ASTM C367-99

(Test Method)Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling Panels

Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling Panels

SCOPE

1.1 These test methods cover the determination of the strength properties of prefabricated architectural acoustical tile or lay-in ceiling panels as follows: Tests Sections Hardness 2 to 7 Friability 8 to 13 Sag 14 to 20 Transverse strength 21 to 26

1.2 Not all of the tests described in these test methods may be necessary to evaluate any particular product for a specific use. In each instance, it will be necessary to determine which properties are required.

1.3 These test methods specify procedures that may be used in product development, manufacturing control, specification acceptance, and service evaluation.

1.4 Properties determined by these test methods reflect the performance of the materials under the specific conditions of the test, and do not necessarily indicate performance under conditions other than those specified herein.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C367 –99

Standard Test Methods for

Strength Properties of Prefabricated Architectural

Acoustical Tile or Lay-In Ceiling Panels

This standard is issued under the fixed designation C 367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Materials used for absorbing sound generally have a porous, low-density structure. In comparison

with many building materials they may be relatively fragile. Materials are available that possess

adequate strength and stability and at the same time provide good sound absorption. The test methods

described here cover procedures for evaluating those physical properties related to strength. The

methods are of use in developing, manufacturing, and selecting acoustical tile or lay-in panels.

It should be kept in mind that a property related to strength is only one of several considerations

important in judging the usefulness of an acoustical material. For example, a material judged to be

quite weak by one of these tests may still be desired for other reasons, and with adequate precautions,

may be shipped and installed successfully.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods cover the determination of the

strength properties of prefabricated architectual acoustical tile

HARDNESS

or lay-in ceiling panels as follows:

Tests Sections 2. Significance and Use

Hardness 2 to 7

2.1 Knowledgeofhardnessisusefulinthedevelopmentand

Friability 8 to 13

Sag 14 to 20 the quality control of acoustical tile. Deviation from an

Transverse strength 21 to 26

established hardness range will assist in pointing out proc-

essing errors or defective raw materials, thereby aiding the

1.2 Not all of the tests described in these test methods may

be necessary to evaluate any particular product for a specific maintenance of uniform product quality.

2.2 This property is also useful in comparing the relative

use. In each instance, it will be necessary to determine which

properties are required. abilities of materials to resist indentations on the panel surface

caused by impacts.

1.3 These test methods specify procedures that may be used

in product development, manufacturing control, specification 2.3 Since the hardness varies with the thickness, only

samples of the same thickness may be directly compared.

acceptance, and service evaluation.

1.4 Properties determined by these test methods reflect the

3. Apparatus

performance of the materials under the specific conditions of

3.1 Testing Machine—Any standard mechanical or hydrau-

the test, and do not necessarily indicate performance under

lic testing machine capable of applying and measuring the

conditions other than those specified herein.

required load within an accuracy of 61 % may be used. It shall

1.5 This standard does not purport to address all of the

be equipped with a 50.8-mm (2.00-in.) diameter metal ball, or

safety concerns, if any, associated with its use. It is the

hemispherically shaped penetrator that bears upon the speci-

responsibility of the user of this standard to establish appro-

men surface.

4. Test Specimens

These test methods are under the jurisdiction of ASTM Committee E-33 on

Environmental Acoustics and are the direct responsibility of Subcommittee E33.04

4.1 Cut five 100 by 100-mm (4 by 4-in.) specimens from a

on Application of Acoustical Materials and Systems.

single tile or panel. Cut the five specimens from representative

Current edition approved September 10, 1999. Published November 1999.

Originally published as C 367 – 55 T. Last previous edition C 367 – 95. areas of the tile or ceiling panel.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C367

5. Conditioning 9.4 Timer, consisting of a watch or clock capable of

measuring intervals of 10 min within 6 5.0 s.

5.1 The strength properties of acoustical materials often

depend on the moisture content at the time of the test.

10. Test Specimens

Therefore,conditionmaterialsfortestunder“roomconditions”

10.1 Cut twelve 25 by 25-mm (1 by 1-in.) square specimens

to constant weight (within 61 %) in an atmosphere maintained

from a single tile or panel. The specimen thickness is equal to

at a relative humidity of 50 6 2 %, and a temperature of 23 6

the tile or panel thickness.

1°C (73 6 2°F). State in the test report any departure from this

recommended condition.

NOTE 3—If the friability of original edges is of importance, separate

tests should be run on 25 by 25-mm (1 by 1-in.) specimens having one or

6. Procedure

two original edges.

6.1 Place the specimen in the conditioning chamber and let

11. Conditioning

it remain until equilibrium is obtained.

11.1 Maintainstandardconditionsasdescribedin5.1during

6.2 Place the specimen on a flat surface under the loading

preparation and testing of specimens.

penetrator of the test machine. Force the penetrator into the

specimen 6.46 0.3 mm (0.25 6 0.01 in.) below the original

12. Procedure

surface (Note 1) at a rate of 2.5 mm (0.10 in.)/min (Note 2).

12.1 Weigh the twelve specimens and record the combined

NOTE 1—The original surface is defined as the point where the

weight to the nearest 0.1 g.

penetrator first contacts the specimen.

12.2 Place the 12 specimens and the 24 oak cubes in the

NOTE 2—When possible, the penetrator should bear between perfora-

tions or fissures when testing perforated or fissured material. testing container. Close the top of the testing container and

rotate the container about its axis at a speed of 60 rpm for two

6.3 Record the load shown on the testing machine when the

10-min periods. At the end of each 10-min period, remove the

penetrator reaches the specified depression as the hardness of

specimens from the box and determine the percentage of loss

the specimen in newtons or pounds-force.

in weight, due to pulverization and breakage. In the case of

badly abraded specimens, remove up to twelve of the largest

7. Report

pieces remaining and weigh these for the determination. In rare

7.1 The report shall include the following:

cases, no pieces may remain from an individual specimen. In

7.1.1 Identification of the test material,

this case, the weight loss shall be reported as 100 %.

7.1.2 Method of conditioning including time of condition-

ing, temperature, °C or °F, and relative humidity, %,

13. Report

7.1.3 Statement describing whether the finished or unfin-

13.1 The report shall include the following:

ished surface was tested,

13.1.1 Identification of the test material,

7.1.4 Average thickness for the five specimens, mm or in.,

13.1.2 Method of conditioning including time of condition-

7.1.5 Individual thicknesses for each of the five specimens,

ing, temperature, °C or °F, and relative humidity, %, and

mm or in.,

13.1.3 Percentage loss in weight for the 10- and 20-min

7.1.6 Average hardness for the five specimens, N or lbf, and

periods.

7.1.7 Individual hardness for each of the five specimens, N

or lbf.

SAG

FRIABILITY

14. Significance and Use

8. Significance and Use

14.1 This test method is for the purpose of determining the

8.1 The friability test measures the susceptibility of an sag properties of ceiling tile or panels under various conditions

of humidity exposure. Tiles or panels of various sizes can be

acoustical product to edge and corner damage that might be

tested by using appropriately sized supporting frames.

sustained during shipping, handling, and installing. Products

14.2 The test method will provide both the initial sag below

that are friable and soft may erode considerably when sub-

the plane of the grid system and the total moisture-induced sag.

jected to rough treatment.

14.3 This test method is not designed to establish the

9. Apparatus

expected performance of the ceiling panels under field condi-

tions of use, but only the sag properties for the specific

9.1 Balance, accurate to within 0.5 % of the weight of the

temperature, humidity, exposure time, and mounting condi-

smallest specimen tested.

tions used in the test.

9.2 Testing Container, consisting of a red oak box with

3 1

inside dimensions of 200 mm (7 ⁄4 in.) square by 190 mm (7 ⁄2

15. Apparatus

in.) deep and fitted with a cover on one end for inserting and

removing the specimens. The box shall be mounted so that it 15.1 Controlled-Atmosphere Chamber, capable of operating

may be rotated at 60 r/min on a horizontal axis that is at a dry-bulb temperature of 23 to 326 1.5°C (73 to 90 6 3°F),

perpendicular to its square dimension. and relative humidities of 50, 60, 70, 80, or 90 6 2 %. The

3 1

9.3 Red Oak Cubes, 24, 19 6 0.8 mm ( ⁄4 6 ⁄32 in.) on an chambershouldbeequippedwithsuitablerecordingequipment

edge, having a specific gravity of 0.65 6 0.02. to record wet- and dry-bulb temperatures (or dry bulb and

C367

This consists of placing a zero-plane plate in the test specimen frame

relative humidity). This equipment shall be checked periodi-

parallel with the shortest member of the frame, and centered in the longest

cally and calibrated with a psychrometer that shall also be used

member of the frame.The sag bar is then placed beneath the frame and the

to establish the test conditions.

dial gage is adjusted to read zero at the plane of the specimen surface.

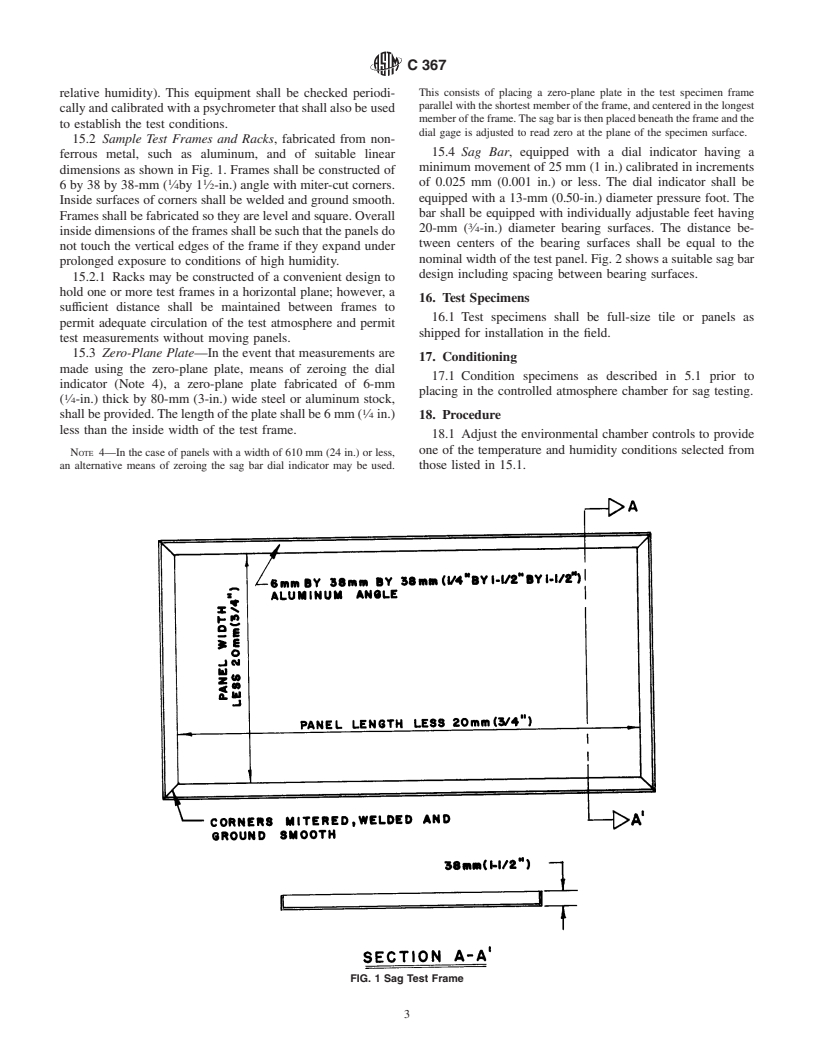

15.2 Sample Test Frames and Racks, fabricated from non-

15.4 Sag Bar, equipped with a dial indicator having a

ferrous metal, such as aluminum, and of suitable linear

minimum movement of 25 mm (1 in.) calibrated in increments

dimension

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.