ASTM D3233-19

(Test Method)Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

SIGNIFICANCE AND USE

5.1 Evaluations by both test methods differentiate between fluids having low, medium, and high levels of extreme-pressure properties. The user should establish any correlation between results by either method and service performance.

Note 3: Relative ratings by both test methods on the fluids covered in Table X2.1 and Table X2.2 are in good general agreement with four-ball weld-point relative ratings obtained on these same fluids, covered in Test Method D2783.

SCOPE

1.1 These test methods cover two procedures for making a preliminary evaluation of the load-carrying properties of fluid lubricants by means of the Falex Pin and Vee Block Test Machine.

Note 1: Additional information can be found in Appendix X1 regarding coefficient of friction, load gauge conversions, and load gauge calibration curve.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3233 − 19

Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid

1

Lubricants (Falex Pin and Vee Block Methods)

This standard is issued under the fixed designation D3233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Properties of Lubricating Fluids (Four-Ball Method)

1.1 These test methods cover two procedures for making a

3. Terminology

preliminary evaluation of the load-carrying properties of fluid

lubricants by means of the Falex Pin and Vee Block Test

3.1 Definitions of Terms Specific to This Standard:

Machine.

3.1.1 actual gauge load, n—the value obtained from the

gauge while running the test and before any corrections are

NOTE 1—Additional information can be found in Appendix X1 regard-

ing coefficient of friction, load gauge conversions, and load gauge made.

calibration curve.

3.1.1.1 Discussion—This gauge reading is irrespective of

1.2 The values stated in inch-pound units are to be regarded

the particular gauge used, and corrections are made by com-

as standard. The values given in parentheses are mathematical

parison to a standard reference.

conversions to SI units that are provided for information only

3.1.2 direct load, n—thatwhichisappliedlinearly,bisecting

and are not considered standard.

the angle of the vee block corrected to either the 800lbf or

1.3 This standard does not purport to address all of the

3000lbf gauge reference.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—This load is equivalent to the true load

responsibility of the user of this standard to establish appro-

times the cos 42°.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1.3 true load, n—the sum of the applied forces normal to

1.4 This international standard was developed in accor-

the tangents of contact between the faces of one vee block and

dance with internationally recognized principles on standard-

the journal pin corrected to the 4500lbf gauge reference line.

ization established in the Decision on Principles for the

3.1.4 true load failure value, n—the true load at which the

Development of International Standards, Guides and Recom-

lubricanttestedcannolongersupporttheappliedloadresulting

mendations issued by the World Trade Organization Technical

in either test pin or shear pin breakage, or inability to maintain

Barriers to Trade (TBT) Committee.

or increase load.

3.1.4.1 Discussion—This value is also referred to as the

2. Referenced Documents

2 limit of extreme pressure.

2.1 ASTM Standards:

B16/B16MSpecification for Free-Cutting Brass Rod, Bar

4. Summary of Test Methods

and Shapes for Use in Screw Machines

D2670Test Method for Measuring Wear Properties of Fluid

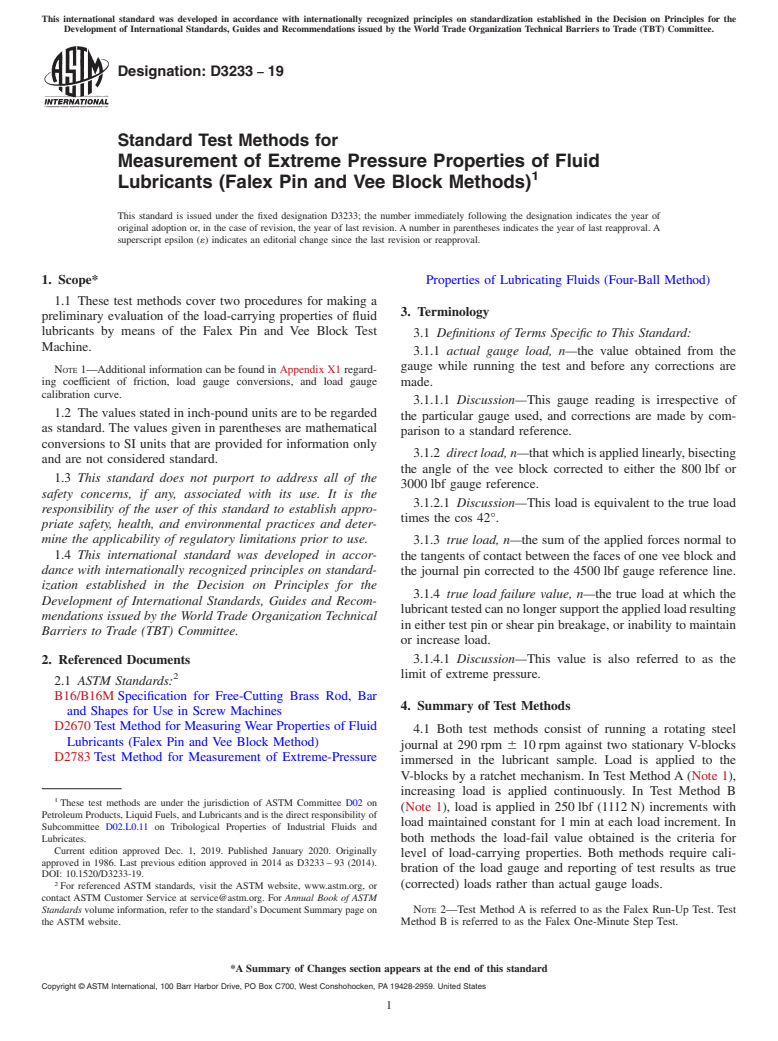

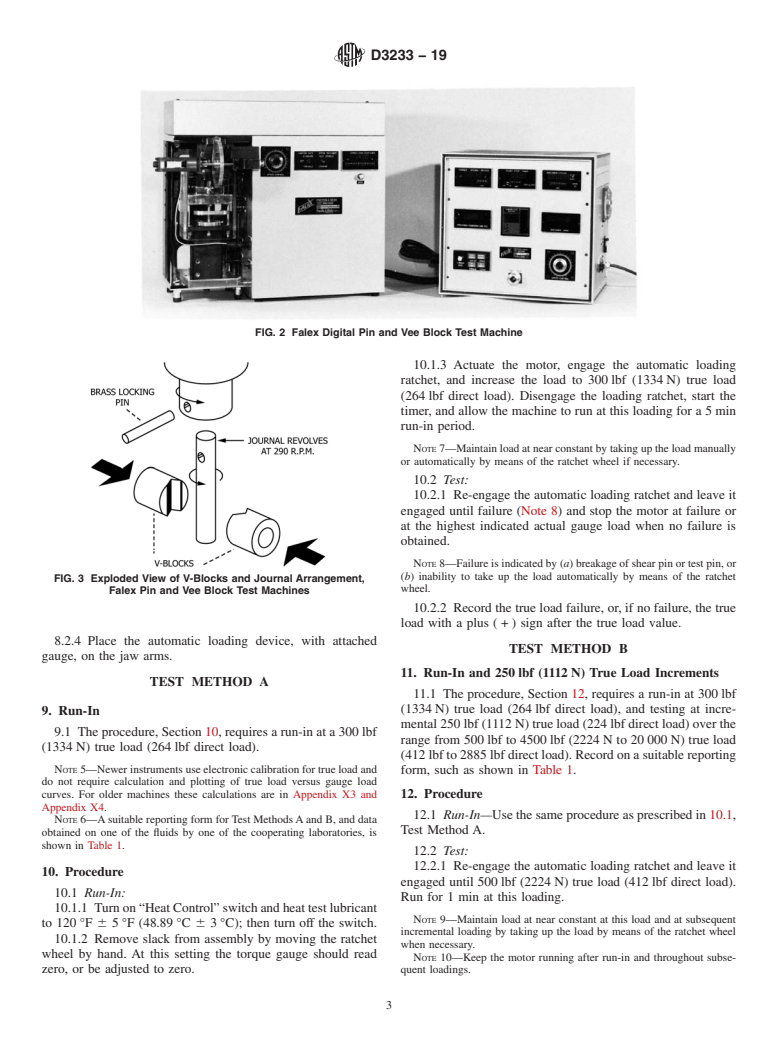

4.1 Both test methods consist of running a rotating steel

Lubricants (Falex Pin and Vee Block Method)

journal at 290rpm 6 10rpm against two stationary V-blocks

D2783Test Method for Measurement of Extreme-Pressure

immersed in the lubricant sample. Load is applied to the

V-blocks by a ratchet mechanism. In Test MethodA(Note 1),

increasing load is applied continuously. In Test Method B

1

These test methods are under the jurisdiction of ASTM Committee D02 on

(Note 1), load is applied in 250lbf (1112N) increments with

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

load maintained constant for 1min at each load increment. In

Subcommittee D02.L0.11 on Tribological Properties of Industrial Fluids and

Lubricates. both methods the load-fail value obtained is the criteria for

Current edition approved Dec. 1, 2019. Published January 2020. Originally

level of load-carrying properties. Both methods require cali-

approved in 1986. Last previous edition approved in 2014 as D3233–93 (2014).

bration of the load gauge and reporting of test results as true

DOI: 10.1520/D3233-19.

2

(corrected) loads rather than actual gauge loads.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 2—Test Method A is referred to as the Falex Run-Up Test. Test

the ASTM website. Method B is referred to as the Falex One-Minute Step Test.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700,

...

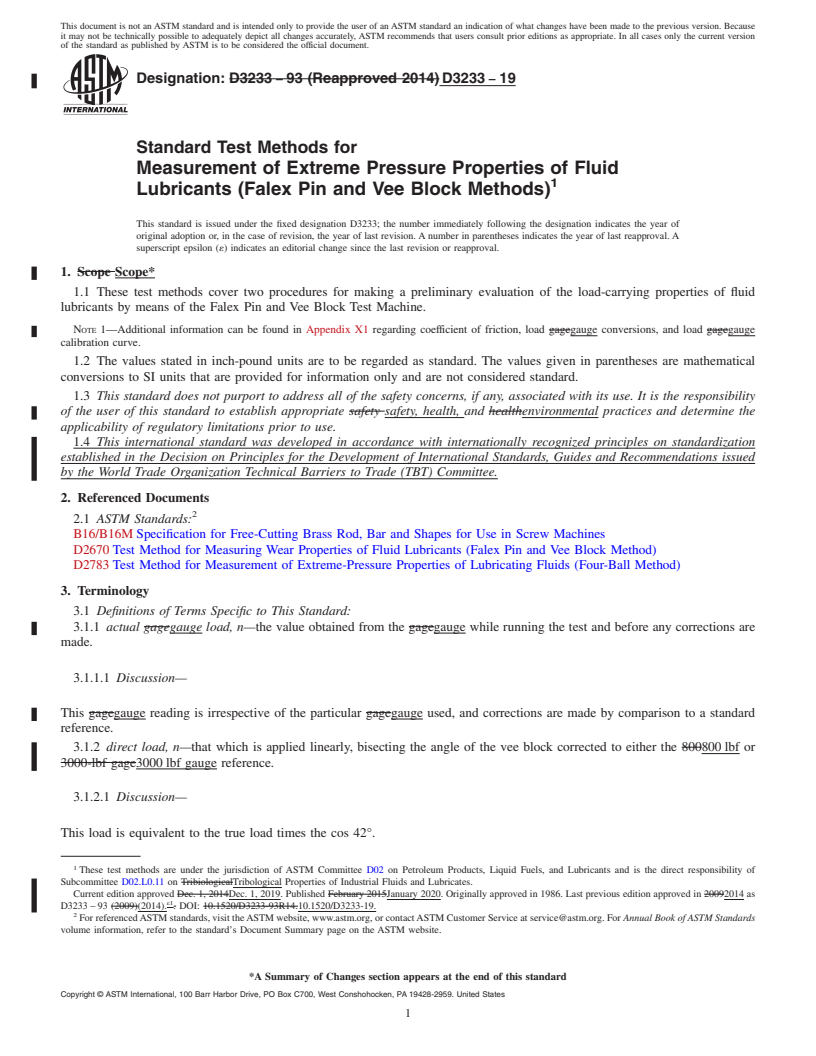

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3233 − 93 (Reapproved 2014) D3233 − 19

Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid

1

Lubricants (Falex Pin and Vee Block Methods)

This standard is issued under the fixed designation D3233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 These test methods cover two procedures for making a preliminary evaluation of the load-carrying properties of fluid

lubricants by means of the Falex Pin and Vee Block Test Machine.

NOTE 1—Additional information can be found in Appendix X1 regarding coefficient of friction, load gagegauge conversions, and load gagegauge

calibration curve.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B16/B16M Specification for Free-Cutting Brass Rod, Bar and Shapes for Use in Screw Machines

D2670 Test Method for Measuring Wear Properties of Fluid Lubricants (Falex Pin and Vee Block Method)

D2783 Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids (Four-Ball Method)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual gagegauge load, n—the value obtained from the gagegauge while running the test and before any corrections are

made.

3.1.1.1 Discussion—

This gagegauge reading is irrespective of the particular gagegauge used, and corrections are made by comparison to a standard

reference.

3.1.2 direct load, n—that which is applied linearly, bisecting the angle of the vee block corrected to either the 800800 lbf or

3000-lbf gage3000 lbf gauge reference.

3.1.2.1 Discussion—

This load is equivalent to the true load times the cos 42°.

1

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.11 on TribiologicalTribological Properties of Industrial Fluids and Lubricates.

Current edition approved Dec. 1, 2014Dec. 1, 2019. Published February 2015January 2020. Originally approved in 1986. Last previous edition approved in 20092014 as

ε1

D3233 – 93 (2009)(2014). . DOI: 10.1520/D3233-93R14.10.1520/D3233-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3233 − 19

3.1.3 true load, n—the sum of the applied forces normal to the tangents of contact between the faces of one vee block and the

journal pin corrected to the 4500 lbf gage 4500 lbf gauge reference line.

3.1.4 true load failure value, n—the true load at which the lubricant tested can no longer support the applied load resulting in

either test pin or shear pin breakage, or inability to maintain or increase load.

3.1.4.1 Discussion—

This value is also referred to as the limit of extreme pressure.

4. Summary of Test Methods

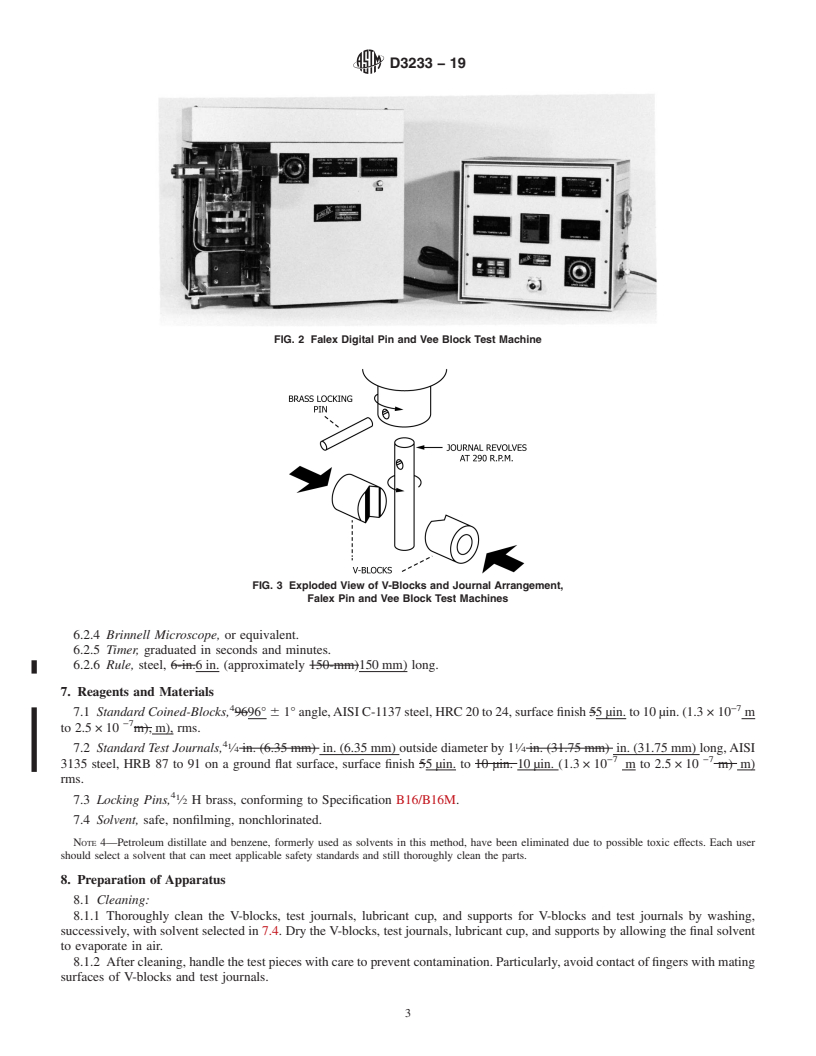

4.1 Both test methods consist of running a rotating steel journal at 290290 rpm 6 10 rpm 10 rpm against two stationary

V-blocks immersed in the lubricant sample. Load is applied to the V-blocks by a ratchet mechanism. In Test Method A (Note 1),

increasing load is applied continuously. In Test Method B (Note 1), load is applied in 250-lbf (111

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.