ASTM D3233-93(2014)

(Test Method)Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

SIGNIFICANCE AND USE

5.1 Evaluations by both test methods differentiate between fluids having low, medium, and high levels of extreme-pressure properties. The user should establish any correlation between results by either method and service performance.

Note 3: Relative ratings by both test methods on the reference fluids covered in Table 1 and Table 2 are in good general agreement with four-ball weld-point relative ratings obtained on these same reference fluids, covered in Test Method D2783.

Repeatability

Reproducibility

s = 0.0624

S = 0.140

r = 0.179 (TL)D

R = 0.402 (TL)D

(A) Reference fluids used and described in Test Method D2783.(B) Calibration curves shifted.(C) Six laboratories.(D) TL = average true load, lbf, of sample tested.

Repeatability

Reproducibility

s = 0.0624

S = 0.137

r = 0.179 (TL)E

R = 0.391 (TL)E

(A) Reference fluids used and described in Test Method D2783.(B) Calibration curves shifted.(C) Seven laboratories.(D) Six laboratories.(E) TL = average true load, lbf, of sample tested.

SCOPE

1.1 These test methods cover two procedures for making a preliminary evaluation of the load-carrying properties of fluid lubricants by means of the Falex Pin and Vee Block Test Machine.

Note 1: Additional information can be found in Appendix X1 regarding coefficient of friction, load gage conversions, and load gage calibration curve.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3233 − 93 (Reapproved 2014)

Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid

Lubricants (Falex Pin and Vee Block Methods)

This standard is issued under the fixed designation D3233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—This gage reading is irrespective of the

particular gage used, and corrections are made by comparison

1.1 These test methods cover two procedures for making a

to a standard reference.

preliminary evaluation of the load-carrying properties of fluid

3.1.2 direct load, n—thatwhichisappliedlinearly,bisecting

lubricants by means of the Falex Pin and Vee Block Test

the angle of the vee block corrected to either the 800 or

Machine.

3000-lbf gage reference.

NOTE 1—Additional information can be found in Appendix X1 regard-

3.1.2.1 Discussion—This load is equivalent to the true load

ingcoefficientoffriction,loadgageconversions,andloadgagecalibration

times the cos 42°.

curve.

3.1.3 true load, n—the sum of the applied forces normal to

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

the tangents of contact between the faces of one vee block and

as standard. The values given in parentheses are mathematical

the journal pin corrected to the 4500 lbf gage reference line.

conversions to SI units that are provided for information only

and are not considered standard.

3.1.4 true load failure value, n—the true load at which the

lubricanttestedcannolongersupporttheappliedloadresulting

1.3 This standard does not purport to address all of the

in either test pin or shear pin breakage, or inability to maintain

safety concerns, if any, associated with its use. It is the

or increase load.

responsibility of the user of this standard to establish appro-

3.1.4.1 Discussion—This value is also referred to as the

priate safety and health practices and determine the applica-

limit of extreme pressure.

bility of regulatory limitations prior to use.

4. Summary of Test Methods

2. Referenced Documents

2 4.1 Both test methods consist of running a rotating steel

2.1 ASTM Standards:

journal at 290 6 10 rpm against two stationary V-blocks

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

immersed in the lubricant sample. Load is applied to the

and Shapes for Use in Screw Machines

V-blocks by a ratchet mechanism. In Test MethodA(Note 1),

D2670Test Method for Measuring Wear Properties of Fluid

increasing load is applied continuously. In Test Method B

Lubricants (Falex Pin and Vee Block Method)

(Note 1), load is applied in 250-lbf (1112-N) increments with

D2783Test Method for Measurement of Extreme-Pressure

load maintained constant for 1 min at each load increment. In

Properties of Lubricating Fluids (Four-Ball Method)

both methods the load-fail value obtained is the criteria for

level of load-carrying properties. Both methods require cali-

3. Terminology

bration of the load gage and reporting of test results as true

3.1 Definitions of Terms Specific to This Standard:

(corrected) loads rather than actual gage loads.

3.1.1 actual gage load, n—thevalueobtainedfromthegage

while running the test and before any corrections are made. NOTE 2—Test Method A is referred to as the Falex Run-Up Test. Test

Method B is referred to as the Falex One-Minute Step Test.

5. Significance and Use

These test methods are under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

5.1 Evaluations by both test methods differentiate between

Subcommittee D02.L0.11 on Tribiological Properties of Industrial Fluids and

fluidshavinglow,medium,andhighlevelsofextreme-pressure

Lubricates.

properties. The user should establish any correlation between

Current edition approved Dec. 1, 2014. Published February 2015. Originally

ε1

approved in 1986. Last previous edition approved in 2009 as D3233–93 (2009) . results by either method and service performance.

DOI: 10.1520/D3233-93R14.

NOTE 3—Relative ratings by both test methods on the reference fluids

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

covered in Table 1 and Table 2 are in good general agreement with

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on four-ball weld-point relative ratings obtained on these same reference

the ASTM website. fluids, covered in Test Method D2783.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3233 − 93 (2014)

A

TABLE 1 Results of Cooperative Tests on Reference Fluids L-XI-1-2-A, B, C, D, E

(TEST METHOD A)

L-XI-1-2-A L-XI-1-2-B L-XI-1-2-C L-XI-1-2-D L-XI-1-2-E

Labora-

Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf

Test

tory

Gage True Gage True Gage True Gage True Gage True

A1 1200 840 1200 840 4500 + 4100 + 4300 3950 2600 2100

2 1275 920 1275 920 4500 + 4100 + 4500 + 4100 + 2400 1925

B1 800 860 1000 1050 4500 + 4250 + 4100 3900 2050 2050

2 850 900 950 1025 4500 + 4250 + 4300 4100 1950 1950

C1 725 990 775 1020 4500 + 3200 + 3950 2900 1350 1460

2 650 910 750 980 4500 + 3200 + 4100 3000 1300 1430

D1 1400 1050 1100 770 4500 + 3500 + 4500 + 3500 + 2900 2150

2 1400 1050 1250 900 4500 + 3500 + 4500 + 3500 + 2650 1975

E1 825 900 1000 1060 4450 4500 + 4100 4475 1825 1970

2 750 820 925 1000 4450 4500 + 4150 4500 1825 1970

B B

F1 1000 920 1000 800 4500 + 4500 + 3500 4500 1850 1900

B B

990 910

2 1050 850 4500 + 4500 + 2900 3510 1720 1720

G1 800 900 690 800 4000 4275 3325 3625 1430 1600

2 700 800 660 750 3750 4000 3150 3450 1500 1675

H1 700 700 1000 1000 4500 + 4500 + 3750 3750 1900 1900

2 700 700 1000 1000 4500 + 4500 + 4000 4000 1650 1650

I1 750 600 1250 1000 4500 + 3750 + 4500 + 3750 + 1750 1450

2 750 600 1000 800 4500 + 3750 + 4500 + 3750 + 1750 1450

C

Min Avg 600 775 2950 1445

C

Max Avg 1050 1037 2063

C

Grand Avg 854 920 1796

Repeatability Reproducibility

s = 0.0624 S = 0.140

D D

r = 0.179 (TL) R = 0.402 (TL)

A

Reference fluids used and described in Test Method D2783.

B

Calibration curves shifted.

C

Six laboratories.

D

TL = average true load, lbf, of sample tested.

6. Apparatus 7.2 Standard Test Journals, ⁄4 in. (6.35 mm) outside diam-

eterby1 ⁄4in.(31.75mm)long,AISI3135steel,HRB87to91

6.1 Falex Pin and Vee Block Test Machine, illustrated in

−7

on a ground flat surface, surface finish 5 to 10 µin. (1.3×10

Fig. 1, Fig. 2, and Fig. 3, fitted with 4500-lbf (20000-N) gage

−7

to 2.5×10 m) rms.

or 3000-lbf (13350-N) gage.

7.3 Locking Pins, ⁄2 H brass, conforming to Specification

6.2 Required for Calibration:

4 B16/B16M.

6.2.1 Allen Screw, with attached 10-mm Brinnell ball.

6.2.2 Back-Up Plug. 7.4 Solvent, safe, nonfilming, nonchlorinated.

6.2.3 Standard Test Coupon, soft, annealed copper, Hb

NOTE4—Petroleumdistillateandbenzene,formerlyusedassolventsin

37–39.

this method, have been eliminated due to possible toxic effects. Each user

6.2.4 Brinnell Microscope, or equivalent.

should select a solvent that can meet applicable safety standards and still

thoroughly clean the parts.

6.2.5 Timer, graduated in seconds and minutes.

6.2.6 Rule, steel, 6-in. (approximately 150-mm) long.

8. Preparation of Apparatus

7. Reagents and Materials

8.1 Cleaning:

7.1 Standard Coined-Blocks, 96 6 1° angle, AISI C-1137 8.1.1 ThoroughlycleantheV-blocks,testjournals,lubricant

−7

steel, HRC 20 to 24, surface finish 5 to 10 µin. (1.3×10 to cup, and supports for V-blocks and test journals by washing,

−7

2.5×10 m), rms. successively, with solvent selected in 7.4. Dry the V-blocks,

test journals, lubricant cup, and supports by allowing the final

solvent to evaporate in air.

The Falex Pin and Vee Block Test Machine, available from the Falex Corp.,

8.1.2 After cleaning, handle the test pieces with care to

1020 Airpark Dr., Sugar Grove, IL 60554 has been found satisfactory for this

purpose. A new model of this machine has been available since 1983. Certain prevent contamination. Particularly, avoid contact of fingers

operatingproceduresaredifferentforthisnewmodel.Consultinstructionmanualof

with mating surfaces of V-blocks and test journals.

machine for this information.

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554. 8.2 Assembly:

D3233 − 93 (2014)

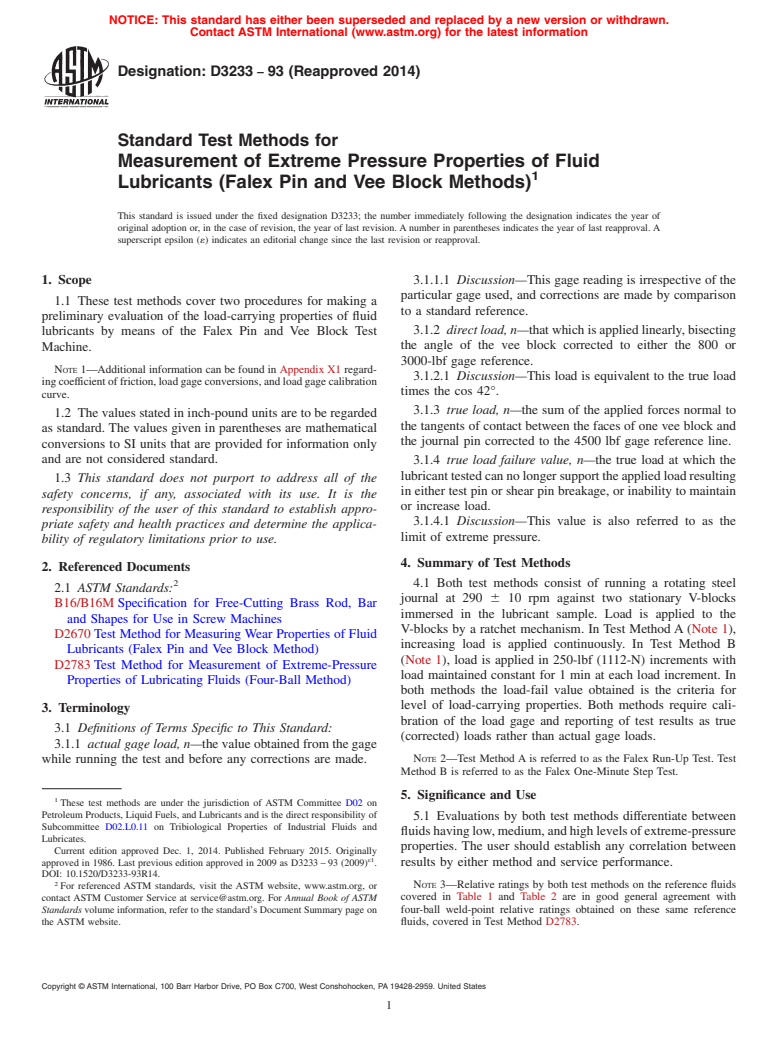

A

TABLE 2 Results of Cooperative Tests on Reference Fluids L-XI-1-2-A, B, C, D, E

(TEST METHOD B)

L-XI-1-2-A L-XI-1-2-B L-XI-1-2-C L-XI-1-2-D L-XI-1-2-E

Labora- Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf

Test

tory Gage True Gage True Gage True Gage True Gage True

A1 1100 750 1400 1000 4150 3750 4350 4000 2750 2250

2 1100 750 1400 1000 4350 4000 4150 3750 2200 1750

B1 670 750 940 1000 4200 4000 3900 3750 2000 2000

2 670 750 670 750 3900 3750 4200 4000 1750 1750

C1 520 750 520 750 4100 + 3000 + 4100 3000 1750 1750

2 520 750 790 1000 4100 + 3000 + 4100 + 3000 + 1750 1750

D1 1600 1250 1080 750 4500 + 3500 + 4500 + 3500 + 3000 2250

2 1600 1250 1080 750 4500 + 3500 + 4500 + 3500 + 3300 2500

E1 700 750 925 1000 3850 4250 3850 4250 1380 1500

2 700 750 925 1000 4150 4500 3650 4000 1850 2000

B B

F1 1075 1000 950 750 3350 4250 3350 4250 1925 2000

B B

1075 1000

2 950 750 3500 4500 3050 3750 1560 1500

G1 660 750 660 750 3500 3750 3000 3250 1550 1750

2 660 750 800 1000 3200 3500 2800 3000 1350 1500

H1 750 750 1000 1000 3500 3500 4250 4250 1500 1500

2 750 750 1000 1000 4000 4000 4000 4000 1750 1750

I1 930 750 910 750 4400 3750 4400 + 3750 + 1800 1500

2 930 750 910 750 4400 3750 4400 + 3750 + 1800 1500

C D

Min Avg 750 750 3625 3125 1500

C D

4375 4125

Max Avg 1250 1000 2375

C D

3932 3837

Grand Avg 833 875 1846

Repeatability Reproducibility

s = 0.0624 S = 0.137

E E

r = 0.179 (TL) R = 0.391 (TL)

A

Reference fluids used and described in Test Method D2783.

B

Calibration curves shifted.

C

Seven laboratories.

D

Six laboratories.

E

TL = average true load, lbf, of sample tested.

FIG. 1 Schematic Diagram of Falex Standard Pin and Vee Block Test Machine

8.2.1 Insert the test journal into the test shaft and secure 8.2.2 Insert the V-blocks into the recesses of the loading

with a new brass locking pin, as shown in Fig. 1 and Fig. 3. deviceandswingtheV-blocksinwardtocontactthejournalso

D3233 − 93 (2014)

FIG. 2 Falex Digital Pin and Vee Block Test Machine

by 11 in., are available at a nominal cost from ASTM. Although not

originally used in development of these test methods, the 3000-lb direct

reading load gage should be satisfactory providing results are corrected

and reported with respect to the true load (4500-lbf) reference line. Refer

to Test Method D2670 for calibration of 3000-lb load gage.

10. Calibration of Load Gage 4500 lbf (20 000 N)

10.1 RemovetheAllensetscrewand ⁄2-in.(12.70-mm)ball

from the left jaw socket (Fig. 5).

10.2 InsertthespecialAllenscrewwiththeattached10-mm

Brinnell ball into the working face of the left jaw. Adjust so

that the ball projects about ⁄32 in. (approximately 4 mm) from

the face of the jaw.

10.3 Insert the back-up plug in the counterbore of the

FIG. 3 Exploded View of V-Blocks and Journal Arrangement, 1

right-hand jaw. Adjust so that the plug projects about ⁄32 in.

Falex Pin and Vee Block Test Machines

(approximately 0.8 mm) from the face.

10.4 Supportthestandardtestcouponsothattheupperedge

of the coupon is about ⁄32 in. (approximately 2.5 mm) below

that the V-grooves are aligned with the journal major axis, as

the upper surface of the jaws. Place a steel rule across the face

shown in Fig. 1 and Fig. 3.

of the jaws. Adjust the Allen screw with the attached 10-mm

8.2.3 Place 60 mL of test lubricant in the lubricant cup and

ball until the face of the jaws are parallel to the steel rule with

raise the cup so that the V-blocks are immersed in the test

the test coupon in position for indentation.

lubricant. With highly viscous fluids, open the jaws slightly to

ensure that the wear surfaces are covered with the lubricant.

10.5 With the test coupon in position for the first

8.2.4 Place the automatic loading device, with attached

impression, place the load gage assembly on the level arms.

gage, on the jaw arms.

Remove the slack from the assembly by moving the ratchet

wheel by hand.

9. Preparation of True Load Calibration Curve

10.6 Placetheloadingleverontheratchetwheelandactuate

9.1 On log-log paper (K & E467080 or equivalent) draw a

the motor.Allow the motor to run until the load gage indicates

straight-line plot of load, pounds-force (newtons) (ordinate),

a load of 500 lbf (2224 N). A slight take-up on the ratchet

versus indentation diameter, millimetres (abscissa) using the

wheel is required to hold the load due to the ball sinking into

data points shown below. Label this curve “True Load” (Note

thetestcoupon.Aftera500-lbf(2224-N)loadisobtained,hold

5).

for 1 min for the indentation to form.

Load, lbf (N) Diameter, mm

10.7 Turnoffthemachineandbackofftheloaduntilthetest

(Ordinate) (Abscissa)

coupon is free of the jaws. Advance the test coupon approxi-

500 (2224) 2.62

mately ⁄8 in. (approximately 9.5 mm).Additional indentations

1000 (4450) 3.42

should be separated by a minimum distance of 2.5 times the

1500 (6672) 4.00

2000 (8896) 4.47

diameter of the initial indentation. Check the alignment of the

jaws, and repeat the procedure described in 10.6 at gage loads

NOTE5—Fig.3showsthetrue-loadcalibrationcurvefortheprescribed

4500-lbf (20000-N) gage, prepared as covered in 9.1. Copies of Fig. 4,8 of 1000, 1500, and 2000 lbf (4448, 6672, and 8896 N).

D3233 − 93 (2014)

FIG. 4 Calibration Curve for 4500-lb Gage, Using 37-39 HB Copper Coupon

diameter, rotating the test coupon to ensure that no two

measurements represent the same points. Average the three

measurements of each impression and record.

10.9 Plot the four impression readings on the same log-log

plot of true load prepared as prescribed in 9.1 and shown as

Fig. 4. Draw a straight line through the four impression

readings and label the line “Actual Gage Load.”

NOTE6—Currently,loadgagesarecalibratedatthefactorysuchthatthe

actual 4500-lb gage load is equivalent to true load. Periodic calibrations

should be made to ensure correct values are being reported for true load.

TEST METHOD A

11. Determination of Actual Gage Load for Run-In

11.1 The procedure, Section 12, requires a run-in at an

actual gage load equivalent to 300-lbf (1334-N) true load

(264-lbf dir

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3233 − 93 (Reapproved 2009) D3233 − 93 (Reapproved 2014)

Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid

Lubricants (Falex Pin and Vee Block Methods)

This standard is issued under the fixed designation D3233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected SI equivalent in 12.1.1 editorially in October 2010.

1. Scope

1.1 These test methods cover two procedures for making a preliminary evaluation of the load-carrying properties of fluid

lubricants by means of the Falex Pin and Vee Block Test Machine.

NOTE 1—Additional information can be found in Appendix X1 regarding coefficient of friction, load gage conversions, and load gage calibration curve.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

D2670 Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

D2783 Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual gage load, n—the value obtained from the gage while running the test and before any corrections are made.

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.11 on Tribiological Properties of Industrial Fluids and Lubricates.

Current edition approved April 15, 2009Dec. 1, 2014. Published July 2009February 2015. Originally approved in 1986. Last previous edition approved in 20032009 as

ε1

D3233–93(2003).D3233 – 93 (2009) . DOI: 10.1520/D3233-93R09.10.1520/D3233-93R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

This gage reading is irrespective of the particular gage used, and corrections are made by comparison to a standard reference.

3.1.2 direct load, n—that which is applied linearly, bisecting the angle of the vee block corrected to either the 800 or 3000-lbf

gage reference.

3.1.2.1 Discussion—

This load is equivalent to the true load times the cos 42°.

3.1.3 true load, n—the sum of the applied forces normal to the tangents of contact between the faces of one vee block and the

journal pin corrected to the 4500 lbf gage reference line.

3.1.4 true load failure value, n—the true load at which the lubricant tested can no longer support the applied load resulting in

either test pin or shear pin breakage, or inability to maintain or increase load.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3233 − 93 (2014)

A

TABLE 1 Results of Cooperative Tests on Reference Fluids L-XI-1-2-A, B, C, D, E

(TEST METHOD A)

L-XI-1-2-A L-XI-1-2-B L-XI-1-2-C L-XI-1-2-D L-XI-1-2-E

Labora-

Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf

Test

tory

Gage True Gage True Gage True Gage True Gage True

A 1 1200 840 1200 840 4500 + 4100 + 4300 3950 2600 2100

2 1275 920 1275 920 4500 + 4100 + 4500 + 4100 + 2400 1925

B 1 800 860 1000 1050 4500 + 4250 + 4100 3900 2050 2050

2 850 900 950 1025 4500 + 4250 + 4300 4100 1950 1950

C 1 725 990 775 1020 4500 + 3200 + 3950 2900 1350 1460

2 650 910 750 980 4500 + 3200 + 4100 3000 1300 1430

D 1 1400 1050 1100 770 4500 + 3500 + 4500 + 3500 + 2900 2150

2 1400 1050 1250 900 4500 + 3500 + 4500 + 3500 + 2650 1975

E 1 825 900 1000 1060 4450 4500 + 4100 4475 1825 1970

2 750 820 925 1000 4450 4500 + 4150 4500 1825 1970

B B

F 1 1000 920 1000 800 4500 + 4500 + 3500 4500 1850 1900

B B

990 910

2 1050 850 4500 + 4500 + 2900 3510 1720 1720

G 1 800 900 690 800 4000 4275 3325 3625 1430 1600

2 700 800 660 750 3750 4000 3150 3450 1500 1675

H 1 700 700 1000 1000 4500 + 4500 + 3750 3750 1900 1900

2 700 700 1000 1000 4500 + 4500 + 4000 4000 1650 1650

I 1 750 600 1250 1000 4500 + 3750 + 4500 + 3750 + 1750 1450

2 750 600 1000 800 4500 + 3750 + 4500 + 3750 + 1750 1450

C

Min Avg 600 775 2950 1445

C

Max Avg 1050 1037 2063

C

Grand Avg 854 920 1796

Repeatability Reproducibility

s = 0.0624 S = 0.140

D D

r = 0.179 (TL) R = 0.402 (TL)

A

Reference fluids used and described in Test Method D2783.

B

Calibration curves shifted.

C

Six laboratories.

D

TL = average true load, lbf, of sample tested.

3.1.4.1 Discussion—

This value is also referred to as the limit of extreme pressure.

4. Summary of Test Methods

4.1 Both test methods consist of running a rotating steel journal at 290 6 10 rpm against two stationary V-blocks immersed in

the lubricant sample. Load is applied to the V-blocks by a ratchet mechanism. In Test Method A (Note 1), increasing load is applied

continuously. In Test Method B (Note 1), load is applied in 250-lbf (1112-N) increments with load maintained constant for 1 min

at each load increment. In both methods the load-fail value obtained is the criteria for level of load-carrying properties. Both

methods require calibration of the load gage and reporting of test results as true (corrected) loads rather than actual gage loads.

NOTE 2—Test Method A is referred to as the Falex Run-Up Test. Test Method B is referred to as the Falex One-Minute Step Test.

5. Significance and Use

5.1 Evaluations by both test methods differentiate between fluids having low, medium, and high levels of extreme-pressure

properties. The user should establish any correlation between results by either method and service performance.

NOTE 3—Relative ratings by both test methods on the reference fluids covered in Table 1 and Table 2 are in good general agreement with four-ball

weld-point relative ratings obtained on these same reference fluids, covered in Test Method D2783.

D3233 − 93 (2014)

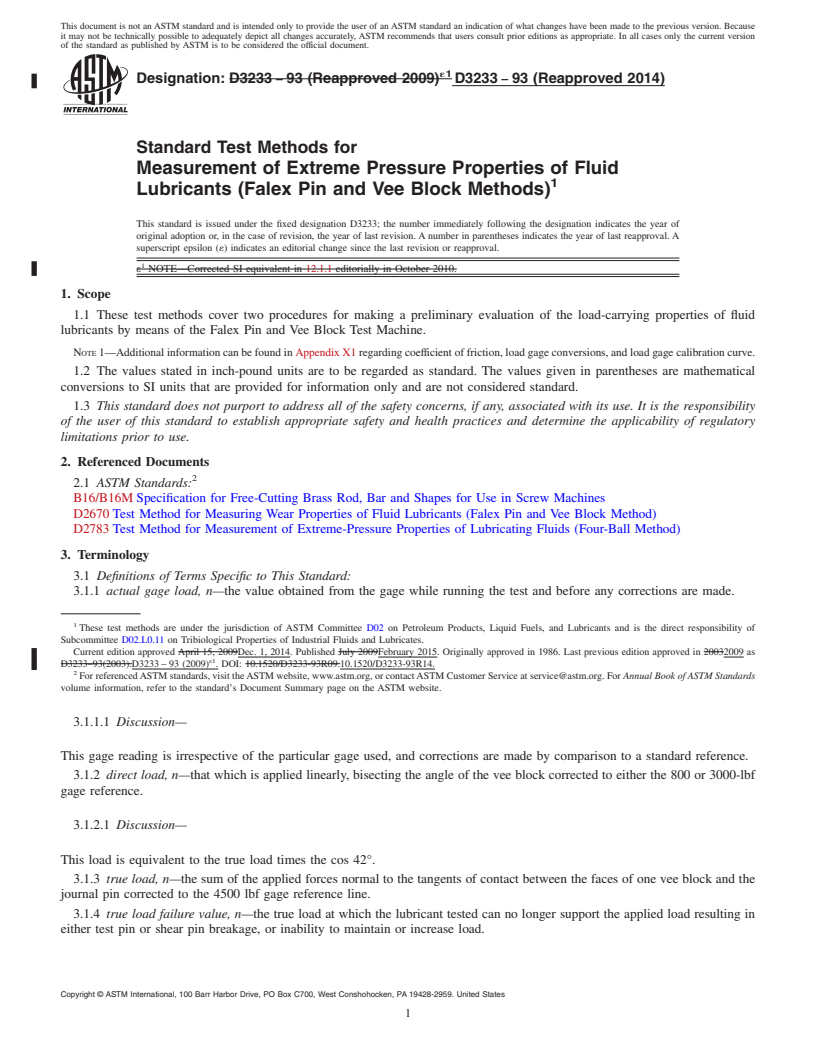

A

TABLE 2 Results of Cooperative Tests on Reference Fluids L-XI-1-2-A, B, C, D, E

(TEST METHOD B)

L-XI-1-2-A L-XI-1-2-B L-XI-1-2-C L-XI-1-2-D L-XI-1-2-E

Labora- Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf

Test

tory Gage True Gage True Gage True Gage True Gage True

A 1 1100 750 1400 1000 4150 3750 4350 4000 2750 2250

2 1100 750 1400 1000 4350 4000 4150 3750 2200 1750

B 1 670 750 940 1000 4200 4000 3900 3750 2000 2000

2 670 750 670 750 3900 3750 4200 4000 1750 1750

C 1 520 750 520 750 4100 + 3000 + 4100 3000 1750 1750

2 520 750 790 1000 4100 + 3000 + 4100 + 3000 + 1750 1750

D 1 1600 1250 1080 750 4500 + 3500 + 4500 + 3500 + 3000 2250

2 1600 1250 1080 750 4500 + 3500 + 4500 + 3500 + 3300 2500

E 1 700 750 925 1000 3850 4250 3850 4250 1380 1500

2 700 750 925 1000 4150 4500 3650 4000 1850 2000

B B

F 1 1075 1000 950 750 3350 4250 3350 4250 1925 2000

B B

1075 1000

2 950 750 3500 4500 3050 3750 1560 1500

G 1 660 750 660 750 3500 3750 3000 3250 1550 1750

2 660 750 800 1000 3200 3500 2800 3000 1350 1500

H 1 750 750 1000 1000 3500 3500 4250 4250 1500 1500

2 750 750 1000 1000 4000 4000 4000 4000 1750 1750

I 1 930 750 910 750 4400 3750 4400 + 3750 + 1800 1500

2 930 750 910 750 4400 3750 4400 + 3750 + 1800 1500

C D

Min Avg 750 750 3625 3125 1500

C D

4375 4125

Max Avg 1250 1000 2375

C D

3932 3837

Grand Avg 833 875 1846

Repeatability Reproducibility

s = 0.0624 S = 0.137

E E

r = 0.179 (TL) R = 0.391 (TL)

A

Reference fluids used and described in Test Method D2783.

B

Calibration curves shifted.

C

Seven laboratories.

D

Six laboratories.

E

TL = average true load, lbf, of sample tested.

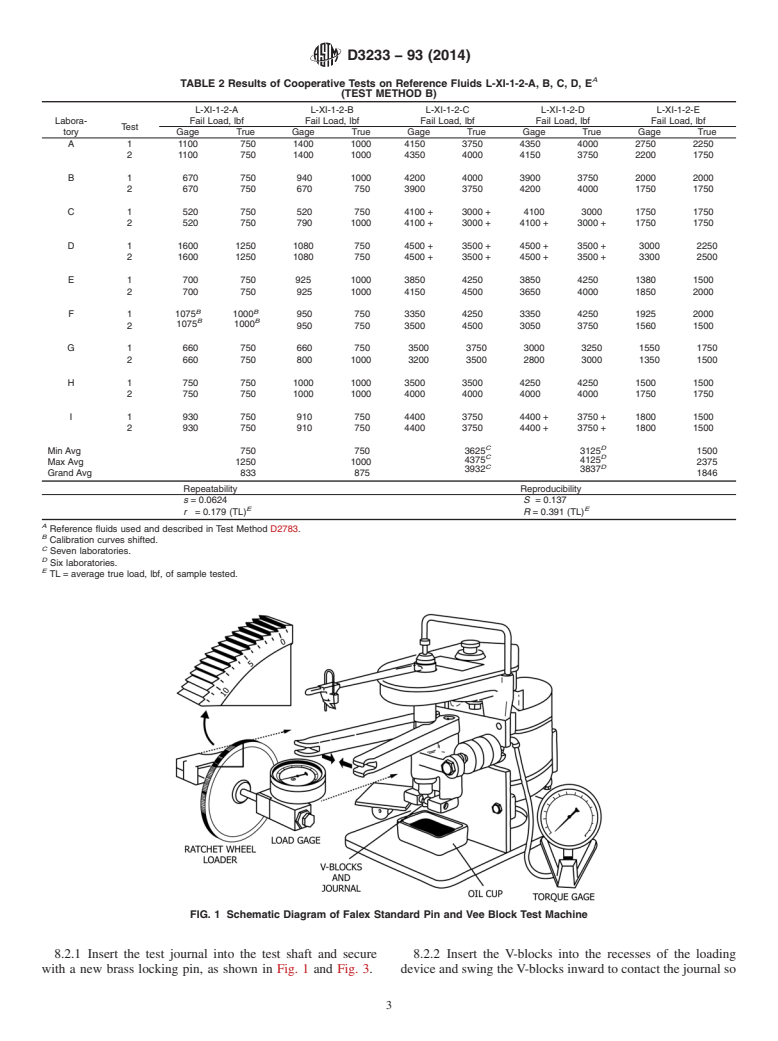

6. Apparatus

6.1 Falex Pin and Vee Block Test Machine, illustrated in Fig. 1, Fig. 2, and Fig. 3, fitted with 4500-lbf (20 000-N) gage or

3000-lbf (13 350-N) gage.

6.2 Required for Calibration:

6.2.1 Allen Screw, with attached 10-mm Brinnell ball.

6.2.2 Back-Up Plug.

6.2.3 Standard Test Coupon, soft, annealed copper, Hb 37–39.

6.2.4 Brinnell Microscope, or equivalent.

6.2.5 Timer, graduated in seconds and minutes.

6.2.6 Rule, steel, 6-in. (approximately 150-mm) long.

7. Reagents and Materials

4 −7

7.1 Standard Coined-Blocks, 96 6 1° angle, AISI C-1137 steel, HRC 20 to 24, surface finish 5 to 10 μin. (1.3 × 10 to 2.5 × 10

− m), rms.

1 1

7.2 Standard Test Journals, ⁄4 in. (6.35 mm) outside diameter by 1 ⁄4 in. (31.75 mm) long, AISI 3135 steel, HRB 87 to 91 on

−7 −7

a ground flat surface, surface finish 5 to 10 μin. (1.3 × 10 to 2.5 × 10 m) rms.

7.3 Locking Pins, ⁄2 H brass, conforming to Specification B16/B16M.

The Falex Pin and Vee Block Test Machine, available from the Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554 has been found satisfactory for this purpose. A

new model of this machine has been available since 1983. Certain operating procedures are different for this new model. Consult instruction manual of machine for this

information.

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554.

D3233 − 93 (2014)

FIG. 1 Schematic Diagram of Falex Standard Pin and Vee Block Test Machine

FIG. 2 Falex Digital Pin and Vee Block Test Machine

FIG. 3 Exploded View of V-Blocks and Journal Arrangement,

Falex Pin and Vee Block Test Machines

7.4 Solvent, safe, nonfilming, nonchlorinated.

D3233 − 93 (2014)

NOTE 4—Petroleum distillate and benzene, formerly used as solvents in this method, have been eliminated due to possible toxic effects. Each user

should select a solvent that can meet applicable safety standards and still thoroughly clean the parts.

8. Preparation of Apparatus

8.1 Cleaning:

8.1.1 Thoroughly clean the V-blocks, test journals, lubricant cup, and supports for V-blocks and test journals by washing,

successively, with solvent selected in 7.4. Dry the V-blocks, test journals, lubricant cup, and supports by allowing the final solvent

to evaporate in air.

8.1.2 After cleaning, handle the test pieces with care to prevent contamination. Particularly, avoid contact of fingers with mating

surfaces of V-blocks and test journals.

8.2 Assembly:

8.2.1 Insert the test journal into the test shaft and secure with a new brass locking pin, as shown in Fig. 1 and Fig. 3.

8.2.2 Insert the V-blocks into the recesses of the loading device and swing the V-blocks inward to contact the journal so that

the V-grooves are aligned with the journal major axis, as shown in Fig. 1 and Fig. 3.

8.2.3 Place 60 mL of test lubricant in the lubricant cup and raise the cup so that the V-blocks are immersed in the test lubricant.

With highly viscous fluids, open the jaws slightly to ensure that the wear surfaces are covered with the lubricant.

8.2.4 Place the automatic loading device, with attached gage, on the jaw arms.

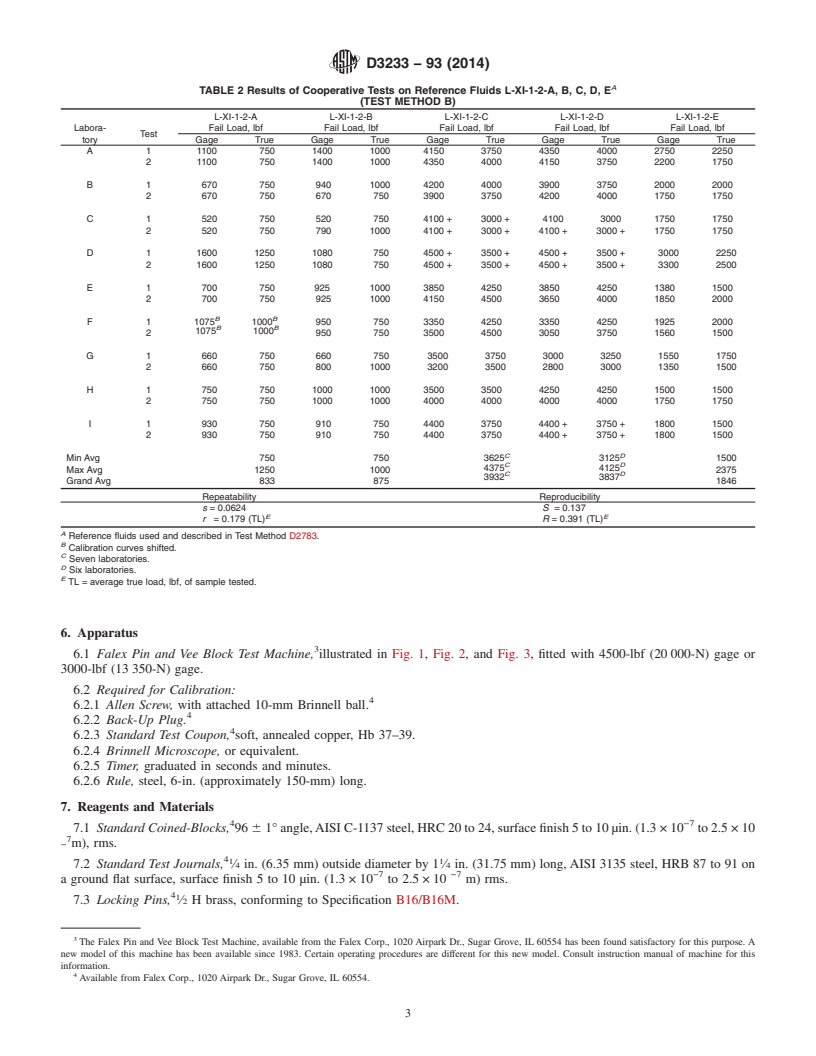

9. Preparation of True Load Calibration Curve

9.1 On log-log paper (K & E467080 or equivalent) draw a straight-line plot of load, pounds-force (newtons) (ordinate), versus

indentation diameter, millimetres (abscissa) using the data points shown below. Label this curve “True Load” (Note 5).

Load, lbf (N) Diameter, mm

(Ordinate) (Abscissa)

500 (2224) 2.62

1000 (4450) 3.42

1500 (6672) 4.00

2000 (8896) 4.47

NOTE 5—Fig. 3 shows the true-load calibration curve for the prescribed 4500-lbf (20 000-N) gage, prepared as covered in 9.1. Copies of Fig. 4, 8 by

11 in., are available at a nominal cost from ASTM. Although not originally used in development of these test methods, the 3000-lb direct reading load

gage should be satisfactory providing results are corrected and reported with respect to the true load (4500-lbf) reference line. Refer to Test Method D2670

for calibration of 3000-lb load gage.

10. Calibration of Load Gage 4500 lbf (20 000 N)

10.1 Remove the Allen set screw and ⁄2-in. (12.70-mm) ball from the left jaw socket (Fig. 5).

10.2 Insert the special Allen screw with the attached 10-mm Brinnell ball into the working face of the left jaw. Adjust so that

the ball projects about ⁄32 in. (approximately 4 mm) from the face of the jaw.

10.3 Insert the back-up plug in the counterbore of the right-hand jaw. Adjust so that the plug projects about ⁄32 in.

(approximately 0.8 mm) from the face.

10.4 Support the standard test coupon so that the upper edge of the coupon is about ⁄32 in. (approximately 2.5 mm) below the

upper surface of the jaws. Place a steel rule across the face of the jaws. Adjust the Allen screw with the attached 10-mm ball until

the face of the jaws are parallel to the steel rule with the test coupon in position for indentation.

10.5 With the test coupon in position for the first impression, place the load gage assembly on the level arms. Remove the slack

from the assembly by moving the ratchet wheel by hand.

10.6 Place the loading lever on the ratchet wheel and actuate the motor. Allow the motor to run until the load gage indicates

a load of 500 lbf (2224 N). A slight take-up on the ratchet wheel is required to hold the load due to the ball sinking into the test

coupon. After a 500-lbf (2224-N) load is obtained, hold for 1 min for the indentation to form.

10.7 Turn off the machine and back off the load until the test coupon is free of the jaws. Advance the test coupon approximately

⁄8 in. (approximately 9.5 mm). Additional indentations should be separated by a minimum distance of 2.5 times the diameter of

the initial indentation. Check the alignment of the jaws, and repeat the procedure described in 10.6 at gage loads of 1000, 1500,

and 2000 lbf (4448, 6672, and 8896 N).

10.8 Remove the load gage assembly and test coupon and measure the diameter of each indentation to 0.01 mm with a

microscope. Make three measurements of the indentation diameter, rotating the test coupon to ensure that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.