ASTM D2945-90(1998)

(Test Method)Standard Test Method for Gas Content of Insulating Oils

Standard Test Method for Gas Content of Insulating Oils

SCOPE

1.1 This test method covers the determination of the gas content of electrical insulating oils of low and medium viscosities in the general range of 100 SUS and below at 100°F (37.8°C), and is suitable for field or laboratory use. Note 1-For testing insulating oils with viscosities above 100 SUS, see Test Method D831. For individual gas concentrations, see Method D3612.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 2945 – 90 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Gas Content of Insulating Oils

This standard is issued under the fixed designation D 2945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope gas content transformer oil in order to prevent foaming and to

avoid air pockets that might result in gaseous ionization. This

1.1 This test method covers the determination of the gas

procedure provides a simple method to measure the gas content

content of electrical insulating oils of low and medium

of the oil, and may be used as a factory-control test and as a

viscosities in the general range of 100 SUS and below at 100°F

control or functional test in installation and maintenance work

(37.8°C), and is suitable for field or laboratory use.

by utilities.

NOTE 1—For testing insulating oils with viscosities above 100 SUS, see

Test Method D 831. For individual gas concentrations, see Method

5. Apparatus

D 3612.

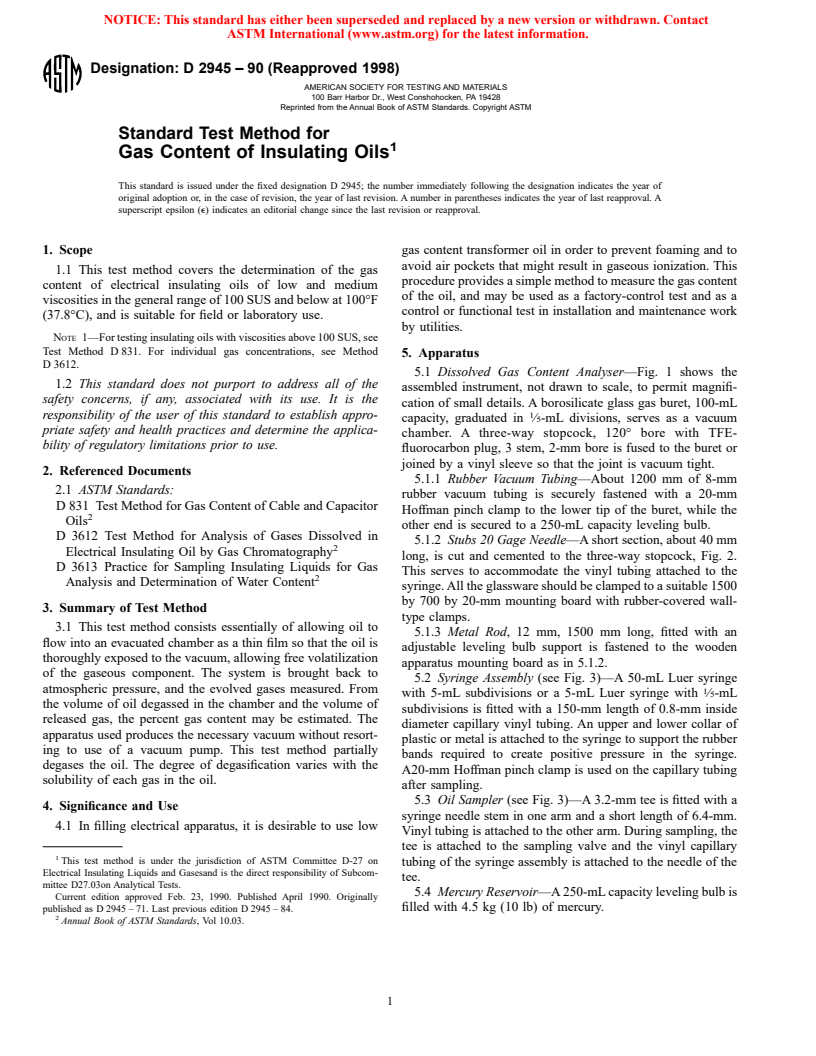

5.1 Dissolved Gas Content Analyser—Fig. 1 shows the

1.2 This standard does not purport to address all of the

assembled instrument, not drawn to scale, to permit magnifi-

safety concerns, if any, associated with its use. It is the

cation of small details. A borosilicate glass gas buret, 100-mL

responsibility of the user of this standard to establish appro- 1

capacity, graduated in ⁄5-mL divisions, serves as a vacuum

priate safety and health practices and determine the applica-

chamber. A three-way stopcock, 120° bore with TFE-

bility of regulatory limitations prior to use.

fluorocarbon plug, 3 stem, 2-mm bore is fused to the buret or

joined by a vinyl sleeve so that the joint is vacuum tight.

2. Referenced Documents

5.1.1 Rubber Vacuum Tubing—About 1200 mm of 8-mm

2.1 ASTM Standards:

rubber vacuum tubing is securely fastened with a 20-mm

D 831 Test Method for Gas Content of Cable and Capacitor

Hoffman pinch clamp to the lower tip of the buret, while the

Oils

other end is secured to a 250-mL capacity leveling bulb.

D 3612 Test Method for Analysis of Gases Dissolved in

5.1.2 Stubs 20 Gage Needle—A short section, about 40 mm

Electrical Insulating Oil by Gas Chromatography

long, is cut and cemented to the three-way stopcock, Fig. 2.

D 3613 Practice for Sampling Insulating Liquids for Gas

This serves to accommodate the vinyl tubing attached to the

Analysis and Determination of Water Content

syringe. All the glassware should be clamped to a suitable 1500

by 700 by 20-mm mounting board with rubber-covered wall-

3. Summary of Test Method

type clamps.

3.1 This test method consists essentially of allowing oil to

5.1.3 Metal Rod, 12 mm, 1500 mm long, fitted with an

flow into an evacuated chamber as a thin film so that the oil is

adjustable leveling bulb support is fastened to the wooden

thoroughly exposed to the vacuum, allowing free volatilization

apparatus mounting board as in 5.1.2.

of the gaseous component. The system is brought back to

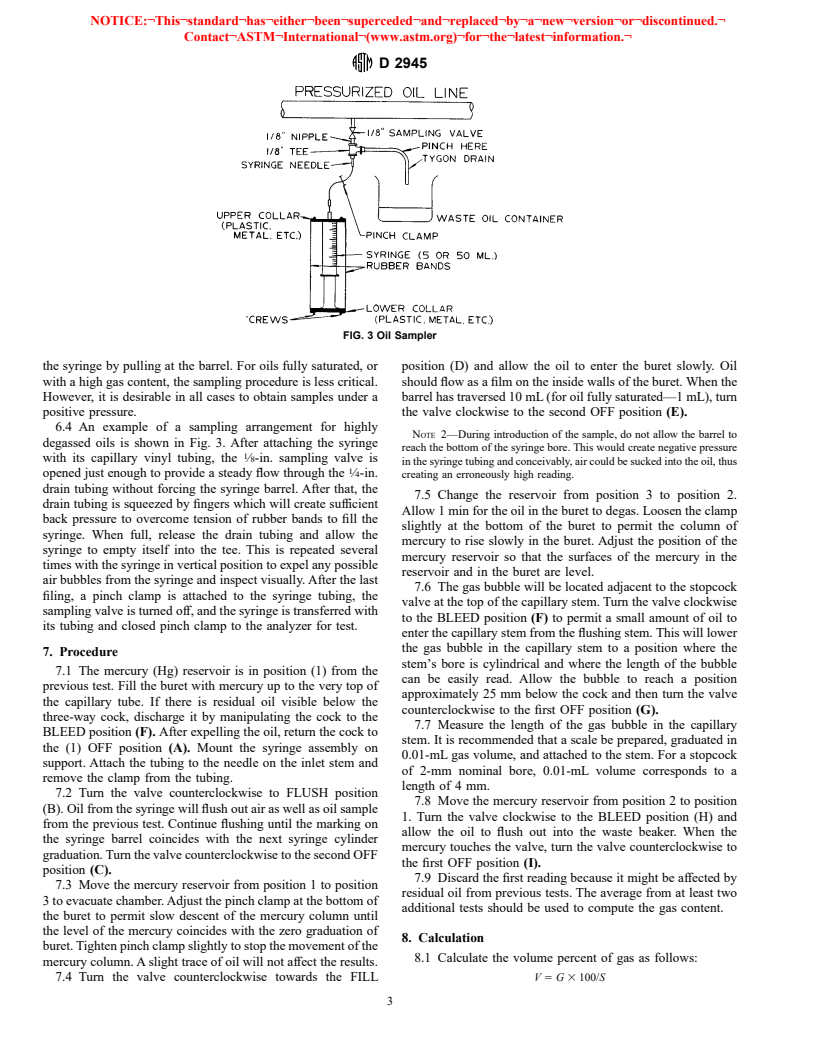

5.2 Syringe Assembly (see Fig. 3)—A 50-mL Luer syringe

atmospheric pressure, and the evolved gases measured. From

with 5-mL subdivisions or a 5-mL Luer syringe with ⁄5-mL

the volume of oil degassed in the chamber and the volume of

subdivisions is fitted with a 150-mm length of 0.8-mm inside

released gas, the percent gas content may be estimated. The

diameter capillary vinyl tubing. An upper and lower collar of

apparatus used produces the necessary vacuum without resort-

plastic or metal is attached to the syringe to support the rubber

ing to use of a vacuum pump. This test method partially

bands required to create positive pressure in the syringe.

degases the oil. The degree of degasification varies with the

A20-mm Hoffman pinch clamp is used on the capillary tubing

solubility of each gas in the oil.

after sampling.

5.3 Oil Sampler (see Fig. 3)—A 3.2-mm tee is fitted with a

4. Significance and Use

syringe needle stem in one arm and a short length of 6.4-mm.

4.1 In filling electrical apparatus, it is desirable to use low

Vinyl tubing is attached to the other arm. During sampling, the

tee is attached to the sampling valve and the vinyl capillary

This test method is under the jurisdiction of ASTM Committee D-27 on

tubing of the syringe assembly is attached to the needle of the

Electrical Insulating Liquids and Gasesand is the direct responsibility of Subcom-

tee.

mittee D27.03on Analytical Tests.

5.4 Mercury Reservoir—A 250-mL capacity leveling bulb is

Current edition approved Feb. 23, 1990. Published April 1990. Originally

published as D 2945 – 71. Last previous edition D 2945 – 84. filled with 4.5 kg (10 lb) of mercury.

Annual Book of ASTM Standards, Vol 10.03.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

D 2945

1 gas buret, capacity 100 mL, graduated in ⁄5-mL divisions

1 stopcock, 120° bore with TFE fluorocarbon plug, 3 stems, 2-mm bore

1 leveling bulb, capacity 250 mL

1 beaker, capacity 250 mL

1200 mm (4 ft) vacuum rubber tubing, 8-mm ( ⁄16-in.) inside diameter

2 rubber tubing clamps, adjustable, cadmium-plated steel

2-pinch clamps, Hoffman swivel jaw, screw compressor, ⁄4 by 1 in. for vinyl tubing for 5 and 50-mL syringes

1 pinch clamp, Hoffman screw compressor for rubber tubing, ⁄4 by 1 in.

6 clamps, wall type with wood screw to support buret, stopcock, and rod

1 leveling bulb support, adjustable, Fisher-Castaloy-R, self-locking

1 rod, diameter 12 mm ( ⁄2 in.), length 1500 mm (58 in.)

1 syringe, Luer, resistance glass, 50 mL, subdivisions 5 mL

1 syringe, Luer, resistance glass, 5 mL, subdivisions ⁄5 mL

1 1

Vinyl tubing, 2.6-mm ( ⁄16-in.) inside diameter, wall thickness 1.3 mm ( ⁄32 in.), length 150 mm (6 in.)

4.5 kg (10 lb) mercury

1 needle, 50 mm long, Stubbs gage 20

1 wooden board 1500 by 700 by 20 mm (58 by 28 by ⁄8 in.)

Components for Gas-Content Apparatus

FIG. 1 Dissolved Gas Content Analyser

FIG. 2 Detail of Needle Inlet

6. Sampling maintained under slight positive pressure during the taking of

the sample, during sample transfer, and during the introduction

6.1 Samples should be drawn in accordance wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.