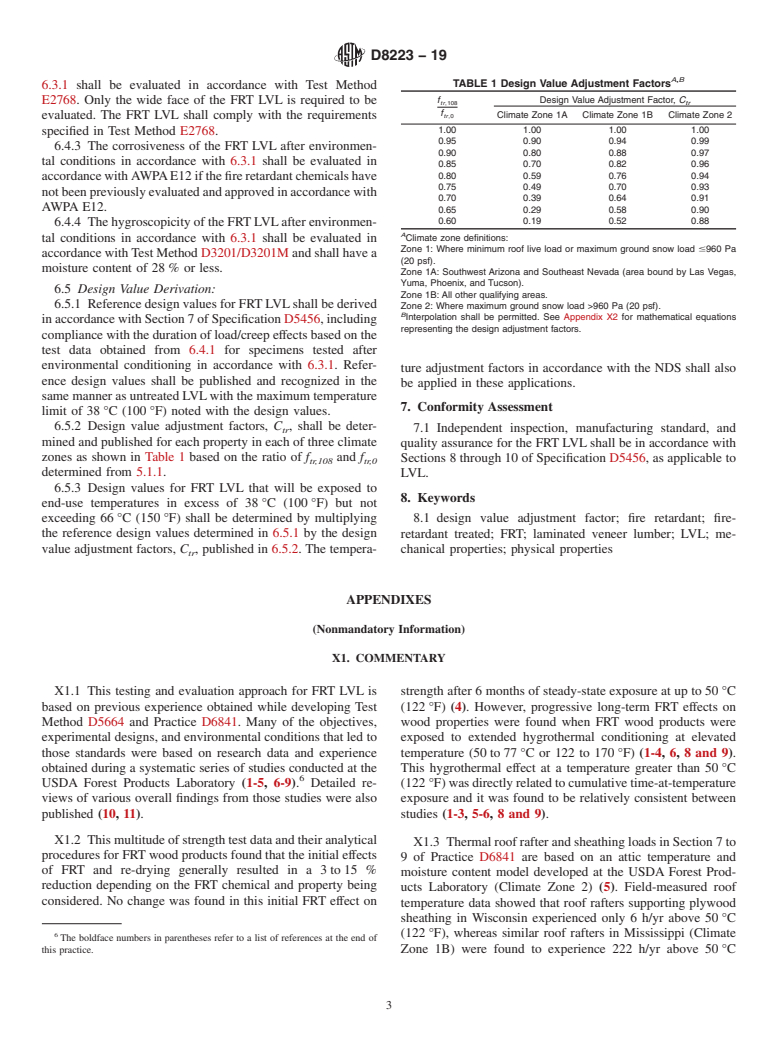

5.1.1 The mean test values for the properties evaluated in 4.2 (ftr,0) and 4.3 (ftr,108) shall be used to determine design value adjustment factors for FRT LVL that will be exposed to end-use temperatures in excess of 38 °C (100 °F) but not exceeding 66 °C (150 °F). Temperature adjustment factors in accordance with the National Design Specification for Wood Construction (NDS) shall also be applied in these applications.

SCOPE

1.1 This practice covers procedures for the evaluation of laminated veneer lumber (LVL) pressure-treated with commercially available fire retardants after exposure to both standard environmental conditions and an extended exposure to elevated temperature.

1.2 LVL products utilizing overlays or fire-retardant paints and coatings require other considerations and are outside of the scope of this practice.

1.3 LVL products manufactured for rim board applications require other considerations and are outside of the scope of this practice.

1.4 This practice provides one method to establish design values for fire-retardant treated (FRT) LVL. It is not intended to preclude the use of alternative methods for deriving design values, such as Test Method D5664 and Practice D6841 for FRT lumber.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8223 − 19

Standard Practice for

Evaluation of Fire-Retardant Treated Laminated Veneer

1

Lumber

This standard is issued under the fixed designation D8223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3201/D3201M Test Method for Hygroscopic Properties of

Fire-Retardant Wood and Wood-Based Products

1.1 This practice covers procedures for the evaluation of

D5456 Specification for Evaluation of Structural Composite

laminated veneer lumber (LVL) pressure-treated with commer-

Lumber Products

cially available fire retardants after exposure to both standard

D5664 Test Method for Evaluating the Effects of Fire-

environmentalconditionsandanextendedexposuretoelevated

Retardant Treatments and Elevated Temperatures on

temperature.

Strength Properties of Fire-Retardant Treated Lumber

1.2 LVL products utilizing overlays or fire-retardant paints

D6841 Practice for Calculating Design Value Treatment

andcoatingsrequireotherconsiderationsandareoutsideofthe

Adjustment Factors for Fire-Retardant-Treated Lumber

scope of this practice.

E84 Test Method for Surface Burning Characteristics of

1.3 LVL products manufactured for rim board applications Building Materials

E2768 Test Method for Extended Duration Surface Burning

requireotherconsiderationsandareoutsideofthescopeofthis

practice. CharacteristicsofBuildingMaterials(30minTunnelTest)

2.2 Other Standards:

1.4 This practice provides one method to establish design

ANSI/AWC National Design Specification for Wood Con-

valuesforfire-retardanttreated(FRT)LVL.Itisnotintendedto

3

struction

preclude the use of alternative methods for deriving design

AWPA E12 Standard Method for Determining Corrosion of

values, such as Test Method D5664 and Practice D6841 for

4

Metal in Contact with Treated Wood

FRT lumber.

UL723 Test for Surface Burning Characteristics of Building

1.5 This standard does not purport to address all of the

5

Materials

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Definitions—Definitions used in this practice are in

mine the applicability of regulatory limitations prior to use.

accordance with Terminology D9 and Specification D5456.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.2 Definitions of Terms Specific to This Standard:

ization established in the Decision on Principles for the

3.2.1 design value adjustment factor, C —factor used to

tr

Development of International Standards, Guides and Recom- adjust the design value for FRT LVL that will be exposed to

mendations issued by the World Trade Organization Technical

end-use temperatures in excess of 38 °C (100 °F) but not

Barriers to Trade (TBT) Committee. exceeding 66 °C (150 °F), depending on the ratio of f and

tr,108

f , and the climate zone.

tr,0

2. Referenced Documents

3.2.2 f —mean property of FRT LVL equilibrated to

tr,0

2

2.1 ASTM Standards:

standard conditions of 6.3.1.

D9 Terminology Relating to Wood and Wood-Based Prod-

3.2.3 f —mean property of FRT LVL after 108-day

tr,108

ucts

exposure to elevated temperature and relative humidity of

6.3.2.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

and is the direct responsibility of Subcommittee D07.07 on Fire Performance of

Wood.

3

Current edition approved July 1, 2019. Published August 2019. DOI: 10.1520/ AvailablefromAmericanWoodCouncil(AWC),222CatoctinCircle,SE,Suite

D8223-19. 201, Leesburg, VA 20175, http://www.awc.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Wood Protection Association (AWPA), P.O. Box

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

5

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), 333 Pfingsten Road,

the ASTM website. Northbrook, IL 60062-2096, https://www.ulstandards.ul.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8223 − 19

4. Summary of Practice untreated LVL that has been previously evaluated in accor-

dance with Specification D5456, this section is not required.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.