ASTM F1472-08e1

(Specification)Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications (UNS R56400)

Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications (UNS R56400)

ABSTRACT

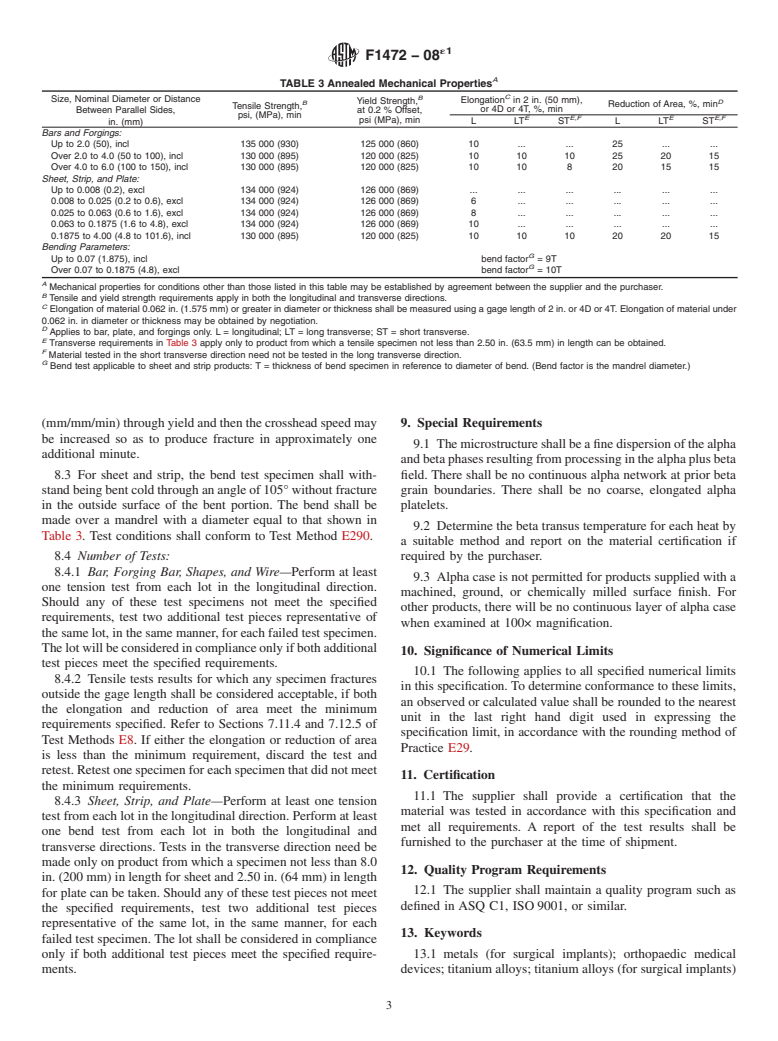

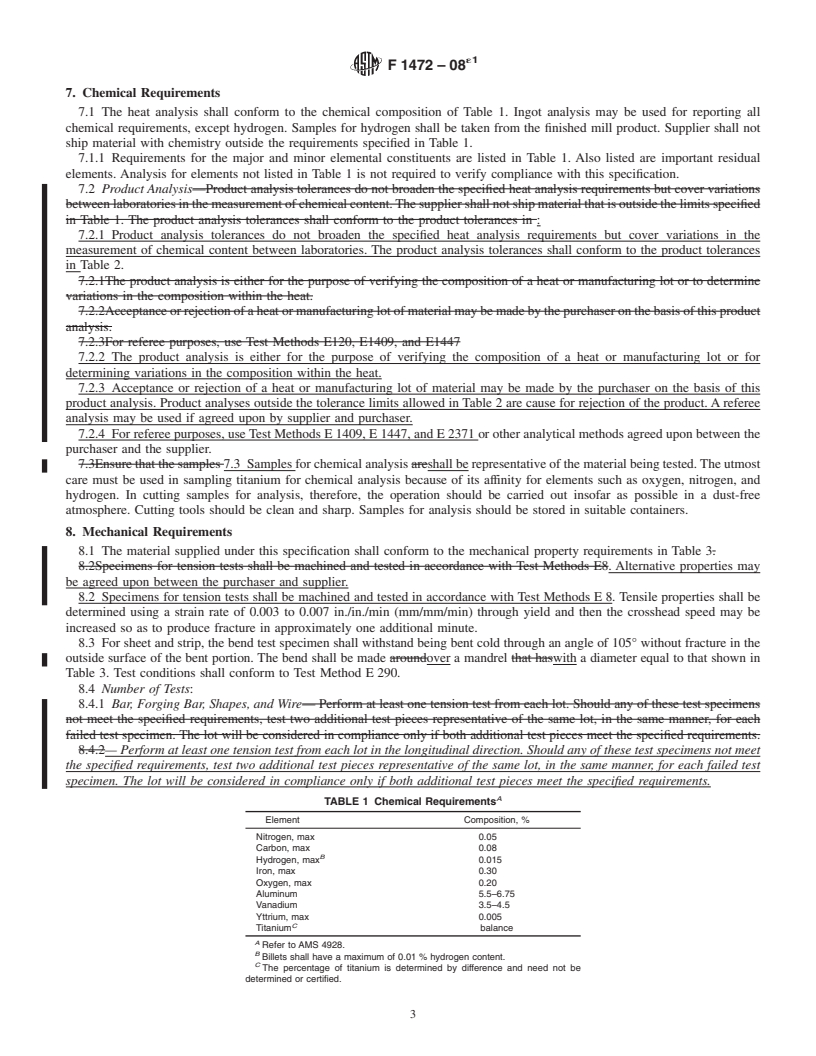

This specification covers the requirements for wrought titanium-6aluminum-4vanadium alloy for use in surgical implant applications. The material shall be manufactured by multiple melting in plasma arc and electron beam furnaces into strip, sheet, plate, bar, forging bar, or wire. The material shall be available in the annealed or cold-worked condition, with the surface mechanically descaled or pickled, sandblasted, chemically milled, ground, machined, peeled, polished, or a combination of these. Heat and product analyses as well as tension and bend (for sheet, strip, and plate) tests shall be performed and shall conform to the requirements specified. In addition, the material shall have a microstructure consisting of a fine dispersion of alpha and beta phases as a result of processing in the alpha plus beta field, with no continuous alpha network at prior beta grain boundaries and no coarse, elongated alpha platelets.

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought annealed titanium-6aluminum-4vanadium alloy (UNS R56400) to be used in the manufacture of surgical implants.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F1472 −08

StandardSpecification for

Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical

1

Implant Applications (UNS R56400)

This standard is issued under the fixed designation F1472; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorially corrected the ISO 5832–3 designation throughout in December 2008.

4

1. Scope* 2.3 Aerospace Material Specifications:

AMS 2249 Chemical CheckAnalysis Limits, Titanium and

1.1 This specification covers the chemical, mechanical, and

Titanium Alloys

metallurgical requirements for wrought annealed titanium-

AMS 4911Titanium Alloy Sheet, Strip, and Plate 6Al-4V

6aluminum-4vanadium alloy (UNS R56400) to be used in the

Annealed

manufacture of surgical implants.

AMS 4928TitaniumAlloy Bars,Wire, Forgings, Rings, and

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

Drawn Shapes 6Al-4VAnnealed

as standard. The values given in parentheses are mathematical

AMS 4965TitaniumAlloy, Bars,Wire, Forgings, and Rings

conversions to SI units that are provided for information only

6.0Al-4.0V Solution Heat Treated and Aged

5

and are not considered standard.

2.4 ISO Standards:

ISO 5832–3Implants for Surgery—Metallic Materials—

2. Referenced Documents

Part 3, Wrought Titanium-6Aluminum-4Vanadium Alloy

2

2.1 ASTM Standards:

ISO 9001Quality Management Systems—Requirements

E8Test Methods for Tension Testing of Metallic Materials

4,6

2.5 Society of Automotive Engineers Standard:

E29Practice for Using Significant Digits in Test Data to

SAE J1086Practice for Numbering Metals and Alloys

Determine Conformance with Specifications

(UNS)

E290Test Methods for Bend Testing of Material for Ductil-

ity 3. Terminology

E527Practice for Numbering Metals and Alloys in the

3.1 Definitions of Terms Specific to This Standard:

Unified Numbering System (UNS)

3.1.1 lot, n—the total number of mill products produced

E1409TestMethodforDeterminationofOxygenandNitro-

fromoneheatunderthesameconditionsatessentiallythesame

gen in Titanium and Titanium Alloys by the Inert Gas

time.

Fusion Technique

E1447Test Method for Determination of Hydrogen in Tita- 4. Product Classification

nium and Titanium Alloys by Inert Gas Fusion Thermal

4.1 Strip—Any product under 0.188 in. (4.76 mm) in

Conductivity/Infrared Detection Method

thickness and under 24 in. (610 mm) wide.

E2371Test Method for Analysis of Titanium and Titanium

4.2 Sheet—Any product under 0.188 in. (4.76 mm) in

Alloys by Atomic Emission Plasma Spectrometry

3 thickness and 24 in. (610 mm) or more in width.

2.2 ASQ Standard:

ASQC1SpecificationsofGeneralRequirementsforaQual- 4.3 Plate—Any product 0.188 in. (4.76 mm) thick and over

ity Program and 10 in. (254 mm) wide and over, with widths greater than

five times thickness. Plate up to 4.00 in. (102 mm) thick,

1

inclusive, is covered by this specification.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

4.4 Bar—Round bars and flats from 0.188 in. (4.76 mm) to

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved Oct. 1, 2008. Published October 2008. Originally 4.00 in. (102 mm) in diameter or thickness (other sizes and

published in 1993. Last previous edition approved in 2002 as F1472–02a. DOI:

shapes by special order).

10.1520/F1472-08E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Standards volume information, refer to the standard’s Document Summary page on Dr., Warrendale, PA 15096-0001, http://www.sae.org.

5

the ASTM website. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

Available fromAmerican Society for Quality (ASQ), 600 N. PlankintonAve., 4th Floor, New York, NY 10036, http://www.ansi.org.

6

Milwaukee, WI 53203, http://www.asq.org. New designation established in accordance with E527 and SAE J1086.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F1472−08

4.5 Forging Bar—Bar as described in 4.4, used in the genshallbetakenfromthefinishedmillproduct.Suppliershall

production of forgings. This product may be furnished in the not ship material with chemistry outside the requirements

hot worked condition. specified in Table 1.

7.1.1 Requirements for the major and minor elemental

4.6 Wire—R

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:F1472–02a Designation: F 1472 – 08

Standard Specification for

Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical

1

Implant Applications (UNS R56400)

This standard is issued under the fixed designation F 1472; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Editorially corrected the ISO 5832–3 designation throughout in December 2008.

1. Scope*

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought annealed titanium-

6aluminum-4vanadium alloy (UNS R56400) to be used in the manufacture of surgical implants.

1.2The values stated in inch-pound units are to be regarded as the standard. The SI equivalents in parentheses are provided for

information only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

E 8 Test Methods offor Tension Testing of Metallic Materials

E120TestMethodsforChemicalAnalysisofTitaniumandTitaniumAlloys 29 PracticeforUsingSignificantDigitsinTestData

to Determine Conformance with Specifications

E 290 Test Methods for Bend Testing of MaterialsMaterial for Ductility

E 527Practice for Numbering Metals andAlloys (UNS) Practice for Numbering Metals andAlloys in the Unified Numbering

System (UNS)

E 1409 Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by the Inert Gas Fusion

Technique

E 1447Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by the Inert Gas Fusion Thermal

Conductivity Method

F981Practice for Assessment of Compatibility of Biomaterials for Surgical Implants with Respect to Effect of Materials on

Muscle and Bone Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by the Inert Gas Fusion

Thermal Conductivity/Infrared Detection Method

E 2371 Test Method for Analysis of Titanium and Titanium Alloys by Atomic Emission Plasma Spectrometry

3

2.2 ASQ Standard:

ASQ C1 Specifications of General Requirements for a Quality Program

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved Nov. 10, 2002.Oct. 1, 2008. Published January 2003.October 2008. Originally published in 1993. Last previous edition approved in 2002 as

F 1472 – 02a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 03.05.

3

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave., Milwaukee, WI 53203, http://www.asq.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F1472–08

4

2.3 Aerospace Material Specifications:

AMS 2249 Chemical Check Analysis Limits, Titanium and Titanium Alloys

AMS 4911 Titanium Alloy Sheet, Strip, and Plate 6Al-4V Annealed

AMS 4928 Titanium Alloy Bars, Wire, Forgings, Rings, and Drawn Shapes 6Al-4V Annealed

AMS 4965 Titanium Alloy, Bars, Wire, Forgings, and Rings 6.0Al-4.0V Solution Heat Treated and Aged

5

2.4 Society of Automotive Engineers Standard: ISO Standards:

ISO 5832–3 Implants for Surgery—Metallic Materials—Part 3, Wrought Titanium-6Aluminum-4Vanadium Alloy

ISO 9001 Quality Management Systems—Requirements

4, 6

2.5 Society of Automotive Engineers Standard:

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.2 lot, n—the total number of mill products produced from one heat under the same conditions at essentially the same time.

4. Product Classification

4.1 Strip—Any product under 0.18750.188 in. (4.75(4.76 mm) in thickness and under 24 in. (610 mm) wide.

4.2 Sheet—Any product under 0.18750.188 in. (4.75(4.76 mm) in thickness and 24 in. (610 mm) or more in width.

4.3 Plate—Anypro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.