ASTM D2210-00(2008)

(Test Method)Standard Test Method for Grain Crack and Extension of Leather by the Mullen Test

Standard Test Method for Grain Crack and Extension of Leather by the Mullen Test

SIGNIFICANCE AND USE

The test method is designed to measure the force required to crack the grain of leather by steady hydraulic pressure on a diaphragm of definite diameter applied to the flesh side of the specimen to form a sphere. The cracking of the grain is a result of failure under elongation or stretch. The elongation or stretch of the leather can be measured at different loads or at the failure of the grain to determine if the stress leather will withstand under lasting conditions. Cuts, scratches, and other defects will cause considerable variation in the results by concentration of the applied force to the weak points. This test method is excellent for manufacturing control, specification acceptance, and service evaluation in the lasting property of leather. This test method may not apply when the conditions of the test employed differ widely from those specified in the test method.

SCOPE

1.1 This test method covers the determination of the resistance of leather to grain cracking and for measuring the extension of the leather. It is limited to light leathers such as shoe uppers, garment, gloves, and upholstery. This test method does not apply to wet blue.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2210 − 00 (Reapproved2008)

Standard Test Method for

1

Grain Crack and Extension of Leather by the Mullen Test

This standard is issued under the fixed designation D2210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope fleshsideofthespecimentoformasphere.Thecrackingofthe

grain is a result of failure under elongation or stretch. The

1.1 This test method covers the determination of the resis-

elongationorstretchoftheleathercanbemeasuredatdifferent

tance of leather to grain cracking and for measuring the

loads or at the failure of the grain to determine if the stress

extension of the leather. It is limited to light leathers such as

leatherwillwithstandunderlastingconditions.Cuts,scratches,

shoe uppers, garment, gloves, and upholstery.This test method

and other defects will cause considerable variation in the

does not apply to wet blue.

resultsbyconcentrationoftheappliedforcetotheweakpoints.

1.2 This standard does not purport to address all of the

This test method is excellent for manufacturing control, speci-

safety concerns, if any, associated with its use. It is the

fication acceptance, and service evaluation in the lasting

responsibility of the user of this standard to establish appro-

property of leather. This test method may not apply when the

priate safety and health practices and determine the applica-

conditions of the test employed differ widely from those

bility of regulatory limitations prior to use.

specified in the test method.

2. Referenced Documents

5. Apparatus

2

2.1 ASTM Standards:

3

5.1 Testing Machine, asshowninFig.1.Themachineshall

D1610Practice for Conditioning Leather and Leather Prod-

be hand- or power-driven. The machine shall hold the speci-

ucts for Testing

men firmly, without slippage, between two annular, plane,

D1813Test Method for Measuring Thickness of Leather

unpolished (matte) surfaces that may have fine, spiral tool

Test Specimens

marks not over 0.010 in. (0.25 mm) in depth.

3. Terminology

5.2 Upper Clamping Surface—The upper clamping surface

(clampingring)shallhaveacircularopening1.240 60.010in.

3.1 Definitions:

(31.50 6 0.25 mm) in diameter and shall be connected to the

3.1.1 extension—the amount of stretch of leather over the

clamping mechanism through a swivel joint to ensure an even

diaphragm under pressure.

clamping pressure.

3.1.2 grain cracking—the appearance of cracks on the

5.3 Lower Clamping Surface—The lower clamping surface

surface of the leather as the leather is extended over a

(diaphragmplate)shallbe0.219 60.003in.(5.56 60.08mm)

diaphragm under pressure to form a sphere.

thick and have an opening of 1.240 6 0.01 in. (31.50 6 0.52

4. Significance and Use

mm) in diameter.The circular edges of the openings that come

incontactwiththespecimenandtherubberdiaphragmshallbe

4.1 The test method is designed to measure the force

rounded to a radius of not over 0.025 in. (0.64 mm) to prevent

required to crack the grain of leather by steady hydraulic

any cutting action. During the test, the circular edges of the

pressure on a diaphragm of definite diameter applied to the

openings in the two clamping plates shall be substantially

concentric with no overlapping of any point.

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

5.4 Diaphragm, of rubber, 0.034 6 0.002 in. (0.86 6 0.05

and is the direct responsibility of Subcommittee D31.03 on Footwear. This test

mm) thick, clamped under the lower clamping plate so that,

method was developed in cooperation with the American Leather Chemists Assn.

(Standard Method E58–1965).

Current edition approved Sept. 1, 2008. Published December 2008. Originally

approved in 1963 as D2210–63T. Last previous edition approved in 2004 as

3

D2210–00(2004). DOI: 10.1520/D2210-00R08. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is B. F. Perkins, 939 Chicopee St., Chicopee, MA 01013-2797, (413) 536-1311. If

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM you are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

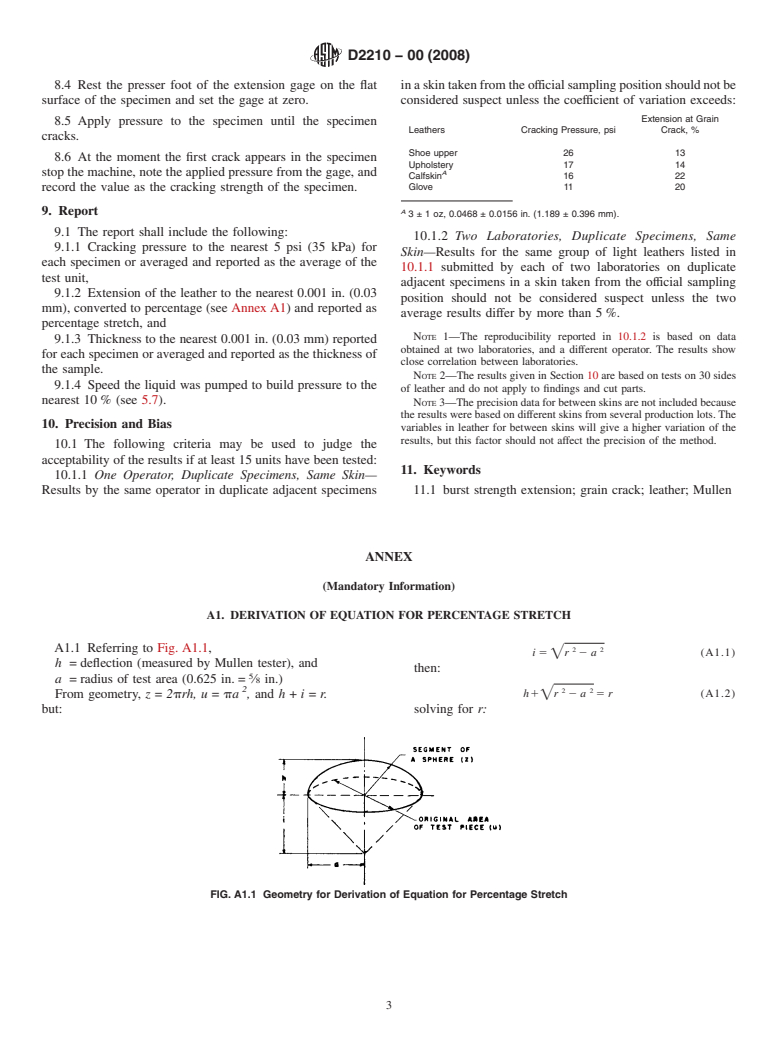

------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2210–00(Reapproved 2004) Designation:D2210–00(Reapproved 2008)

Standard Test Method for

1

Grain Crack and Extension of Leather by the Mullen Test

This standard is issued under the fixed designation D 2210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the resistance of leather to grain cracking and for measuring the extension of

the leather. It is limited to light leathers such as shoe uppers, garment, gloves, and upholstery. This test method does not apply to

wet blue.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1610 Practice for Conditioning Leather and Leather Products for Testing

D 1813 Test Method for Measuring Thickness of Leather Test Specimens

3. Terminology

3.1 Definitions:

3.1.1 extension—the amount of stretch of leather over the diaphragm under pressure.

3.1.2 grain cracking—the appearance of cracks on the surface of the leather as the leather is extended over a diaphragm under

pressure to form a sphere.

4. Significance and Use

4.1 The test method is designed to measure the force required to crack the grain of leather by steady hydraulic pressure on a

diaphragm of definite diameter applied to the flesh side of the specimen to form a sphere. The cracking of the grain is a result of

failure under elongation or stretch. The elongation or stretch of the leather can be measured at different loads or at the failure of

the grain to determine if the stress leather will withstand under lasting conditions. Cuts, scratches, and other defects will cause

considerable variation in the results by concentration of the applied force to the weak points. This test method is excellent for

manufacturing control, specification acceptance, and service evaluation in the lasting property of leather. This test method may not

apply when the conditions of the test employed differ widely from those specified in the test method.

5. Apparatus

3

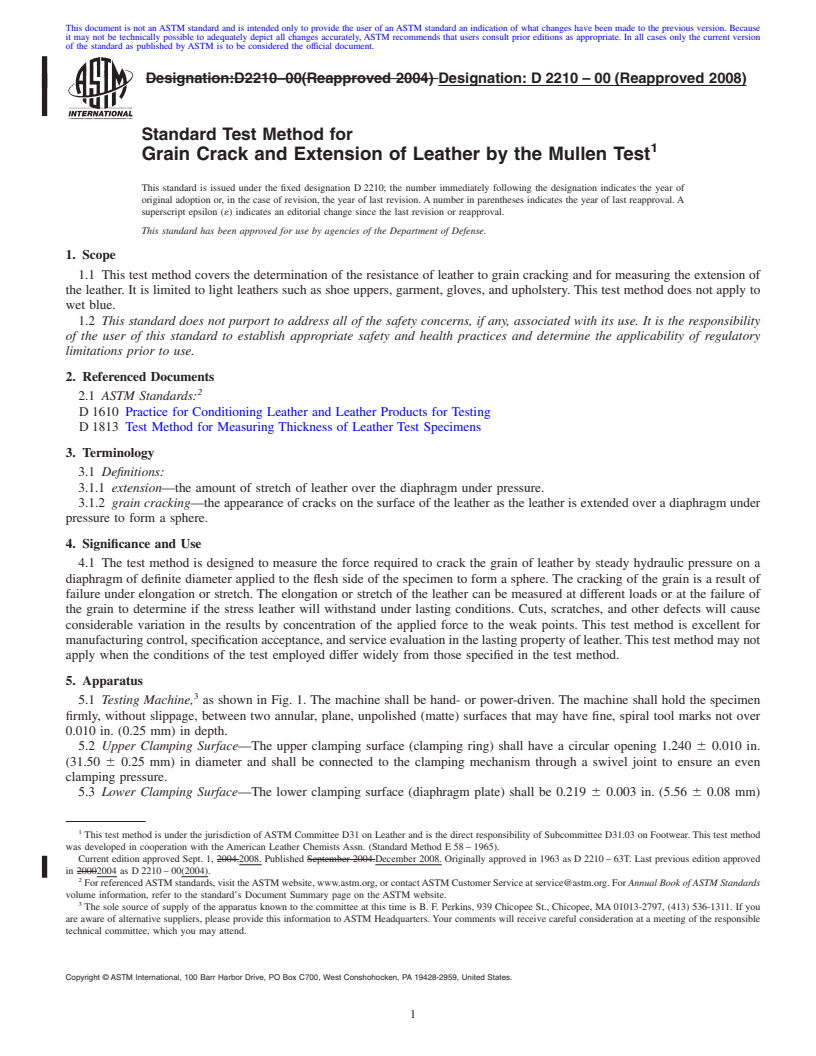

5.1 Testing Machine, as shown in Fig. 1. The machine shall be hand- or power-driven. The machine shall hold the specimen

firmly, without slippage, between two annular, plane, unpolished (matte) surfaces that may have fine, spiral tool marks not over

0.010 in. (0.25 mm) in depth.

5.2 Upper Clamping Surface—The upper clamping surface (clamping ring) shall have a circular opening 1.240 6 0.010 in.

(31.50 6 0.25 mm) in diameter and shall be connected to the clamping mechanism through a swivel joint to ensure an even

clamping pressure.

5.3 Lower Clamping Surface—The lower clamping surface (diaphragm plate) shall be 0.219 6 0.003 in. (5.56 6 0.08 mm)

1

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.03 on Footwear. This test method

was developed in cooperation with the American Leather Chemists Assn. (Standard Method E 58 – 1965).

Current edition approved Sept. 1, 2004.2008. Published September 2004.December 2008. Originally approved in 1963 as D 2210 – 63T. Last previous edition approved

in 20002004 as D 2210 – 00(2004).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The sole source of supply of the apparatus known to the committee at this time is B. F. Perkins, 939 Chicopee St., Chicopee, MA 01013-2797, (413) 536-1311. If you

are aware of alternative suppliers, please provide this information to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2210–00 (2008)

FIG. 1 Mullen Tester, Model A

thick and have an opening of 1.240 6 0.01 in. (31.50

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2210–93 (Reapproved 1997) Designation:D2210–00(Reapproved 2008)

Standard Test Method for

1

Grain Crack and Extension of Leather by the Mullen Test

This standard is issued under the fixed designation D 2210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the resistance of leather to grain cracking and for measuring the extension of

the leather. It is limited to light leathers such as shoe uppers, garment, gloves, and upholstery. This test method does not apply to

wet blue.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1610 Practice for Conditioning Leather and Leather Products for Testing

D 1813 Test Method for Measuring Thickness of Leather Test Specimens

3. Terminology

3.1 Definitions:

3.1.1 extension—the amount of stretch of leather over the diaphragm under pressure.

3.1.2 grain cracking—the appearance of cracks on the surface of the leather as the leather is extended over a diaphragm under

pressure to form a sphere.

4. Significance and Use

4.1 The test method is designed to measure the force required to crack the grain of leather by steady hydraulic pressure on a

diaphragm of definite diameter applied to the flesh side of the specimen to form a sphere. The cracking of the grain is a result of

failure under elongation or stretch. The elongation or stretch of the leather can be measured at different loads or at the failure of

the grain to determine if the stress leather will withstand under lasting conditions. Cuts, scratches, and other defects will cause

considerable variation in the results by concentration of the applied force to the weak points. This test method is excellent for

manufacturing control, specification acceptance, and service evaluation in the lasting property of leather.This test method may not

apply when the conditions of the test employed differ widely from those specified in the test method.

5. Apparatus

3

5.1 Testing Machine, as shown in Fig. 1. The machine shall be hand- or power-driven. The machine shall hold the specimen

firmly, without slippage, between two annular, plane, unpolished (matte) surfaces that may have fine, spiral tool marks not over

0.010 in. (0.25 mm) in depth.

5.2 Upper Clamping Surface—The upper clamping surface (clamping ring) shall have a circular opening 1.240 6 0.010 in.

(31.50 6 0.25 mm) in diameter and shall be connected to the clamping mechanism through a swivel joint to ensure an even

clamping pressure.

5.3 Lower Clamping Surface—The lower clamping surface (diaphragm plate) shall be 0.219 6 0.003 in. (5.56 6 0.08 mm)

1

This test method is under the jurisdiction of ASTM Committee D-31D31 on Leather and is the direct responsibility of Subcommittee D31.03 on Footwear. This test

method was developed in cooperation with the American Leather Chemists Assn. (Standard Method E 58 – 1965).

Current edition approved July 15, 1993.Sept. 1, 2008. Published September 1993.December 2008. Originally published approved in 1963 as D 2210 – 63T. Last previous

1

edition D2210–89´ . approved in 2004 as D 2210 – 00(2004).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 15.04.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The sole source of supply of the apparatus known to the committee at this time is B. F. Perkins, 939 Chicopee St., Chicopee, MA 01013-2797, (413) 536-1311. If you

are aware of alternative suppliers, please provide this information to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2210–00 (2008)

FIG. 1 Mullen Tester, Model A

thick a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.