ASTM D6238-98(2011)

(Test Method)Standard Test Method for Total Oxygen Demand in Water

Standard Test Method for Total Oxygen Demand in Water

SIGNIFICANCE AND USE

The measurement of oxygen demand parameters is critical to the control of process wastewaters. Biochemical oxygen demand (BOD) and chemical oxygen demand (COD) analyzers have long time cycles and in the case of COD analyzers use corrosive reagents with the inherent problem of disposal. Total oxygen demand analysis is faster, approximately 3 min, and uses no liquid reagents in its analysis.

TOD can be correlated to both COD and BOD, providing effective on-line control.

TOD offers several features which make it a more attractive measurement than carbon monitoring using Total Carbon (TC) or Total Organic Carbon (TOC) analyzers. TOD is unaffected by the presence of inorganic carbon. TOD analysis will also indicate noncarbonaceous materials that consume or contribute oxygen. For example, the oxygen demand of ammonia, sulfite and sulfides will be reflected in the TOD measurement. Also, since the actual measurement is oxygen consumption, TOD reflects the oxidation state of the chemical compound (that is, urea and formic acid have the same number of carbon atoms, yet urea has five times the oxygen demand of formic acid).

SCOPE

1.1 This test method covers the determination of total oxygen demand in the range from 100 to 100 000 mg/L, in water and wastewater including brackish waters and brines (see 6.5). Larger concentrations, or samples with high suspended solids, or both, may be determined by suitable dilution of the sample.

1.1.1 Since the analysis is based on the change in oxygen reading of the carrier gas compared to that when a sample is introduced (see 4.1), the measurement range is a function of the amount of oxygen in the carrier gas. The higher the desired concentration range, the more oxygen required in the carrier gas. Under recommended conditions, the carrier gas concentration should be between two to four times the maximum desired oxygen demand.

1.1.2 The lower measurement range is limited by the stability of the baseline oxygen detector output. This signal is a function of the permeation system temperature, carrier gas flow rate, oxygen detector temperature, and reference sensor voltage. Combined, these variables limit the minimum recommended range to 2 to 100 mg/L.

1.1.3 The upper measurement range is limited by the maximum oxygen concentration in the carrier gas (100 %). With the recommended conditions of carrier gas concentration being two to four times the maximum oxygen demand, this limits the maximum possible oxygen demand to between 250 000 to 500 000 mg/L. However, as a practical application to water analysis, this test method will consider a maximum range of 100 000 mg/L.

1.2 This test method is applicable to all oxygen-demanding substances under the conditions of the test contained in the sample that can be injected into the reaction zone. The injector opening limits the maximum size of particles that can be injected. If oxygen-demanding substances that are water-insoluble liquids or solids are present, a preliminary treatment may be desired. These pretreatment methods are described in Annex A2.

1.3 This test method is particularly useful for measuring oxygen demand in certain industrial effluents and process streams. Its application for monitoring secondary sewage effluents is not established. Its use for the monitoring of natural waters is greatly limited by the interferences defined in Section 6.

1.4 In addition to laboratory analysis, this test method is applicable to on-stream monitoring. Sample conditioning techniques for solids pretreatment applications are noted in Annex A2.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regu...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6238 − 98 (Reapproved 2011)

Standard Test Method for

Total Oxygen Demand in Water

This standard is issued under the fixed designation D6238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 This test method is particularly useful for measuring

oxygen demand in certain industrial effluents and process

1.1 This test method covers the determination of total

streams. Its application for monitoring secondary sewage

oxygen demand in the range from 100 to 100 000 mg/L, in

effluents is not established. Its use for the monitoring of natural

waterandwastewaterincludingbrackishwatersandbrines(see

waters is greatly limited by the interferences defined in Section

6.5). Larger concentrations, or samples with high suspended

6.

solids, or both, may be determined by suitable dilution of the

sample. 1.4 In addition to laboratory analysis, this test method is

1.1.1 Since the analysis is based on the change in oxygen applicable to on-stream monitoring. Sample conditioning tech-

reading of the carrier gas compared to that when a sample is niques for solids pretreatment applications are noted in Annex

introduced(see4.1),themeasurementrangeisafunctionofthe A2.

amount of oxygen in the carrier gas. The higher the desired

1.5 The values stated in SI units are to be regarded as

concentration range, the more oxygen required in the carrier

standard. No other units of measurement are included in this

gas. Under recommended conditions, the carrier gas concen-

standard.

tration should be between two to four times the maximum

1.6 This standard does not purport to address all of the

desired oxygen demand.

safety concerns, if any, associated with its use. It is the

1.1.2 The lower measurement range is limited by the

responsibility of the user of this standard to establish appro-

stability of the baseline oxygen detector output. This signal is

priate safety and health practices and determine the applica-

a function of the permeation system temperature, carrier gas

bility of regulatory limitations prior to use.

flow rate, oxygen detector temperature, and reference sensor

voltage. Combined, these variables limit the minimum recom-

2. Referenced Documents

mended range to 2 to 100 mg/L.

2.1 ASTM Standards:

1.1.3 The upper measurement range is limited by the

D888 Test Methods for Dissolved Oxygen in Water

maximum oxygen concentration in the carrier gas (100 %).

D1129 Terminology Relating to Water

With the recommended conditions of carrier gas concentration

D1192 Guide for Equipment for Sampling Water and Steam

being two to four times the maximum oxygen demand, this

in Closed Conduits (Withdrawn 2003)

limits the maximum possible oxygen demand to between

D1193 Specification for Reagent Water

250 000 to 500 000 mg/L. However, as a practical application

D2777 Practice for Determination of Precision and Bias of

to water analysis, this test method will consider a maximum

Applicable Test Methods of Committee D19 on Water

range of 100 000 mg/L.

D3370 Practices for Sampling Water from Closed Conduits

1.2 This test method is applicable to all oxygen-demanding

D3856 Guide for Management Systems in Laboratories

substances under the conditions of the test contained in the

Engaged in Analysis of Water

sample that can be injected into the reaction zone. The injector

D5789 Practice for Writing Quality Control Specifications

opening limits the maximum size of particles that can be

for Standard Test Methods for Organic Constituents

injected. If oxygen-demanding substances that are water-

(Withdrawn 2002)

insoluble liquids or solids are present, a preliminary treatment

D5847 Practice for Writing Quality Control Specifications

may be desired. These pretreatment methods are described in

for Standard Test Methods for Water Analysis

Annex A2.

1 2

This test method is under the jurisdiction of ASTM Committee D19 on Water For referenced ASTM standards, visit the ASTM website, www.astm.org, or

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Organic Substances in Water. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2011. Published June 2011. Originally the ASTM website.

approved in 1998. Last previous edition approved in 2003 as D6238 – 98 (2003). The last approved version of this historical standard is referenced on

DOI: 10.1520/D6238-98R11. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6238 − 98 (2011)

3. Terminology same number of carbon atoms, yet urea has five times the

oxygen demand of formic acid).

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer

6. Interferences

to Terminology D1129.

6.1 The dissolved oxygen concentrations will contribute a

3.2 Definitions of Terms Specific to This Standard:

maximum error of 8 ppm. This error is only significant on

3.2.1 total oxygen demand (TOD)—the amount of oxygen

ranges below 0 to 100 ppm when samples have no dissolved

required to convert the elements in compounds to their most

oxygen (DO) content. When operating in this range and

stable oxidized forms.

samples contain low DO concentrations then compensation

may be necessary. Measure the dissolved oxygen (DO) in both

4. Summary of Test Method

solutions in accordance with Test Method D888. Adjust the

4.1 The total oxygen demand (TOD) measurement is TOD result as follows: If DO of the sample is less than in the

standard, subtract DO variation. If DO of the sample is greater

achievedbycontinuousanalysisoftheconcentrationofoxygen

in a combustion process gas effluent. The decrease in oxygen than in the standard, add DO variation to the TOD result.

resulting from introduction of the sample into the combustion

6.2 Sulfuric acid will normally decompose under sample

zone is a measure of oxygen demand.

combustion conditions as follows:

4.2 The oxidizable components in a liquid sample intro-

900°C 1

H SO H O1SO 1 O (1)

duced into a carrier gas stream containing a fixed amount of 2 4 2 2 2

Catalyst 2

oxygen flowing through a 900°C combustion tube are con-

The oxygen release will result in a reduction in the TOD

verted to their stable oxides. The momentary reduction in the

reading. However, alkali metal sulfates (that is, sodium and

oxygen concentration in the carrier gas is detected by an

potassium salts) do not decompose under the combustion

oxygen sensor and indicated on a digital display or recorded.

conditions. If sulfates are present in the samples, adjust to pH

4.3 The TOD for the sample is obtained by comparing the

11 with NaOH prior to analysis.

peak height to a calibration curve of peak heights for TOD

6.3 Nitrate salts decompose under sample combustion con-

standard solutions. The TOD for the standard solution is based

ditions as follows:

on experimentally observed reactions in which carbon is

converted to carbon dioxide, hydrogen to water, combined 900°C 1

2 NaNO Na O12NO11 O (2)

3 2 2

nitrogen including ammonia to nitric oxide, and elemental or Catalyst 2

organic sulfur to sulfur dioxide. Sample injection is achieved

The resulting generation of oxygen reduces the oxygen

by means of an automatic valve, that provides unattended

demand.

multiple sampling in the laboratory or on-stream monitoring.

6.4 Heavy metal ions have been reported to accumulate in

4.4 For monitoring applications, pretreatment of the sample

the system resulting in a significant loss of sensitivity. The

may be required. However, no single instruction can be written

history of the combustion column appears to be a major factor

since pretreatment steps will be a function of the specific

contributing to interferences of this nature. Similarly, high

characteristics of the sample stream.

concentrationsofdissolvedinorganicsaltswilltendtobuildup

and coat the catalyst as indicated by a loss of sensitivity. To

5. Significance and Use

correct the problem, replace the combustion tube and refrac-

5.1 The measurement of oxygen demand parameters is tory packing material and clean the catalyst in accordance with

critical to the control of process wastewaters. Biochemical the manufacturer’s recommendations. The effects of these

problems can be minimized by dilution of the sample.

oxygen demand (BOD) and chemical oxygen demand (COD)

analyzers have long time cycles and in the case of COD

6.5 Some brackish waters and natural brines may exhibit

analyzers use corrosive reagents with the inherent problem of

base line drift. In such cases, continue to inject samples until a

disposal. Total oxygen demand analysis is faster, approxi-

stable response is observed.

mately 3 min, and uses no liquid reagents in its analysis.

7. Apparatus

5.2 TOD can be correlated to both COD and BOD, provid-

ing effective on-line control.

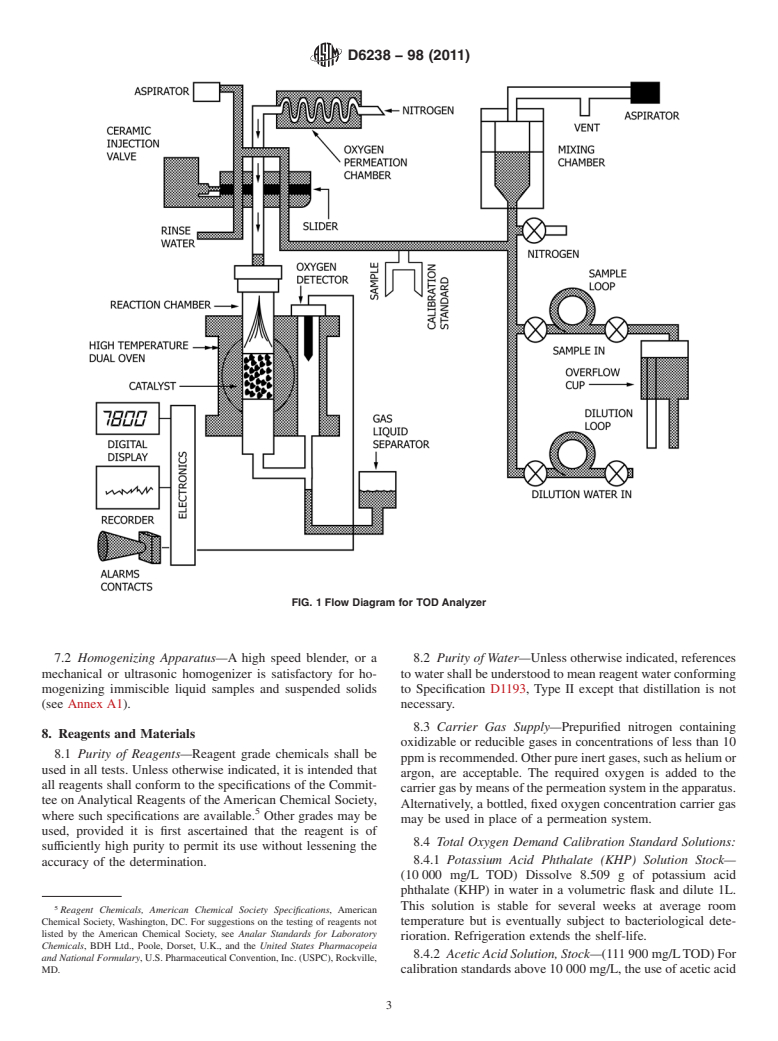

7.1 Total Oxygen Demand Instrument—(See Fig. 1), includ-

ing a pure nitrogen source, an oxygen permeation system,

5.3 TOD offers several features which make it a more

sample injection valve, catalyst-combustion zone, gas flow

attractive measurement than carbon monitoring using Total

controls, oxygen sensor and display or recorder, as detailed in

Carbon (TC) or Total Organic Carbon (TOC) analyzers. TOD

Annex A2.

is unaffected by the presence of inorganic carbon. TOD

analysis will also indicate noncarbonaceous materials that

consume or contribute oxygen. For example, the oxygen

The sole source of supply of the apparatus known to the committee at this time

demandofammonia,sulfiteandsulfideswillbereflectedinthe

is Ionics, Inc., P.O. Box 9131, 65 Grove Street, Watertown, MA 02272. If you are

TOD measurement. Also, since the actual measurement is

aware of alternative suppliers, please provide this information toASTM Headquar-

oxygen consumption, TOD reflects the oxidation state of the

ters. Your comments will receive careful consideration at a meeting of the

chemical compound (that is, urea and formic acid have the responsible technical committee that you may attend.

D6238 − 98 (2011)

FIG. 1 Flow Diagram for TOD Analyzer

7.2 Homogenizing Apparatus—A high speed blender, or a 8.2 Purity of Water—Unless otherwise indicated, references

mechanical or ultrasonic homogenizer is satisfactory for ho- to water shall be understood to mean reagent water conforming

mogenizing immiscible liquid samples and suspended solids to Specification D1193, Type II except that distillation is not

(see Annex A1). necessary.

8.3 Carrier Gas Supply—Prepurified nitrogen containing

8. Reagents and Materials

oxidizable or reducible gases in concentrations of less than 10

8.1 Purity of Reagents—Reagent grade chemicals shall be

ppmisrecommended.Otherpureinertgases,suchasheliumor

used in all tests. Unless otherwise indicated, it is intended that

argon, are acceptable. The required oxygen is added to the

all reagents shall conform to the specifications of the Commit-

carriergasbymeansofthepermeationsystemintheapparatus.

tee onAnalytical Reagents of theAmerican Chemical Society,

Alternatively, a bottled, fixed oxygen concentration carrier gas

where such specifications are available. Other grades may be

may be used in place of a permeation system.

used, provided it is first ascertained that the reagent is of

8.4 Total Oxygen Demand Calibration Standard Solutions:

sufficiently high purity to permit its use without lessening the

8.4.1 Potassium Acid Phthalate (KHP) Solution Stock—

accuracy of the determination.

(10 000 mg/L TOD) Dissolve 8.509 g of potassium acid

phthalate (KHP) in water in a volumetric flask and dilute 1L.

5 This solution is stable for several weeks at average room

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not temperature but is eventually subject to bacteriological dete-

listed by the American Chemical Society, see Analar Standards for Laboratory

rioration. Refrigeration extends the shelf-life.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

8.4.2 AceticAcid Solution, Stock—(111 900mg/LTOD)For

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. calibration standards above 10 000 mg/L, the use of acetic acid

D6238 − 98 (2011)

is recommended. Pipet 100 mL of glacial acetic acid toa1L 10 000 mg⁄L stock standard solution into separate 100 mL

volumetric flask containing approximately 500 mL of water. volumetric flasks and dilute to volume with reagent water.

Dilute to 1 L with water and mix thoroughly. This solution is

11.2 In operation, standard (or sample) is drawn from the

stable for several weeks at average room temperature but is

sample/standard inlet tubing to a sample injection valve which

eventually subject to bacteriological deterioration. Refrigera-

delivers a 20 to 100 µL sample into the combustion chamber.

tion extends the shelf-life.

Insert the sample/standard inlet tubing into the container of

8.4.3 Water solutions of other pure organic compounds may

standard.

be used as standards based on the compound’s theoretical

oxygen demand.

NOTE 1—Nominal consumption 10 mL/analysis.

8.4.4 Calibration Standards—Prepare by appropriate dilu-

11.2.1 Introduce the highest concentration standard solution

tion of the above stock solutions.

for the selected range into the analyzer and run three peaks.

Adjust peak height by means of the calibration dial so that this

9. Sampling

standard reads 100 % of full scale.

9.1 Collect the sample in accordance with Specification

11.3 Successively introduce each standard to the sample/

D1192 and Practices D3370.

standard inlet tube and automatically run three replicates of

9.2 Because of the possibility of oxidation or bacterial

each standard. The peak should automatically return to base-

decomposition of some components of aqueous samples, the

line between injections. Replicates must agree within 63%of

time lapse between collection of samples and analysis must be

full scale.

kept to a minimum. After collection, keep the samples at

11.4 Prepare a standard curve by plotting mg/LTOD versus

approximately 4°C.

peak height on rectangular coordinate paper.

9.3 Sample preservation may also be accomplished by the

addition of NaOH to a pH of 12 or higher, or HCl to a pH of 11.5 Use a single mid-range standard for checking calibra-

tion curve drift. If this result deviates more than 6 3 % then

2 or lowe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.