ASTM D5071-06(2013)

(Practice)Standard Practice for Exposure of Photodegradable Plastics in a Xenon Arc Apparatus

Standard Practice for Exposure of Photodegradable Plastics in a Xenon Arc Apparatus

SIGNIFICANCE AND USE

4.1 Materials made from photodegradable plastics are intended to deteriorate rapidly when exposed to solar radiation, oxygen, heat, moisture and other degrading elements of the weather. This practice is used for evaluating the photodegradability of plastics when exposed in an apparatus that produces simulated daylight (1,2)6 and controlled temperature and moisture. The exposure used in this practice is not intended to simulate the deterioration caused by localized weather phenomena such as atmospheric pollution, biological attack, and salt water exposure. There can be no positive correlation of exposure results between this and other laboratory weathering devices.

4.2 Variations in results can be expected when operating conditions are varied within the accepted limits of this practice. Therefore, all test results using this practice must be accompanied by the specific operating conditions required in Section 9. Refer to Practice G151 for detailed information on the caveats applicable to use of results obtained in accordance with this practice.

4.3 The results of laboratory exposure cannot be directly extrapolated to estimate absolute rate of deterioration by the environment because the acceleration factor is material dependent and can be significantly different for each material and for different formulations of the same material. However, exposure of a similar material of known outdoor performance, a control, at the same time as the test specimens allows comparison of the durability relative to that of the control under the test conditions. Evaluation in terms of relative durabilities also greatly improves the agreement in test results among different laboratories (3).

4.4 Test results will depend on the care that is taken to operate the equipment in accordance with Practice G155. Significant factors include regulation of line voltage, freedom from salt or other deposits from water, temperature and humidity control and condition and age of the burners and ...

SCOPE

1.1 This practice covers specific procedures and test conditions that are applicable for xenon arc exposure of photodegradable plastics conducted in accordance with Practices G151 and G155. This practice also covers the preparation of test specimens, the test conditions best suited for photodegradable plastics, and the evaluation of test results.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1—This practice is technically equivalent to ISO 4892-2 and Practice D2565 which cover xenon arc exposures of plastics intended for long term use in outdoor applications.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5071 − 06 (Reapproved 2013)

Standard Practice for

Exposure of Photodegradable Plastics in a Xenon Arc

Apparatus

This standard is issued under the fixed designation D5071; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D3890 Test Method for Number of Strokes to Prime a

Mechanical Pump Dispenser

1.1 This practice covers specific procedures and test condi-

D5870 Practice for Calculating Property Retention Index of

tions that are applicable for xenon arc exposure of photode-

Plastics

gradable plastics conducted in accordance with Practices G151

E691 Practice for Conducting an Interlaboratory Study to

and G155. This practice also covers the preparation of test

Determine the Precision of a Test Method

specimens, the test conditions best suited for photodegradable

G113 Terminology Relating to Natural andArtificial Weath-

plastics, and the evaluation of test results.

ering Tests of Nonmetallic Materials

1.2 This standard does not purport to address all of the

G141 Guide for Addressing Variability in Exposure Testing

safety concerns, if any, associated with its use. It is the

of Nonmetallic Materials

responsibility of the user of this standard to establish appro-

G147 Practice for Conditioning and Handling of Nonmetal-

priate safety and health practices and determine the applica-

lic Materials for Natural and Artificial Weathering Tests

bility of regulatory limitations prior to use.

G151 Practice for Exposing Nonmetallic Materials inAccel-

erated Test Devices that Use Laboratory Light Sources

NOTE 1—This practice is technically equivalent to ISO 4892-2 and

Practice D2565 which cover xenon arc exposures of plastics intended for

G155 Practice for Operating XenonArc LightApparatus for

long term use in outdoor applications.

Exposure of Non-Metallic Materials

G169 Guide for Application of Basic Statistical Methods to

2. Referenced Documents

Weathering Tests

2.1 ASTM Standards:

2.2 Other Standards:

D882 Test Method for Tensile Properties of Thin Plastic

ISO 4892-2 Plastics—Method of Exposure to Laboratory

Sheeting

Light Sources—Part 2, Xenon Arc Sources

D883 Terminology Relating to Plastics

Publication C.I.E. No. 85 (1989)

D1293 Test Methods for pH of Water

DIN 53384 Testing of Plastics: Artificial Weathering or

D2565 Practice for Xenon-Arc Exposure of Plastics In-

ExposureinLaboratoryExposureWeatheringorExposure

tended for Outdoor Applications

in Laboratory Exposure Apparatus to UV Radiation

D3593 Test Method for Molecular Weight Averages/ Distri-

bution of Certain Polymers by Liquid Size-Exclusion

3. Terminology

Chromatography (Gel Permeation Chromatography GPC)

3.1 Definitions—The definitions given in Terminologies

Using Universal Calibration (Withdrawn 1993)

D883 and G113 are applicable to this practice.

D3826 Practice for Determining Degradation End Point in

Degradable Polyethylene and Polypropylene Using a Ten-

4. Significance and Use

sile Test

4.1 Materials made from photodegradable plastics are in-

tended to deteriorate rapidly when exposed to solar radiation,

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

oxygen, heat, moisture and other degrading elements of the

isthedirectresponsibilityofSubcommitteeD20.96onEnvironmentallyDegradable

weather. This practice is used for evaluating the photodegrad-

Plastics and Biobased Products.

Current edition approved April 1, 2013. Published April 2013. Originally

ability of plastics when exposed in an apparatus that produces

approved in 1991. Last previous edition approved in 2006 as D5071 - 06. DOI:

10.1520/D5071-06R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Standards volume information, refer to the standard’s Document Summary page on 4th Floor, New York, NY 10036.

5 st

the ASTM website. Publication No. CIE 85, 1 Ed., 1989 Technical Report, “Solar Spectral

The last approved version of this historical standard is referenced on Irradiance,” available from U.S. National Committee CIE, Mr.Thomas M. Lemons,

www.astm.org. TLA-Lighting Consultants, Inc., 72 Loring Ave., Salem, MA 01970.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5071 − 06 (2013)

simulated daylight (1,2) and controlled temperature and mois- used to evaluate the effects of the exposure on the specimens;

ture. The exposure used in this practice is not intended to the test method shall be determined by the parties concerned.

simulate the deterioration caused by localized weather phe- Where practical, it is recommended that specimens be sized to

nomena such as atmospheric pollution, biological attack, and fit specimen holders and racks supplied with the exposure

salt water exposure. There can be no positive correlation of apparatus. Unless supplied with a specific backing as an

exposure results between this and other laboratory weathering integral part of the test, specimens shall be mounted so that

devices. only the minimum specimen area required for support by the

holder is covered. This unexposed surface must not be used as

4.2 Variations in results can be expected when operating

part of the test area. To provide rigidity, flexible specimens are

conditionsarevariedwithintheacceptedlimitsofthispractice.

typically attached to, or backed by, a panel made of aluminum,

Therefore, all test results using this practice must be accom-

0.025-in. (0.64-mm) thick.

panied by the specific operating conditions required in Section

9. Refer to Practice G151 for detailed information on the

6.2 Unless otherwise specified, prepare at least three repli-

caveatsapplicabletouseofresultsobtainedinaccordancewith

cate specimens of each test and control material to be exposed.

this practice.

6.3 Retain a supply of unexposed file specimens of all

4.3 The results of laboratory exposure cannot be directly

materials evaluated.

extrapolated to estimate absolute rate of deterioration by the

6.3.1 When destructive tests are used, it is recommended

environment because the acceleration factor is material depen-

thatasufficientnumberoffilespecimensberetainedsothatthe

dent and can be significantly different for each material and for

property of interest can be determined on the file specimens

differentformulationsofthesamematerial.However,exposure

each time the exposed materials are evaluated.

of a similar material of known outdoor performance, a control,

6.4 Follow the procedures described in Practice G147 for

atthesametimeasthetestspecimensallowscomparisonofthe

identification and conditioning and handling of specimens of

durability relative to that of the control under the test condi-

test, control, and reference materials prior to, during, and after

tions. Evaluation in terms of relative durabilities also greatly

exposure.

improves the agreement in test results among different labora-

tories (3).

6.5 Do not mask the face of a specimen for the purpose of

showing on one panel the effects of various exposure times.

4.4 Test results will depend on the care that is taken to

Accurateresultsarenotguaranteedsincethemaskedportionof

operate the equipment in accordance with Practice G155.

the specimen is still exposed to temperature and humidity

Significant factors include regulation of line voltage, freedom

cycles that, in many cases, will affect results.

from salt or other deposits from water, temperature and

humidity control and condition and age of the burners and

6.6 In some materials, specimen thickness markedly affects

filters.

thetestresults.Thicknessoftestandcontrolspecimensshallbe

within 610 % of the nominal dimensions.

NOTE 2—Additional information on sources of variability and on

strategies for addressing variability in the design, execution and data

NOTE 3—Thickness of a specimen is especially important when

analysis of laboratory accelerated exposure tests is found in Guide G141.

mechanical properties are being investigated.

4.5 Before proceeding with this practice, it is common

practice to reference the specifications of the material being

7. Procedure

tested. Any test specimen preparation, conditioning,

7.1 It is recommended that a control material be exposed

dimensions, or testing parameters, or combination thereof,

simultaneously with experimental materials for determination

coveredinthematerialspecificationshalltakeprecedenceover

of relative performance, if performance comparisons are not

those mentioned in this practice. If there are no material

being made between the test materials themselves. All con-

specifications, then the default conditions apply.

cerned parties must agree on the control material used.

5. Apparatus

7.1.1 Identification of any control specimen used shall

accompany the report.

5.1 The exposure apparatus employed shall use as the

source of radiation a xenon arc lamp and apparatus which

7.2 Mount the test specimens in the specimen exposure area

conforms to the requirements defined in Practices G151 and

with the test surfaces facing the lamp.When the test specimens

G155.

do not completely fill the exposure area, fill the empty spaces

5.1.1 Unless otherwise specified, the spectral power distri-

with blank metal panels to maintain the test conditions within

bution (SPD) of the xenon lamp shall conform to the require-

the chamber.

ments of Table 1 in Practice G155 for a xenon lamp with

7.3 Confine specimens to an exposure area where the

daylight filters.

irradiance is at least 90 % of that measured at the center of the

6. Test Specimens

exposure area. In areas where the irradiance is between 70 and

90 % of maximum irradiance, either reposition in accordance

6.1 The size and shape of specimens to be exposed will be

with the schedule agreed upon by all concerned parties, or

determined by the specifications of the particular test method

randomly position replicate specimens and determine the

averagechangeinproperty.Determineirradianceuniformityin

The boldface numbers in parentheses refer to a list of references at the end of

this standard. accordance with Practice G151.

D5071 − 06 (2013)

NOTE 4—Since the stability of the file specimen can also be time-

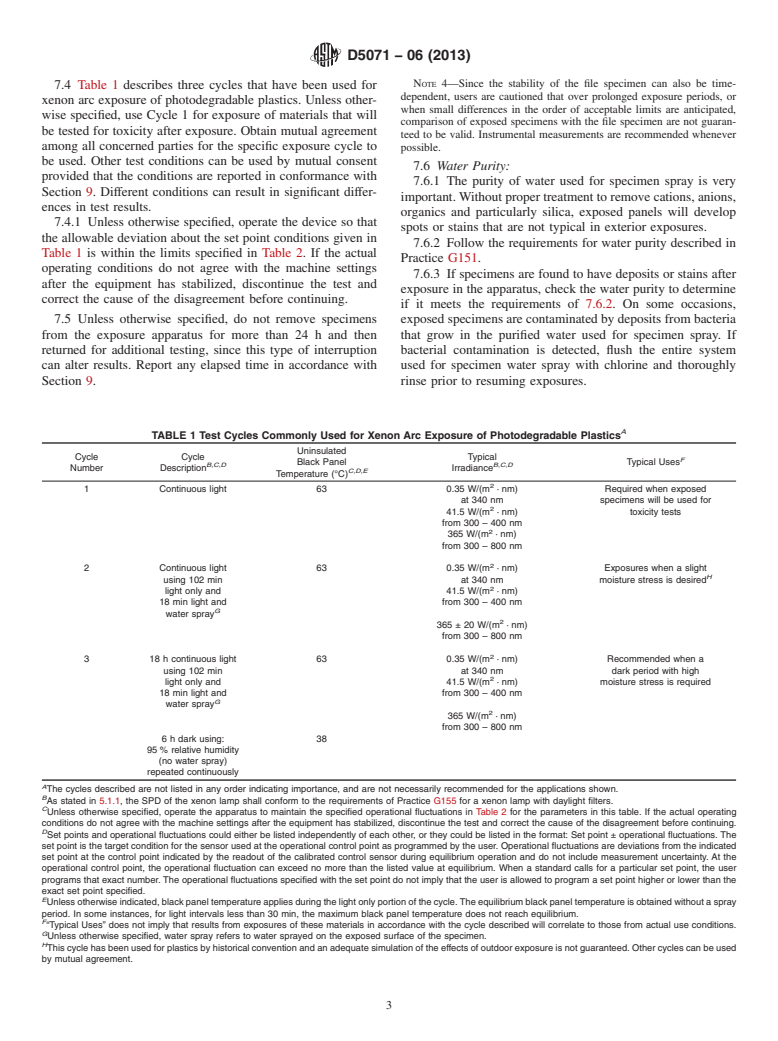

7.4 Table 1 describes three cycles that have been used for

dependent, users are cautioned that over prolonged exposure periods, or

xenon arc exposure of photodegradable plastics. Unless other-

when small differences in the order of acceptable limits are anticipated,

wise specified, use Cycle 1 for exposure of materials that will

comparison of exposed specimens with the file specimen are not guaran-

be tested for toxicity after exposure. Obtain mutual agreement

teed to be valid. Instrumental measurements are recommended whenever

among all concerned parties for the specific exposure cycle to

possible.

be used. Other test conditions can be used by mutual consent

7.6 Water Purity:

provided that the conditions are reported in conformance with

7.6.1 The purity of water used for specimen spray is very

Section 9. Different conditions can result in significant differ-

important.Without proper treatment to remove cations, anions,

ences in test results.

organics and particularly silica, exposed panels will develop

7.4.1 Unless otherwise specified, operate the device so that

spots or stains that are not typical in exterior exposures.

the allowable deviation about the set point conditions given in

7.6.2 Follow the requirements for water purity described in

Table 1 is within the limits specified in Table 2. If the actual

Practice G151.

operating conditions do not agree with the machine settings

7.6.3 If specimens are found to have deposits or stains after

after the equipment has stabilized, discontinue the test and

exposure in the apparatus, check the water purity to determine

correct the cause of the disagreement before continuing.

if it meets the requirements of 7.6.2. On some occasions,

7.5 Unless otherwise specified, do not remove specimens exposed specimens are contaminated by deposits from bacteria

from the exposure apparatus for more than 24 h and then that grow in the purified water used for specimen spray. If

returned for additional testing, since this type of interruption bacterial contamination is detected, flush the entire system

can alter results. Report any elapsed time in accordance with used for specimen water spray with chlorine and thoroughly

Section 9. rinse prior to resuming exposures.

A

TABLE 1 Test Cycles Commonly Used for Xenon Arc Exposure of Photodegradable Plastics

Uninsulated

Cycle Cycle Typical

F

Black Panel Typical Uses

B,C,D B,C,D

Number Description Irradiance

C,D,E

Temperature (°C)

1 Continuous light 63 0.35 W/(m · nm) Required when exposed

at 340 nm specimens will be used for

41.5 W/(m · nm) toxicity tests

from 300 – 400 nm

365 W/(m · nm)

from 300 – 800 nm

2 Continuous light 63 0.35 W/(m · nm) Exposures when a slight

H

using 102 min at 340 nm moisture stress is desired

light only and 41.5 W/(m · nm)

18 min light and from 300 – 400 nm

G

water spray

365±20W/(m · nm)

from 300 – 800 nm

3 18 h continuous light 63 0.35 W/(m · nm) Recommended when a

using 102 min at 340 nm dark period with high

light only and 41.5 W/(m · nm) moisture stress is required

18 min light and from 300 – 400 nm

G

water spray

365 W/(m · nm)

from 300 – 800 nm

6 h dark using: 38

95 % relative humidity

(no water spray)

repeated continuously

A

The cycles described are not listed in any order indicating importance, and are not necessarily recommended for the applications shown.

B

As stated in 5.1.1, the SPD of the xenon lamp shall conform to the requirements of Practice G155 for a xenon lamp with daylight filters.

C

Unless otherwise specified, operate the apparatus to maintain the specified operational fluctuations in Table 2 for the parameters in this table. If the actual operating

conditions do not agree with the machine settings after the equipment has stabilized, discontinue the test and correct the cause of the disagreement before continuing.

D

Set points and operational fluctuations could either be listed independently of each other, or they could be listed in the format: Set point ± operational fluctuations. The

set point is the target condition for the sensor used at the operational control point as programmed by the user. Operational fluctuations are deviations from the indicated

set point at the control point indi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.