ASTM C801-98

(Test Method)Standard Test Method for Determining the Mechanical Properties of Hardened Concrete Under Triaxial Loads (Withdrawn 2004)

Standard Test Method for Determining the Mechanical Properties of Hardened Concrete Under Triaxial Loads (Withdrawn 2004)

SCOPE

1.1 This test method covers the procedures for testing hardened concrete when subjected to triaxial stress conditions. Materials other than concrete, cement paste, or mortar are excluded. When the determination of the strength of concrete under a triaxial state of stress is made according to this test method, two of the three principal stresses are always equal. There is no provision made for the measurement of pore pressures; therefore all strength values are in terms of total stress.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the procedures for testing hardened concrete when subjected to triaxial stress conditions. Materials other than concrete, cement paste, or mortar are excluded. When the determination of the strength of concrete under a triaxial state of stress is made according to this test method, two of the three principal stresses are always equal. There is no provision made for the measurement of pore pressures; therefore, all strength values are in terms of total stress.

Formerly under the jurisdiction of Committee C09 on Concrete and Concrete Aggregates, this test method was withdrawn in July 2004 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C801–98

Standard Test Method for

Determining the Mechanical Properties of

1

Hardened Concrete Under Triaxial Loads

This standard is issued under the fixed designation C801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Apparatus

1.1 This test method covers the procedures for testing 4.1 Loading Device—A suitable device for applying and

hardened concrete when subjected to triaxial stress conditions. measuring axial load to the specimen. It must be of sufficient

Materials other than concrete, cement paste, or mortar are capacitytoapplytherequiredloadsatspecifiedrates.Itshould

excluded. When the determination of the strength of concrete be verified at suitable time intervals in accordance with the

under a triaxial state of stress is made according to this test procedures given in Practices E4, and should comply with the

method, two of the three principal stresses are always equal. requirements prescribed therein.

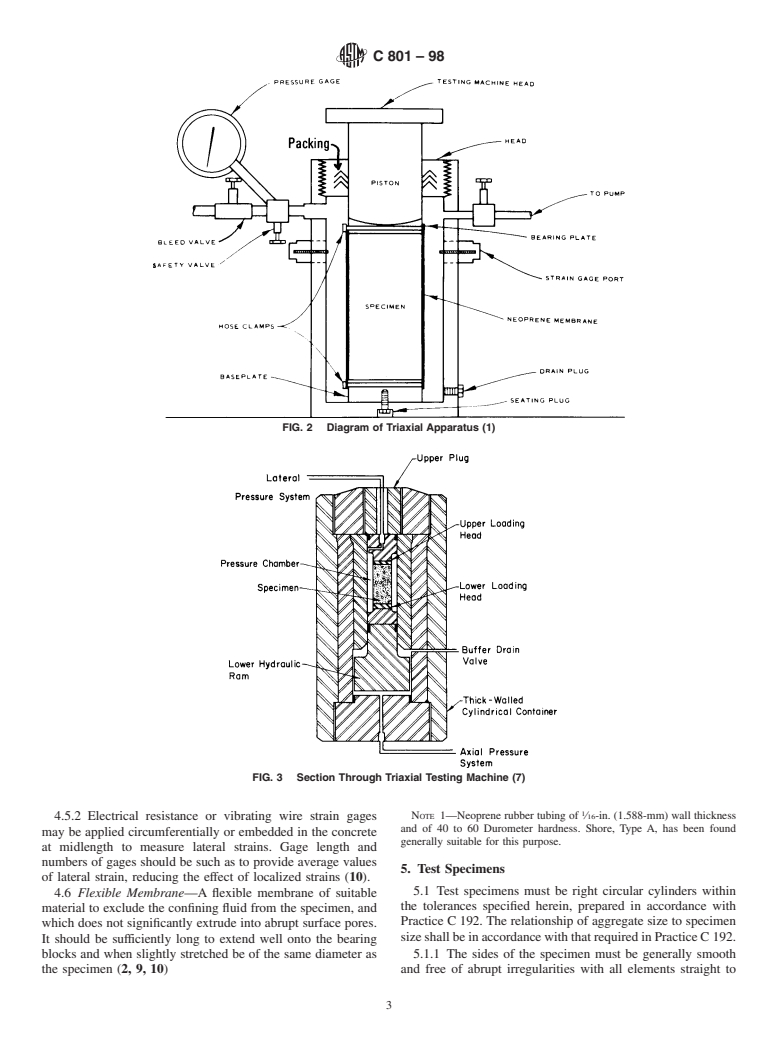

There is no provision made for the measurement of pore 4.2 Triaxial Compression Chamber—Adevice in which the

pressures; therefore all strength values are in terms of total test specimen may be enclosed in an impermeable, flexible

stress. membrane, placed between two hardened bearing blocks, and

1.2 The values stated in inch-pound units are to be regarded subjectedtohydraulicpressureanddeviatorstress.Thebearing

asthestandard.Thevaluesgiveninparenthesesaremathemati- blocks must be of steel, the bearing faces of which should be

cal conversions to SI units which are provided for information hardened to a minimum of 55 HRC, and which should not

only and are not considered standard. depart from plane surfaces by more than 0.0005 in. (0.0127

1.3 This standard does not purport to address all of the mm)whentheblocksarenewandshouldbemaintainedwithin

safety problems, if any, associated with its use. It is the a permissible variation of 0.001 in. (0.0254 mm). In order to

responsibility of the user of this standard to establish appro- develop the required hydraulic pressure, the apparatus should

priate safety and health practices and determine the applica- consist of a high pressure cylinder with an overflow valve, a

bility of regulatory limitations prior to use. base, suitable entry ports for filling the cylinder with hydraulic

fluid and applying the lateral pressure, and hoses, gages and

2. Referenced Documents 3

valvesasneeded(1,2,3,4). Fig.1andFig.2illustratetriaxial

2.1 ASTM Standards: chambers which have proved to be satisfactory.

C39 Test Method for Compressive Strength of Cylindrical

4.3 Combination Devices—Alternatively, devices may be

2

Concrete Specimens used which combine the function of loading device and

C192 PracticeforMakingandCuringConcreteTestSpeci-

pressurechamber.Fig.3illustratesonesuchdevice(5, 6, 7, 8).

2

mens in the Laboratory 4.4 Pressure-Maintaining Device—Ahydraulicpump,pres-

2

C512 Test Method for Creep of Concrete in Compression

sure intensifier, or other system of sufficient capacity to

C617 Practice for Capping Cylindrical Concrete Speci- maintain the desired pressures in the triaxial compression

2

mens

chamber.

2

E4 Practices for Load Verification of Testing Machines

4.5 Strain-Measuring Devices—Suitable devices must be

provided for the measurement of strain in the specimen. Such

3. Significance and Use

devices should be readable to the nearest 0.0001 in. (0.00254

3.1 Thistestmethodprovidesdatausefulindeterminingthe

mm) and accurate to within 0.0001 in. (0.00254 mm) in any

strength and deformation characteristics of concrete such as

0.001-in. (0.0254-mm) range, and within 0.0002 in. (0.00508

shear strength at various lateral pressures, angle of shearing

mm) in any 0.0100-in. (0.254-mm) range. Such devices may

resistance, strength in pure shear, deformation modulus, and

consist of micrometer screws, dial micrometers or linear

creep behavior.

variable differential transformers securely attached to the high

pressurecylinder,anddesignedtomeasurebearingblocktravel

(5, 6, 7, 9).

1

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.61 on Testing for Strength.

Current edition approved Nov. 10, 1998. Published March 1999. Originally

3

published as C801–75. Last previous edition C801–91. Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

2

Annual Book of ASTM Standards, Vol 04.02. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 -----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.