ASTM C842-05

(Specification)Standard Specification for Application of Interior Gypsum Plaster

Standard Specification for Application of Interior Gypsum Plaster

ABSTRACT

This specification covers the minimum requirements for full-thickness interior gypsum plastering on gypsum, metal, masonry, or monolithic concrete bases designed or prepared to receive gypsum plaster. Gypsum plaster applied to the interior side of exterior walls of masonry or concrete shall be isolated from the exterior wall. Gypsum plasters shall not be used in exterior locations or interior wet areas. Plasters and other cementitious materials shall be kept dry until used; they shall be stored off the ground, under cover, and away from walls with condensation and other damp surfaces. Metal products shall be protected, while stored, against rusting. The surface preparations of plasters are presented in details. All plaster mixing shall be done by mechanical means unless hand mixing is specified. Plaster shall be applied by hand or machine as specified.

SCOPE

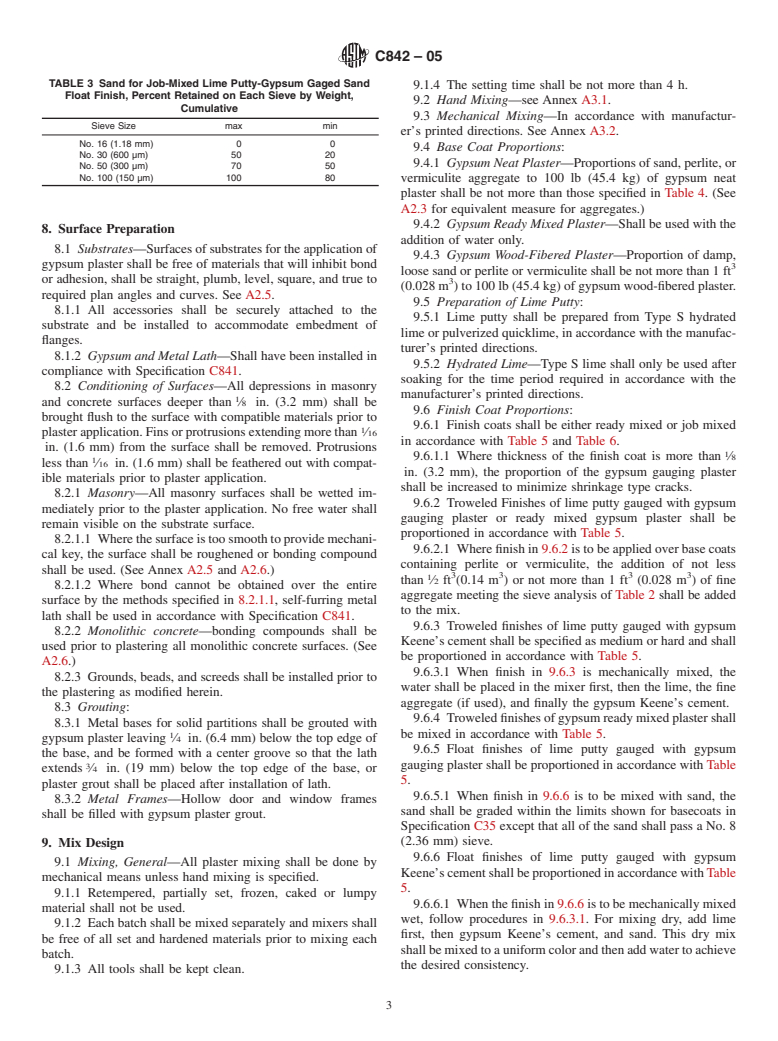

1.1 This specification covers the minimum requirements for full-thickness (in accordance with Table 1) interior gypsum plastering on gypsum, metal, masonry, or monolithic concrete bases designed or prepared to receive gypsum plaster.

1.1.1 Gypsum plaster applied to the interior side of exterior walls of masonry or concrete shall be isolated from the exterior wall.

1.2 Gypsum plasters shall not be used in exterior locations or interior "wet" areas.

Note 1—To secure desirable results, this specification should be coordinated with the provisions of Specification C 841. General information concerning full thickness gypsum plastering is contained in Annex A2, Annex A3, and Annex A4.

1.3 Details of construction for a specific assembly to achieve the required fire resistance shall be obtained from reports of fire-resistance tests, engineering evaluations, or listings from recognized fire testing laboratories.

1.4 Details of construction to achieve required sound control shall be obtained from reports of tests conducted at recognized sound testing laboratories in accordance with the applicable sound tests of Test Methods E 90, C 423, or E 492.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI (metric) values given in parentheses are approximate and are provided for information purposes only.

1.6 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C842 – 05

Standard Specification for

1

Application of Interior Gypsum Plaster

This standard is issued under the fixed designation C842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C11 TerminologyRelatingtoGypsumandRelatedBuilding

Materials and Systems

1.1 This specification covers the minimum requirements for

C28/C28M Specification for Gypsum Plasters

full-thickness (in accordance with Table 1) interior gypsum

C35 Specification for Inorganic Aggregates for Use in

plastering on gypsum, metal, masonry, or monolithic concrete

Gypsum Plaster

bases designed or prepared to receive gypsum plaster.

C59/C59M Specification for Gypsum Casting Plaster and

1.1.1 Gypsum plaster applied to the interior side of exterior

Gypsum Molding Plaster

wallsofmasonryorconcreteshallbeisolatedfromtheexterior

C61/C61M Specification for Gypsum Keene’s Cement

wall.

C206 Specification for Finishing Hydrated Lime

1.2 Gypsum plasters shall not be used in exterior locations

C423 Test Method for Sound Absorption and Sound Ab-

or interior “wet” areas.

sorption Coefficients by the Reverberation Room Method

NOTE 1—To secure desirable results, this specification should be

C631 Specification for Bonding Compounds for Interior

coordinated with the provisions of Specification C841. General informa-

Gypsum Plastering

tion concerning full thickness gypsum plastering is contained in Annex

C841 Specification for Installation of Interior Lathing and

A2, Annex A3, and Annex A4.

Furring

1.3 Details of construction for a specific assembly to

C1489 Specification for Lime Putty for Structural Purposes

achieve the required fire resistance shall be obtained from

E90 Test Method for Laboratory Measurement of Airborne

reports of fire-resistance tests, engineering evaluations, or

Sound Transmission Loss of Building Partitions and Ele-

listings from recognized fire testing laboratories.

ments

1.4 Details of construction to achieve required sound con-

E492 Test Method for Laboratory Measurement of Impact

trol shall be obtained from reports of tests conducted at

Sound Transmission Through Floor-Ceiling Assemblies

recognized sound testing laboratories in accordance with the

Using the Tapping Machine

applicable sound tests of Test Methods E90, C423,or E492.

1.5 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard.The SI (metric) values given in parentheses are

3.1 Definitions:

approximate and are provided for information purposes only.

3.1.1 Definitions shall be in accordance with Terminology

1.6 The text of this standard references notes and footnotes

C11.

which provide explanatory material. These notes and footnotes

3.2 Definitions of Terms Specific to This Standard:

(excluding those in tables and figures) shall not be considered

3.2.1 catfaces, n—blemishes or rough depressions in the

as requirements of the standard.

finish coat.

3.2.2 coat, n—a thickness or layer of plaster applied over a

2. Referenced Documents

surface in a single application.

2

2.1 ASTM Standards:

3.2.2.1 base coat, n—the sum of the scratch and brown

C5 Specification for Quicklime for Structural Purposes

coats or the total coats in place prior to application of finish

coats.

1

3.2.2.2 brown coat, n—the second coat of plaster applied in

This specification is under the jurisdiction of ASTM Committee C11 on

GypsumandRelatedBuildingMaterialsandSystemsandisthedirectresponsibility

three-coat work.

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther

3.2.2.3 finish coat, n—the last coat of plaster applied in

Products in Assemblies.

either two-coat or three-coat work.

Current edition approved May 1, 2005. Published May 2005. Originally

3.2.2.4 scratch coat, n—the first coat of plaster applied over

approved in 1976. Last previous edition approved in 1999 as C842 – 99. DOI:

10.1520/C0842-05.

a lath or other substrate.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C842 – 05

3.2.2.5 three-coat work, n—plaster applied in three succes- or uneven heat or cold on the plaster, and maintained until the

sive coats, leaving time between coats for setting or drying, or permanent HVAC system is activated.

both, of the plaster

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.