ASTM F1914-07

(Test Method)Standard Test Methods for Short-Term Indentation and Residual Indentation of Resilient Floor Covering

Standard Test Methods for Short-Term Indentation and Residual Indentation of Resilient Floor Covering

SIGNIFICANCE AND USE

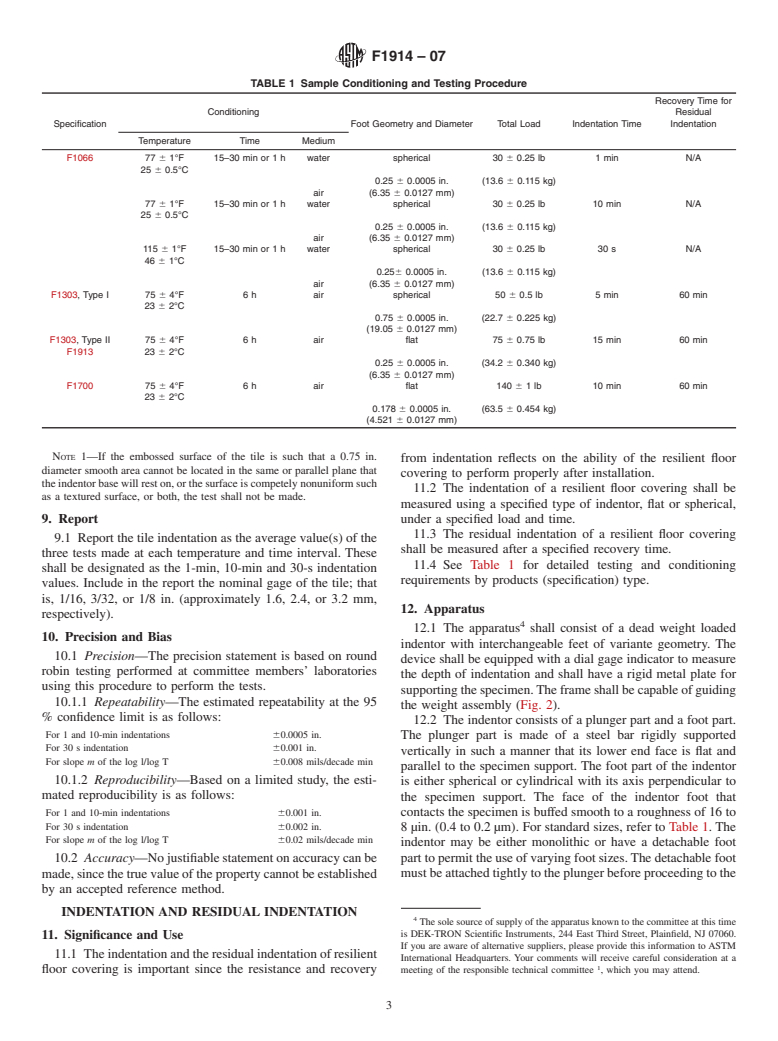

The indentation and the residual indentation of resilient floor covering is important since the resistance and recovery from indentation reflects on the ability of the resilient floor covering to perform properly after installation.

The indentation of a resilient floor covering shall be measured using a specified type of indentor, flat or spherical, under a specified load and time.

The residual indentation of a resilient floor covering shall be measured after a specified recovery time.

See Table 1 for detailed testing and conditioning requirements by products (specification) type.

SCOPE

1.1 This test method covers procedures to determine short-term indentation and residual indentation of resilient flooring, when subjected to concentrated loads.

1.2 The test methods appear in the following order:SectionIndentation by McBurney Test4 to 10Indentation and Residual Indentation11 to 15

1.3 There are two procedures with their respective apparatus. The first (McBurney Test) is described in Sections 4 to 10 and is restricted to a spherical foot. It is only used for initial indentation measurements of VCT. The second is described in Sections 11 to 15 and has interchangeable feet with variable geometry. It is used to measure initial and residual indentation.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1914–07

Standard Test Methods for

Short-Term Indentation and Residual Indentation of

1

Resilient Floor Covering

This standard is issued under the fixed designation F1914; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope eters with Low-Hazard Precision Liquids

F141 Terminology Relating to Resilient Floor Coverings

1.1 This test method covers procedures to determine short-

F1066 Specification for Vinyl Composition Floor Tile

term indentation and residual indentation of resilient flooring,

F1303 Specification for Sheet Vinyl Floor Covering with

when subjected to concentrated loads.

Backing

1.2 The test methods appear in the following order:

F1700 Specification for Solid Vinyl Floor Tile

F1913 Specification for Vinyl Sheet Floor Covering With-

Section

2

Indentation by McBurney Test 4 to 10

out Backing

Indentation and Residual Indentation 11 to 15

3. Terminology

1.3 There are two procedures with their respective appara-

tus. The first (McBurney Test) is described in Sections 4 to 10 3.1 Definitions—For definitions of terms used in this test

and is restricted to a spherical foot. It is only used for initial method, refer to Terminology F141.

indentation measurements of VCT. The second is described in

INITIAL INDENTATION MEASUREMENTS OF VCT

Sections 11 to 15 and has interchangeable feet with variable

2

(MCBURNEY TEST)

geometry. It is used to measure initial and residual indentation.

1.4 The values stated in inch-pound units are to be regarded

4. Significance and Use

as the standard. The values given in parentheses are provided

4.1 This test method measures short-term indentation of

for information only.

resilient flooring and is useful as a predictor of performance in

1.5 This standard does not purport to address all of the

actual installations over time.

safety concerns, if any, associated with its use. It is the

4.2 The slope, m, of a log-log plot indentation (I) versus

responsibility of the user of this standard to establish appro-

time (T), is related to the indentation of tile in service. The

priate safety and health practices and determine the applica-

115°F (46°C) indentation is a measure of the tendency of the

bility of regulatory limitations prior to use.

tile to indent at temperatures above 77°F (25°C).

2. Referenced Documents

5. Apparatus

3

2.1 ASTM Standards:

2

5.1 Apparatus —The indentation tester is a spherical foot

E691 Practice for Conducting an Interlaboratory Study to

device consisting essentially of a rigidly mounted indentor

Determine the Precision of a Test Method

acting under an initial load of 2.00 6 0.02 lbf (8.90 6 0.09 N)

E2251 Specification for Liquid-in-Glass ASTM Thermom-

and a total deadweight load of 30.00 lbf 6 0.25 lbf (133.45 6

1.11 N) with a suitable dial indicator, calibrated in 0.0005 in.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient (0.01 mm) increments. The spherical foot shall be 0.250 6

Floor Coverings and is the direct responsibility of Subcommittee F06.30 on Test

0.0005 in. (6.35 6 0.01 mm) in diameter.Asuitable apparatus

Methods - Performance.

is shown in Fig. 1.

Current edition approved Oct. 1, 2007. Published October 2007. Originally

5.2 Flat Glass Plate, of 0.25 in. (6.35 mm) minimum

approved in 1998. Last previous edition approved in 2006 as F1914–06. DOI:

10.1520/F1914-07.

thickness for supporting the specimen and tester during test.

2

The sole source of supply of the McBurney Indentation Tester known to the

5.3 Timing Device that will indicate the time in seconds.

committee at this time is Frazier Precision Co, Gaithersburg, MD. If you are aware

5.4 Thermometer, calibrated as in Specification E2251.

of alternative suppliers, please provide this information to ASTM International

5.5 Circular Plexiglas Template, 3.50 in. (88.9 mm) in

Headquarters.Your comments will receive careful consideration at a meeting of the

1

responsible technical committee , which you may attend.

diameter, 0.25 in. (6.35 mm) thick and having a 0.3125 in.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(7.94 mm) diameter hole drilled in the center and a 0.75 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(19.05 mm) diameter concentric circle etched on the face.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1914–07

FIG. 1 Apparatus for Measuring Indentation: McBurney

5.6 Wa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.