ASTM D748-00

(Specification)Standard Specification for Natural Block Mica and Mica Films Suitable for Use in Fixed Mica-Dielectric Capacitors

Standard Specification for Natural Block Mica and Mica Films Suitable for Use in Fixed Mica-Dielectric Capacitors

SCOPE

1.1 This specification covers natural block mica and mica films (cut and uncut) suitable for use in the manufacture of fixed mica-dielectric capacitors, based on electrical, visual, and physical properties as determined by tests specified herein.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 748 – 00

Standard Specification for

Natural Block Mica and Mica Films Suitable for Use in Fixed

Mica-Dielectric Capacitors

This standard is issued under the fixed designation D 748; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope become available. Natural block mica and mica films that do

2 not conform to the requirements of this specification for

1.1 This specification covers natural block mica and mica

capacitor use may well be capable of meeting the requirements

films (cut and uncut) suitable for use in the manufacture of

for other critical electrical insulation purposes.

fixedmica-dielectriccapacitors,basedonelectrical,visual,and

4.2 The system of classifying electrical quality of natural

physical properties as determined by tests specified herein.

block and mica films (cut and uncut) covered by this specifi-

1.2 The values stated in inch-pound units are to be regarded

cation is based on a combination of electrical and physical

as the standard.

properties,andvisualqualitiesspecifiedherein,whichthemica

2. Referenced Documents

must possess. This system differs radically from past practices

and previous concepts of mica quality for capacitor use. The

2.1 ASTM Standards:

electrical classification system does not discriminate against

D 149 Test Method for Dielectric Breakdown Voltage and

the presence of spots and stains in even first quality electrically

Dielectric Strength of Solid Electrical Insulating Materials

selected mica, provided the mica conforms to specific and

at Commercial Power Frequencies

physical requirements. Appreciable amounts of air inclusions

D 150 Test Methods for A-C Loss Characteristics and

and waviness also are permitted in all electrical quality classes,

Permittivity (Dielectric Constant) of Solid Electrical Insu-

provided the mica meets specific electrical and physical

lating Materials

requirements. Mica meeting these requirements is acceptable

D 351 Classification for Natural Muscovite Block Mica and

without regard to color or origin. However, mica meeting these

Thins Based on Visual Quality

electrical and physical requirements but having lower visual

D 1082 Test Method for Power Factor and Dielectric Con-

qualitythanthatmeetingtherequirementsforthevisualquality

stant of Mica

classification is not considered generally as desirable.

3. Terminology

4.3 In capacitor fabrication, one or more pieces of cut film

or block mica having lower than required electrical and

3.1 For definitions pertaining to this specification see Clas-

physical properties may prevent meeting the end requirements

sification D 351.

ofthecapacitor.Itisthereforerequiredthateachpieceofblock

4. Significance and Use

(cut) or film (cut or uncut), or both, be tested for the electrical

requirementsandinspectedforthevisualrequirementslistedin

4.1 The properties included in this specification are those

this specification.

required to identify the types of natural block mica and mica

films (cut and uncut) suitable for use in the manufacture of

5. Forms

fixed mica-dielectric capacitors. There may be other require-

5.1 This specification covers the following three forms of

ments necessary to identify particular characteristics. These

natural mica, suitable for use in the manufacture of mica-

will be added to the specification as their inclusion becomes

dielectric capacitors:

generally desirable, and the necessary test data and methods

5.1.1 Form1—Full-knife trimmed natural block mica 0.007

to 0.035 in. (0.18 to 0.89 mm) in thickness.

This specification is under the jurisdiction of ASTM Committee D09 on

NOTE 1—Acertain percentage of block mica thinner than 0.007 in. may

Electrical and Electronic Insulating Materials and is the direct responsibility of

be accepted under this specification, upon agreement between the pur-

Subcommittee D09.19 on Dielectric Sheet and Roll Products.

chaser and the manufacturer.

Current edition approved Sept. 10, 2000. Published November 2000. Originally

{1

published as D 748 – 43. Last previous edition D 748 – 71 (1994) .

5.1.2 Form 2—Half-knife trimmed natural block mica

Coutlee, K. G., “Electrical Quality Classification of Raw Mica by a Rapid,

0.007 to 0.035 in. in thickness.

Direct-Reading Test Method,” Proceedings, ASTM, Vol 46, 1946, p. 1486.

Annual Book of ASTM Standards, Vol. 10.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D748–00

5.1.3 Form 3—Films (cut or uncut) split or manufactured and coupling purposes where high Q value, high stability, and

from natural block mica in any range from 0.0008 up to and low temperature coefficient are not required.

including 0.006 in. (0.020 to 0.15 mm).

NOTE 3—Experience has shown that silver electrode molded capacitors

made with Class C-3 mica which contained slightly conducting spots and

6. Grades (Sizes)

stains but contained“ very slight” air inclusions and “nearly flat” waves,

had temperature coefficient and capacitance stability characteristics just as

6.1 For grades see Classification D 351.

good as that obtained with capacitors made with the best Class C-1 mica.

7. Classes

8. Electrical and Physical Properties, and Visual

7.1 This specification covers the following four classes and

Qualities

subdivisions of natural block mica or mica films. The class of

8.1 Natural block mica and mica films shall conform to the

mica desired shall be specified by the purchaser. Block mica or

requirements as to electrical and physical properties and visual

mica films shall conform to all of the requirements of its

qualities as prescribed in Table 1. Visual qualities not covered

respective class, unless otherwise specified by the purchaser.

in this specification are permitted provided mica meets the

7.1.1 Class C-1 Special—Class C-1 special mica films, in

electrical and physical requirements.

addition to having the highest Q obtainable for mica in the

megacycle range also have the highest Q generally obtainable

9. Test Methods

for mica in the audio frequency range (1000 min at 1 kHz).

Such mica therefore is particularly suitable for capacitors 9.1 The properties enumerated in this specification shall be

which must meet highest Q requirements at both high and low determined in accordance with the following:

frequencies.

9.2 Grading According to Size—Classification D 351.

7.1.2 Class C-1—Class C-1 block mica or mica films have

9.3 Electrical Conductivity—See Annex A1.

the highestQ value obtainable for mica (2500 min at 1 MHz in

NOTE 4—Forthepurposeofthisspecification,electricalconductivityin

capacitors)andissuitableforuseinallsizesandtypesofsilver

spotted and stained areas of block mica is revealed when visible sparking

and foil electrode, molded and clamped unit capacitors, includ-

or glowing takes place inside or on the surface of the mica in the vicinity

ing the most critical types, for use in high stability tuned

of the test probe and not by actual puncture of the mica by the

circuits,aswellashighcurrentradiofrequencycapacitorsused high-potential current. If actual puncture of the test specimen does take

place this indicates the presence of mechanical faults, such as pinholes,

in radio transmitter circuits.

tears, or cracks which extend completely through the mica. While this test

NOTE 2—Based on commerical experience Class C-1 block mica or

method had been found suitable for controlling conductivity in spots and

micafilmsaresatisfactoryforthemanufactureofallofthesetypesofmica

stains and dielectric weakness due to mechanical faults in block mica, an

capacitors.However,ithasbeenfoundthat“mediumtoheavy”air-stained

even greater factor of safety will be realized if this flash test is applied

mica may produce a slightly lower yield of highest stability and high

directly to capacitor films. In this instance the purpose of the test is to

current radio frequency types of capacitors as well as a somewhat lower

detect dielectric weakness due to any cause.

yieldofsatisfactorysilverelectrodemicalaminations.Likewise,“medium

9.4 QValueorDissipationFactor—Test Method D 1082 at

to heavy” wavy mica may also adversely influence the application of

silver electrodes. In addition, there is some possibility that excessive

1 MHz, or by the rapid, direct-reading method described in

waviness may cause cracked laminations in molded capacitors due to the

Appendix X1.

high molding pressures employed and it may be less suitable from a

NOTE 5—IncasesofdisputearisingfromborderlinecasesofQvalueor

stacking standpoint. Similarly, some reduction in unit volume capacitance

dissipation factor and dielectric strength, the test specimens shall be baked

offoilelectrodecapacitorsmayresultfromexcessiveamountsofeitherair

foraminimumperiodof2hatatemperatureof121°C(250°F),andtested

inclusions or waviness.

immediately upon cooling to room temperature.

7.1.3 ClassC-2—Class C-2 block mica and mica films have

a high order of Q value (1500 min at 1 MHz in capacitors) and 9.5 Dielectric Strength—Test Method D 149, using the

are suitable for use in all sizes and types of silver and foil short-time test with ⁄4-in. (6.4-mm) diameter electrodes in oil.

electrode molded and clamped unit capacitors similar to those 9.6 Weight Loss on Heating—Preheat the test specimens in

specified for Class C-1 mica. However, a certain percentage of an oven at 121°C (250°F) for a minimum time of 2 h and then

capacitors made with Class C-2 block mica and films may weigh. Then heat the specimens in the oven at 600°C (1110°F)

show a somewhat higher temperature rise in transmitter types

for 5 min and reweigh. Calculate the percentage loss in weight

than capacitors made with Class C-1 block mica or mica films. after heating based on the weight of the specimen at the end of

7.1.4 ClassC-3—Class C-3 block mica and mica films have

the 2-h preheating period.

the lowest Q value (200 min at 1 MHz in capacitors) of the

9.7 Thickness [Uniformity(Films)]—Judgesplittingquality

three classes covered by this specification. Such Q value,

by the uniformity of thickness of films split from mica by

however, is sufficiently high to permit this mica to be classed

viewing between crossed polaroids.

as a low-loss insulating material. This mica is particularly

9.8 Visual Qualities—See Classification D 351.

suitable for use in foil electrode molded and clamped type

9.8.1 Air Inclusions—Reflected daylight or equivalent.

capacitors (Note 3) used in less critical circuits for blocking

9.8.2 Waves,Buckles,Ridges,etc.—Reflecteddaylightorits

equivalent where distortion of parallel and vertical lines of

reflected image, such as a window frame, can be judged.

9.8.3 Cracks, Tears, Pinholes, and Stones—Determine the

Coutlee, K. G., “Judging Mica Quality Electrically,” Transactions, Am. Inst.

Electrical Engrs., Vol 64, 1945. presence of such mechanical defects as cracks, tears, pinholes,

D748–00

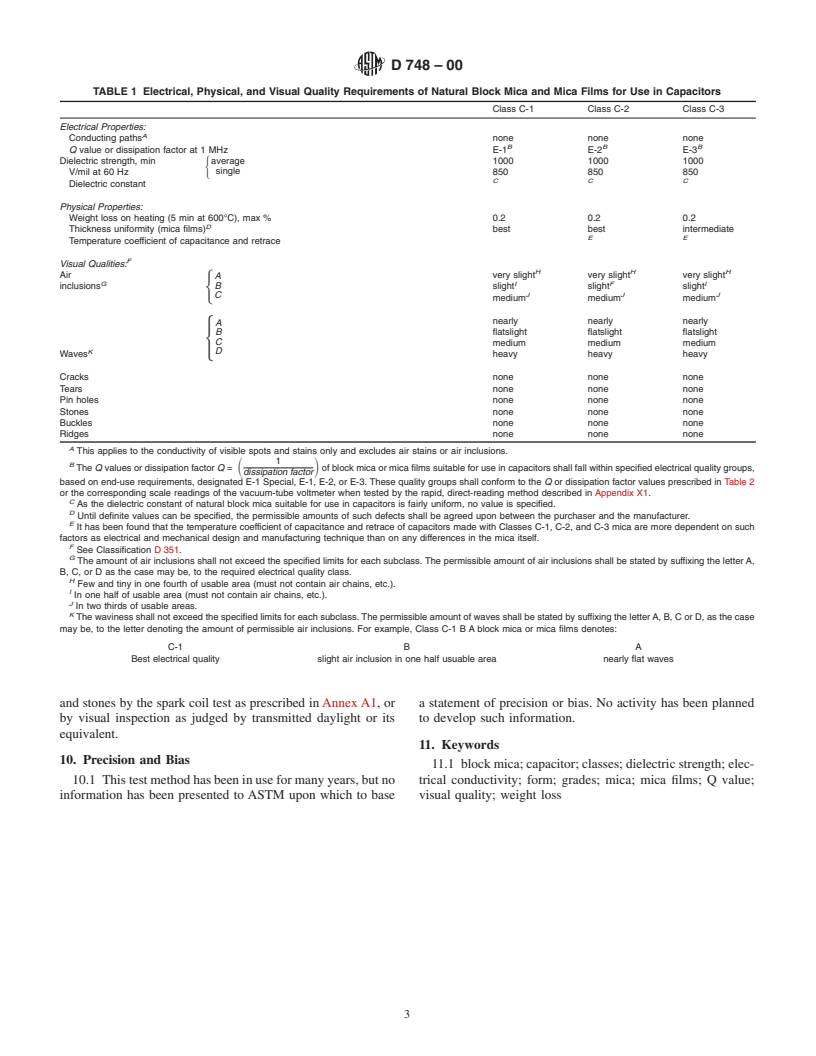

TABLE 1 Electrical, Physical, and Visual Quality Requirements of Natural Block Mica and Mica Films for Use in Capacitors

Class C-1 Class C-2 Class C-3

Electrical Properties:

A

Conducting paths none none none

B B B

Q value or dissipation factor at 1 MHz E-1 E-2 E-3

Dielectric strength, min average 1000 1000 1000

H

single

V/mil at 60 Hz 850 850 850

CCC

Dielectric constant

Physical Properties:

Weight loss on heating (5 min at 600°C), max % 0.2 0.2 0.2

D

Thickness uniformity (mica films) best best intermediate

EE

Temperature coefficient of capacitance and retrace

F

Visual Qualities:

H H H

Air very slight very slight very slight

A

G I F I

B

inclusions slight slight slight

H

J J J

C

medium medium medium

nearly nearly nearly

A

B flatslight flatslight flatslight

C

medium medium medium

K D

Waves heavy heavy heavy

Cracks none none none

Tears none none none

Pin holes none none none

Stones none none none

Buckles none none none

Ridges none none none

A

This applies to the conductivity of visible spots and stains only and excludes air stains or air inclusions.

B

The Q values or dissipation factor Q = of block mica or mica films suitable for use in capacitors shall fall within specified electrical quality groups,

S D

dissipation factor

based on end-use requirements, designated E-1 Special, E-1, E-2, or E-3. These quality groups shall conform to the Q or dissipation factor values prescribed in Table 2

or the corresponding scale readings of the vacuum-tube voltmeter when tested by the rapid, direct-reading method described in Appendix X1.

C

As the dielectric constant of natural block mica suitable for use in capacitors is fairly uniform, no value is specified.

D

Until definite values can be specified, the permissible amounts of such defects shall be agreed upon between the purchaser and the manufacturer.

E

It has been found that the temperature coefficient of capacitance and retrace of capacitors made with Classes C-1, C-2, and C-3 mica are more dependent on such

factors as electrical and mechanical design and manufacturing technique than on any differences in the mica itself.

F

See Classification D 351.

G

The amount of air inclusions shall not exceed the specified limits for each subclass. The permissible amount of air inclusions shall be stated by suffixing the letter A,

B, C, or D as the case may be, to the required electrical quality class.

H

Few and tiny in one fourth of usable area (must not contain air chains, etc.).

I

In one half of usable area (must not contain air chains, etc.).

J

In two thirds of usable areas.

K

The waviness shall not exceed the specified limits for each subclass. The permissible amount of waves shall be stated by suffixing the letter A, B, C or D, as the case

may be, to the letter denoting the amount of permissible air inclusions. For example, Class C-1 B A block mica or mica films denotes:

C-1 B A

Best electrical quality slight air inclusion in one half usuable area nearly flat waves

and stones by the spark coil test as prescribed inAnnexA1,or a statement of precision or bias. No activity has been planned

by visual inspection as judged by transmitted daylight or its to develop such information.

equivalent.

11. Keywords

10. Precision and Bias

11.1 block mica; capacitor; classes; dielectric strength; elec-

10.1 Thistestmethodhasbeeninuseformanyyears,butno trical conductivity; form; grades; mica; mica films; Q value;

information has been presented to ASTM upon which to base visual quality; weight loss

D748–00

TABLE 2 Q and Dissipation Factor Values for Electrical Quality Group E-1 Special, E-1, E-2, and E-3

Rapid M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.