ASTM E674-12(2021)

(Specification)Standard Specification for Industrial Perforated Plate and Screens (Round Opening Series)

Standard Specification for Industrial Perforated Plate and Screens (Round Opening Series)

ABSTRACT

This specification covers the various sizes of round opening perforated plates and screens for general industrial uses, including the separating or grading of materials according to designated nominal particle size, and lists standards for openings punched with various bar sizes and thicknesses of plate for various grades of service. This specification does not apply to perforated plates or screens with square, hexagon, slotted, or other shaped openings.

SCOPE

1.1 This specification covers the sizes of round opening perforated plate and screens for general industrial uses, including the separating or grading of materials according to designated nominal particle size, and lists standards for openings from 5 in. (125 mm) to 0.020 in. (500 μm) punched with bar sizes and thicknesses of plate for various grades of service. Methods of checking industrial perforated plate and screens are included as information in Appendix X3.

1.2 This specification does not apply to perforated plate or screens with square, hexagon, slotted, or other shaped openings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E674 −12 (Reapproved 2021)

Standard Specification for

Industrial Perforated Plate and Screens (Round Opening

Series)

This standard is issued under the fixed designation E674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Industrial perforated plate can be produced in many thousands of combinations of size and shape

of opening, bar size, thickness of material, and type of metal. Such variety is often confusing and, to

the vast majority of perforated plate users, unnecessary, since each usually requires only a very few

specifications.

The purpose of this specification is to simplify this problem by a condensed table of recommended

specifications covering a wide range of openings in which industrial perforated plate is made, with

several recommended bar sizes and thicknesses of plate for each opening, for use in various grades of

service.

By making selections from this specification, the user will be guided to specifications that are being

regularly produced, thus avoiding inadvertent selection of specifications that, because of little or no

demand,areunobtainable,exceptonspecialorder(usuallyquiteexpensiveunlessthequantityordered

is sufficient to justify the cost of special tooling).

Ifauserhasaspecificapplicationforindustrialperforatedplatethatcannotbesolvedbyaselection

from this specification, it is recommended that he consult his perforated plate supplier on the

availability of an acceptable alternative specification.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This specification covers the sizes of round opening

responsibility of the user of this standard to establish appro-

perforated plate and screens for general industrial uses, includ-

priate safety, health, and environmental practices and deter-

ing the separating or grading of materials according to desig-

mine the applicability of regulatory limitations prior to use.

nated nominal particle size, and lists standards for openings

1.5 This international standard was developed in accor-

from 5 in. (125 mm) to 0.020 in. (500 µm) punched with bar

dance with internationally recognized principles on standard-

sizes and thicknesses of plate for various grades of service.

ization established in the Decision on Principles for the

Methodsofcheckingindustrialperforatedplateandscreensare

Development of International Standards, Guides and Recom-

included as information in Appendix X3.

mendations issued by the World Trade Organization Technical

1.2 This specification does not apply to perforated plate or

Barriers to Trade (TBT) Committee.

screens with square, hexagon, slotted, or other shaped open-

ings.

2. Referenced Documents

1.3 The values stated in inch-pound units are to be regarded

2.1 ASTM Standards:

as standard. The values given in parentheses are mathematical

E323 Specification for Perforated-Plate Sieves for Testing

conversions to SI units that are provided for information only

Purposes

and are not considered standard.

E1638 Terminology Relating to Sieves, Sieving Methods,

and Screening Media

ThisspecificationisunderthejurisdictionofASTMCommitteeE29onParticle

and Spray Characterization and is the direct responsibility of Subcommittee E29.01

on Sieves, Sieving Methods, and Screening Media. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2021. Published October 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1979. Last previous edition approved in 2016 as E674 – 12 (2016). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0674-12R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E674−12 (2021)

2.2 ISO Standards: 3.2.10 percent open area, n—theratioofthetotalareaofthe

ISO 2194 Industrial screens —Woven wire cloth, perforated apertures to the total area expressed in percentage.

plate and electroformed sheet — Designation and nominal

3.2.11 perforated pattern, n—the patterns that the perfora-

sizes of openings

tions are arranged in, usually in a staggered pattern with

2.3 Other Documents:

midpoints nominally at the vertices of isosceles triangles or

Fed. Std. 123 Marking for Shipments (Civil Agencies)

square patterns arranged in line with their midpoints nominally

Mil-Std-129 Marking for Shipment and Storage

at the vertices of squares.

3.2.12 screen, n—(1) surface provided with apertures of

3. Terminology

uniform size and shape; (2) another term used interchangeably

3.1 Definitions—For general terms related to sieves, sieving

for woven wire cloth; (3) machine provided with one or more

methods, and screening media, see Terminology E1638.

screen surfaces.

3.2 Definitions of Terms Specific to This Standard:

3.2.13 screening, v—process of separating a mixture of

3.2.1 aperture, n—the opening in a screening or sieving

different sizes by means of one or more screen surfaces.

medium.

3.2.14 smooth side or punch side, n—surface of the plate

3.2.2 bar, n—the metal between perforations.

that was uppermost during the punching operation and through

3.2.3 blank, n—unperforated area located other than along

which the punch entered the plate.

the perimeter of a plate.

3.2.15 unfinished end pattern, n—condition that occurs with

3.2.4 break-out, n—term applied to the action that occurs

somespecificationsofstaggeredpatternperforationsasaresult

ahead of the punch in its going through the plate.

of tool design.

3.2.4.1 Discussion—The fracturing of the material results in

3.2.15.1 Discussion—On one end of the plate, the pattern

a tapered hole with the small dimensions on the punch side.

will appear to be incomplete as a result of unperforated holes

3.2.5 centers, n—dimensional sum of one perforation and

in the even numbered rows, while on the other end of the same

one bar or the dimensional distance from the center of one

plate, the pattern will appear to be incomplete because of

perforation to the center of an adjacent perforation.

unperforated holes in the odd numbered rows (Fig. 2).

3.2.6 die side, n—surface of the plate that was against the

4. Standard Specifications

die during the punching operation.

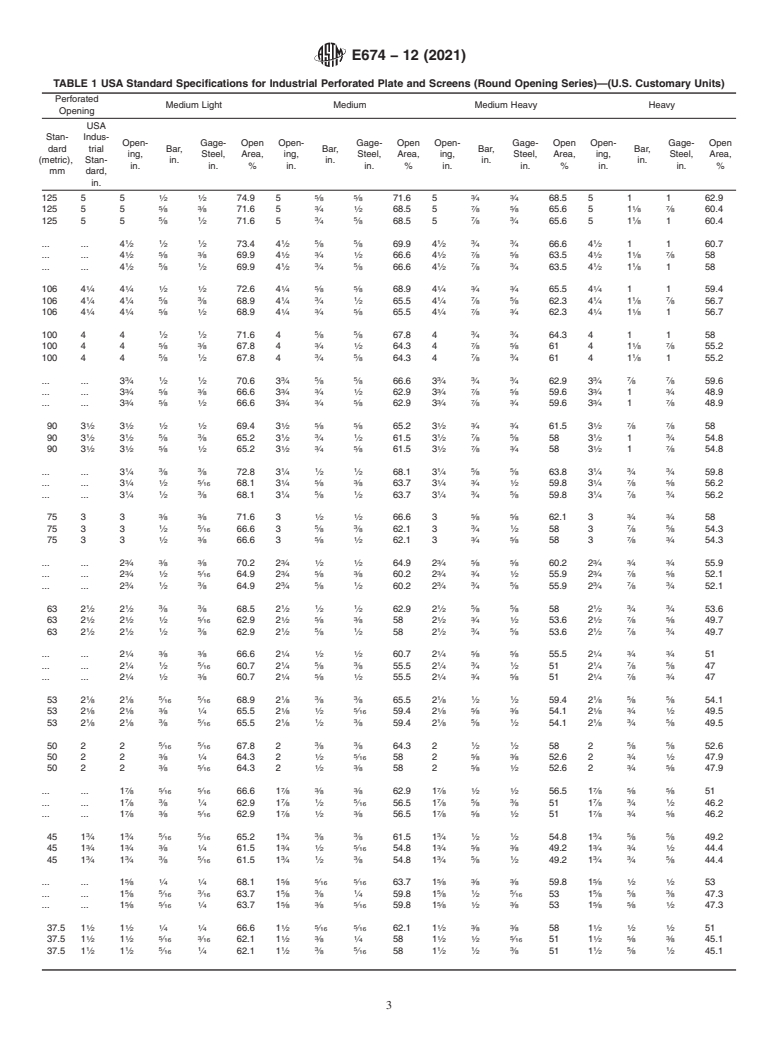

4.1 Standard specifications for industrial perforated plate

3.2.7 finished end pattern, n—condition that occurs with

and screens are listed in Table 1.

somespecificationsofstaggeredpatternperforationsasaresult

4.2 Openings—The series of standard openings listed in

of tool design in which the pattern is completed on both ends

Table 1 include those of the USA Standard Sieve Series,

of the plate (Fig. 1).

Specification E323, and those of the ISO apertures for indus-

3.2.8 gage (also gauge), n—a number designating a specific

trial plate screens, ISO 2194, with the addition of those

thicknessofmetalsheettabulatedinastandardizedseries,each

openings in common usage.

of which represents a decimal fraction of an inch.

4.3 Relationship of Grades—The purpose of the several

3.2.9 margin or border, n—unperforated area located along

grades is to provide combinations of opening and bar size for

the perimeter of a plate.

various types of service, from medium-light to heavy. Since it

is possible to vary the bar size independently from the plate

thickness, each of the service grades lists up to three combi-

Available from International Organization for Standardization (ISO), 1, ch. de

nations of bar and gage for each opening. The entire standard

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch.

series has been designed for a logical relationship of bar size to

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

opening in each grade and between grades with the capability

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

of also being able to vary the plate thickness.

FIG. 1 Finished End Pattern FIG. 2 Unfinished End Pattern

E674−12 (2021)

TABLE 1 USA Standard Specifications for Industrial Perforated Plate and Screens (Round Opening Series)—(U.S. Customary Units)

Perforated

Medium Light Medium Medium Heavy Heavy

Opening

USA

Stan- Indus-

Open- Gage- Open Open- Gage- Open Open- Gage- Open Open- Gage- Open

dard trial Bar, Bar, Bar, Bar,

ing, Steel, Area, ing, Steel, Area, ing, Steel, Area, ing, Steel, Area,

(metric), Stan- in. in. in. in.

in. in. % in. in. % in. in. % in. in. %

mm dard,

in.

1 1 5 5 3 3

125 5 5 ⁄2 ⁄2 74.9 5 ⁄8 ⁄8 71.6 5 ⁄4 ⁄4 68.5 5 1 1 62.9

5 3 3 1 7 5 1 7

125 5 5 ⁄8 ⁄8 71.6 5 ⁄4 ⁄2 68.5 5 ⁄8 ⁄8 65.6 5 1 ⁄8 ⁄8 60.4

5 1 3 5 7 3 1

125 5 5 ⁄8 ⁄2 71.6 5 ⁄4 ⁄8 68.5 5 ⁄8 ⁄4 65.6 5 1 ⁄8 1 60.4

1 1 1 1 5 5 1 3 3 1

... ... 4 ⁄2 ⁄2 ⁄2 73.4 4 ⁄2 ⁄8 ⁄8 69.9 4 ⁄2 ⁄4 ⁄4 66.6 4 ⁄2 1 1 60.7

1 5 3 1 3 1 1 7 5 1 1 7

... ... 4 ⁄2 ⁄8 ⁄8 69.9 4 ⁄2 ⁄4 ⁄2 66.6 4 ⁄2 ⁄8 ⁄8 63.5 4 ⁄2 1 ⁄8 ⁄8 58

1 5 1 1 3 5 1 7 3 1 1

... ... 4 ⁄2 ⁄8 ⁄2 69.9 4 ⁄2 ⁄4 ⁄8 66.6 4 ⁄2 ⁄8 ⁄4 63.5 4 ⁄2 1 ⁄8 158

1 1 1 1 1 5 5 1 3 3 1

106 4 ⁄4 4 ⁄4 ⁄2 ⁄2 72.6 4 ⁄4 ⁄8 ⁄8 68.9 4 ⁄4 ⁄4 ⁄4 65.5 4 ⁄4 1 1 59.4

1 1 5 3 1 3 1 1 7 5 1 1 7

106 4 ⁄4 4 ⁄4 ⁄8 ⁄8 68.9 4 ⁄4 ⁄4 ⁄2 65.5 4 ⁄4 ⁄8 ⁄8 62.3 4 ⁄4 1 ⁄8 ⁄8 56.7

1 1 5 1 1 3 5 1 7 3 1 1

106 4 ⁄4 4 ⁄4 ⁄8 ⁄2 68.9 4 ⁄4 ⁄4 ⁄8 65.5 4 ⁄4 ⁄8 ⁄4 62.3 4 ⁄4 1 ⁄8 1 56.7

1 1 5 5 3 3

100 4 4 ⁄2 ⁄2 71.6 4 ⁄8 ⁄8 67.8 4 ⁄4 ⁄4 64.3 41158

5 3 3 1 7 5 1 7

100 4 4 ⁄8 ⁄8 67.8 4 ⁄4 ⁄2 64.3 4 ⁄8 ⁄8 61 4 1 ⁄8 ⁄8 55.2

5 1 3 5 7 3 1

100 4 4 ⁄8 ⁄2 67.8 4 ⁄4 ⁄8 64.3 4 ⁄8 ⁄4 61 4 1 ⁄8 1 55.2

3 1 1 3 5 5 3 3 3 3 7 7

... ... 3 ⁄4 ⁄2 ⁄2 70.6 3 ⁄4 ⁄8 ⁄8 66.6 3 ⁄4 ⁄4 ⁄4 62.9 3 ⁄4 ⁄8 ⁄8 59.6

3 5 3 3 3 1 3 7 5 3 3

... ... 3 ⁄4 ⁄8 ⁄8 66.6 3 ⁄4 ⁄4 ⁄2 62.9 3 ⁄4 ⁄8 ⁄8 59.6 3 ⁄4 1 ⁄4 48.9

3 5 1 3 3 5 3 7 3 3 7

... ... 3 ⁄4 ⁄8 ⁄2 66.6 3 ⁄4 ⁄4 ⁄8 62.9 3 ⁄4 ⁄8 ⁄4 59.6 3 ⁄4 1 ⁄8 48.9

1 1 1 1 1 5 5 1 3 3 1 7 7

90 3 ⁄2 3 ⁄2 ⁄2 ⁄2 69.4 3 ⁄2 ⁄8 ⁄8 65.2 3 ⁄2 ⁄4 ⁄4 61.5 3 ⁄2 ⁄8 ⁄8 58

1 1 5 3 1 3 1 1 7 5 1 3

90 3 ⁄2 3 ⁄2 ⁄8 ⁄8 65.2 3 ⁄2 ⁄4 ⁄2 61.5 3 ⁄2 ⁄8 ⁄8 58 3 ⁄2 1 ⁄4 54.8

1 1 5 1 1 3 5 1 7 3 1 7

90 3 ⁄2 3 ⁄2 ⁄8 ⁄2 65.2 3 ⁄2 ⁄4 ⁄8 61.5 3 ⁄2 ⁄8 ⁄4 58 3 ⁄2 1 ⁄8 54.8

1 3 3 1 1 1 1 5 5 1 3 3

... ... 3 ⁄4 ⁄8 ⁄8 72.8 3 ⁄4 ⁄2 ⁄2 68.1 3 ⁄4 ⁄8 ⁄8 63.8 3 ⁄4 ⁄4 ⁄4 59.8

1 1 5 1 5 3 1 3 1 1 7 5

... ... 3 ⁄4 ⁄2 ⁄16 68.1 3 ⁄4 ⁄8 ⁄8 63.7 3 ⁄4 ⁄4 ⁄2 59.8 3 ⁄4 ⁄8 ⁄8 56.2

1 1 3 1 5 1 1 3 5 1 7 3

... ... 3 ⁄4 ⁄2 ⁄8 68.1 3 ⁄4 ⁄8 ⁄2 63.7 3 ⁄4 ⁄4 ⁄8 59.8 3 ⁄4 ⁄8 ⁄4 56.2

3 3 1 1 5 5 3 3

75 3 3 ⁄8 ⁄8 71.6 3 ⁄2 ⁄2 66.6 3 ⁄8 ⁄8 62.1 3 ⁄4 ⁄4 58

1 5 5 3 3 1 7 5

75 3 3 ⁄2 ⁄16 66.6 3 ⁄8 ⁄8 62.1 3 ⁄4 ⁄2 58 3 ⁄8 ⁄8 54.3

1 3 5 1 3 5 7 3

75 3 3 ⁄2 ⁄8 66.6 3 ⁄8 ⁄2 62.1 3 ⁄4 ⁄8 58 3 ⁄8 ⁄4 54.3

3 3 3 3 1 1 3 5 5 3 3 3

... ... 2 ⁄4 ⁄8 ⁄8 70.2 2 ⁄4 ⁄2 ⁄2 64.9 2 ⁄4 ⁄8 ⁄8 60.2 2 ⁄4 ⁄4 ⁄4 55.9

3 1 5 3 5 3 3 3 1 3 7 5

... ... 2 ⁄4 ⁄2 ⁄16 64.9 2 ⁄4 ⁄8 ⁄8 60.2 2 ⁄4 ⁄4 ⁄2 55.9 2 ⁄4 ⁄8 ⁄8 52.1

3 1 3 3 5 1 3 3 5 3 7 3

... ... 2 ⁄4 ⁄2 ⁄8 64.9 2 ⁄4 ⁄8 ⁄2 60.2 2 ⁄4 ⁄4 ⁄8 55.9 2 ⁄4 ⁄8 ⁄4 52.1

1 1 3 3 1 1 1 1 5 5 1 3 3

63 2 ⁄2 2 ⁄2 ⁄8 ⁄8 68.5 2 ⁄2 ⁄2 ⁄2 62.9 2 ⁄2 ⁄8 ⁄8 58 2 ⁄2 ⁄4 ⁄4 53.6

1 1 1 5 1 5 3 1 3 1 1 7 5

63 2 ⁄2 2 ⁄2 ⁄2 ⁄16 62.9 2 ⁄2 ⁄8 ⁄8 58 2 ⁄2 ⁄4 ⁄2 53.6 2 ⁄2 ⁄8 ⁄8 49.7

1 1 1 3 1 5 1 1 3 5 1 7 3

63 2 ⁄2 2 ⁄2 ⁄2 ⁄8 62.9 2 ⁄2 ⁄8 ⁄2 58 2 ⁄2 ⁄4 ⁄8 53.6 2 ⁄2 ⁄8 ⁄4 49.7

1 3 3 1 1 1 1 5 5 1 3 3

... ... 2 ⁄4 ⁄8 ⁄8 66.6 2 ⁄4 ⁄2 ⁄2 60.7 2 ⁄4 ⁄8 ⁄8 55.5 2 ⁄4 ⁄4 ⁄4 51

1 1 5 1 5 3 1 3 1 1 7 5

... ... 2 ⁄4 ⁄2 ⁄16 60.7 2 ⁄4 ⁄8 ⁄8 55.5 2 ⁄4 ⁄4 ⁄2 51 2 ⁄4 ⁄8 ⁄8 47

1 1 3 1 5 1 1 3 5 1 7 3

... ... 2 ⁄4 ⁄2 ⁄8 60.7 2 ⁄4 ⁄8 ⁄2 55.5 2 ⁄4 ⁄4 ⁄8 51 2 ⁄4 ⁄8 ⁄4 47

1 1 5 5 1 3 3 1 1 1 1 5 5

53 2 ⁄8 2 ⁄8 ⁄16 ⁄16 68.9 2 ⁄8 ⁄8 ⁄8 65.5 2 ⁄8 ⁄2 ⁄2 59.4 2 ⁄8 ⁄8 ⁄8 54.1

1 1 3 1 1 1 5 1 5 3 1 3 1

53 2 ⁄8 2 ⁄8 ⁄8 ⁄4 65.5 2 ⁄8 ⁄2 ⁄16 59.4 2 ⁄8 ⁄8 ⁄8 54.1 2 ⁄8 ⁄4 ⁄2 49.5

1 1 3 5 1 1 3 1 5 1 1 3 5

53 2 ⁄8 2 ⁄8 ⁄8 ⁄16 65.5 2 ⁄8 ⁄2 ⁄8 59.4 2 ⁄8 ⁄8 ⁄2 54.1 2 ⁄8 ⁄4 ⁄8 49.5

5 5 3 3 1 1 5 5

50 2 2 ⁄16 ⁄16 67.8 2 ⁄8 ⁄8 64.3 2 ⁄2 ⁄2 58 2 ⁄8 ⁄8 52.6

3 1 1 5 5 3 3 1

50 2 2 ⁄8 ⁄4 64.3 2 ⁄2 ⁄16 58 2 ⁄8 ⁄8 52.6 2 ⁄4 ⁄2 47.9

3 5 1 3 5 1 3 5

50 2 2 ⁄8 ⁄16 64.3 2 ⁄2 ⁄8 58 2 ⁄8 ⁄2 52.6 2 ⁄4 ⁄8 47.9

7 5 5 7 3 3 7 1 1 7 5 5

... ... 1 ⁄8 ⁄16 ⁄16 66.6 1 ⁄8 ⁄8 ⁄8 62.9 1 ⁄8 ⁄2 ⁄2 56.5 1 ⁄8 ⁄8 ⁄8 51

7 3 1 7 1 5 7 5 3 7 3 1

... ... 1 ⁄8 ⁄8 ⁄4 62.9 1 ⁄8 ⁄2 ⁄16 56.5 1 ⁄8 ⁄8 ⁄8 51 1 ⁄8 ⁄4 ⁄2 46.2

7 3 5 7 1 3 7 5 1 7 3 5

... ... 1 ⁄8 ⁄8 ⁄16 62.9 1 ⁄8 ⁄2 ⁄8 56.5 1 ⁄8 ⁄8 ⁄2 51 1 ⁄8 ⁄4 ⁄8 46.2

3 3 5 5 3 3 3 3 1 1 3 5 5

45 1 ⁄4 1 ⁄4 ⁄16 ⁄16 65.2 1 ⁄4 ⁄8 ⁄8 61.5 1 ⁄4 ⁄2 ⁄2 54.8 1 ⁄4 ⁄8 ⁄8 49.2

3 3 3 1 3 1 5 3 5 3 3 3 1

45 1 ⁄4 1 ⁄4 ⁄8 ⁄4 61.5 1 ⁄4 ⁄2 ⁄16 54.8 1 ⁄4 ⁄8 ⁄8 49.2 1 ⁄4 ⁄4 ⁄2 44.4

3 3 3 5 3 1 3 3 5 1 3 3 5

45 1 ⁄4 1 ⁄4 ⁄8 ⁄16 61.5 1 ⁄4 ⁄2 ⁄8 54.8 1 ⁄4 ⁄8 ⁄2 49.2 1 ⁄4 ⁄4 ⁄8 44.4

5 1 1 5 5 5 5 3 3 5 1 1

... ... 1 ⁄8 ⁄4 ⁄4 68.1 1 ⁄8 ⁄16 ⁄16 63.7 1 ⁄8 ⁄8 ⁄8 59.8 1 ⁄8 ⁄2 ⁄2 53

5 5 3 5 3 1 5 1 5 5 5 3

... ... 1 ⁄8 ⁄16 ⁄16 63.7 1 ⁄8 ⁄8 ⁄4 59.8 1 ⁄8 ⁄2 ⁄16 53 1 ⁄8 ⁄8 ⁄8 47.3

5 5 1 5 3 5 5 1 3 5 5 1

... ... 1 ⁄8 ⁄16 ⁄4 63.7 1 ⁄8 ⁄8 ⁄16 59.8 1 ⁄8 ⁄2 ⁄8 53 1 ⁄8 ⁄8 ⁄2 47.3

1 1 1 1 1 5 5 1 3 3 1 1 1

37.5 1 ⁄2 1 ⁄2 ⁄4 ⁄4 66.6 1 ⁄2 ⁄16 ⁄16 62.1 1 ⁄2 ⁄8 ⁄8 58 1 ⁄2 ⁄2 ⁄2 51

1 1 5 3 1 3 1 1 1 5 1 5 3

37.5 1 ⁄2 1 ⁄2 ⁄16 ⁄16 62.1 1 ⁄2 ⁄8 ⁄4 58 1 ⁄2 ⁄2 ⁄16 51 1 ⁄2 ⁄8 ⁄8 45.1

1 1 5 1 1 3 5 1 1 3 1 5 1

37.5 1 ⁄2 1 ⁄2 ⁄16 ⁄4 62.1 1 ⁄2 ⁄8 ⁄16 58 1 ⁄2 ⁄2 ⁄8 51 1 ⁄2 ⁄8 ⁄2 45.1

E674−12 (2021)

TABLE1 Continued

Perforated

Medium Light Medium Medium Heavy Heavy

Opening

USA

Stan- Indus-

Open- Gage- Open Open- Gage- Open Open- Gage- Open Open- Gage- Open

dard trial Bar, Bar, Bar, Bar,

ing, Steel, Area, ing, Steel, Area, ing, Steel, Area, ing, Steel, Area,

(metric), Stan- in. in. in. in.

in. in. % in. in. % in. in. % in. in. %

mm dard,

in.

3 1 1 3 5 5 3 3 3 3 1 1

... ... 1 ⁄8 ⁄4 ⁄4 64.9 1 ⁄8 ⁄16 ⁄16 60.2 1 ⁄8 ⁄8 ⁄8 55.9 1 ⁄8 ⁄2 ⁄2 48.7

3 5 3 3 3 1 3 1 5 3 5 3

... ... 1 ⁄8 ⁄16 ⁄16 60.2 1 ⁄8 ⁄8 ⁄4 55.9 1 ⁄8 ⁄2 ⁄16 48.7 1 ⁄8 ⁄8 ⁄8 42.8

3 5 1 3 3 5 3 1 3 3 5 1

... ... 1 ⁄8 ⁄16 ⁄4 60.2 1 ⁄8 ⁄8 ⁄16 55.9 1 ⁄8 ⁄2 ⁄8 48.7 1 ⁄8 ⁄8 ⁄2 42.8

1 1 1 1 1 5 5 1 3 3 1 1 1

31.5 1 ⁄4 1 ⁄4 ⁄4 ⁄4 62.9 1 ⁄4 ⁄16 ⁄16 58 1 ⁄4 ⁄8 ⁄8 53.6 1 ⁄4 ⁄2 ⁄2 46.2

1 1 5 3 1 3 1 1 1 5 1 5 3

31.5 1 ⁄4 1 ⁄4 ⁄16 ⁄16 58 1 ⁄4 ⁄8 ⁄4 53.6 1 ⁄4 ⁄2 ⁄16 46.2 1 ⁄4 ⁄8 ⁄8 40.3

1 1 5 1 1 3 5 1 1 3 1 5 1

31.5 1 ⁄4 1 ⁄4 ⁄16 ⁄4 58 1 ⁄4 ⁄8 ⁄16 53.6 1 ⁄4 ⁄2 ⁄8 46.2 1 ⁄4 ⁄8 ⁄2 40.3

3 3 3 3 1 1 3 5 5 3 3 3

... ... 1 ⁄16 ⁄16 ⁄16 67.6 1 ⁄16 ⁄4 ⁄4 61.8 1 ⁄16 ⁄16 ⁄16 56.8 1 ⁄16 ⁄8 ⁄8 52.3

3 1 3 5 3 3 3 1 3 1 5

... ... 1 ⁄16 ⁄4 8 61.8 1 ⁄16 ⁄16 ⁄16 56.8 1 ⁄16 ⁄8 ⁄4 52.3 1 ⁄16 ⁄2 ⁄16 44.9

3 1 3 3 5 1 3 3 5 3 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.