ASTM A506-16(2021)

(Specification)Standard Specification for Alloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-Rolled

Standard Specification for Alloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-Rolled

ABSTRACT

This specification covers the standard for hot-rolled and cold-rolled alloy and structural alloy-steel sheet and strip. The material shall be furnished in several conditions: heat treatments such as hot-rolling and cold rolling; surface conditions; and edges, as specified herein, in coils or cut lengths. Heat analysis shall be performed on the material and shall conform to the required chemical compositions for carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. Materials in the annealed, normalized, or normalized-and-tempered condition shall be capable of meeting the longitudinal bend test requirements. Two tension tests and two hardness tests shall be made from coupons obtained from each heat (cast) and heat treatment lot.

SCOPE

1.1 This specification covers hot-rolled and cold-rolled alloy and structural alloy-steel sheet and strip. Alloy steel is furnished to chemical composition requirements and is intended primarily for general or miscellaneous use where bending and moderate forming is a requirement. Structural alloy steel is furnished to chemical composition requirements and to specific mechanical property requirements which may include tension tests, hardness tests, or other commonly accepted mechanical tests.

1.2 If material of a higher degree of uniformity of internal soundness and freedom from surface imperfections is required, reference should be made to Specification A507.

1.3 Alloy and structural alloy-steel sheet and strip are not produced to internal cleanliness requirements. Normally surface imperfections are not objectionable, and a good finish is not a prime requirement.

1.4 The formability of structural alloy steel decreases with increasing yield strength or hardness. Therefore, product design in relation to the mechanical properties of the grade used must be considered.

1.5 The material covered by this specification may be furnished in several conditions: heat treatments, surface conditions, and edges, as specified herein, in coils or cut lengths.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A506 −16 (Reapproved 2021)

Standard Specification for

Alloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled

and Cold-Rolled

This standard is issued under the fixed designation A506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers hot-rolled and cold-rolled

alloy and structural alloy-steel sheet and strip. Alloy steel is

2. Referenced Documents

furnished to chemical composition requirements and is in-

tended primarily for general or miscellaneous use where 2.1 ASTM Standards:

bending and moderate forming is a requirement. Structural A505 Specification for Steel, Sheet and Strip, Alloy, Hot-

alloy steel is furnished to chemical composition requirements Rolled and Cold-Rolled, General Requirements for

and to specific mechanical property requirements which may A507 SpecificationforDrawingAlloySteel,SheetandStrip,

Hot-Rolled and Cold-Rolled

include tension tests, hardness tests, or other commonly

accepted mechanical tests.

3. Terminology

1.2 If material of a higher degree of uniformity of internal

soundness and freedom from surface imperfections is required, 3.1 Acronyms:

3.1.1 SAE—Society of Automotive Engineers.

reference should be made to Specification A507.

3.2 Definitions of Terms Specific to This Standard:

1.3 Alloy and structural alloy-steel sheet and strip are not

3.2.1 alloy steel—alloy-steel sheet and strip furnished to

produced to internal cleanliness requirements. Normally sur-

chemicalcompositionrequirementsandintendedforgeneralor

face imperfections are not objectionable, and a good finish is

miscellaneous applications where normal surface imperfec-

not a prime requirement.

tions are not objectionable and a good finish is not the prime

1.4 The formability of structural alloy steel decreases with

requirement.

increasing yield strength or hardness. Therefore, product de-

3.2.2 standard steels—steel chemical compositions defined

sign in relation to the mechanical properties of the grade used

as “standard” by SAE, shown in Table 1.

must be considered.

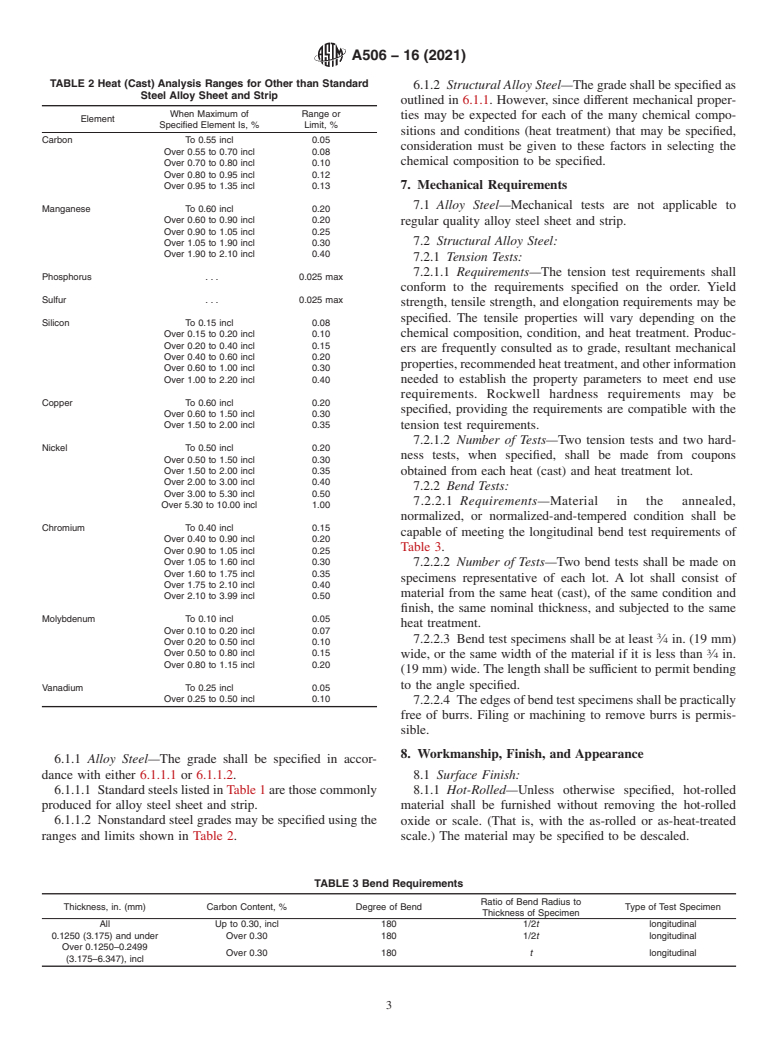

3.2.3 steels other than standard—steel chemical composi-

1.5 The material covered by this specification may be

tions other than those defined as “standard,” and furnished to

furnished in several conditions: heat treatments, surface

the composition limits shown in Table 2.

conditions, and edges, as specified herein, in coils or cut

lengths.

3.2.4 structural alloy steel—alloy-steelsheetandstripmeet-

ing the requirements of regular quality and also produced to

1.6 The values stated in inch-pound units are to be regarded

specific mechanical property requirements.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. General Requirements and Ordering Information

and are not considered standard.

4.1 Material supplied to this specification shall conform to

1.7 This international standard was developed in accor-

Specification A505, which includes the general requirements

dance with internationally recognized principles on standard-

and establishes the rules for the ordering information that

ization established in the Decision on Principles for the

should be complied with when purchasing material to this

Development of International Standards, Guides and Recom-

specification.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2021. Published September 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1964. Last previous edition approved in 2016 as A506 – 16. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0506-16R21. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A506 − 16 (2021)

TABLE 1 Standard Steels Commonly Produced for Alloy-Steel Sheet and Strip

A

Steel

Chemical Composition Ranges and Limits, % (Heat Analysis)

Designation

B

CMn P S Si Ni Cr Mo V

No.

C

E3310 0.08–0.13 0.45–0.60 0.025 0.025 0.15–0.35 3.25–3.75 1.40–1.75 . . . . . .

C

4012 0.09–0.14 0.75–1.00 0.025 0.025 0.15–0.35 . . . . . . 0.15–0.25 . . .

4118 0.18–0.23 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.40–0.60 0.08–0.15 . . .

4130 0.28–0.33 0.40–0.60 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4135 0.33–0.38 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4137 0.35–0.40 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4140 0.38–0.43 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4142 0.40–0.45 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4145 0.43–0.48 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

C

4147 0.45–0.50 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4150 0.48–0.53 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.80–1.10 0.15–0.25 . . .

4320 0.17–0.22 0.45–0.65 0.025 0.025 0.15–0.35 1.65–2.00 0.40–0.60 0.20–0.30 . . .

4340 0.38–0.43 0.60–0.80 0.025 0.025 0.15–0.35 1.65–2.00 0.70–0.90 0.20–0.30 . . .

E4340 0.38–0.43 0.65–0.85 0.025 0.025 0.15–0.35 1.65–2.00 0.70–0.90 0.20–0.30 . . .

C

4520 0.18–0.23 0.45–0.65 0.025 0.025 0.15–0.35 . . . . . . 0.45–0.60 . . .

4615 0.13–0.18 0.45–0.65 0.025 0.025 0.15–0.35 1.65–2.00 . . . 0.20–0.30 . . .

4620 0.17–0.22 0.45–0.65 0.025 0.025 0.15–0.35 1.65–2.00 . . . 0.20–0.30 . . .

4718 0.16–0.21 0.70–0.90 0.025 0.025 0.15–0.35 0.90–1.20 0.30–0.50 0.30–0.40 . . .

4815 0.13–0.18 0.40–0.60 0.025 0.025 0.15–0.35 3.25–3.75 . . . 0.20–0.30 . . .

4820 0.18–0.23 0.50–0.70 0.025 0.025 0.15–0.35 3.25–3.75 . . . 0.20–0.30 . . .

5015 0.12–0.17 0.30–0.50 0.025 0.025 0.15–0.35 . . . 0.30–0.50 . . . . . .

5046 0.43–0.50 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.20–0.35 . . . . . .

5115 0.13–0.18 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.70–0.90 . . . . . .

5120 0.17–0.22 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.70–0.90 . . . . . .

5130 0.28–0.33 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.80–1.10 . . . . . .

5132 0.30–0.35 0.60–0.80 0.025 0.025 0.15–0.35 . . . 0.75–1.00 . . . . . .

5140 0.38–0.43 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.70–0.90 . . . . . .

5150 0.48–0.53 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.70–0.90 . . . . . .

5160 0.56–0.64 0.75–1.00 0.025 0.025 0.15–0.35 . . . 0.70–0.90 . . . . . .

C

E51100 0.95–1.10 0.25–0.45 0.025 0.025 0.15–0.35 . . . 0.90–1.15 . . . . . .

E52100 0.98–1.10 0.25–0.45 0.025 0.025 0.15–0.35 . . . 1.30–1.60 . . . . . .

6150 0.48–0.53 0.70–0.90 0.025 0.025 0.15–0.35 . . . 0.80–1.10 . . . 0.15 min

C

6158 0.55–0.62 0.70–1.10 0.025 0.025 0.15–0.35 . . . 0.90–1.20 . . . 0.10–0.20

8615 0.13–0.18 0.70–0.90 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8617 0.15–0.20 0.70–0.90 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8620 0.18–0.23 0.70–0.90 0.035 0.035 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8630 0.28–0.33 0.70–0.90 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8640 0.38–0.43 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

C

8642 0.40–0.45 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8645 0.43–0.48 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

C

8650 0.48–0.53 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8655 0.51–0.59 0.75–100 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8660 0.55–0.65 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.15–0.25 . . .

8720 0.18–0.23 0.70–0.90 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60 0.20–0.30 . . .

C

8735 0.33–0.38 0.75–1.00 0.025 0.025 0.15–0.35 0.40–0.70 0.40–0.60

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.