ASTM D7575-10

(Test Method)Standard Test Method for Solvent-Free Membrane Recoverable Oil and Grease by Infrared Determination

Standard Test Method for Solvent-Free Membrane Recoverable Oil and Grease by Infrared Determination

SIGNIFICANCE AND USE

The presence and concentration of oil and grease in domestic and industrial wastewater is of concern to the public because of its deleterious health, environmental, safety, and aesthetic effects.

Regulations and standards have been established that require monitoring of oil and grease in water and wastewater.

Note 1—Different oil and grease materials may have different infrared absorptivities. Certain materials, such as synthetic silicone-based or perfluorinated oils, may have absoptivities inconsistent with those of naturally occurring oil and grease materials. Caution should be taken when testing matrices suspected of containing proportions of these materials. In such cases, laboratory spike samples, laboratory check samples, equivalency testing, or combinations thereof, using these materials in question may be appropriate.

SCOPE

1.1 This test method covers the determination of oil and grease in water extracted with an infrared-amenable membrane and measured by infrared transmission through the membrane.

1.2 This method defines oil and grease in water as that which is extractable in the test method and measured by infrared transmission.

1.3 The method detection limit (MDL) and recommended reporting range are listed in Table 1.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D7575–10

Standard Test Method for

Solvent-Free Membrane Recoverable Oil and Grease by

Infrared Determination

This standard is issued under the fixed designation D7575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

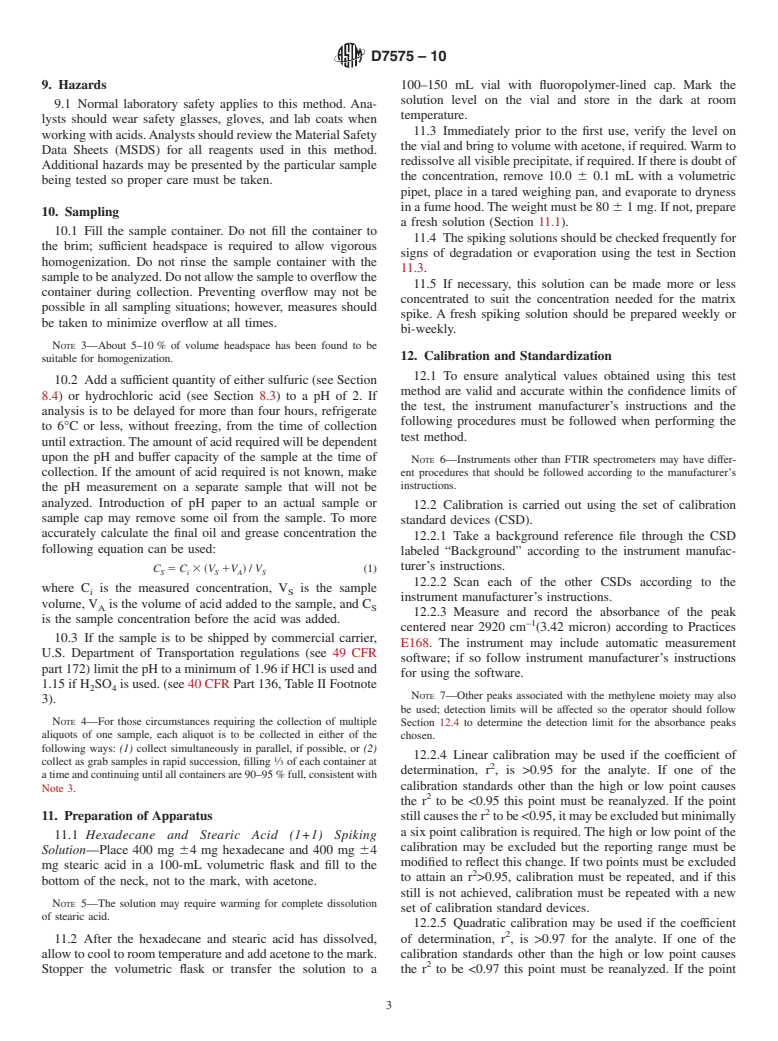

TABLE 1 MDL and Reporting Range

1. Scope

A A

Analyte MDL (mg/L) Reporting Range (mg/L)

1.1 This test method covers the determination of oil and

Oil and Grease 1.0 5–200

grease in water extracted with an infrared-amenable membrane

A

and measured by infrared transmission through the membrane. MDL and recommended reporting range determined by Section 12.4, which

follows the Code of Federal Regulations, 40 CFR Part 136, Appendix B; limits

1.2 This method defines oil and grease in water as that

should be determined by each operator.

which is extractable in the test method and measured by

infrared transmission.

1.3 The method detection limit (MDL) and recommended

2.2 EPA Standards

reporting range are listed in Table 1.

EPA Method 1664 Revision A: N-Hexane Extractable Ma-

1.4 The values stated in SI units are to be regarded as

terial (HEM; Oil and Grease) and Silica Gel Treated

standard. No other units of measurement are included in this

N-Hexane Extractable Material (SGT-HEM; Non-polar

standard.

Material) By Extraction and Gravimetry

1.5 This standard does not purport to address all of the

40 CFR

safety concerns, if any, associated with its use. It is the

49 CFR

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1 Definitions: For definitions of terms used in this test

method, refer to Terminology D1129 and Practices E168.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.2.1 oil and grease, n—“membrane-recoverable oil and

D1129 Terminology Relating to Water

grease” is a method-defined analyte; that is, the definition of

D1193 Specification for Reagent Water

membrane-recoverable oil and grease is dependent on the

D2777 Practice for Determination of Precision and Bias of

procedure used.

Applicable Test Methods of Committee D19 on Water

3.2.1.1 Discussion—The nature of the oils or greases (or

D5847 Practice for Writing Quality Control Specifications

both), and the presence of recoverable non-oily matter in the

for Standard Test Methods for Water Analysis

sample will influence the material measured and interpretation

E168 Practices for General Techniques of Infrared Quanti-

of results.

tative Analysis

3.2.2 extractor, n—a device that contains an infrared-

E178 Practice for Dealing With Outlying Observations

amenable oil-and-grease solid-phase-extraction-membrane and

directs water flow through the membrane under applied pres-

sure.

4. Summary of Test Method

4.1 This is a performance-based method and modifications

This test method is under the jurisdiction of ASTM Committee D19 on Water

are allowed to improve performance.

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

Organic Substances in Water. 4.2 A sample of water is processed through an extractor.

Current edition approved Jan. 1, 2010. Published January 2010. DOI: 10.1520/

D7575-10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from United States Environmental Protection Agency (EPA), Ariel

Standards volume information, refer to the standard’s Document Summary page on Rios Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460, http://

the ASTM website. www.epa.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7575–10

4.3 The extractor is then sufficiently dried of water so as to extractor. Each set contains devices with a specified amount of

allow infrared analysis. oil and grease; set should include seven devices that cover the

4.4 The extractor is examined by an infrared analyzer for an reporting range.

oil and grease measurement.

7.3 Syringe—A one-time use plastic syringe with low-

4.5 Calibrations and data are processed manually or with

extractable components and connection to attach to the extrac-

appropriate software.

tor, capable of flowing the sample volume to be processed.

7.4 Infrared Instrument—Infrared absorption measurement

5. Significance and Use

instrument; the instrument may be spectroscopic, dispersive,

5.1 The presence and concentration of oil and grease in

radiometricorfiltometricbased.Themethodwasvalidatedand

domestic and industrial wastewater is of concern to the public

the detection limit was determined with an MB3000 FTIR

because of its deleterious health, environmental, safety, and

spectrometer manufactured by ABB according to 12.4; the

aesthetic effects.

detection limit and reporting range may vary with the instru-

5.2 Regulations and standards have been established that

ment chosen to perform the analysis; the user should perform

require monitoring of oil and grease in water and wastewater.

a detection limit study as described in 12.4 to determine the

method detection limit and reporting range when using the

NOTE 1—Different oil and grease materials may have different infrared

absorptivities. Certain materials, such as synthetic silicone-based or chosen instrument.

perfluorinated oils, may have absoptivities inconsistent with those of

7.5 Homogenizer—Adevice capable of sufficiently homog-

naturally occurring oil and grease materials. Caution should be taken

enizing a collected sample, if a grab sample is collected and

when testing matrices suspected of containing proportions of these

stored prior to testing; examples are a paint can shaker or table

materials. In such cases, laboratory spike samples, laboratory check

shaker (optional).

samples, equivalency testing, or combinations thereof, using these mate-

7.6 Fluid Flow Device—A device capable of forcing the

rials in question may be appropriate.

fluid through the extractor, such as a syringe pump (optional).

6. Interferences

7.7 Drying System—Asystem capable of drying the extrac-

6.1 Method interferences may be caused by contaminants in

tor sufficiently for infrared analysis without compromising

instrumentation, reagents, glassware and other apparatus pro-

analyte retention; an example is a clean, compressed air line at

ducing artifacts. Routine laboratory method blanks will dem-

80 psi (552 kPa).

onstrate all these materials are free from interferences.

6.2 Matrix interference may be caused by contaminants that

8. Reagents and Materials

are co-extracted from the sample. The extent of matrix inter-

8.1 Purity of Reagents—Reagent grade chemicals shall be

ferences can vary considerably from sample to sample.

used in all tests. Unless otherwise indicated, it is intended that

6.3 In cases of samples which contain a relatively large

allreagentsshallconformtothespecificationoftheCommittee

amount of particulate or biological material, processing the

on Analytical Reagents of the American Chemical Society,

standard 10 mLamount of sample may not be possible. Note 2

where such specifications are available. Other grades may be

andNote10discusshowtodealwithprocessingsuchsamples.

used, provided it is first ascertained that the reagent is of

NOTE 2—It is important to note that the capture of solid matter on the sufficiently high purity to permit its use without lessening the

extractordoesnotprecludeIRmeasurement;inthemajorityofcasesthere

accuracy of the determination.

is sufficient IR throughput to still perform the measurement as described

8.2 Purity of Water—Unless otherwise indicated, references

herein. This is the case with most metal-oxide materials (that is, clay or

to water shall be understood to mean reagent water that meets

sand) and biological material (that is, algae or cellulose). There may of

the purity specifications of Type II water, presented in Speci-

course be samples encountered wherein the solid matter is not sufficiently

fication D1193.

IR transmitting; one example may be a sample containing a large

concentration of metal particulate. In these instances a different measure-

8.3 Hydrochloric Acid—Concentration of 12.1 M.

ment technique may be necessary.

8.4 Sulfuric Acid—Concentration of 18.4 M; optional re-

placement for hydrochloric acid for preservation.

7. Apparatus

8.5 Acetone—ACS, residue less than 1 mg/L.

7.1 Extractor—Device which contains an infrared-

8.6 Hexadecane—98 % minimum purity.

amenable oil and grease solid phase extraction membrane,

8.7 Stearic Acid—98 % minimum purity.

includes a connection to a syringe, such as a Luer connection,

and is designed for pressurized flow of water through the

membrane.

7.2 Calibration Standard Devices Set—Calibration stan-

The sole source of supply of the apparatus known to the committee at this time

dards have the same or similar outward appearance as the

is Orono Spectral Solutions, P/N 1018SPE-CSD. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters.

Your comments will receive careful consideration at a meeting of the responsible

40 CFR 136 technical committee, which you may attend.

5 7

The sole source of supply of the apparatus known to the committee at this time Reagent Chemicals, American Chemical Society Specifications, American

is Orono Spectral Solutions, P/N 1018SPE (US Patent Application number Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

12/324,688). If you are aware of alternative suppliers, please provide this informa- listed by the American Chemical Society, see Annual Standards for Laboratory

tion to ASTM International Headquarters. Your comments will receive careful Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

consideration at a meeting of the responsible technical committee, which you may and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

attend. MD.

D7575–10

9. Hazards 100–150 mL vial with fluoropolymer-lined cap. Mark the

solution level on the vial and store in the dark at room

9.1 Normal laboratory safety applies to this method. Ana-

temperature.

lysts should wear safety glasses, gloves, and lab coats when

11.3 Immediately prior to the first use, verify the level on

workingwithacids.AnalystsshouldreviewtheMaterialSafety

the vial and bring to volume with acetone, if required.Warm to

Data Sheets (MSDS) for all reagents used in this method.

redissolveallvisibleprecipitate,ifrequired.Ifthereisdoubtof

Additional hazards may be presented by the particular sample

the concentration, remove 10.0 6 0.1 mL with a volumetric

being tested so proper care must be taken.

pipet, place in a tared weighing pan, and evaporate to dryness

in a fume hood.The weight must be 80 6 1 mg. If not, prepare

10. Sampling

a fresh solution (Section 11.1).

10.1 Fill the sample container. Do not fill the container to

11.4 The spiking solutions should be checked frequently for

the brim; sufficient headspace is required to allow vigorous

signs of degradation or evaporation using the test in Section

homogenization. Do not rinse the sample container with the

11.3.

sampletobeanalyzed.Donotallowthesampletooverflowthe

11.5 If necessary, this solution can be made more or less

container during collection. Preventing overflow may not be

concentrated to suit the concentration needed for the matrix

possible in all sampling situations; however, measures should

spike. A fresh spiking solution should be prepared weekly or

be taken to minimize overflow at all times.

bi-weekly.

NOTE 3—About 5–10 % of volume headspace has been found to be

12. Calibration and Standardization

suitable for homogenization.

12.1 To ensure analytical values obtained using this test

10.2 Add a sufficient quantity of either sulfuric (see Section

method are valid and accurate within the confidence limits of

8.4) or hydrochloric acid (see Section 8.3)toapHof2.If

the test, the instrument manufacturer’s instructions and the

analysis is to be delayed for more than four hours, refrigerate

following procedures must be followed when performing the

to 6°C or less, without freezing, from the time of collection

test method.

untilextraction.Theamountofacidrequiredwillbedependent

upon the pH and buffer capacity of the sample at the time of

NOTE 6—Instruments other than FTIR spectrometers may have differ-

collection. If the amount of acid required is not known, make ent procedures that should be followed according to the manufacturer’s

instructions.

the pH measurement on a separate sample that will not be

analyzed. Introduction of pH paper to an actual sample or

12.2 Calibration is carried out using the set of calibration

sample cap may remove some oil from the sample. To more

standard devices (CSD).

accurately calculate the final oil and grease concentration the

12.2.1 Take a background reference file through the CSD

following equation can be used:

labeled “Background” according to the instrument manufac-

turer’s instructions.

C 5 C 3 ~V 1V !/ V (1)

S i S A S

12.2.2 Scan each of the other CSDs according to the

where C is the measured concentration, V is the sample

i S

instrument manufacturer’s instructions.

volume, V is the volume of acid added to the sample, and C

A S

12.2.3 Measure and record the absorbance of the peak

is the sample concentration before the acid was added.

–1

centered near 2920 cm (3.42 micron) according to Practices

10.3 If the sample is to be shipped by commercial carrier,

E168. The instrument may include automatic measurement

U.S. Department of Transportation regulations (see 49 CFR

software; if so follow instrument manufacturer’s instructions

part 172) limit the pH to a minimum of 1.96 if HCl is used and

for using the software.

1.15 if H SO is used. (see 40 CFR Part 136,Table II Footnote

2 4

NOTE 7—Other peaks associated with the methylene moiety may also

3).

be used; detection limits will be affected so the operator should follow

NOTE 4—For those circumstances requiring the collection of multiple Section 12.4 to determine the detection limit for the absorbance peaks

aliquots of one sample, each aliquot is to be collected in either of the chosen.

following ways: (1) collect simultaneously in parallel, if possible, or (2)

12.2.4 Linear calibration may be used if the coefficient of

collect as grab samples in rapid succession, filling ⁄3 of each container at

determination, r , is >0.95 for the analyte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.