ASTM D2385-81(1990)

(Test Method)Test Method for Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate-Iodometric Titration Method) (Withdrawn 1995)

Test Method for Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate-Iodometric Titration Method) (Withdrawn 1995)

General Information

Standards Content (Sample)

ASTM DE!385 BL m 0759530 0078497 7 m

Designation: D 2385 - 81 (Reapproved 1990) An Am&can National Standard

4lb

Standard Test Method for

Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas

(Cadmium Sulfate lodometric Titration Method)’

This standard is issued under the fixed designation D 2385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (t) indicates an editorial change since the last revision or reapproval.

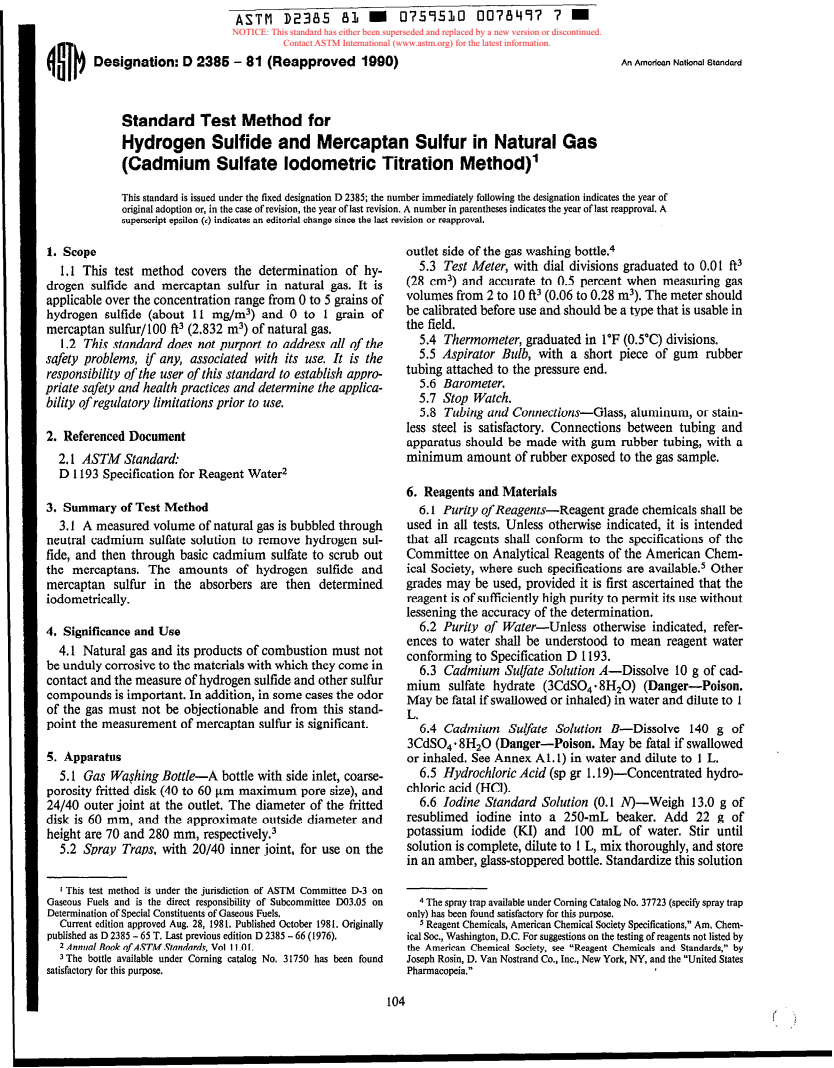

1. Scope outlet side of the gas washing bottle.4

5.3 Test Meter, with dial divisions graduated to 0.01 ft3

1.1 This test method covers the determination of hy-

(28 cm’) and accurate to 0.5 percent when measuring gas

drogen sulfide and mercaptan sulfur in natural gas. It is

volumes from 2 to 10 fi3 (0.06 to 0.28 m3). The meter should

applicable over the concentration range from 0 to 5 grains of

be calibrated before use and should be a type that is usable in

hydrogen sulfide (about 11 mg/m3) and 0 to 1 grain of

the field.

mercaptan sulfur/100 ft3 (2.832 m3) of natural gas.

5.4 Thermometer, graduated in 1°F (0.5”C) divisions.

1.2 This standard does not purport to address all of the

5.5 Aspirator Bulb, with a short piece of gum rubber

safety problems, tf any, associated with its use. It is the

tubing attached to the pressure end.

responsibility of the user of this standard to establish appro-

5.6 Barometer.

priate safety and health practices and determine the applica-

5.7 Stop Watch.

bility of regulatory limitations prior to use.

5.8 Tubing and Connections-Glass, aluminum, or stain-

less steel is satisfactory. Connections between tubing and

2. Referenced Document

apparatus should be made with gum rubber tubing, with a

minimum amount of rubber exposed to the gas sample.

2.1 ASTM Standard:

D 1193 Specification for Reagent Water2

6. Reagents and Materials

3. Summary of Test Method

6.1 Purity of Reagents-Reagent grade chemicals shall be

3.1 A measured volume of natural gas is bubbled through used in all tests. Unless otherwise indicated, it is intended

neutral cadmium sulfate solution to remove hydrogen sul- that all reagents shall conform to the specifications of the

fide, and then through basic cadmium sulfate to scrub out Committee on Analytical Reagents of the American Chem-

the mercaptans. The amounts of hydrogen sulfide and ical Society, where such specifications are available.5 Other

mercaptan sulfur in the absorbers are then determined grades may be used, provided it is fast ascertained that the

reagent is of sufficiently high purity to permit its use without

iodometrically.

lessening the accuracy of the determination.

6.2 Purity of Water-Unless otherwise indicated, refer-

4. Significance and Use

ences to water shall be understood to mean reagent water

4.1 Natural gas and its products of combustion must not

conforming to Specification D 1193.

be unduly corrosive to the materials with which they come in

6.3 Cadmium Sulfate Solution A-Dissolve 10 g of cad-

contact and the measure of hydrogen sulfide and other sulfur

mium sulfate hydrate (3CdS04.8H20) (Danger-Poison.

compounds is important. In addition, in some cases the odor

May be fatal if swallowed or inhaled) in water and dilute to 1

of the gas must not be objectionable and from this stand-

L.

point the measurement of mercaptan sulfur is significant.

6.4 Cadmium &Kate Solution B-Dissolve 140 g of

3CdS04*8H,0 (Danger-Poison. May be fatal if swallowed

5. Apparatus

or inhaled. See Annex All) in water and dilute to 1 L.

6.5 Hydrochloric Acid (sp gr 1.19)-Concentrated hydro-

5.1 Gas Washing Bottle-A bottle with side inlet, coarse-

chloric acid (HCI).

porosity fiitted disk (40 to 60 pm maximum pore size), and

6.6 Iodine Standard Solution (0.1 N&Weigh 13.0 g of

24/40 outer joint at the outlet. The diameter of the fritted

resublimed iodine into a 250-mL beaker. Add 22 g of

disk is 60 mm, and the approximate outside diameter and

potassium iodide (RI) and 100 mL of water. Stir until

height are 70 and 280 mm, respectively.3

solution is complete, dilute to 1 L, mix thoroughly, and store

5.2 Spray Traps, with 20140 inner joint, for use on the

in an amber, glass-stoppered bottle. Standardize this solution

t This test method is under the jurisdiction of ASTM Committee D-3 on

Gaseous Fuels and is the direct responsibility of Subcommittee DO3.05 on

4 The spray trap available under Coming Catalog No. 37723 (specify spray trap

Determination of Special Constituents of Gaseous Fuels.

only) has been found satisfactory for this purpose.

Current edition approved Aug. 28, 1981. Published October 1981. Originally

s Reagent Chemicals, American Chemical Society Specifications,” Am. Chem-

published as D 2385 - 65 T. Last previous edition D 2385 - 66 (1976).

ical Sot., Washington, D.C. For suggestions on the te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.