ASTM D3038-93(2004)

(Test Method)Standard Test Method for Drop Shatter Test for Coke

Standard Test Method for Drop Shatter Test for Coke

SIGNIFICANCE AND USE

The values determined in this test, when evaluated in terms of pertinent experience with other cokes, may be used as indications of the extent to which a given coke will break in conventional transit and handling beyond the point of sampling.

SCOPE

1.1 This test method covers the application of two procedures for the determination of the property of coke of withstanding breakage when dropped under specified test conditions.

1.2 Procedure A used when the coke sample contains 50 % or less of 100 mm (4 in.) after removal of coke smaller than 50 mm (2 in.). Procedure A appears in Sections .

1.3 Procedure B used when the coke sample contains more than 50 % 100 mm (4 in.) after removal of coke smaller than 50 mm (2 in.). Procedure B appears in Sections .

1.4 &si-value;

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3038–93 (Reapproved 2004)

Standard Test Method for

Drop Shatter Test for Coke

This standard is issued under the fixed designation D3038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E323 Specification for Perforated-Plate Sieves for Testing

Purposes

1.1 This test method covers the application of two proce-

dures for the determination of the property of coke of with-

3. Significance and Use

standing breakage when dropped under specified test condi-

3.1 The values determined in this test, when evaluated in

tions.

terms of pertinent experience with other cokes, may be used as

1.2 Procedure A, used when the coke sample contains 50 %

indications of the extent to which a given coke will break in

or less of 100 mm (4 in.) after removal of coke smaller than 50

conventional transit and handling beyond the point of sam-

mm (2 in.). Procedure A appears in Sections 6-9.

pling.

1.3 Procedure B, used when the coke sample contains more

than 50 % 100 mm (4 in.) after removal of coke smaller than

4. Apparatus

50 mm (2 in.). Procedure B appears in Sections 10-13.

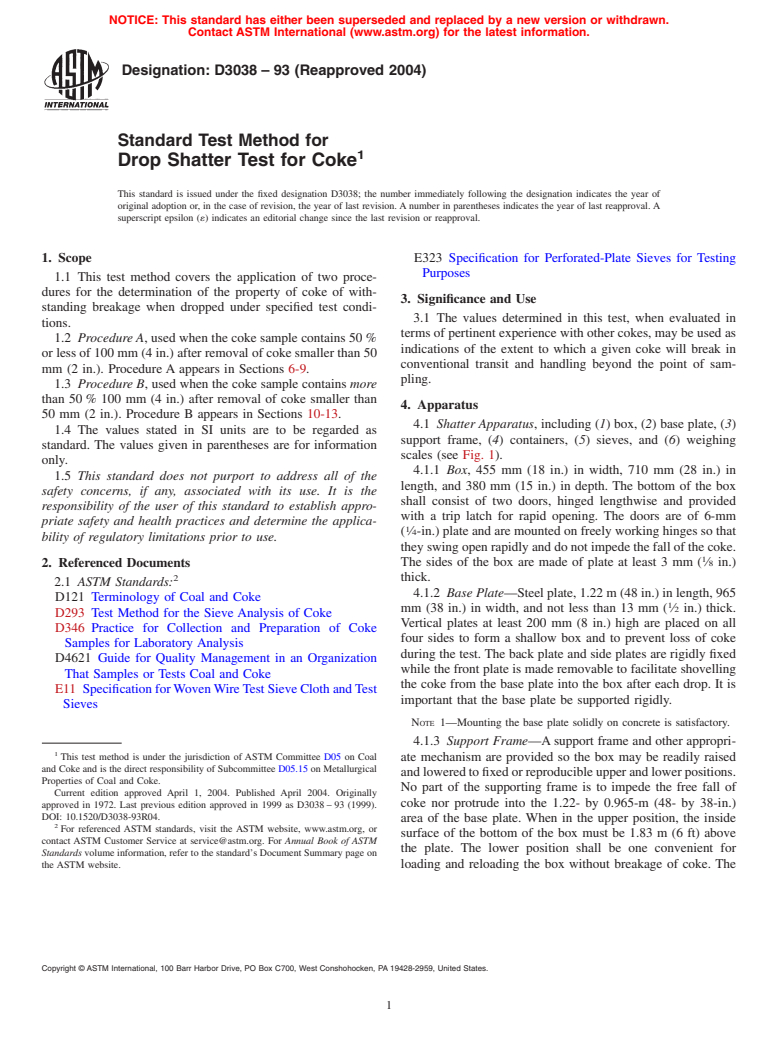

4.1 Shatter Apparatus, including (1) box, (2) base plate, (3)

1.4 The values stated in SI units are to be regarded as

support frame, (4) containers, (5) sieves, and (6) weighing

standard. The values given in parentheses are for information

scales (see Fig. 1).

only.

4.1.1 Box, 455 mm (18 in.) in width, 710 mm (28 in.) in

1.5 This standard does not purport to address all of the

length, and 380 mm (15 in.) in depth. The bottom of the box

safety concerns, if any, associated with its use. It is the

shall consist of two doors, hinged lengthwise and provided

responsibility of the user of this standard to establish appro-

with a trip latch for rapid opening. The doors are of 6-mm

priate safety and health practices and determine the applica-

( ⁄4-in.) plate and are mounted on freely working hinges so that

bility of regulatory limitations prior to use.

they swing open rapidly and do not impede the fall of the coke.

2. Referenced Documents The sides of the box are made of plate at least 3 mm ( ⁄8 in.)

2 thick.

2.1 ASTM Standards:

4.1.2 Base Plate—Steel plate, 1.22 m (48 in.) in length, 965

D121 Terminology of Coal and Coke

mm (38 in.) in width, and not less than 13 mm ( ⁄2 in.) thick.

D293 Test Method for the Sieve Analysis of Coke

Vertical plates at least 200 mm (8 in.) high are placed on all

D346 Practice for Collection and Preparation of Coke

four sides to form a shallow box and to prevent loss of coke

Samples for Laboratory Analysis

during the test. The back plate and side plates are rigidly fixed

D4621 Guide for Quality Management in an Organization

while the front plate is made removable to facilitate shovelling

That Samples or Tests Coal and Coke

the coke from the base plate into the box after each drop. It is

E11 SpecificationforWovenWireTestSieveClothandTest

important that the base plate be supported rigidly.

Sieves

NOTE 1—Mounting the base plate solidly on concrete is satisfactory.

4.1.3 Support Frame—Asupport frame and other appropri-

This test method is under the jurisdiction of ASTM Committee D05 on Coal

ate mechanism are provided so the box may be readily raised

and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

andloweredtofixedorreproducibleupperandlowerpositions.

Properties of Coal and Coke.

No part of the supporting frame is to impede the free fall of

Current edition approved April 1, 2004. Published April 2004. Originally

coke nor protrude into the 1.22- by 0.965-m (48- by 38-in.)

approved in 1972. Last previous edition approved in 1999 as D3038 – 93 (1999).

DOI: 10.1520/D3038-93R04.

area of the base plate. When in the upper position, the inside

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

surface of the bottom of the box must be 1.83 m (6 ft) above

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the plate. The lower position shall be one convenient for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. loading and reloading the box without breakage of coke. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3038–93 (2004)

FIG. 1 Shatter Test Machine

NOTE 3—For Procedure A, in which the coke samples do not contain

box may be constrained to only vertical movement by suitable

more than 50 % plus 100-mm (4-in.) sizes, the 150-mm (6-in.), 125-mm

lateral guides and may be conveniently supported by wire rope

(5-in.), and 100-mm (4-in.) sieves may be excluded. For Procedure B, in

passing over pulleys. Counterweighting will reduce labor.

which the coke samples contain more than 50 % plus 100-mm (4-in.)

4.1.4 Containers—Conventional galvanized-iron tubs are

sizes, it is permissible to exclude the 37.5-mm (1 ⁄2-in.), 25-mm (1-in.),

convenientcontainersinwhichtocollectandweighcokeinthe

and the 12.5-mm ( ⁄2-in.) sieves.

various stages of the test.

4.1.6 Weighing Scale—For Procedure A, a scale having a

4.1.5 Sieves—Woven-wire square-mesh sieves of the fol-

capacity of 35 kg (75 lb) is to be provided and be graduated so

lowing sizes: 150 mm (6 in.), 125 mm (5 in.), 100 mm (4 in.),

that it may be read directly, without interpolation, to 0.05 kg

75 mm (3 in.), 50 mm (2 in.), 37.5 mm (1 ⁄2 in.), 25 mm (1 in.),

(0.1lb).Thesensitivityistobenotlessthan0.025kg(0.05lb).

and12.5mm( ⁄2in.).ThesievesmustconformtoSpecification

4.1.6.1 For Procedure B, this scale is to have a capacity of

E11.

60 kg (125 lb) graduated to 0.1 kg (0.2 lb) and have a

NOTE 2—The 150-mm (6-in.) and the 125-mm (5-in.) sieves are not

sensitivity not less than 0.05 kg (0.10 lb).

defined in Specifications E11 but shall have nominal wire diameters of

7.11 mm (0.2800 in.) and 6.73 mm (0.2650 in.), respectively, and have

5. Sampling

permissible variations in average opening, permissible variations for not

5.1 The gross sample of coke must be taken as close as

more than 5 % of openings, and maximum variation in individual

openings equivalent to that specified for the 100-mm (4-in.) sieve. possible to the point of interest, include all sizes, and be

D3038–93 (2004)

collected in such a way as to be representative of the total lot plus 50-mm (2-in.) part of the gross sample as found in a

or quantity in question, in accordance with Practice D346. preliminary size analysis to which the whole of the gross

5.2 For ProcedureA, the minimum size of the gross sample sample is subjected.

must be such as to yield 68 to 75 kg (150 to 165 lb) of coke 7.2 This preliminary size analysis is carried out, mainly, by

retained on 50-mm (2-in.) sieve when processed according to hand placing, a process in which each piece of coke is handled

the procedure set forth in Section 7. and counted as undersize if it will, in some position and

withoutforcing,passthroughthesieve.Proceedinginthisway,

5.2.1 For Procedure B, this sample must be such as to yield

atleast140kg(300lb)ofcokeretainedon75-mm(3-in.)sieve andtakingcareinalloperationstoavoidbreakage,separatethe

gross sample into the following fractions which are segregated

when processed in accordance with the procedure set forth in

Section 11. appropriately in tubs:

5.2.2 If experience shows that more than three tests are Passing Retained on Percent

usually necessary, the quantity of gross sample will need to be

__________________ 100-mm (4-in.) sieve ________

increased appropriately.

100-mm (4-in.) sieve 75-mm (3-in) sieve ________

75-mm (3-in.) sieve 50-mm (2-in.) sieve ________

5.3 The gross sample is to be assembled from increments

50-mm (2-in.) sieve ________

regularly and systematically collected, so that the entire quan-

tity of coke sampled will be represented proportionately in the

7.3 Make appropriate weighings so that the percentage of

gross sample, and with such frequency that a gross sample of

each size in the portion of the original gross sample retained on

at least the minimum required amount is collected.

a 50.8-mm (2-in.) sieve can be calculated.

5.4 Increments may be collected from a stopped conveyor

7.4 Reconstitute each sample for testing, 23 to 25 kg (50 to

belt or by interposing a collecting container into a moving

55 lb), from the segregated sizes above 50 mm (2 in.). Select

stream while the coke is being loaded or unloaded or otherwise

pieces at random from the total amount of each size, the

transported. The increment collected from a stopped belt must quantity of each size fraction taken being based on the data of

be all the coke on the belt between parallel planes separated by

the preliminary size analysis.

a distance 2.5 times the nominal top size of the coke. In the 7.5 If the coke contains 5 % of moisture or less, test the

same way, when collecting from a moving stream, the collect-

sample as is. Wetter coke is to be dried to 5 % or less before

ing container must be as wide as the stream, or be moved testing.

uniformly through its whole width and have a mouth opening

2.5 times the nominal top size of the coke. The nominal top

8. Procedure

size, for this method, is that nearest standard sieve for which

8.1 Weigh 23 to 25 kg (50 to 55 lb) of the prepared

about 5 % of the coke is oversize.

reconstituted sample to the nearest 0.05 kg (0.1 lb). Transfer

5.5 Samples collected from the surface of coke in piles,

the coke carefully into the box of the shatter test apparatus by

bins, cars, ships, or barges, are in general unreliable because of

either inserting the container into the box

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.