ASTM F1138-98(2007)

(Specification)Standard Specification for Spray Shields for Mechanical Joints

Standard Specification for Spray Shields for Mechanical Joints

ABSTRACT

This specification describes the manufacturing requirements for spray shield stock and the fabrication and installation requirements for spray shields made from that stock. The physical and mechanical properties for the aluminized glass cloth, thread, and protective outer jacket shall be as specified. If lacing hooks or rings are of the type that fastens by stitching, the hooks or rings shall be attached to the backup washers using a wire stitch machine and wire. The methods for testing the aluminized glass cloth, thread, and protective outer jacket shall be as specified.

SCOPE

1.1 This specification describes the manufacturing requirements for spray shield stock and the fabrication and installation requirements for spray shields made from that stock.

1.1.1 Sections 2-14 address the manufacturing requirements for the spray shield stock. Annex A1 addresses the fabrication and installation requirements for the spray shields.

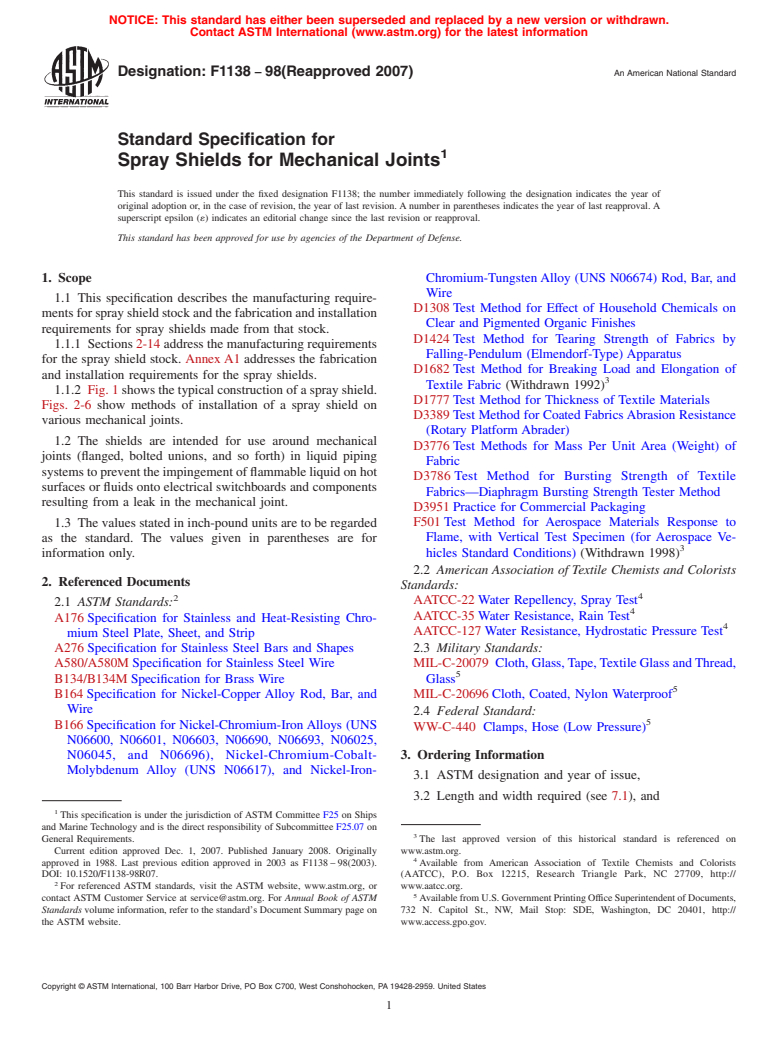

1.1.2 Fig. 1 shows the typical construction of a spray shield. Figs. 2-6 show methods of installation of a spray shield on various mechanical joints.

1.2 The shields are intended for use around mechanical joints (flanged, bolted unions, and so forth) in liquid piping systems to prevent the impingement of flammable liquid on hot surfaces or fluids onto electrical switchboards and components resulting from a leak in the mechanical joint.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1138 −98(Reapproved 2007) An American National Standard

Standard Specification for

Spray Shields for Mechanical Joints

This standard is issued under the fixed designation F1138; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Chromium-TungstenAlloy (UNS N06674) Rod, Bar, and

Wire

1.1 This specification describes the manufacturing require-

D1308Test Method for Effect of Household Chemicals on

mentsforsprayshieldstockandthefabricationandinstallation

Clear and Pigmented Organic Finishes

requirements for spray shields made from that stock.

D1424Test Method for Tearing Strength of Fabrics by

1.1.1 Sections2-14addressthemanufacturingrequirements

Falling-Pendulum (Elmendorf-Type) Apparatus

for the spray shield stock. AnnexA1 addresses the fabrication

D1682Test Method for Breaking Load and Elongation of

and installation requirements for the spray shields.

Textile Fabric (Withdrawn 1992)

1.1.2 Fig.1showsthetypicalconstructionofasprayshield.

D1777Test Method for Thickness of Textile Materials

Figs. 2-6 show methods of installation of a spray shield on

D3389Test Method for Coated FabricsAbrasion Resistance

various mechanical joints.

(Rotary Platform Abrader)

1.2 The shields are intended for use around mechanical

D3776Test Methods for Mass Per Unit Area (Weight) of

joints (flanged, bolted unions, and so forth) in liquid piping

Fabric

systemstopreventtheimpingementofflammableliquidonhot

D3786 Test Method for Bursting Strength of Textile

surfaces or fluids onto electrical switchboards and components

Fabrics—Diaphragm Bursting Strength Tester Method

resulting from a leak in the mechanical joint.

D3951Practice for Commercial Packaging

1.3 The values stated in inch-pound units are to be regarded F501Test Method for Aerospace Materials Response to

Flame, with Vertical Test Specimen (for Aerospace Ve-

as the standard. The values given in parentheses are for

information only. hicles Standard Conditions) (Withdrawn 1998)

2.2 American Association of Textile Chemists and Colorists

2. Referenced Documents

Standards:

AATCC-22Water Repellency, Spray Test

2.1 ASTM Standards:

AATCC-35Water Resistance, Rain Test

A176Specification for Stainless and Heat-Resisting Chro-

AATCC-127Water Resistance, Hydrostatic Pressure Test

mium Steel Plate, Sheet, and Strip

A276Specification for Stainless Steel Bars and Shapes 2.3 Military Standards:

A580/A580MSpecification for Stainless Steel Wire MIL-C-20079 Cloth,Glass,Tape,TextileGlassandThread,

B134/B134MSpecification for Brass Wire Glass

B164Specification for Nickel-Copper Alloy Rod, Bar, and MIL-C-20696Cloth, Coated, Nylon Waterproof

Wire

2.4 Federal Standard:

B166Specification for Nickel-Chromium-IronAlloys (UNS

WW-C-440 Clamps, Hose (Low Pressure)

N06600, N06601, N06603, N06690, N06693, N06025,

3. Ordering Information

N06045, and N06696), Nickel-Chromium-Cobalt-

Molybdenum Alloy (UNS N06617), and Nickel-Iron-

3.1 ASTM designation and year of issue,

3.2 Length and width required (see 7.1), and

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

General Requirements. The last approved version of this historical standard is referenced on

Current edition approved Dec. 1, 2007. Published January 2008. Originally www.astm.org.

approved in 1988. Last previous edition approved in 2003 as F1138–98(2003). Available from American Association of Textile Chemists and Colorists

DOI: 10.1520/F1138-98R07. (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.aatcc.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1138−98 (2007)

FIG. 1 Spray Shield Construction (Typical)

FIG. 3 Spray Shield for Pump Inlet Head

FIG. 2 Installation of Butterfly Valve Shield

4.3 The aluminized glass cloth, thread, and the protective

3.3 Type of stainless steel (see 4.1).

outer jacket shall be constructed of material as specified in

Table 1 and Table 2.

3.4 Type of lacing hardware required (see 4.1.1).

4. Materials and Manufacture 5. Physical and Mechanical Properties

4.1 Lacing hooks, lacing rings, and lacing washers (see Fig.

5.1 The physical and mechanical properties for the alumi-

7) shall be constructed of stainless steel in accordance with nizedglasscloth,thread,andprotectiveouterjacketshallbeas

Specifications A176, A276,or A580/A580M.

specified in Table 1 and Table 2.

4.1.1 Lacing rings may be used instead of lacing hooks

where practicable or preferable (see 3.3). 6. Requirements

4.1.2 Lacing washers for fastening hooks or rings shall be

6.1 If lacing hooks or rings are of the type that fasten by

two-hole washers.

stitching, the hooks or rings shall be attached to the backup

4.2 Stitch wire (Piece 5 in Table 1) shall be constructed of washers using a wire stitch machine and wire (Pieces 5 or 8 in

stainless steel in accordance with Specification A580/A580M. Table 1).

F1138−98 (2007)

9. Sampling, Selection, and Number of Specimens

9.1 Unless otherwise specified, the sampling of, selection

of, and number of specimens for the aluminized glass cloth,

thread, and protective outer jacket shall be as specified in the

applicable test methods listed in Table 1 and Table 2.

10. Test Methods

10.1 The methods for testing the aluminized glass cloth,

thread,andprotectiveouterjacketshallbeasspecifiedinTable

1 and Table 2.

11. Inspection

11.1 Unless otherwise specified in the contract or purchase

order, the contractor is responsible for performing inspections

to determine conformance to the requirements specified in

Section 8 of this specification.

12. Rejection and Rehearing

12.1 Material that fails to conform to the requirements of

thisspecificationmayberejected.Rejectionshouldbereported

to the producer or supplier promptly and in writing. In case of

FIG. 4 Spray Shield for Simplex Strainer

dissatisfaction with the results of the test, the producer or

supplier may make claim for a rehearing.

6.2 Lacing anchor/self-locking washer-type systems shall

13. Product Marking

not be used on spray shields.

13.1 Indelible stamp denoting the width of the shield shall

7. Dimensions and Permissible Variations

be placed at 24-in. (610-mm) intervals on the visible foil side

7.1 Thematerialforshieldsshallbestandardizedasgivenin

of the shield so that it will be visible when the shield is rolled

Table 3 tolerances to be + ⁄4 in. (6 mm) and −0 in. for width.

and packaged.

8. Workmanship, Finish, and Appearance

14. Packaging and Package Marking

8.1 The seam on both sides of the spray shield shall be

14.1 The packaging, packing, and marking of containers

intact.

shall be in accordance with Practice D3951, with the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.