ASTM D4807-05(2020)

(Test Method)Standard Test Method for Sediment in Crude Oil by Membrane Filtration

Standard Test Method for Sediment in Crude Oil by Membrane Filtration

SIGNIFICANCE AND USE

4.1 A knowledge of the sediment content of crude oil is important both in refinery operations and in crude oil commerce.

SCOPE

1.1 This test method covers the determination of sediment in crude oils by membrane filtration. This test method has been validated for crude oils with sediments up to approximately 0.15 % by mass.

1.2 The accepted unit of measure for this test method is mass %, but an equation to convert to volume % is provided (see Note 6).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.1 and Annex A1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4807 − 05 (Reapproved 2020)

Manual of Petroleum Measurement Standards (MPMS), Chapter 10.8

Standard Test Method for

1

Sediment in Crude Oil by Membrane Filtration

This standard is issued under the fixed designation D4807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D473TestMethodforSedimentinCrudeOilsandFuelOils

by the Extraction Method

1.1 This test method covers the determination of sediment

D4057Practice for Manual Sampling of Petroleum and

incrudeoilsbymembranefiltration.Thistestmethodhasbeen

Petroleum Products

validated for crude oils with sediments up to approximately

D4177Practice for Automatic Sampling of Petroleum and

0.15% by mass.

Petroleum Products

1.2 The accepted unit of measure for this test method is

D4865Guide for Generation and Dissipation of Static Elec-

mass%, but an equation to convert to volume% is provided

tricity in Petroleum Fuel Systems

(see Note 6).

D5854Practice for Mixing and Handling of Liquid Samples

1.3 The values stated in SI units are to be regarded as the

of Petroleum and Petroleum Products

standard. The values given in parentheses are for information

3

2.2 API Standards:

only.

MPMS Chapter 8.1Manual Sampling of Petroleum and

1.4 This standard does not purport to address all of the

Petroleum Products (ASTM Practice D4057)

safety concerns, if any, associated with its use. It is the

MPMS Chapter 8.2Automatic Sampling of Petroleum and

responsibility of the user of this standard to establish appro-

Petroleum Products (ASTM Practice D4177)

priate safety, health, and environmental practices and deter-

MPMSChapter8.3MixingandHandlingofLiquidSamples

mine the applicability of regulatory limitations prior to use.

of Petroleum and Petroleum Products (ASTM Practice

For specific warning statements, see 6.1 and Annex A1.

D5854)

1.5 This international standard was developed in accor-

MPMS Chapter 10.1Test Method for Sediment in Crude

dance with internationally recognized principles on standard-

Oils and Fuel Oils by the Extraction Method (ASTMTest

ization established in the Decision on Principles for the

Method D473)

Development of International Standards, Guides and Recom-

4

mendations issued by the World Trade Organization Technical 2.3 ISO Standard:

Barriers to Trade (TBT) Committee. ISO 5272:1979Toluene for Industrial Use—Specifications

2. Referenced Documents

3. Summary of Test Method

2

2.1 ASTM Standards:

3.1 A portion of a representative crude oil sample is

dissolved in hot toluene and filtered under vacuum through a

1

This test method is under the jurisdiction of ASTM Committee D02 on

0.45µm porosity membrane filter. The filter with residue is

Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on

washed, dried, and weighed to give the final result.

Petroleum Measurement, and is the direct responsibility of Subcommittee D02.02

/COMQ on Hydrocarbon Measurement for Custody Transfer (Joint ASTM-API).

Current edition approved May 1, 2020. Published June 2020. Originally

approved in 1988. Last previous edition approved in 2015 as D4807 – 05 (2015).

3

DOI: 10.1520/D4807-05R20. Published as Manual of Petroleum Measurement Standards. Available from

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AmericanPetroleumInstitute(API),1220L.St.,NW,Washington,DC20005-4070,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM http://www.api.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

© Jointly copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, USA and the American Petroleum Institute (API), 1220 L Street NW, Washington DC 20005, USA

1

---------------------- Page: 1 ----------------------

D4807 − 05 (2020)

5.4 Vacuum Pump—Use a vacuum pump capable of reduc-

ing and maintaining the pressure at −80kPa (−24in. Hg)

during the filtering.

5.5 Analytical Balance—Use an analytical balance capable

of measuring to the nearest 0.0001g. Verify the balance, at

least annually, against weights traceable to a national metrol-

ogy institute such as the National Institute of Standards and

Technology (NIST).

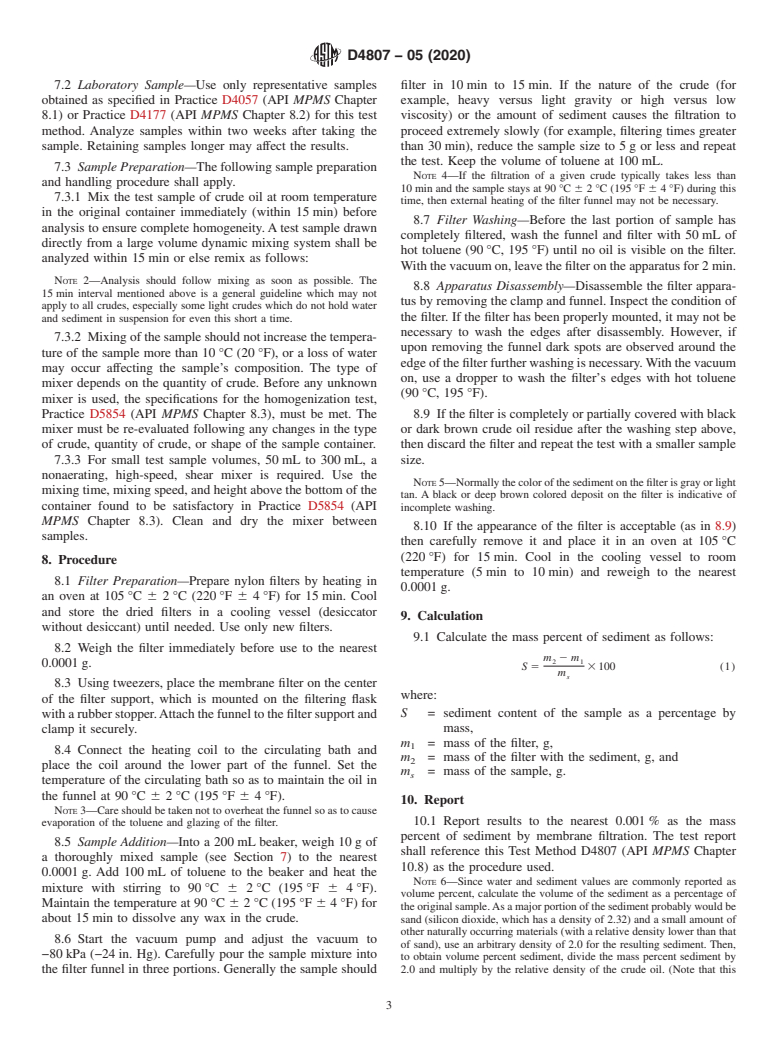

FIG. 1 Membrane Filtration Assembly

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.