ASTM C367-05

(Test Method)Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling Panels

Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling Panels

SIGNIFICANCE AND USE

Knowledge of hardness is useful in the development and the quality control of acoustical tile and lay-in ceiling panels. Deviation from an established hardness range will assist in pointing out processing errors or defective raw materials, thereby aiding the maintenance of uniform product quality.

This property is also useful in comparing the relative abilities of materials to resist indentations on the panel surface caused by impacts.

Since the hardness varies with the thickness, only samples of the same thickness may be directly compared.

SCOPE

1.1 These test methods cover the determination of the strength properties of prefabricated architectual acoustical tile or lay-in ceiling panels as follows:TestsSectionsHardness4 to 9Friability10 to 16Sag17 to 23Transverse strength24 to 30

1.2 Not all of the tests described in these test methods may be necessary to evaluate any particular product for a specific use. In each instance, it will be necessary to determine which properties are required.

1.3 These test methods specify procedures that may be used in product development, manufacturing control, specification acceptance, and service evaluation.

1.4 Properties determined by these test methods reflect the performance of the materials under the specific conditions of the test, and do not necessarily indicate performance under conditions other than those specified herein.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C367–05

Standard Test Methods for

Strength Properties of Prefabricated Architectural

1

Acoustical Tile or Lay-In Ceiling Panels

This standard is issued under the fixed designation C367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Materials used for absorbing sound generally have a porous, low-density structure. In comparison

with many building materials they may be relatively fragile. Materials are available that possess

adequate strength and stability and at the same time provide good sound absorption. The test methods

described here cover procedures for evaluating those physical properties related to strength. The

methods are of use in developing, manufacturing, and selecting acoustical tile or lay-in panels.

It should be kept in mind that a property related to strength is only one of several considerations

important in judging the usefulness of an acoustical material. For example, a material judged to be

quite weak by one of these tests may still be desired for other reasons, and with adequate precautions,

may be shipped and installed successfully.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover the determination of the 2.1 ASTM Standards:

strength properties of prefabricated architectual acoustical tile C634 Terminology Relating to Building and Environmental

or lay-in ceiling panels as follows: Acoustics

Tests Sections

3. Terminology

Hardness 4 to 9

Friability 10 to 16

3.1 Terms defined in Terminology C634.

Sag 17 to 23

3.1.1 acoustical material

Transverse strength 24 to 30

3.1.2 sound absorption

1.2 Not all of the tests described in these test methods may

3.2 Definitions of Terms Specific to this Standard:

be necessary to evaluate any particular product for a specific

3.2.1 fissures—irregular depressions of varying lengths

use. In each instance, it will be necessary to determine which

widths, and depths extending below the basic product face.

properties are required.

3.2.2 friable—easily crumbled.

1.3 These test methods specify procedures that may be used

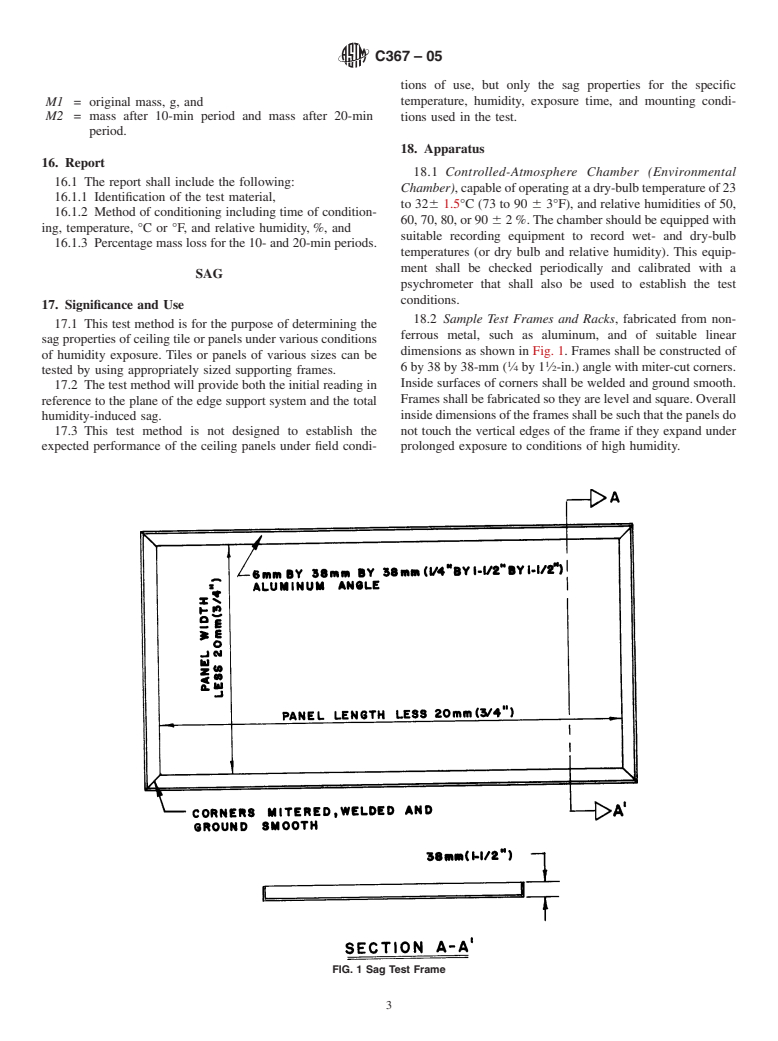

3.2.3 sag—deviation of the acoustical tile or panel at its

in product development, manufacturing control, specification

geometric center from the plane formed by the edges.

acceptance, and service evaluation.

1.4 Properties determined by these test methods reflect the

HARDNESS

performance of the materials under the specific conditions of

4. Significance and Use

the test, and do not necessarily indicate performance under

conditions other than those specified herein.

4.1 Knowledgeofhardnessisusefulinthedevelopmentand

1.5 This standard does not purport to address all of the

the quality control of acoustical tile and lay-in ceiling panels.

safety concerns, if any, associated with its use. It is the

Deviation from an established hardness range will assist in

responsibility of the user of this standard to establish appro-

pointing out processing errors or defective raw materials,

priate safety and health practices and determine the applica-

thereby aiding the maintenance of uniform product quality.

bility of regulatory limitations prior to use.

4.2 This property is also useful in comparing the relative

abilities of materials to resist indentations on the panel surface

caused by impacts.

1

These test methods are under the jurisdiction of ASTM Committee E-33 on

Environmental Acoustics and are the direct responsibility of Subcommittee E33.04

2

on Application of Acoustical Materials and Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2005. Published October 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1955. Last previous edition approved in 1999 as C367 – 99. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0367-05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C367–05

4.3 Since the hardness varies with the thickness, only sustained during shipping, handling, and installing. Products

samples of the same thickness may be directly compared. that are friable and soft may erode considerably when sub-

jected to rough treatment.

5. Apparatus

5.1 Testing Machine—Any standard mechanical or hydrau-

11. Apparatus

lic testing machine capable of applying and measuring the

11.1 Balance, accurate to within 0.5 % of the weight of the

required load within an accuracy of 61 % may be used. It shall

smallest specimen tested

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.