ASTM D7635/D7635M-10

(Test Method)Standard Test Method for Measurement of Thickness of Coatings Over Fabric Reinforcement

Standard Test Method for Measurement of Thickness of Coatings Over Fabric Reinforcement

SCOPE

1.1 This test method covers measuring the thickness of the coating over fiber backing or reinforcing fabric.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7635/D7635M − 10

Standard Test Method for

Measurement of Thickness of Coatings Over Fabric

1

Reinforcement

This standard is issued under the fixed designation D7635/D7635M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Light Source—If the light source on the microscope is

not adequate, use a small high-intensity lamp.

1.1 This test method covers measuring the thickness of the

4.1.2 Stage Micrometer, 25 µm [0.001 in.] divisions.

coating over fiber backing or reinforcing fabric.

4.2 Calibrated Viewing Device—A digital or analog device

1.2 The values stated in either SI units or inch-pound units

designed to provide an enlarged electronic image with calibra-

are to be regarded separately as standard. The values stated in

tions to provide measurements.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

5. Calibration Procedure

values from the two systems may result in non-conformance

with the standard. 5.1 Place a standard reflectance stage micrometer or cali-

brated sample blocks in place of the specimen.

1.3 This standard may involve hazardous materials,

operations, and equipment. This standard does not purport to 5.2 Turn on the light source.

address all of the safety concerns, if any, associated with its

5.3 Position the viewing device (calibrated reticule or cam-

use. It is the responsibility of the user of this standard to

era) such that the scales are superimposed. For electronic

establish appropriate safety and health practices and deter-

imaging, place the calibrated scale marker on the microscope

mine the applicability of regulatory limitations prior to use.

stage. Focus the viewing device on the specimen.

2. Referenced Documents

5.4 Calibrate using micrometer or calibrated sample blocks

2

to nearest 10 µm.

2.1 ASTM Standards:

D4434SpecificationforPoly(VinylChloride)SheetRoofing

5.5 If using digital image for calibration step, record reso-

E177Practice for Use of the Terms Precision and Bias in

lution and magnification of calibration image.

ASTM Test Methods

E691Practice for Conducting an Interlaboratory Study to

6. Specimen Preparation

Determine the Precision of a Test Method

6.1 Make a clean cut perpendicular to the plane of the

specimen,normaltooneofthethreadintersections,completely

MEASUREMENT METHOD

throughthesheetexposingtheareatobemeasured(seeFig.1).

3. Principle

6.2 Remove the razor-cut section and mount with the cut

3.1 The thickness of coating material over fiber, fabric, or

surface (analytical plane) facing downward into a sample clip.

scrim can be measured with a standard or digital optical or

Securesampleclipin3.175-cm[1.25-in.]samplecupwithcap.

reflectancemicroscope.Measurementismadewithacalibrated

Use a piece of double-sided tape to securely attach clip to the

viewing device.

cap part of the cup. Record sample orientation and position

within cup. Multiclips can be used for mounting multiple

4. Apparatus

samples per mount. Assure all that all samples are oriented

4.1 Microscope, 30 to 100× magnification capability.

normal to the plane of the sample cup cap.

6.3 Mixedlong-cureepoxyataratioof6.3partsresintoone

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD08onRoofing

part hardener, per volume. A 3.175-cm [1.25-in.] mount

and Waterproofing and is the direct responsibility of Subcommittee D08.18 on

Nonbituminous Organic Roof Coverings. requires 19 ml of epoxy.

Current edition approved June 1, 2010. Published July 2010. DOI: 10.1520/

6.4 The mounts are allowed to cure for at least 24 h at

D7635_D7635M–10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ambient temperature and humidity.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.5 After curing (24 hours), polish using the procedure

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. exhibited in Table 1. Clean and dry mounts after each step to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7635/D7635M − 10

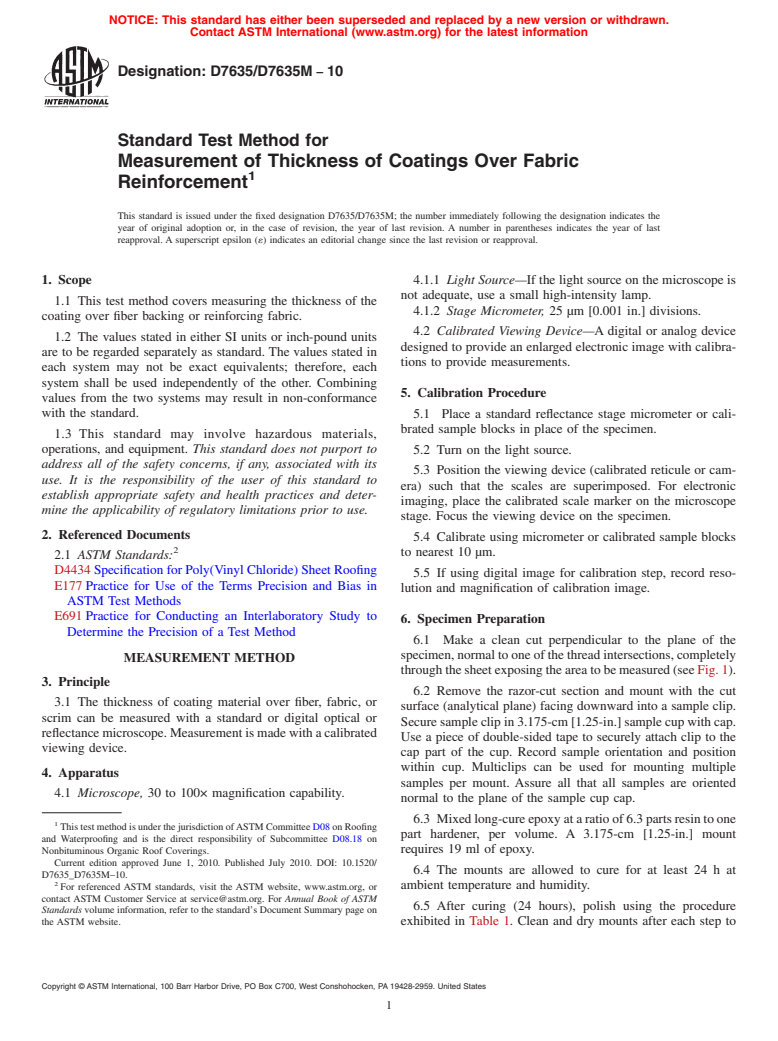

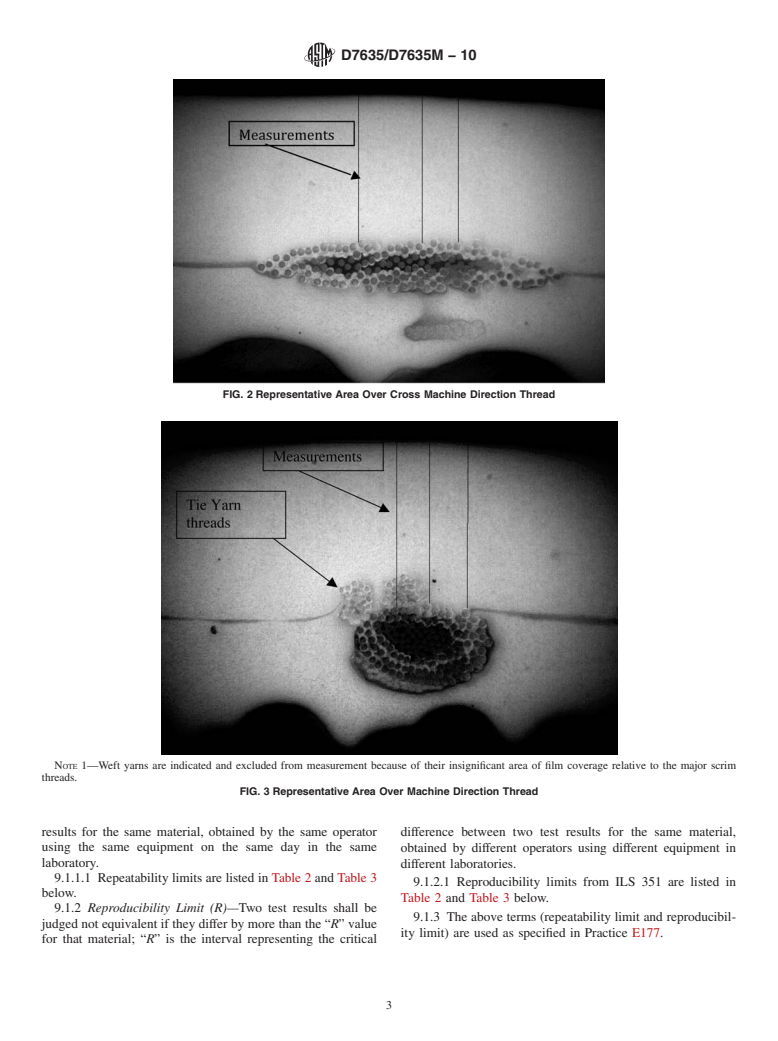

FIG. 1 Schematic of Preparation Illustrating Cuts Normal to Scrim Directions

TABLE 1 Recommended Metallographic Polishing Procedure

Grinding Lubricant Time Pressure Wheel Material Removed

Min:Sec KPa [psi] Speed (approximate)

RPM mm [mils]

320 Grit Water 0:30 241.2 [35] 300 0.7 [28]

400 Grit Water 0:30 241.2 [35] 300 0.5 [19]

600 Grit Water 0:30 241.2 [35] 300 0.25 [10]

800 Grit Water 0:30 241.2 [35] 300 0.13

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.