ASTM D7506/D7506M-12

(Test Method)Standard Test Method for Pocket Reinforcement

Standard Test Method for Pocket Reinforcement

ABSTRACT

This test method employs the grab procedures used to determine localized weakness due to bar-tacking in the pocket areas of all types of garments such as shirts, including the side or back pockets of trousers, pants, or jeans. To test its breaking strength, a specimen of the pocket area shall be mounted centrally in clamps of a constant-rate-of-extension tensile testing machine and a force shall be applied until the specimen breaks. Reports on the test results shall include the mode of failure and the location of where the break occurs.

SCOPE

1.1 This test method utilizes the grab procedures to determine localized weakness due to bar-tacking in the pocket areas of all types of garments. This can be utilized to test bar-tacking in the pockets of shirts, as well as side or back pockets of trousers, pants, or jeans.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7506/D7506M − 12

Standard Test Method for

1

Pocket Reinforcement

This standard is issued under the fixed designation D7506/D7506M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 tensile test, n—in textiles, a test in which a textile

material is stretched in one direction to determine the load

1.1 This test method utilizes the grab procedures to deter-

elongation characteristics, in the breaking load, or the breaking

mine localized weakness due to bar-tacking in the pocket areas

elongation.

of all types of garments.This can be utilized to test bar-tacking

in the pockets of shirts, as well as side or back pockets of 3.1.4 For definitions of other terms used in this test method,

trousers, pants, or jeans. refer to Terminology D123.

1.2 The values stated in either SI units or inch-pound units

4. Summary of Test Method

are to be regarded separately as standard. The values stated in

4.1 A specimen of the pocket area with the bar-tacking is

each system may not be exact equivalents; therefore, each

mounted centrally in clamps of the tensile strength machine

system shall be used independently of the other. Combining

and a force is applied until the specimen breaks.

values from the two systems may result in non-conformance

with the standard.

5. Apparatus

1.3 This standard does not purport to address all of the

5.1 Constant-rate-of-extension (CRE) tensile testing

safety concerns, if any, associated with its use. It is the

machine, as used in Test Method D5034, conforming to

responsibility of the user of this standard to establish appro-

Specification D76.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.2 Clamps and jaws, rubber faced or other gripping

surface—jaw faces must measure 1.0 6 0.02 in. (25 6 1 mm)

2. Referenced Documents

wide at least 1 in. (25 mm), perpendicular to the direction of

2

2.1 ASTM Standards:

the force, and not less than 25 nor more than 50 mm (1.0 nor

D76 Specification for Tensile Testing Machines for Textiles

morethan2.0in.).Theback,orbottom,jawfaceofeachclamp

D123 Terminology Relating to Textiles

shall be at least as large as its mate. Use of a larger face for the

D1776 Practice for Conditioning and Testing Textiles

second jaw reduces the problem of front and back jaw face

D5034 TestMethodforBreakingStrengthandElongationof

misalignment.

Textile Fabrics (Grab Test)

6. Safety Precuations

3. Terminology

6.1 It is the users responsibility to use safe and proper

3.1 Definitions

techniques when handling or using any of the equipment

3.1.1 constant-rate-of-extension tensile testing machine

mentioned.

(CRE), n—a testing machine in which the rate of increase of

6.2 Good laboratory practice should be followed. Wear

specimen length is uniform with time.

safety glasses in all laboratory test rooms.

3.1.2 grab test, n—in fabric testing, a tensile test in which

the central part of the width of the specimen is gripped in the

7. Sampling, Test Specimens, and Test Units

clamps.

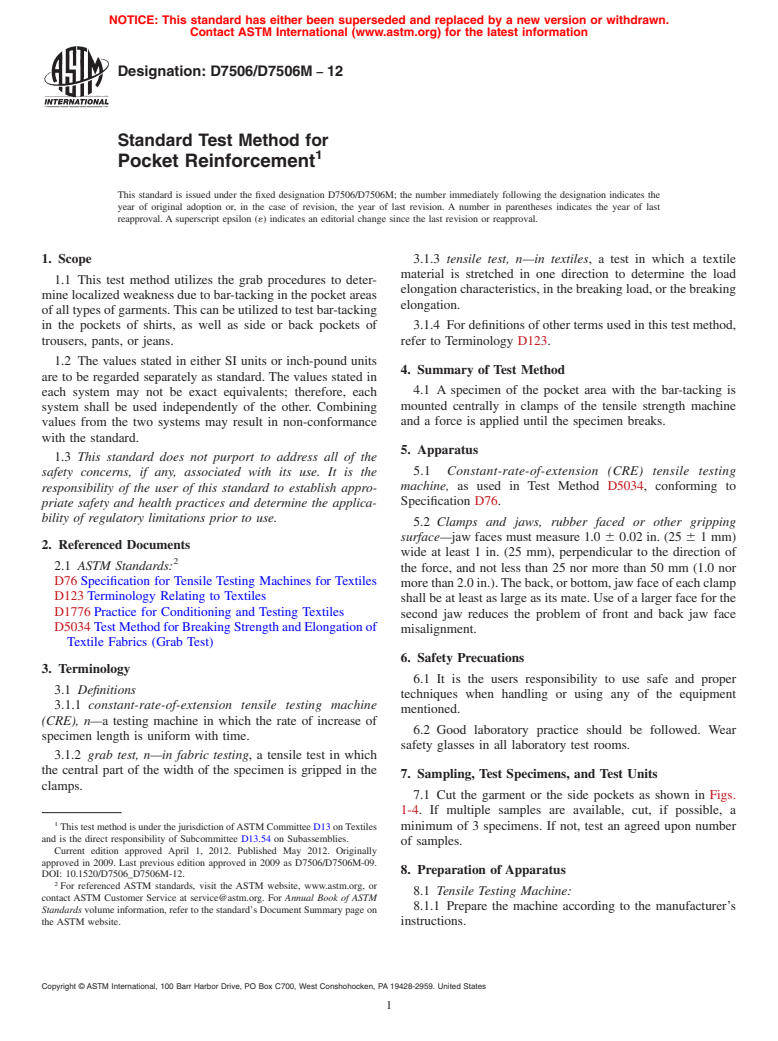

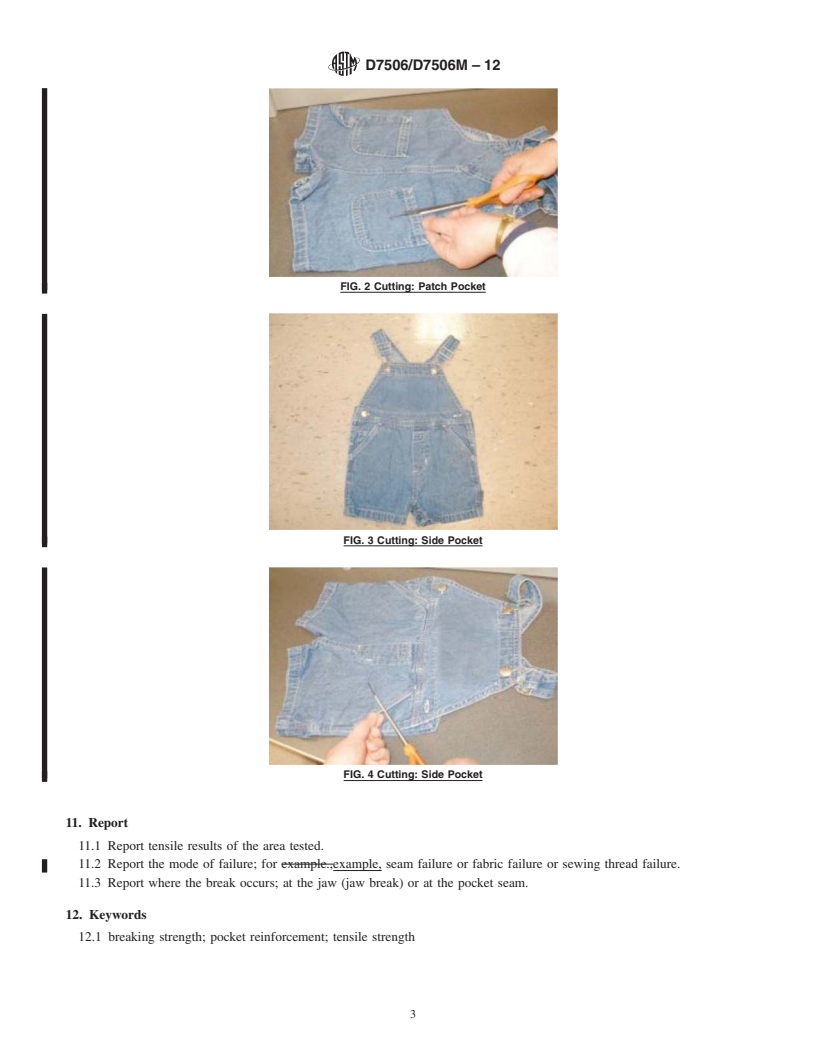

7.1 Cut the garment or the side pockets as shown in Figs.

1-4. If multiple samples are available, cut, if possible, a

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles minimum of 3 specimens. If not, test an agreed upon number

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

of samples.

Current edition approved April 1, 2012. Published May 2012. Originally

approved in 2009. Last previous edition approved in 2009 as D7506/D7506M-09.

8. Preparation of Apparatus

DOI: 10.1520/D7506_D7506M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

8.1 Tensile Testing Machine:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1.1 Prepare the machine according to the manufacturer’s

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. instructions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7506/D7506M − 12

FIG. 4 Cutting: Side Pocket

FIG. 1 Cutting: Patch Pocket

8.2.2 Make a four-ply sandwich or white tissue paper, two

soft carbon papers placed back to back, and a second white

paper (or fold the paper over the two carbons).

8.2.3 Mount the paper–carbon sandwich and examine the

jaw face imprint of uniformity of the carbon deposition on the

tissue paper.

8.2.4 If the imprint is incomplete or off–size, make appro-

priate adjustments of the clamping gripping system and re-

check

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7506/D7506M–09 Designation: D7506/D7506M – 12

Standard Test Method for

1

Pocket Reinforcement

This standard is issued under the fixed designation D7506/D7506M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method utilizes the grab procedures to determine localized weakness due to bar-tacking in the pocket areas of all

types of garments.This can be utilized to test bar-tacking in the pockets of shirts, as well as side or back pockets of trousers, pants,

or jeans.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

3. Terminology

3.1

3.1 Definitions: Definitions

3.1.1 constant-rate-of-extension tensile testing machine (CRE), n—a testing machine in which the rate of increase of specimen

length is uniform with time.

3.1.2 grab test, n—in fabric testing, a tensile test in which the central part of the width of the specimen is gripped in the clamps.

3.1.3 tensile test, n—in textiles, a test in which a textile material is stretched in one direction to determine the load elongation

characteristics, in the breaking load, or the breaking elongation.

3.1.4 For definitions of other terms used in this test method, refer to Terminology D123.

4. Summary of Test Method

4.1 Aspecimenofthepocketareawiththebar-tackingismountedcentrallyinclampsofthetensilestrengthmachineandaforce

is applied until the specimen breaks

5. Apparatus

5.1 Constant-rate-of-extension (CRE) tensile testing machine,asusedinTestMethodD5034,conformingtoSpecificationD76.

5.2 Clamps and jaws, rubber faced or other gripping surface—jawfacesmustmeasure1.060.02in.(2561mm)wideatleast

1 in. (25mm) , perpendicular to the direction of the force, and not less than 25 nor more than 50 mm ( 1.0 nor more than 2.0 in.).

The back, or bottom, jaw face of each clamp shall be at least as large as its mate. Use of a larger face for the second jaw reduces

the problem of front and back jaw face misalignment.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved Aug. 15, 2009. Published October 2009. DOI: 10.1520/D7506_D7506M-09.

Current edition approved April 1, 2012. Published May 2012. Originally approved in 2009. Last previous edition approved in 2009 as D7506/D7506M-09. DOI:

10.1520/D7506_D7506M-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7506/D7506M – 12

6. Safety Precuations

6.1 It is the users responsibility to use safe and proper techniques when handling or using any of the equipment mentioned.

6.2 Good laboratory practice should be followed. Wear safety glasses in all laboratory test rooms.

7. Sampling, Test Specimens, and Test Units

7.1 Cut the garment or the side pockets as shown in Fig. 1Figs. 1-4. If multiple samples are available, cut, if possible, a

minimum of 3 specimens. If not, test an agreed upon number of samples.

8. Preparation of Apparatus

8.1 Tensile Testing Machine:

8.1.1 Prepare the machine according to the manufacturer’s instructions.

8.1.2Set the distance between the clamps at 16 0.05 in (256 1mm) at the crosshead speed s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.