ASTM C842-05(2010)e1

(Specification)Standard Specification for Application of Interior Gypsum Plaster

Standard Specification for Application of Interior Gypsum Plaster

ABSTRACT

This specification covers the minimum requirements for full-thickness interior gypsum plastering on gypsum, metal, masonry, or monolithic concrete bases designed or prepared to receive gypsum plaster. Gypsum plaster applied to the interior side of exterior walls of masonry or concrete shall be isolated from the exterior wall. Gypsum plasters shall not be used in exterior locations or interior wet areas. Plasters and other cementitious materials shall be kept dry until used; they shall be stored off the ground, under cover, and away from walls with condensation and other damp surfaces. Metal products shall be protected, while stored, against rusting. The surface preparations of plasters are presented in details. All plaster mixing shall be done by mechanical means unless hand mixing is specified. Plaster shall be applied by hand or machine as specified.

SCOPE

1.1 This specification covers the minimum requirements for full-thickness (in accordance with Table 1) interior gypsum plastering on gypsum, metal, masonry, or monolithic concrete bases designed or prepared to receive gypsum plaster.

1.1.1 Gypsum plaster applied to the interior side of exterior walls of masonry or concrete shall be isolated from the exterior wall.

1.2 Gypsum plasters shall not be used in exterior locations or interior “wet” areas.

Note 1—To secure desirable results, this specification should be coordinated with the provisions of Specification C841. General information concerning full thickness gypsum plastering is contained in Annex A2, Annex A3, and Annex A4.

1.3 Details of construction for a specific assembly to achieve the required fire resistance shall be obtained from reports of fire-resistance tests, engineering evaluations, or listings from recognized fire testing laboratories.

1.4 Details of construction to achieve required sound control shall be obtained from reports of tests conducted at recognized sound testing laboratories in accordance with the applicable sound tests of Test Methods E90, C423, or E492.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI (metric) values given in parentheses are approximate and are provided for information purposes only.

1.6 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C842 −05(Reapproved 2010)

Standard Specification for

Application of Interior Gypsum Plaster

This standard is issued under the fixed designation C842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Typos were corrected editorially in Table 1 and 9.6.2.1 in October 2010.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers the minimum requirements for

C5 Specification for Quicklime for Structural Purposes

full-thickness (in accordance with Table 1) interior gypsum

C11 Terminology Relating to Gypsum and Related Building

plastering on gypsum, metal, masonry, or monolithic concrete

Materials and Systems

bases designed or prepared to receive gypsum plaster.

C28/C28M Specification for Gypsum Plasters

1.1.1 Gypsum plaster applied to the interior side of exterior

C35 Specification for Inorganic Aggregates for Use in Gyp-

wallsofmasonryorconcreteshallbeisolatedfromtheexterior

sum Plaster

wall.

C59/C59M Specification for Gypsum Casting Plaster and

1.2 Gypsum plasters shall not be used in exterior locations

Gypsum Molding Plaster

or interior “wet” areas.

C61/C61M Specification for Gypsum Keene’s Cement

C206 Specification for Finishing Hydrated Lime

NOTE 1—To secure desirable results, this specification should be

coordinated with the provisions of Specification C841. General informa- C423 Test Method for SoundAbsorption and SoundAbsorp-

tion concerning full thickness gypsum plastering is contained in Annex

tion Coefficients by the Reverberation Room Method

A2, Annex A3, and Annex A4.

C631 Specification for Bonding Compounds for Interior

Gypsum Plastering

1.3 Details of construction for a specific assembly to

achieve the required fire resistance shall be obtained from C841 Specification for Installation of Interior Lathing and

reports of fire-resistance tests, engineering evaluations, or Furring

listings from recognized fire testing laboratories. C1489 Specification for Lime Putty for Structural Purposes

E90 Test Method for Laboratory Measurement of Airborne

1.4 Details of construction to achieve required sound con-

Sound Transmission Loss of Building Partitions and

trol shall be obtained from reports of tests conducted at

Elements

recognized sound testing laboratories in accordance with the

E492 Test Method for Laboratory Measurement of Impact

applicable sound tests of Test Methods E90, C423,or E492.

Sound Transmission Through Floor-Ceiling Assemblies

1.5 The values stated in inch-pound units are to be regarded

Using the Tapping Machine

as the standard.The SI (metric) values given in parentheses are

3. Terminology

approximate and are provided for information purposes only.

3.1 Definitions:

1.6 The text of this standard references notes and footnotes

3.1.1 Definitions shall be in accordance with Terminology

which provide explanatory material. These notes and footnotes

C11.

(excluding those in tables and figures) shall not be considered

3.2 Definitions of Terms Specific to This Standard:

as requirements of the standard.

3.2.1 catfaces, n—blemishes or rough depressions in the

finish coat.

3.2.2 coat, n—a thickness or layer of plaster applied over a

This specification is under the jurisdiction of ASTM Committee C11 on

surface in a single application.

GypsumandRelatedBuildingMaterialsandSystemsandisthedirectresponsibility

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther

Products in Assemblies. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2010. Published December 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1976. Last previous edition approved in 2005 as C842–05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0842-05R10e1. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C842−05 (2010)

3.2.2.1 basecoat,n—thesumofthescratchandbrowncoats and away from walls with condensation and other damp

or the total coats in place prior to application of finish coats. surfaces. Metal products shall be protected, while stored,

against rusting.

3.2.2.2 brown coat, n—the second coat of plaster applied in

three-coat work.

6. Environmental Conditions

3.2.2.3 finish coat, n—the last coat of plaster applied in

6.1 Temperatures—Where the ambient outdoor temperature

either two-coat or three-coat work.

at the building site is less than 55 °F (13 °C), a temperature of

3.2.2.4 scratch coat, n—the first coat of plaster applied over

not less than 55 °F (13 °C) and not more than 80 °F (27 °C)

a lath or other substrate.

shall be maintained continuously inside the building for a

3.2.2.5 three-coat work, n—plaster applied in three succes-

period of not less than one week prior to the application of

sive coats, leaving time between coats for setting or drying, or

plaster (Note 2). Temporary heat shall be evenly distributed,

both, of the plaster.

using deflective or protective screens to prevent concentrated

or uneven heat or cold on the plaster, and maintained until the

3.2.2.6 two-coat work, n—scratch and brown coats applied

permanent HVAC system is activated.

from the same mix with no time allowed for setting of the

scratch coat before the brown coat is applied.

NOTE 2—The requirement should minimize the possibility of plaster

cracking due to structural movements caused by thermal changes from

3.2.3 gypsum ready mixed plaster, n—calcined gypsum

outdoor temperature extremes during construction.

plaster, mixed at the mill with a mineral aggregate, designed to

function as a base coat to receive various finish coats. 6.2 Ventilation—Sufficient ventilation shall be provided to

removeexcesswatergivenoffthroughthedryingprocess.(See

3.2.4 metal bases, n—expanded metal, welded or woven

Appendix X2 for provisions for ventilating underside of roofs

wire, or punched sheet metal plaster bases.

and glazed buildings with and without operable windows.)

3.2.5 smooth-trowel finish, n—a finish resulting from steel

troweling.

7. Materials

3.2.6 texture finish, n—a finish resulting from (1) trowel

7.1 Gypsum Plasters—The following plasters shall conform

applicationfollowedbyfloatingortexturingofthesurfacewith

to Specification C28/C28M:

any of a variety of tools using a minimum of water or (2)

7.1.1 Ready mixed.

machine application which is or is not hand textured.

7.1.2 Neat.

7.1.3 Wood-fibered.

4. Delivery of Materials

7.1.4 Gauging for finish coat.

4.1 All manufactured materials shall be delivered in the

7.2 Gypsum Casting and Molding Plasters—Specification

original packages, containers, or bundles bearing the brand

C5, C59/C59M.

name and manufacturer (or supplier) identification.

7.3 Gypsum Keene’s Cement—Specification C61/C61M.

5. Protection of Materials

7.4 Lime:

5.1 Plasters and other cementitious materials shall be kept 7.4.1 Finishing Hydrated Lime—Specification C206, Type

dry until used; they shall be stored off the ground, under cover,

S.

7.4.2 Quicklime for Structural Purposes—Specification C5.

7.4.3 Lime Putty for Structural Purposes—Specification

C1489.

TABLE 1 Thickness of Plaster

Thickness of Plaster Including Finish 7.5 Lime Putty—Lime putty exceeding 8 weight % of

Plaster Base

Coat, in. (mm)

unhydrated magnesium oxide shall not be used for finish coat

Metal plaster base ⁄8 (16) min

plaster.

All other types of plaster base ⁄2 (13) min

Unit masonry ⁄8 (16) min

7.6 Aggregates:

A

Monolithic concrete surfaces:

7.6.1 Aggregates for Base Coat Plaster—Specification C35.

BC

Vertical ⁄8 (16) min

C †

1 5

7.6.2 Aggregates for Finish Coat Plasters—Specification

Horizontal ⁄8 (3) to ⁄8 (16 )

A C35, except that gradation shall be within the limits specified

Base coat plastering of the same proportions as specified for unit masonry is not

prohibited from being used over plain or reinforced monolithic concrete, provided

in Table 2.

the surface is first covered with a metal plaster base or first coated with a bonding

compound.

B

Finish coat plaster applied direct to a bonding compound over vertical monolithic

concrete shall be not more than ⁄16 in. (4.8 mm) in thickness. Where more

TABLE 2 Aggregate for Finish Coat Plasters, Percentage

than ⁄16 in. of finish coat is required to bring such vertical surface to a true plane,

Retained on Each Sieve, Cumulative

a base coat of plaster shall first be applied to the bonding compound.

C

Perlite, Natural and Manufactured Sand

Where horizontal or vertical monolithic concrete surfaces require more than ⁄8

in. (9.5 mm) or ⁄8 in. (15.9 mm) of plaster, respectively, to produce required lines Sieve Size Volume,% Weight, %

max min max min

orsurfaces,metalplasterbaseshallbeattachedtotheconcretebeforeapplication

ofplaster.Whereconcretesurfacerequirestheapplicationofmorethan1in.(25.4 No. 20 (850 µm) 0 . 0 .

No. 30 (600 µm) 10 . 0.5 .

mm) of plaster to produce required lines or surfaces, lath shall be applied over

furring secured to the concrete. No. 100 (150 µm) 100 40 100 40

†

No. 200 (75 µm) 100 70 100 70

Typo corrected editorially October 2010.

´1

C842−05 (2010)

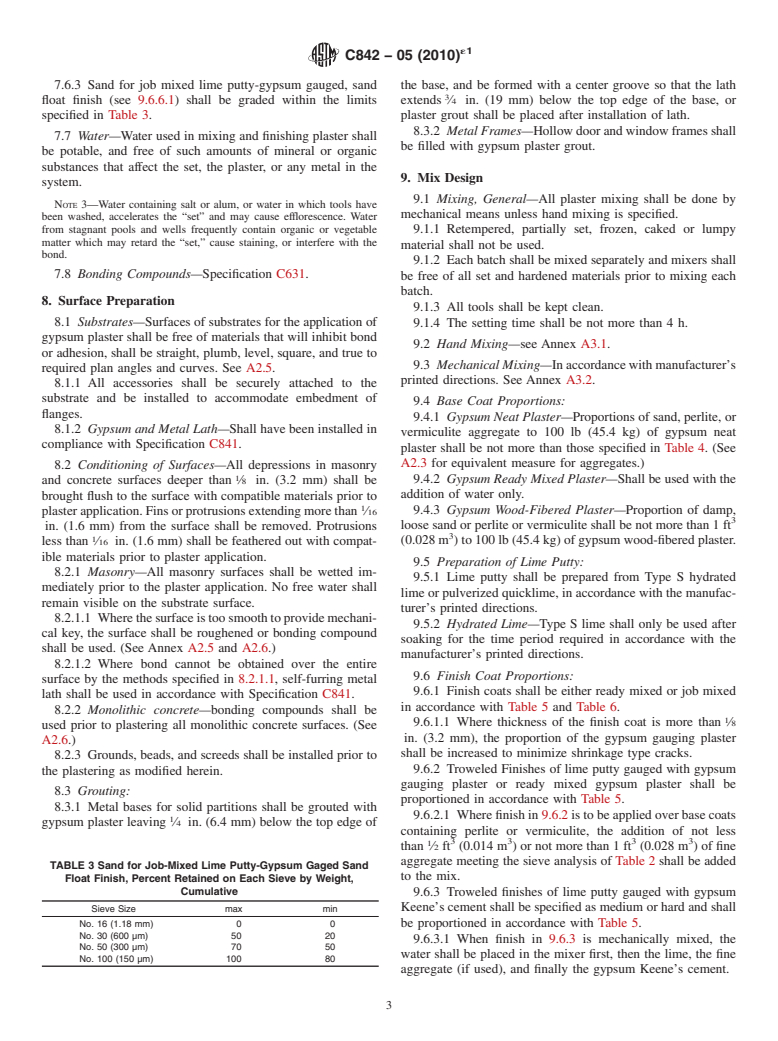

7.6.3 Sand for job mixed lime putty-gypsum gauged, sand the base, and be formed with a center groove so that the lath

float finish (see 9.6.6.1) shall be graded within the limits extends ⁄4 in. (19 mm) below the top edge of the base, or

specified in Table 3. plaster grout shall be placed after installation of lath.

8.3.2 MetalFrames—Hollowdoorandwindowframesshall

7.7 Water—Water used in mixing and finishing plaster shall

be filled with gypsum plaster grout.

be potable, and free of such amounts of mineral or organic

substances that affect the set, the plaster, or any metal in the

9. Mix Design

system.

9.1 Mixing, General—All plaster mixing shall be done by

NOTE 3—Water containing salt or alum, or water in which tools have

mechanical means unless hand mixing is specified.

been washed, accelerates the “set” and may cause efflorescence. Water

from stagnant pools and wells frequently contain organic or vegetable 9.1.1 Retempered, partially set, frozen, caked or lumpy

matter which may retard the “set,” cause staining, or interfere with the

material shall not be used.

bond.

9.1.2 Each batch shall be mixed separately and mixers shall

7.8 Bonding Compounds—Specification C631.

be free of all set and hardened materials prior to mixing each

batch.

8. Surface Preparation

9.1.3 All tools shall be kept clean.

8.1 Substrates—Surfaces of substrates for the application of

9.1.4 The setting time shall be not more than 4 h.

gypsum plaster shall be free of materials that will inhibit bond

9.2 Hand Mixing—see Annex A3.1.

or adhesion, shall be straight, plumb, level, square, and true to

9.3 MechanicalMixing—Inaccordancewithmanufacturer’s

required plan angles and curves. See A2.5.

printed directions. See Annex A3.2.

8.1.1 All accessories shall be securely attached to the

substrate and be installed to accommodate embedment of

9.4 Base Coat Proportions:

flanges.

9.4.1 Gypsum Neat Plaster—Proportions of sand, perlite, or

8.1.2 Gypsum and Metal Lath—Shall have been installed in

vermiculite aggregate to 100 lb (45.4 kg) of gypsum neat

compliance with Specification C841.

plaster shall be not more than those specified in Table 4. (See

A2.3 for equivalent measure for aggregates.)

8.2 Conditioning of Surfaces—All depressions in masonry

9.4.2 Gypsum Ready Mixed Plaster—Shall be used with the

and concrete surfaces deeper than ⁄8 in. (3.2 mm) shall be

addition of water only.

brought flush to the surface with compatible materials prior to

9.4.3 Gypsum Wood-Fibered Plaster—Proportion of damp,

plasterapplication.Finsorprotrusionsextendingmorethan ⁄16

loose sand or perlite or vermiculite shall be not more than 1 ft

in. (1.6 mm) from the surface shall be removed. Protrusions

(0.028 m ) to 100 lb (45.4 kg) of gypsum wood-fibered plaster.

less than ⁄16 in. (1.6 mm) shall be feathered out with compat-

ible materials prior to plaster application.

9.5 Preparation of Lime Putty:

8.2.1 Masonry—All masonry surfaces shall be wetted im-

9.5.1 Lime putty shall be prepared from Type S hydrated

mediately prior to the plaster application. No free water shall

lime or pulverized quicklime, in accordance with the manufac-

remain visible on the substrate surface.

turer’s printed directions.

8.2.1.1 Wherethesurfaceistoosmoothtoprovidemechani-

9.5.2 Hydrated Lime—Type S lime shall only be used after

cal key, the surface shall be roughened or bonding compound

soaking for the time period required in accordance with the

shall be used. (See Annex A2.5 and A2.6.)

manufacturer’s printed directions.

8.2.1.2 Where bond cannot be obtained over the entire

9.6 Finish Coat Proportions:

surface by the methods specified in 8.2.1.1, self-furring metal

9.6.1 Finish coats shall be either ready mixed or job mixed

lath shall be used in accordance with Specification C841.

in accordance with Table 5 and Table 6.

8.2.2 Monolithic concrete—bonding compounds shall be

9.6.1.1 Where thickness of the finish coat is more than ⁄8

used prior to plastering all monolithic concrete surfaces. (See

in. (3.2 mm), the proportion of the gypsum gauging plaster

A2.6.)

shall be increased to minimize shrinkage type cracks.

8.2.3 Grounds, beads, and screeds shall be installed prior to

9.6.2 Troweled Finishes of lime putty gauged with gypsum

the plastering as modified herein.

gauging plaster or ready mixed gypsum plaster shall be

8.3 Grouting:

proportioned in accordance with Table 5.

8.3.1 Metal bases for solid partitions shall be grouted with

9.6.2.1 Where finish in9.6.2 is to be applied over base coats

gypsum plaster leaving ⁄4 in. (6.4 mm) below the top edge of

containing perlite or vermiculite, the addition of not less

3 3 3 3

than ⁄2 ft (0.014 m ) or not more than 1 ft (0.028 m)offine

aggregate meeting the sieve analysis of Table 2 shall be added

TABLE 3 Sand for Job-Mixed Lime Putty-Gypsum Gaged Sand

to the mix.

Float Finish, Percent Retained on Each Sieve by Weight,

Cumulative

9.6.3 Troweled finishes of lime putty gauged with gypsum

Sieve Size max min Keene’s cement shall be specified as medium or hard and shall

be proportioned in accordance with Table 5.

No. 16 (1.18 mm) 0 0

No. 30 (600 µm) 50 20

9.6.3.1 When finish in 9.6.3 is mechanically mixed, the

No. 50 (300 µm) 70 50

water shall be placed in the mixer first, then the lime, the fine

No. 100 (150 µm) 100 80

aggregate (if used), and finally the gypsum Keene’s cement.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.