ASTM D38-94(2000)e1

(Test Method)Standard Test Methods for Sampling Wood Preservatives Prior to Testing (Withdrawn 2006)

Standard Test Methods for Sampling Wood Preservatives Prior to Testing (Withdrawn 2006)

SCOPE

1.1 These test methods cover sampling of creosote, creosote-coal tar solutions, creosote-petroleum solutions, and oilborne and waterborne preservatives. Note 1-See Specification D390, for Coal-Tar Creosote for the Preservative Treatment of Piles, Poles, and Timbers for Marine, Land, and Fresh Water Use, Specification D391 for Creosote-Coal Tar Solution, and Specification D1858, for Creosote-Petroleum Solution.

1.1.1 Creosote and creosote solutions are homogeneous liquids, except for their moisture content. At atmospheric temperatures, however, part of the creosote is usually in crystalline form, and shall be heated to a temperature at which it is entirely liquid before sampling.

1.1.1.1 When sampling creosote and creosote solutions, the object is to obtain a sample that will be representative of the water content, and the methods of sampling described are intended to accomplish that purpose.

1.1.2 Recommended test methods are given for sampling a preservative in a liquid or solid state and in the several types of containers in which they are likely to be encountered. Creosote, creosote-coal tar, and creosote-petroleum solutions may be in the form of a liquid or semiliquid. Oilborne and waterborne preservatives may be in the solid state, in concentrated solutions, or in ready-to-use solutions.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

These test methods cover sampling of creosote, creosote-coal tar solutions, creosote-petroleum solutions, and oilborne and waterborne preservatives.

Formerly under the jurisdiction of Committee D07 on Wood, these test methods were withdrawn with no replacement in July 2006.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D38–94 (Reapproved 2000)

Standard Test Methods for

Sampling Wood Preservatives Prior to Testing

ThisstandardisissuedunderthefixeddesignationD 38;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—A keyword was added editorially in March 2000.

1. Scope D 168 Test Method for Coke Residue of Creosote

D 246 Test Method for Distillation of Creosote and

1.1 These test methods cover sampling of creosote,

Creosote-Coal Tar Solutions

creosote-coal tar solutions, creosote-petroleum solutions, and

D 346 Practice for Collection and Preparation of Coke

oilborne and waterborne preservatives.

Samples for Laboratory Analysis

NOTE 1—See Specification D 390, for Coal-Tar Creosote for the

D 367 Test Method for Xylene-Insoluble Matter in Creo-

PreservativeTreatment of Piles, Poles, andTimbers for Marine, Land, and

sote

2 2

Fresh Water Use, Specification D 391 for Creosote-Coal Tar Solution,

D 368 Test Method for Specific Gravity of Creosote and

and Specification D 1858, for Creosote-Petroleum Solution.

Oil-Type Preservatives

1.1.1 Creosote and creosote solutions are homogeneous

D 369 Test Method for Specific Gravity of Creosote Frac-

liquids, except for their moisture content. At atmospheric

tions and Residues

temperatures, however, part of the creosote is usually in

D 370 Test Method for Dehydration of Oil-Type Preserva-

crystalline form, and shall be heated to a temperature at which

tives

it is entirely liquid before sampling.

D 1033 Methods of Chemical Analysis of Chromated Zinc

1.1.1.1 When sampling creosote and creosote solutions, the

Chloride

object is to obtain a sample that will be representative of the

D 1035 Test Methods for Chemical Analysis of Fluor-

water content, and the methods of sampling described are

Chrome-Arsenate-Phenol

intended to accomplish that purpose.

D 1274 Test Methods for Chemical Analysis of Pentachlo-

1.1.2 Recommended test methods are given for sampling a

rophenol

preservative in a liquid or solid state and in the several types of

D 1326 Methods for Chemical Analysis of Ammoniacal

containersinwhichtheyarelikelytobeencountered.Creosote,

Copper Arsenate

creosote-coal tar, and creosote-petroleum solutions may be in

D 1627 Methods for Chemical Analysis of Acid Copper

the form of a liquid or semiliquid. Oilborne and waterborne

Chromate

preservatives may be in the solid state, in concentrated solu-

D 1628 Test Methods for Chemical Analysis of Chromated

tions, or in ready-to-use solutions.

Copper Arsenate

1.2 This standard does not purport to address all of the

D 3176 Practice for Ultimate Analysis of Coal and Coke

safety concerns, if any, associated with its use. It is the

D 3180 Practice for Calculating Coal and Coke Analyses

responsibility of the user of this standard to establish appro-

from As-Determined to Different Bases

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Significance and Use

3.1 The test methods described are for use in obtaining

2. Referenced Documents

representative samples of wood preservatives under most

2.1 ASTM Standards:

phases of shipment, use, or storage. Since these materials may

D 95 Test Method for Water in Petroleum Products and

have to be sampled under varying conditions, it is not possible

Bituminous Materials by Distillation

to provide a definite standard for each type of wood preserva-

tive under every sampling condition. Individual cases may

have to be worked out by the sampler on the basis of

These test methods are under the jurisdiction of ASTM Committee D07 on

judgement, skill, and experience. The basic principle of each

Wood and are the direct responsibility of Subcommittee D07.06 on Treatments for

Wood Products.

Current edition approved July 15, 1994. Published September 1994. Originally

published as D 38 – 15 T. Last previous edition D 38 – 79 (1989). Annual Book of ASTM Standards, Vol 04.10.

2 4

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 05.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D38–94 (2000)

method, however, is to obtain a sample or a composite of

several samples in such manner and from such locations in the

container that the sample or composite will be truly represen-

tative of the material being sampled.

4. Apparatus

4.1 Continuous-Drip Sampling:

4.1.1 Line Connection constructed substantially as shown

in Fig. 1 shall be inserted in the pipeline through which the

preservative is being transferred, preferably on the discharge

side of the pump. The sampling pipe shall be provided with a

valve.

4.1.2 Receiver—Use a clean, dry container of convenient

size to receive the sample. The container shall be covered with

a lid to protect the sample from foreign contamination.

Metric Equivalents

mm 6.4 9.5

Creosote, creosote-coal tar solutions, and creosote-petroleum

1 3

in. ⁄4 ⁄8

solutions may become semisolid as they cool in the sample

FIG. 1 Continuous Sampling Connection

container during the course of the sampling. These samples

should be heated to complete liquidity before taking an aliquot

for testing.

4.5 Tube Sampling:

4.2 Zone Sampling:

4.5.1 Glass or Metal Tube, designed so that it will reach to

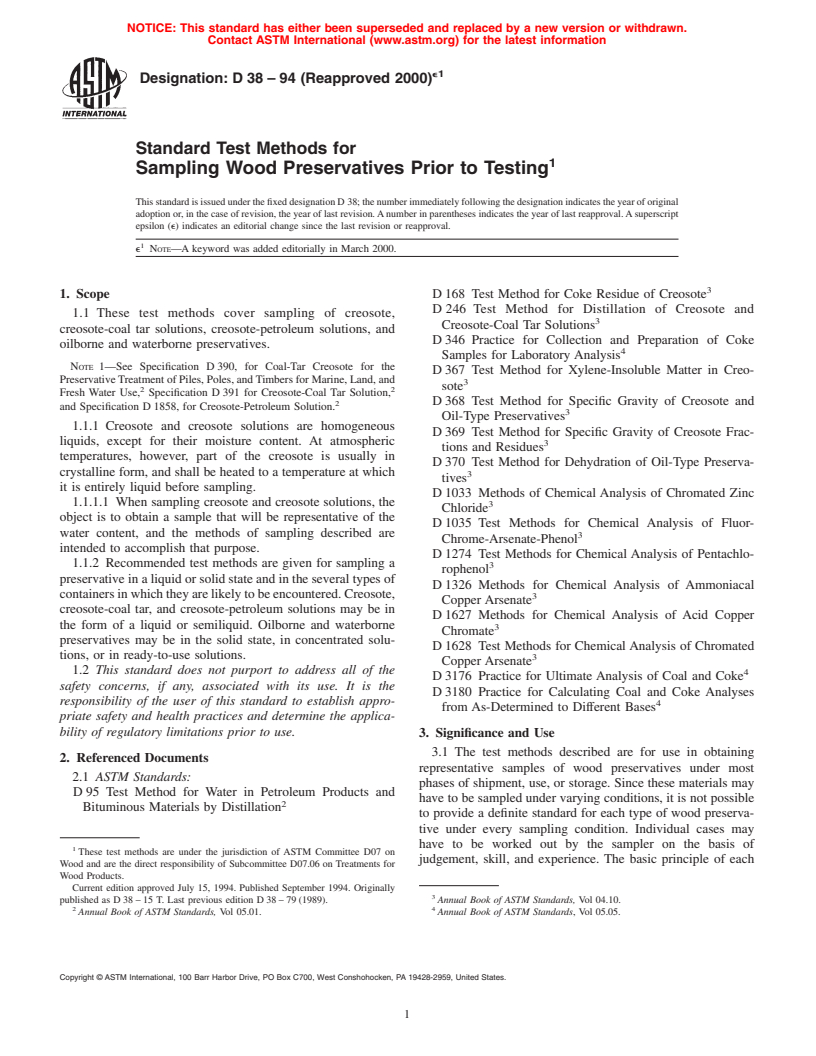

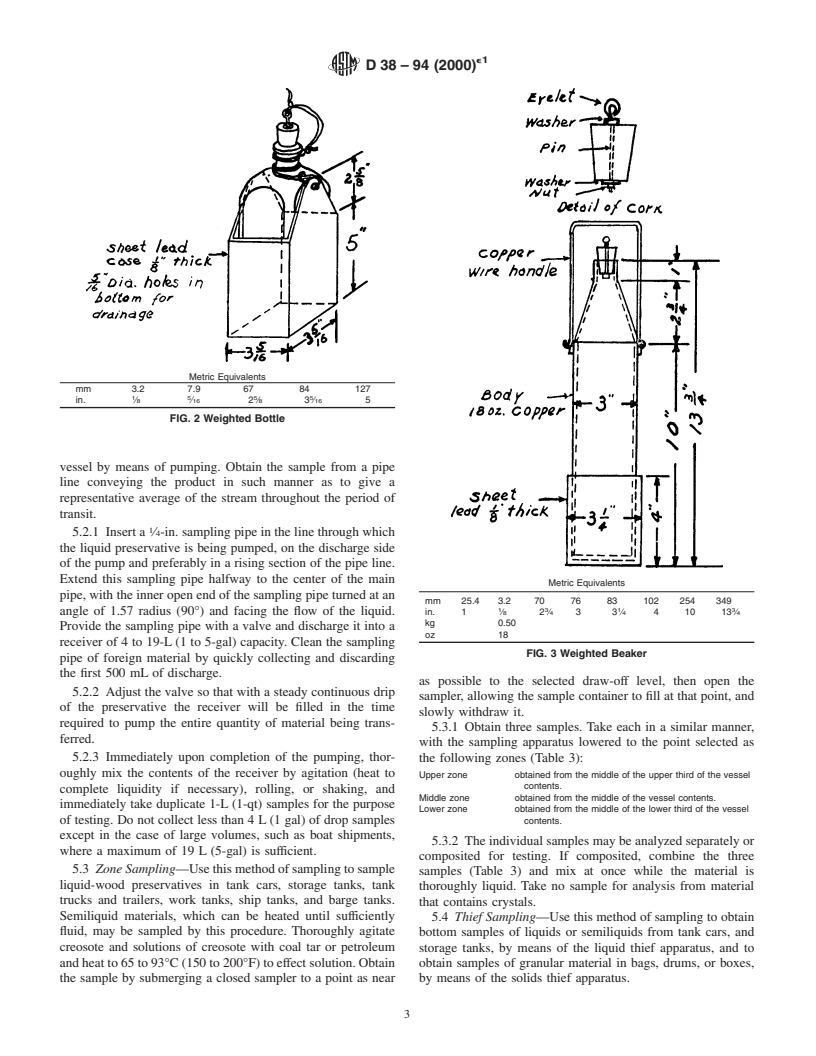

4.2.1 Sampling Bottle (see Figs. 2 and 3) with a 19-mm

3 within 3 mm ( ⁄8 in.) of the bottom of the container. A metal

( ⁄4-in.) diameter opening.

tube for sampling 208-L (55-gal) drums is shown in Fig. 6.

4.3 Thief Sampling:

4.6 Tap Sampling:

4.3.1 For sampling liquids or semiliquids in tank cars, tank

4.6.1 Standard Pipe, with a suitable valve is satisfactory.

trucks, and storage tanks, use a sampling devise designed so

1 The valve should be equipped with a delivery tube which will

that a sample can be obtained within 13 mm ( ⁄2in.) of the

not contaminate or affect the product being sampled.

bottom of the vessel used. A sampling thief for this purpose is

illustrated in Fig. 4.

5. Procedure

4.3.2 For sampling granular material loose carried in bags,

drums, or boxes, use a solids thief sampler 38 mm (1 ⁄2 in.) in 5.1 Recommended Sampling Methods:

diameterandaleast457mm(18in.)longsimilartothatshown 5.1.1 See recommended methods for sampling creosote and

in Fig. 5. creosote solutions in Table 1.

4.4 Grab Sampling: 5.1.2 See recommended methods for sampling oilborne and

4.4.1 Shovel or Scoop, with a width at least twice as great as waterborne preservatives in Table 2.

5.2 Continuous Drip Sampling—Use this method of sam-

the maximum dimension of the largest pieces sampled and a

sample container suitable for the product being sampled. pling wherever a liquid is being loaded or discharged from a

A

TABLE 1 Sampling of Creosote and Creosote Solutions

Size of Sample to be

Shipping, Treating or Storage Preferred Sampling

Time of Sampling Type of Sample Taken from Each Additional Instructions

to be Sampled Method

Container

Ship and barge tanks immediately after loading bottle or beaker all-levels sample approximately 3 gal Gage free water separately if

or prior to unloading sampling creosote is not agitated

thoroughly.

Tank cars and tank trucks immediately after loading bottle or beaker composite of upper 1 gal Gage free water separately if

or prior to unloading sampling middle and lower creosote is not agitated

samples thoroughly. Use Table 1 to

determine proportions of

subsamples in composite

sample.

Vertical storage and working whenever required for bottle or beaker all-levels sample 1–8 gal depending Gage free water separately if

tanks inventory or other sampling on size of tank creosote is not agitated

purposes thoroughly.

Horizontal storage and working whenever required for bottle or beaker composite of upper, 1–3 gal depending Gage free water separately if

tanks inventory or other sampling middle and lower on size of tank creosote is not agitated

purposes samples thoroughly. Use Table 1 to

determine proportions of

subsamples in composite

sample.

Pressure treating cylinders immediately after cylinder tap sampling tap sample 1 gal .

is filled

Non-pressure treating vats immediately after vat is bottle or beaker all-levels sample 1 gal .

filled for cold bath sampling

A

When the sample is taken the temperature of the material should be at least 150°F and the material should be completely liquefied and thoroughly agitated.

e1

D38–94 (2000)

Metric Equivalents

mm 3.2 7.9 67 84 127

1 5 5 5

in. ⁄8 ⁄16 2 ⁄8 3 ⁄16 5

FIG. 2 Weighted Bottle

vessel by means of pumping. Obtain the sample from a pipe

line conveying the product in such manner as to give a

representative average of the stream throughout the period of

transit.

5.2.1 Insert a ⁄4-in. sampling pipe in the line through which

the liquid preservative is being pumped, on the discharge side

of the pump and preferably in a rising section of the pipe line.

Extend this sampling pipe halfway to the center of the main

Metric Equivalents

pipe, with the inner open end of the sampling pipe turned at an

mm 25.4 3.2 70 76 83 102 254 349

1 3 1 3

angle of 1.57 radius (90°) and facing the flow of the liquid.

in. 1 ⁄8 2 ⁄4 33 ⁄4 41013 ⁄4

kg 0.50

Provide the sampling pipe with a valve and discharge it into a

oz 18

receiver of 4 to 19-L (1 to 5-gal) capacity. Clean the sampling

FIG. 3 Weighted Beaker

pipe of foreign material by quickly collecting and discarding

the first 500 mL of discharge.

as possible to the selected draw-off level, then open the

5.2.2 Adjust the valve so that with a steady continuous drip

sampler, allowing the sample container to fill at that point, and

of the preservative the receiver will be filled in the time

slowly withdraw it.

required to pump the entire quantity of material being trans-

5.3.1 Obtain three samples. Take each in a similar manner,

ferred.

with the sampling apparatus lowered to the point selected as

5.2.3 Immediately upon comple

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.