ASTM A563M-06

(Specification)Standard Specification for Carbon and Alloy Steel Nuts [Metric)

Standard Specification for Carbon and Alloy Steel Nuts [Metric)

SCOPE

1.1 This specification covers chemical and mechanical requirements for eight property classes of hex and hex-flange carbon and alloy steel nuts for general structural and mechanical uses on bolts, studs, and other externally threaded parts. Note 1 - Throughout this specification, the term class means property class.Requirements for the four classes 5, 9, 10, and 12 are essentially identical with requirements given for these classes in ISO 898/II. Requirements for Classes 8S and 10S are essentially identical with requirements in an ISO 4775 Hexagon Nuts for High-Strength Structural Bolting with Large Width Across Flats, Product Grade B, Property Classes 8 and 10. Classes 8S3 and 10S3 are not recognized in ISO standards.

1.2 Classes 8S3 and 10S3 nuts have atmospheric corrosion resistance and weathering characteristics comparable to those of the steels covered in Specification A 588/A 588M. The atmospheric corrosion resistance of these steels is substantially better than that of carbon steel with or without copper addition (see ). When properly exposed to the atmosphere, these steels can be used bare (uncoated) for many applications.

1.3 The nut size range for which each class is applicable is given in the table on mechanical requirements.

1.4 gives guidance to assist designers and purchasers in the selection of a suitable class.

1.5 gives data on the properties of slotted hex nuts and hex jam nuts. Note 2This specification is the metric companion of Specification A 563.

1.6 Terms used in this specification are defined in Terminology F 1789 unless otherwise defined herein.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 563M – 06

METRIC

Standard Specification for

1

Carbon and Alloy Steel Nuts [Metric]

This standard is issued under the fixed designation A 563M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers chemical and mechanical re- 2.1 ASTM Standards:

quirements for eight property classes of hex and hex-flange A 153/A 153M Specification for Zinc Coating (Hot-Dip) on

carbon and alloy steel nuts for general structural and mechani- Iron and Steel Hardware

cal uses on bolts, studs, and other externally threaded parts. A 325M Specification for Structural Bolts, Steel, Heat

Treated 830 MPa Minimum Tensile Strength [Metric]

NOTE 1—Throughout this specification, the term class means property

A 394 Specification for Steel Transmission Tower Bolts,

class.

Zinc-Coated and Bare

NOTE 2—Requirements for the four classes 5, 9, 10, and 12 are

essentially identical with requirements given for these classes in ISO A 490M Specification for High-Strength Steel Bolts,

898/II. Requirements for Classes 8S and 10S are essentially identical with

Classes10.9and10.9.3,forStructuralSteelJoints[Metric]

requirements in an ISO 4775 Hexagon Nuts for High-Strength Structural

A 588/A 588M Specification for High-Strength Low-Alloy

BoltingwithLargeWidthAcrossFlats,ProductGradeB,PropertyClasses

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

8 and 10. Classes 8S3 and 10S3 are not recognized in ISO standards.

Point, with Atmospheric Corrosion Resistance

1.2 Classes 8S3 and 10S3 nuts have atmospheric corrosion

A 751 Test Methods, Practices, and Terminology for

resistance and weathering characteristics comparable to those

Chemical Analysis of Steel Products

of the steels covered in Specification A 588/A 588M. The

B 695 Specification for Coatings of Zinc Mechanically

atmospheric corrosion resistance of these steels is substantially

Deposited on Iron and Steel

better than that of carbon steel with or without copper addition

D 3951 Practice for Commercial Packaging

(see 5.2). When properly exposed to the atmosphere, these

F 568M SpecificationforCarbonandAlloySteelExternally

steels can be used bare (uncoated) for many applications.

Threaded Metric Fasteners

1.3 The nut size range for which each class is applicable is

F 606M Test Methods for Determining the Mechanical

given in the table on mechanical requirements.

Properties of Externally and InternallyThreaded Fasteners,

1.4 Appendix X1 gives guidance to assist designers and

Washers, and Rivets [Metric]

purchasers in the selection of a suitable class.

F 812/F 812M Specification for Surface Discontinuities of

3

1.5 Appendix X2 gives data on the properties of slotted hex

Nuts, Inch and Metric Series

nuts and hex jam nuts.

F 1789 Terminology for F16 Mechanical Fasteners

G 101 Guide for Estimating the Atmospheric Corrosion

NOTE 3—This specification is the metric companion of Specification

Resistance of Low-Alloy Steels

A 563.

4

2.2 ANSI Standards:

1.6 Terms used in this specification are defined in Termi-

nology F 1789 unless otherwise defined herein.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee F16 on Standards volume information, refer to the standard’s Document Summary page on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, the ASTM website.

3

Nuts, Rivets and Washers. Withdrawn.

4

Current edition approved June 1, 2006. Published June 2006. Originally Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

approved in 1980. Last previous edition approved in 2004 as A 563M – 04. 4th Floor, New York, NY 10036.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A563M–06

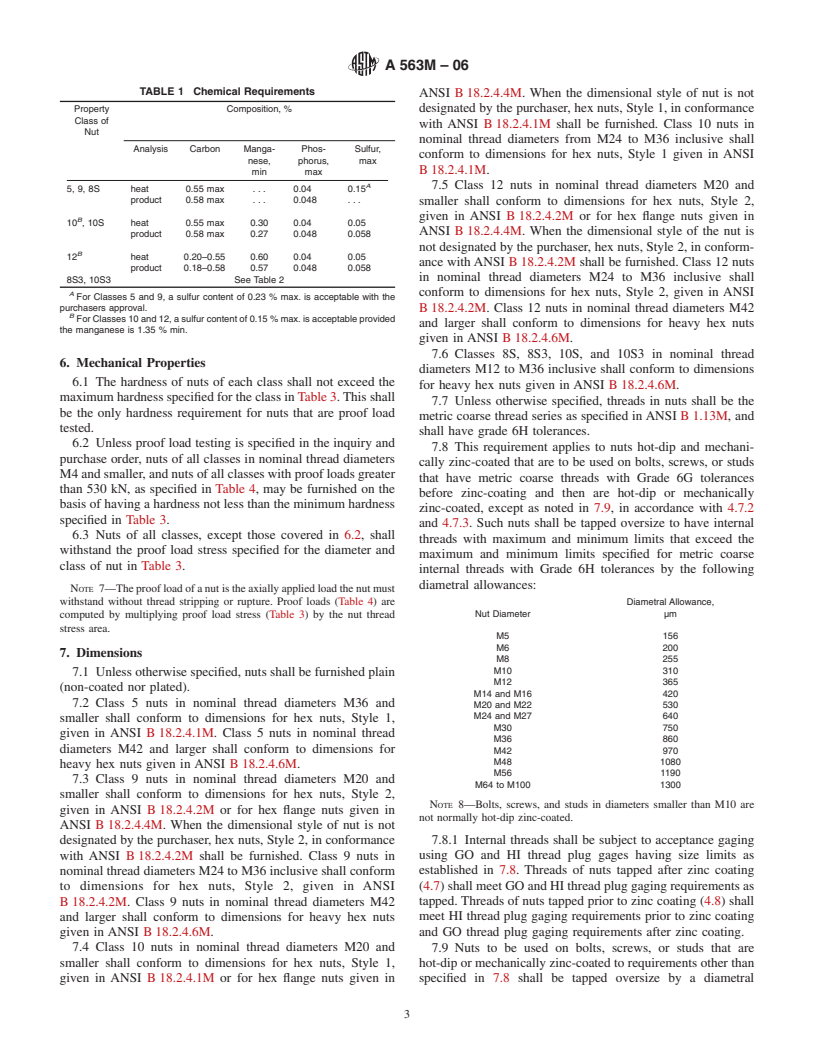

B 1.13M Metric Screw Threads—M Profile 4.5 Class 8S nuts made of steel having a carbon content not

exceeding 0.20 %, phosphorus not exceeding 0.04 %, and

B 18.2.4.1M Metric Hex Nuts, Style 1

sulfur not exceeding 0.05 % by heat analysis may be heat

B 18.2.4.2M Metric Hex Nuts, Style 2

treated by quenching in a liquid medium from a temperature

B 18.2.4.3M Metric Slotted Hex Nuts

above the transformation temperature and need not be tem-

B 18.2.4.4M Metric Hex Flange Nuts

pered. When this hea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.