ASTM G109-99ae1

(Test Method)Standard Test Method for Determining the Effects of Chemical Admixtures on the Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments

Standard Test Method for Determining the Effects of Chemical Admixtures on the Corrosion of Embedded Steel Reinforcement in Concrete Exposed to Chloride Environments

SCOPE

1.1 This test method describes a procedure for determining the effects of chemical admixtures on the corrosion of metals in concrete. This test method can be used to evaluate materials intended to inhibit chloride-induced corrosion of steel in concrete. It can also be used to evaluate the corrosivity of admixtures in a chloride environment.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:G109–99a

Standard Test Method for

Determining the Effects of Chemical Admixtures on the

Corrosion of Embedded Steel Reinforcement in Concrete

Exposed to Chloride Environments

This standard is issued under the fixed designation G 109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Paragraph 1.2 was corrected editorially in August 2000.

1. Scope Concrete by the Pressure Method

C 511 Specification for Moist Cabinets, Moist Rooms, and

1.1 This test method describes a procedure for determining

Water Storage Tanks Used in the Testing of Hydraulic

theeffectsofchemicaladmixturesonthecorrosionofmetalsin

Cements and Concretes

concrete. This test method can be used to evaluate materials

C 876 Test Method for Half-Cell Potentials of Uncoated

intended to inhibit chloride-induced corrosion of steel in

Reinforcing Steel in Concrete

concrete. It can also be used to evaluate the corrosivity of

C 881 Specification for Epoxy-Resin-Base Bonding Sys-

admixtures in a chloride environment.

tems for Concrete

1.2 The values stated in SI units are to be regarded as the

C 1152/C 1152M Test Method for Acid-Soluble Chloride

standard. The inch-pound units in parentheses are provided for

in Mortar and Concrete

information only.

D 448 Classification for Sizes of Aggregate for Road and

1.3 This standard does not purport to address all of the

Bridge Construction

safety concerns, if any, associated with its use. It is the

D 632 Specification for Sodium Chloride

responsibility of the user of this standard to establish appro-

E 177 Practice for Use of the Terms Precision and Bias in

priate safety and health practices and determine the applica-

ASTM Test Methods

bility of regulatory limitations prior to use.

E 691 Practice for Conducting an Interlaboratory Study to

2. Referenced Documents

Determine the Precision of a Test Method

G 3 PracticeforConventionsApplicabletoElectrochemical

2.1 ASTM Standards:

Measurements in Corrosion Testing

A 615/A 615M Specification for Deformed and Plain

G 15 Terminology Relating to Corrosion and Corrosion

Billet-Steel Bars for Concrete Reinforcement

Testing

C 33 Specification for Concrete Aggregates

G 33 Practice for Recording Data from Atmospheric Cor-

C 143/C 143M Test Method for Slump of Hydraulic Ce-

rosion Tests of Metallic-Coated Steel Specimens

ment Concrete

G 46 Guide for Examination and Evaluation of Pitting

C 150 Specification for Portland Cement

Corrosion

C 173 Test Method for Air Content of Freshly Mixed

2.2 NACE Standards:

Concrete by the Volumetric Method

SSPC SP 5 (NACE No. 1) White Metal Blast Cleaning

C 192/C 192M Practice for Making and Curing Concrete

Test Specimens in the Laboratory

3. Significance and Use

C 231 Test Method for Air Content of Freshly Mixed

3.1 This test method provides a reliable means for predict-

ing the inhibiting or corrosive properties of admixtures to be

1 used in concrete.

This test method is under the jurisdiction of ASTM Committee G-1 on

Corrosion, Deterioration, and Degradation of Materials and is the direct responsi-

bility of Subcommittee G01.14 on Corrosion of Reinforcing Steel.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

published as G 109 – 92. Last previous edition G 109 – 99. Annual Book of ASTM Standards, Vol 04.03.

2 6

Annual Book of ASTM Standards, Vol 01.04. Annual Book of ASTM Standards, Vol 14.02.

3 7

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 03.02.

4 8

Annual Book of ASTM Standards, Vol 04.01. Available from Structural Steel Painting Council, Pittsburgh, PA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G109

3.2 This test method is useful for development studies of 5.5 Two-part Waterproof Epoxy — This epoxy shall meet

corrosion inhibitors to be used in concrete. the chemical resistance requirements of a Type IV, Grade 3,

3.3 This test method has been used elsewhere with good Class E of Specification C 881.

agreement between corrosion as measured by this test method 5.6 Sulfuric Acid, 10 % by mass, for pickling (optional).

, , ,

9 10 11 12 15

and corrosion damage on the embedded steel. This test 5.7 Electroplater’s Tape

method might not properly rank the performance of different 5.8 NeopreneTubing, with 3-mm ( ⁄8-in.) wall thickness and

corrosioninhibitors,especiallyatconcretecoversoverthesteel the same ID as the diameter of the bar used.

less than 40 mm (1.5 in.) or water-to-cement ratios above 0.45. 5.9 Sodium Chloride, complying with Specification D 632.

The concrete mixture proportions and cover over the steel are 5.10 Salt Solution, prepared by dissolving 3 parts of sodium

chosen to accelerate chloride ingress. Some inhibitors might chloride (as described in 5.9) in 97 parts of water mass.

have an effect on this process, which could lead to results that 5.11 EpoxySealer,forapplicationtotheconcretespecimens

would differ from what would be expected in actual use. after manufacture. This sealer shall be of Type III, Grade 1,

Class C in accordance with Specification C 881.

4. Apparatus

5.12 Plastic Dams, 75-mm (3-in.) wide and 150-mm (6-in.)

long with a minimum height of 75 mm (3 in.) for placement on

4.1 The apparatus required for the evaluation of corrosion

the test specimens. The wall thickness shall be 61mm( ⁄8 6

inhibitors includes a high impedance voltmeter (at least one

⁄32 in.

Mohm) capable of measuring to 0.01 mV, a 100-ohm (65%)

5.13 Silicone Caulk, for sealing the outside of the plastic

resistor.

dam to the top of the concrete specimen.

5.14 Reference Electrode, such as a saturated calomel or

5. Reagents and Materials

silver/silver chloride electrode for measuring the corrosion

5.1 Cement, that conforms to Type I or Type II of Specifi-

potential of the bars, as defined in Terminology G 15.

cation C 150. Coarse aggregate shall conform to Specification

5.15 Hexane

C 33 and Classification D 448, with nominal maximum size

3 3

between 9.5 and 19 mm ( ⁄8and ⁄4 in.).

6. Preparation of Test Specimens

NOTE 1—Preferred maximum size aggregate is 12.5 mm (0.5 in.).

6.1 Power wire brush or sand blast the bars to near white

5.2 Steel Reinforcement Bars, deformed, meeting the re-

metal (see Specification SSPC SP-50), clean by soaking in

quirement of Specification A 615/A 615M, with a diameter

hexane, and allow to air dry.

between 10 mm (0.4 in.) and 16 mm (0.6 in.).Alength of 360

NOTE 3—Pickling the bars with 10 % sulfuric acid for 10 to 15 min and

mm (14 in.), drilled and tapped at one end to be fitted with

rinsing with potable water prior to wire brushing is recommended when

coarse-thread stainless steel and nuts, as described in 5.3 and

the bars have an excessive amount of rust.

5.4.Thesebarsshallbeusedtomanufacturethetestspecimens,

6.2 Use the same method to clean all bars in the test

as described in Section 6.

program.

NOTE 2—Interlaboratory test program and statistical data in Section 11

6.3 Drill and tap one end of each bar, attach a stainless steel

are based upon 13-mm (0.5-in.) steel bars, 12.5-mm maximum size

screw and two nuts, as described in 5.3 and 5.4, and tape each

aggregate, and 19-mm (0.75-in.) and 25-mm (1 in.) cover

endofthebarwithelectroplater’stapesothata200-mm(8-in.)

5.3 316 Stainless Steel Screws, with diameter smaller than

portion in the middle of the bar is bare. Place a 90-mm (3.5 in.)

bar diameter (coarse thread<5mm (0.2 in.)), 25 to 35-mm (1 length of neoprene tubing, as described in 5.8, over the

to 1.5-in.) long (one per bar).

electroplater’s tape at each end of the bar, and fill the length of

5.4 316 Stainless Steel Nuts, two per bar to fit stainless steel tubingprotrudingfromthebarendswiththetwo-partepoxy,as

screws, as described in 5.3.

described in 5.5.

NOTE 4—For example, for a 12.5-mm (0.5 in.) aggregate, place the top

bar 25 mm (1 in.) from the surface. For a 9.5-mm (0.375-in.) aggregate,

Berke, N. S., Shen, D. F., and Sundberg, K. M., “Comparison of the place the bar 19 mm (.75 in.) from the top surface.

Polarization Resistance Technique to the Macrocell Corrosion Technique,” Corro-

6.4 Specimen size is 280 3 150 3115mm(11 3 6 3 4.5

sion Rates of Steel in Concrete, ASTM STP 1065, N. S. Berke, V. Chaker, and D.

Whitney, editors, ASTM, August 1990, pp. 38–51. in.).

Berke, N. S. and Hicks, M. C., “Electrochemical Methods of Determining the

6.5 Place the bars in the molds so that 40 mm (approxi-

Corrosivity of Steel in Concrete,” Corrosion Testing and Evaluation: Silver

mately 1.5 in.) of the bars are protected within each exit end

Anniversary Volume, Babraiam/Dean editors, ASTM STP 1000, ASTM, November

from the concrete (minimizes edge effects). This will expose

1990, pp. 425–440.

Virmani, Y. P., Clear, K. C., and Pasko, T. J., “Time-to Corrosion of

200mm(8in.)ofsteel.Placethebarswiththelongitudinalribs

Reinforcing Steel in Concrete Slabs, Volume 5: Calcium Nitrite Admixture or

Epoxy-Coated Reinforcing Bars as Corrosion Protection Systems,” Report No.

FHWA/RD-83/-12,FederalHighwayAdministration,WashingtonDC,1983,pp.71.

12 14

Berke, N. S., Pfeifer, D. W., and Weil, T. G., “Protection Against Chloride- PC-Epoxy made by Protective Coating Co.,Allentown, PA, has been found to

Induced Corrosion,” Concrete International, December 1988, pp. 45–55. be suitable for this purpose.

13 15

Berke, N. S., Hicks, M. C., Hoopes, R. J., and Tourney, P. J., “Use of Minnesota Mining and Manufacturing Company (3M), 1999 Mt. Read

Laboratory Techniques to Evaluate Long-Term Durability of Steel Reinforced Boulevard, Rochester, NY 14615, has been found suitable for this purpose.

Concrete Exposed to Chloride Ingress,” ACI SP 145-16, 1994, pp. 299-328. EpoxyConcreteScaler#12560madebyDevconhasbeenfoundtobesuitable

for this purpose.

3M Marine Adhesive 5200 has been found to be suitable for this purpose.

G109

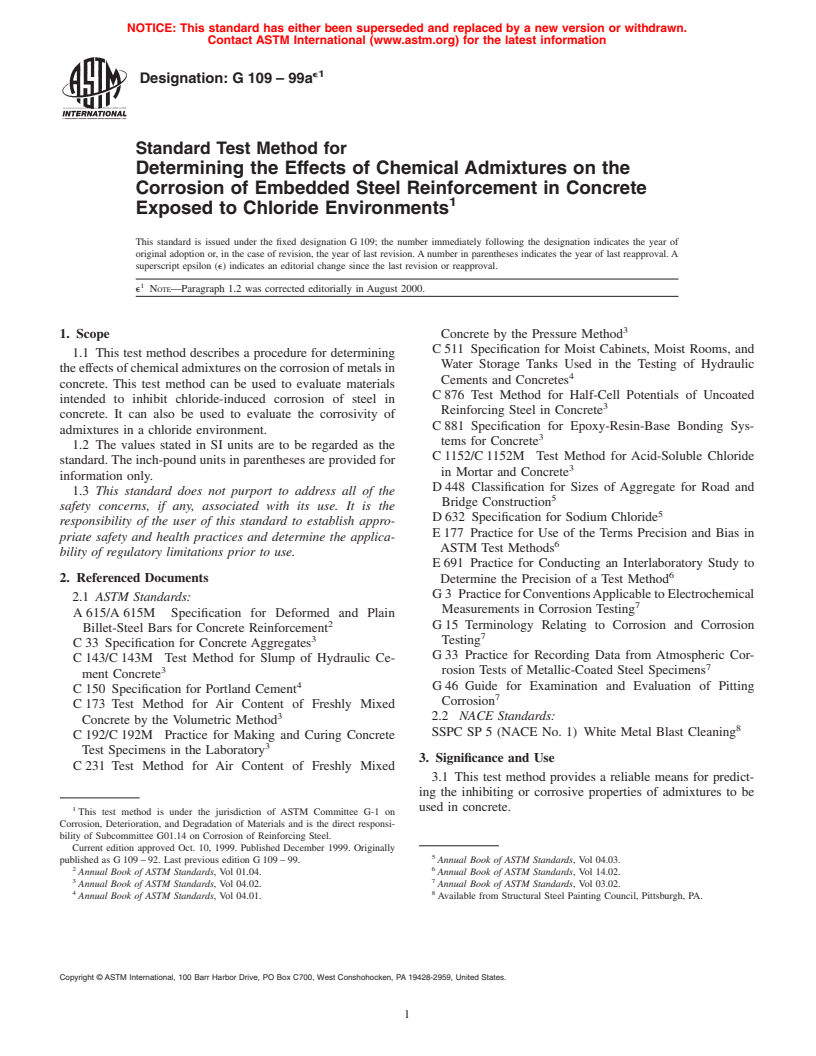

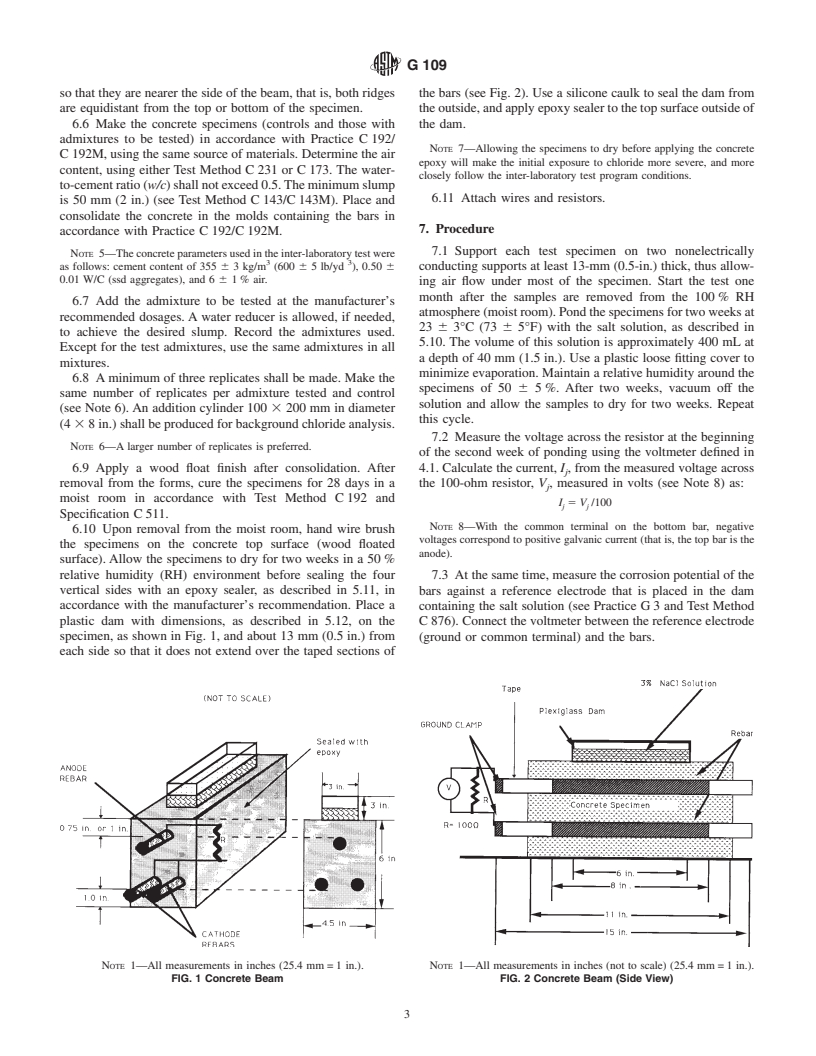

so that they are nearer the side of the beam, that is, both ridges the bars (see Fig. 2). Use a silicone caulk to seal the dam from

are equidistant from the top or bottom of the specimen. theoutside,andapplyepoxysealertothetopsurfaceoutsideof

6.6 Make the concrete specimens (controls and those with the dam.

admixtures to be tested) in accordance with Practice C 192/

NOTE 7—Allowing the specimens to dry before applying the concrete

C 192M, using the same source of materials. Determine the air

epoxy will make the initial exposure to chloride more severe, and more

content, using either Test Method C 231 or C 173. The water-

closely follow the inter-laboratory test program conditions.

to-cementratio(w/c)shallnotexceed0.5.Theminimumslump

6.11 Attach wires and resistors.

is 50 mm (2 in.) (see Test Method C 143/C 143M). Place and

consolidate the concrete in the molds containing the bars in

7. Procedure

accordance with Practice C 192/C 192M.

7.1 Support each test specimen on two nonelectrically

NOTE 5—The concrete parameters used in the inter-laboratory test were

3 3

as follows: cement content of 355 6 3 kg/m (600 6 5 lb/yd ), 0.50 6 conducting supports at least 13-mm (0.5-in.) thick, thus allow-

0.01 W/C (ssd aggregates), and 6 6 1 % air.

ing air flow under most of the specimen. Start the test one

month after the samples are removed from the 100 % RH

6.7 Add the admixture to be tested at the manufacturer’s

atmosphere(moistroom).Pondthespecimensfortwoweeksat

recommended dosages. A water reducer is allowed, if needed,

23 6 3°C (73 6 5°F) with the salt solution, as described in

to achieve the desired slump. Record the admixtures used.

5.10. The volume of this solution is approximately 400 mL at

Except for the test admixtures, use the same admixtures in all

a depth of 40 mm (1.5 in.). Use a plastic loose fitting cover to

mixtures.

minimize evaporation. Maintain a relative humidity around the

6.8 Aminimum of three replicates shall be made. Make the

specimens of 50 6 5 %. After two weeks, vacuum off the

same number of replicates per admixture tested and control

solution and allow the samples to dry for two weeks. Repeat

(see Note 6).An addition cylinder 100 3 200 mm in diameter

this cycle.

(4 3 8 in.) shall be produced for background chloride analysis.

7.2 Measure the voltage across the resistor at the beginning

NOTE 6—A larger number of replicates is preferred.

of the second week of ponding using the voltmeter defined in

6.9 Apply a wood float finish after consolidation. After 4.1. Calculate the current, I, from the measured voltage across

j

removal from the forms, cure the specimens for 28 days in a the 100-ohm resistor, V, measured in volts (see Note 8) as:

j

moist room in accordance with Test Method C 192 and

I 5 V /100

j j

Specification C 511.

NOTE 8—With the common terminal on the bottom bar, negative

6.10 Upon removal from the moist room, hand wire brush

voltages correspond to positive galvanic current (that is, the top bar is the

the specimens on the concrete top surface (wood floated

anode).

surface). Allow the specimens to dry for two weeks in a 50 %

relative humidity (RH) environment before sealing the four 7.3 At the same time, measure the corrosion potential of the

vertical sides with an epoxy sealer, as described in 5.11, in bars against a reference electrode that is placed in the dam

accordance with the manufacturer’s recommendation. Place a

containing the salt solution (see Practice G 3 and Test Method

plastic dam with dimensions, as described in 5.12, on the C 876). Connect the voltmeter between the reference electrode

specimen, as shown in Fig. 1, and about 13 mm (0.5 in.) from

(ground or common terminal) and the bars.

each side so that it does not extend over the taped sections of

NOTE 1—All measurements in inches (25.4 mm = 1 in.). NOTE 1—All measurements in inches (not to scale) (25.4 mm = 1 in.).

FIG. 1 Concrete Beam FIG. 2 Concrete Beam (Side View)

G109

8. Period of Testing 10.1.8 The ratio of total integrated current of the test

specimen to that of the control and time the test ended. The

8.1 Monitor the current as a function of time once every

total integrated current is:

four weeks, as described in 7.2, until the average integrated

macrocell current of the control specimens is 150 C or greater, TC 5 TC 1 @~t 2 t ! 3 ~i 1 i !/2#

j j21 j j21 j j21

as determined in 10.1.8, and at least half the samples show

where:

integrated macrocell currents equal to or greater than 150 C

TC = total corrosion (coulombs),

(see Note 9).

t = time (seconds) at which me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.