ASTM F2781-09

(Practice)Standard Practice for Testing Forced Entry Resistance of Security Fence Systems

Standard Practice for Testing Forced Entry Resistance of Security Fence Systems

SIGNIFICANCE AND USE

The success or failure of any attempt to forcefully penetrate a fence system is dependent upon three primary factors that collectively define the threat—the tools and devices employed, the number of aggressors, and their level of sophistication.

Normally, a test procedure of this scope would be supported by years of laboratory testing intended to qualify and accurately reproduce the destructive effects of a variety of tools, implements, and devices. However, rapidly changing social conditions have created an immediate need for building components resistant to evolving forced entry techniques. Accordingly, the procedures presented herein are based more on field experience than laboratory analysis. They are more representative than inclusive, are intended to provide a basis for the comparative evaluation of different fence systems using forced penetration procedures and are not intended to be used to establish or confirm the absolute prevention of forced entries.

TABLE 1 Schedule of Testing—All Levels of Threat Severity Time of Application (minutes) Structured TestingDiscretionary Testing Tool(s)LMALMA Crowbar

5 lb by 28 in. (2)3-53-53-50-550-550-55 Cold Chisels and

Hammer (2)3-53-53-50-550-550-55 Hacksaw and

Two HSS Blades3-53-53-50-550-550-55 Sledgehammer

16 in. by 6 lb3-53-53-50-550-550-55 Fire Axe

36 in. by 6 lb 3-53-53-50-550-550-55 Bolt Cutter (2)-3-53-5-0-550-55 Fire Axe

36 in. by 10 lb-3-53-5-0-550-55 Hole Saw 2 in. (1)-0-50-5-0-550-55 Pry Bar

30 in. Steel (2)-0-50-5-0-550-55 Sledgehammer

30 in. by 12 lb-0-50-5-0-550-55 Steel Wedge

6 in. long (2)-0-50-5-0-550-55 Circular Saw

8 in., 1100 W, and

3 Blades (1)--0-5--0-55 Disc Grinder

5 in., 1100 W, and 3 Blades (1)--0-5--0-55 Rotary and

Hammer Drill

750 W and 5 Drill Bits, ½ in. (1)--0-5--0-55 Hole Saw

Greater than 2 in. (1)--0-5--0-55 Steel Pinch

Bar 60 in. long (2)--0-5--0-55 Reciprocating

Saw 750 W and

3 Carbide Blades (1)--0-5--0-55 Sledgehammer

30 in. by 15 lb (1)-...

SCOPE

1.1 The forced entry resistance of fence systems is evaluated relative to three levels of forced entry threat using the limited hand tool inventory outlined in Table 1. It also establishes a system for rating the forced entry resistance of those systems (see Table 2). The tools specified to be used for testing at each threat level are those that are known to have a maximum destructive effect on structures and their sub-assemblies and are readily available to aggressors categorized as posing that level of threat.

1.1.1 Low Threat Level (L)—Specifically exempted from the inventory of available tools for the low (L) threat level category are power tools (gasoline, electric or hydraulic), and devices requiring more than one person to transport and operate.

1.1.2 Medium Threat Level (M)—Specifically exempted from the inventory of available tools for the medium (M) threat level category are power tools requiring an outside power source or self contained gasoline or battery driven tools and devices requiring more than two persons to transport and operate.

1.1.3 Aggressive Threat Level (A)—Specifically exempted from the inventory of available tools for the high (H) threat level category are devices requiring more than two persons to transport and operate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2781 – 09

Standard Practice for

Testing Forced Entry Resistance of Security Fence

Systems

This standard is issued under the fixed designation F2781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 The structured portion of the test provides for a zero to

five minute test with specific tools selected as the most

1.1 The forced entry resistance of fence systems is evalu-

debilitating from the tool list inTable 1, regardless of the fence

ated relative to three levels of forced entry threat using the

system being tested.

limited hand tool inventory outlined in Table 1. It also

3.3 Following the structured portion of the test, the discre-

establishes a system for rating the forced entry resistance of

tionary portion of the test provides up to 55 minutes of testing,

those systems (see Table 2). The tools specified to be used for

optimizing forced entry efforts by selecting any (or all) tools

testing at each threat level are those that are known to have a

from the applicable category of the list (low (A), medium (B),

maximum destructive effect on structures and their sub-

or aggressive (C)). Selection of tools is based on the perception

assemblies and are readily available to aggressors categorized

of the test director as to which tools will most effectively result

as posing that level of threat.

in a forced entry.

1.1.1 Low Threat Level (L)—Specifically exempted from

3.4 Testing of security fence systems in accordance with the

the inventory of available tools for the low (L) threat level

requirements of this test method shall result in a rating

category are power tools (gasoline, electric or hydraulic), and

reflecting the severity of the threat and the cumulative resis-

devices requiring more than one person to transport and

tance time (see Table 2).

operate.

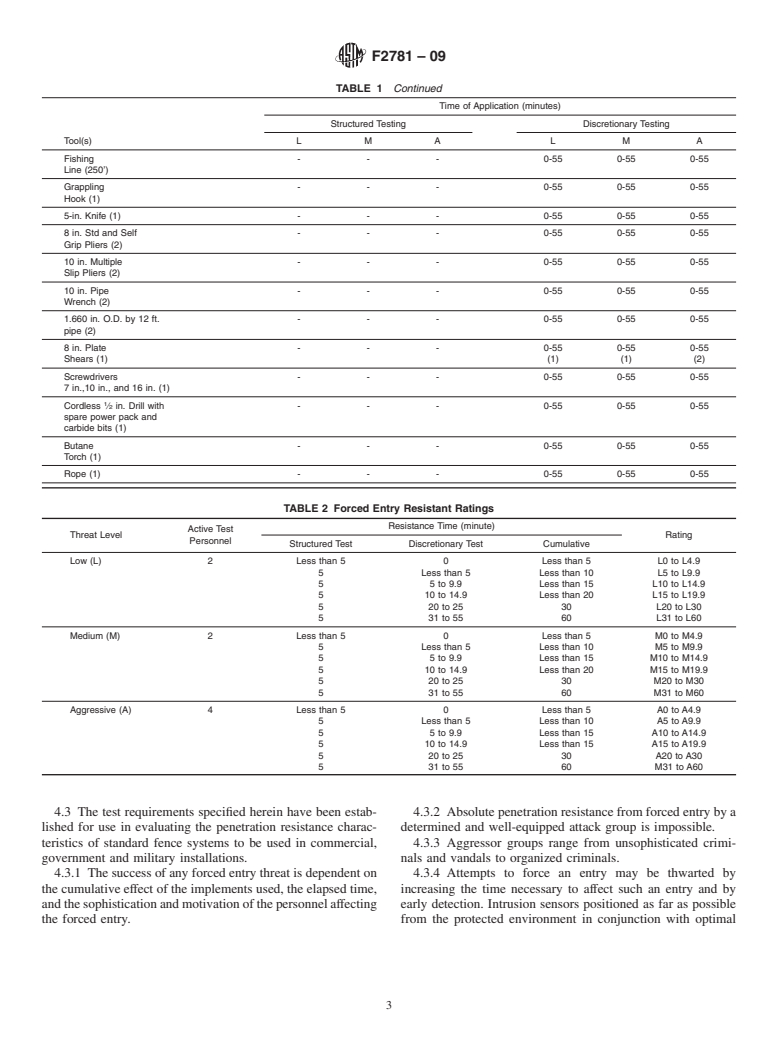

3.5 The times used to establish the protection ratings of

1.1.2 Medium Threat Level (M)—Specifically exempted

Table 2 range from 0–60 minutes and are intended to reflect the

from the inventory of available tools for the medium (M) threat

elapsedtimeofforcedentryresistancenecessaryforaresponse

level category are power tools requiring an outside power

force to arrive and counter the threat with additional defensive

source or self contained gasoline or battery driven tools and

personnel and equipment. It is important to recognize that the

devices requiring more than two persons to transport and

lowest threat level time will establish the maximum time limit

operate.

for a greater threat level.

1.1.3 Aggressive Threat Level (A)—Specifically exempted

from the inventory of available tools for the high (H) threat

4. Significance and Use

level category are devices requiring more than two persons to

4.1 The success or failure of any attempt to forcefully

transport and operate.

penetrate a fence system is dependent upon three primary

2. Terminology factorsthatcollectivelydefinethethreat—thetoolsanddevices

employed, the number of aggressors, and their level of sophis-

2.1 Definitions of Terms Specific to This Standard:

tication.

2.1.1 test director—the individual identified by the indepen-

4.2 Normally, a test procedure of this scope would be

dent testing laboratory as being responsible to complete the

supportedbyyearsoflaboratorytestingintendedtoqualifyand

specified tests and to document the results.

accurately reproduce the destructive effects of a variety of

2.1.2 forced entry—creating a four square feet opening.

tools, implements, and devices. However, rapidly changing

3. Summary of Practice social conditions have created an immediate need for building

components resistant to evolving forced entry techniques.

3.1 For each rating a structured portion and a discretionary

Accordingly, the procedures presented herein are based more

portion as described in 3.2 and 3.3 is required.

on field experience than laboratory analysis. They are more

representative than inclusive, are intended to provide a basis

This practice is under the jurisdiction ofASTM Committee F14 on Fences and

for the comparative evaluation of different fence systems using

is the direct responsibility of Subcommittee F14.50 on High Security Fences and

Perimeter Barriers.

Current edition approved July 1, 2009. Published August 2009. DOI: 10.1520/

F2781-09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2781 – 09

forced penetration procedures and are not intended to be used

to establish or confirm the absolute prevention of forced

entries.

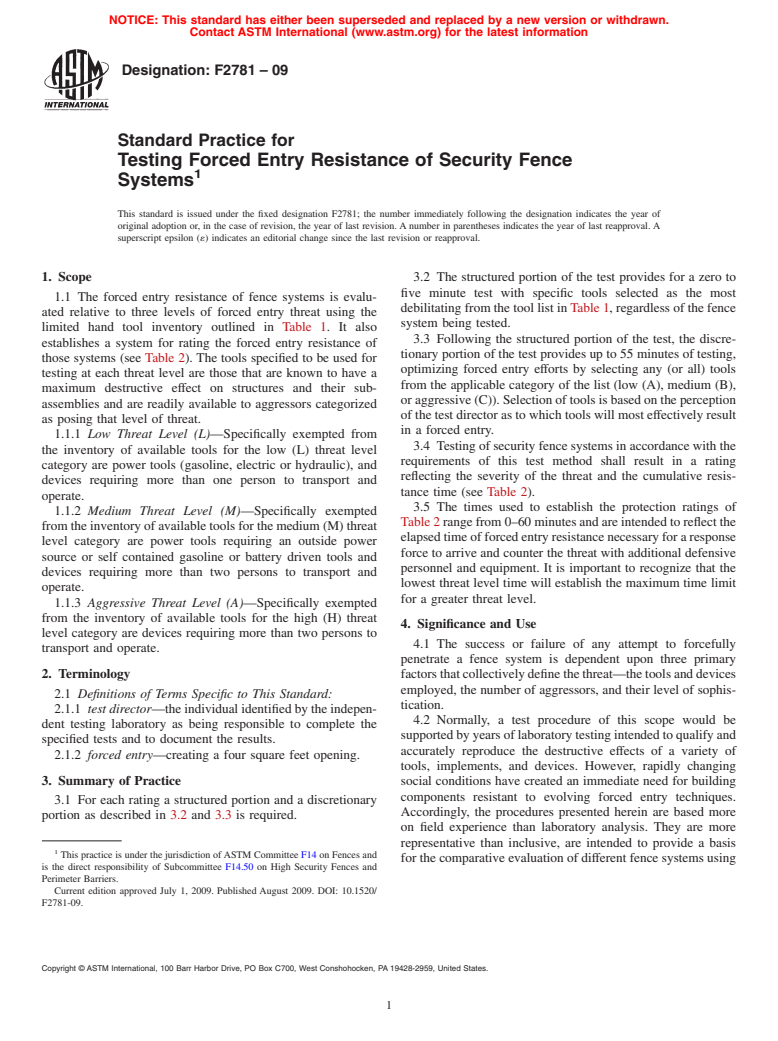

TABLE 1 Schedule of Testing—All Levels of Threat Severity

Time of Application (minutes)

Structured Testing Discretionary Testing

Tool(s) L M A L M A

Crowbar 3-5 3-5 3-5 0-55 0-55 0-55

5lbby28in.(2)

Cold Chisels and 3-5 3-5 3-5 0-55 0-55 0-55

Hammer (2)

Hacksaw and 3-5 3-5 3-5 0-55 0-55 0-55

Two HSS Blades

Sledgehammer 3-5 3-5 3-5 0-55 0-55 0-55

16in.by6lb

Fire Axe 3-5 3-5 3-5 0-55 0-55 0-55

36in.by6lb

Bolt Cutter (2) - 3-5 3-5 - 0-55 0-55

Fire Axe - 3-5 3-5 - 0-55 0-55

36in.by10lb

Hole Saw 2 in. (1) - 0-5 0-5 - 0-55 0-55

Pry Bar - 0-5 0-5 - 0-55 0-55

30 in. Steel (2)

Sledgehammer - 0-5 0-5 - 0-55 0-55

30in.by12lb

Steel Wedge - 0-5 0-5 - 0-55 0-55

6 in. long (2)

Circular Saw - - 0-5 - - 0-55

8 in., 1100 W, and

3 Blades (1)

Disc Grinder - - 0-5 - - 0-55

5 in., 1100 W, and 3 Blades (1)

Rotary and - - 0-5 - - 0-55

Hammer Drill

750 W and 5 Drill Bits, ⁄2 in. (1)

Hole Saw - - 0-5 - - 0-55

Greater than 2 in. (1)

Steel Pinch - - 0-5 - - 0-55

Bar 60 in. long (2)

Reciprocating - - 0-5 - - 0-55

Saw 750 W and

3 Carbide Blades (1)

Sledgehammer - - 0-5 - - 0-55

30in.by15lb(1)

Oxyacetylene - - 0-5 - - 0-55

Torch with 80 ft Oxygen and

40 ft Acetylene Tanks (1)

Cut-Off Saw - - 0-5 - - 0-55

5 KW or HD Gasoline

18 in. Dia. and 3

Blades (1)

Breaker - - 0-5 - - 0-55

(1900 W) 30 lb with

3 Bits (1)

Scissor Jack 1500 lb - - 0-5 - - 0-55

with 4 in. min

retraction and 8 in.

Stroke (1)

Adhesive - - - 0-55 0-55 0-55

Tape (1)

F2781 – 09

TABLE 1 Continued

Time of Application (minutes)

Structured Testing Discretionary Testing

Tool(s) L M A L M A

Fishing - - - 0-55 0-55 0-55

Line (250’)

Grappling - - - 0-55 0-55 0-55

Hook (1)

5-in. Knife (1) - - - 0-55 0-55 0-55

8 in. Std and Self - - - 0-55 0-55 0-55

Grip Pliers (2)

10 in. Multiple - - - 0-55 0-55 0-55

Slip Pliers (2)

10 in. Pipe - - - 0-55 0-55 0-55

Wrench (2)

1.660 in. O.D. by 12 ft. - - - 0-55 0-55 0-55

pipe (2)

8 in. Plate - - - 0-55 0-55 0-55

Shears (1) (1) (1) (2)

Screwdrivers - - - 0-55 0-55 0-55

7 in.,10 in., and 16 in. (1)

Cordless ⁄2 in. Drill with - - - 0-55 0-55 0-55

spare power pack and

carbide bits (1)

Butane - - - 0-55 0-55 0-55

Torch (1)

Rope (1) - - - 0-55 0-55 0-55

TABLE 2 Forced Entry Resistant Ratings

Resistance Time (minute)

Active Test

Threat Level Rating

Personnel

Structured Test Discretionary Test Cumulative

Low (L) 2 Less than 5 0 Less than 5 L0 to L4.9

5 Less than 5 Less than 10 L5 to L9.9

5 5 to 9.9 Less than 15 L10 to L14.9

5 10 to 14.9 Less than 20 L15 to L19.9

5 20 to 25 30 L20 to L30

5 31 to 55 60 L31 to L60

Medium (M) 2 Less than 5 0 Less than 5 M0 to M4.9

5 Less than 5 Less than 10 M5 to M9.9

5 5 to 9.9 Less than 15 M10 to M14.9

5 10 to 14.9 Less than 20 M15 to M19.9

5 20 to 25 30 M20 to M30

5 31 to 55 60 M31 to M60

Aggressive (A) 4 Less than 5 0 Less than 5 A0 to A4.9

5 Less than 5 Less than 10 A5 to A9.9

5 5 to 9.9 Less than 15 A10 to A14.9

5 10 to 14.9 Less than 15 A15 to A19.9

5 20 to 25 30 A20 to A30

5 31 to 55 60 M31 to A60

4.3 The test requirements specified herein have been estab- 4.3.2 Absolute penetration resistance from forced entry by a

lished for use in evaluating the penetration resistance charac- determined and well-equipped attack group is impossible.

teristics of standard fence systems to be used in commercial, 4.3.3 Aggressor groups range from unsophisticated crimi-

government and military installations. nals and vandals to organized criminals.

4.3.1 The success of any forced entry threat is dependent on 4.3.4 Attempts to force an entry may be thwarted by

the cumulative effect of the implements used, the elapsed time, increasing the time necessary to affect such an entry and by

andthesophisticationandmotivationofthepersonnelaffecting early detection. Intrusion sensors positioned as far as possible

the forced entry. from the protected environment in conjunction with optimal

F2781 – 09

structural and component design will maximize the time 7. Preparation of Apparatus

available for a response force to intercept the intruders.

7.1 Tools, Devices and Materials:

4.4 The procedures of this test method are intended to

7.1.1 Analysis of many of the aggressive actions against

evaluate the time necessary for vandals and unsophisticated

installations that have resulted in forced entry has produced an

criminals to forcefully penetrate security fence systems by

extensive list of tools and implements that are readily acces-

using manually operated tools—defined as a low, medium, or

sible to aggressor groups. From this comprehensive listing,

aggressive forced entry threat.

tools and devices have been categorized as to the likelihood of

their use and forced entry threat severity.While infinite in type,

5. Documentation of Test Materials

size, and construction, all can be categorized with respect to

5.1 Configuration Documentation—All materials and as- their principal effect and function—prying, screwing, pulling,

shearing, cutting, and impacting. Additionally, certain tools

semblies to be tested shall conform to and be in compliance

with the latest revision of the appropriate publication or have been identified as those which are not actually tools, but

which have a debilitating effect on protective barriers and are

specification governing the fence system configuration. The

following documents shall apply: readily available (that is, ropes, and so forth).While no attempt

will be made to completely list all the tools and implements

5.1.1 Standard Commercial Materials—Commercial mate-

which can be utilized to effect forced entry, Table 1 presents

rials used in fabricating security fence systems will conform to

those tools and implements which have been determined to be

the configuration and performance standards established for

that material by ASTM International. readily available and representative of the most effective of

forced entry tools for the very low, low, medium, and high

5.1.2 Non-Standard Materials—All materials and sub-

threat severity categories, respectively.

assemblies used in the fabrication of forced entry barriers

7.1.2 All tools proposed for use in this test are to be clean

whose nature and configuration are not otherwise controlled by

and verified for proper operation prior to commencement with

recognized industrial, government, or manufacturer’s specifi-

the test.

cations will be accompanied by full disclosure drawings and

7.2 Low Threat Severity Category Tools:

specifications.

7.2.1 Adhesive Tape.

5.1.2.1 Component Material Details—Specific industrial

7.2.2 Fishing Line.

specifications, including size, thickness composition, etc.

5.1.2.2 Make, model number, serial numbers, and date of 7.2.3 Grappling Hook.

7.2.4 Knife, 5 in.

manufacture (as appropriate).

7.2.5 Standard and Self-Gripping Pliers, 8 in.

5.1.2.3 Construction instructions, including weldments,

bolting, bonding materials, etc. 7.2.6 Multiple Slip Pliers,10in.

7.2.7 Pipe Wrench,10in.

5.1.3 Proprietary Information—None of the requirements

of 5.1.1 through 5.1.2.3 are intended to compromise or 7.2.8 Pipe, 1.660 in. O.D. by 12 ft.

circumvent a manufacturer’s proprietary rights with respect to 7.2.9 Plate Shears, 8 in.

any feature, configuration, material, or design. Those portions 7.2.10 Screwdrivers, 7 in., 10 in., and 16 in. long.

of the design disclosure documentation considered proprietary 7.2.11 Crowbar, 5 lb, 28 in.

would be clearly marked or eliminated from the disclosure

7.2.12 Cold Chisels, 10 in. long by 1 in. wide.

documentation with an appropriate explanation. All submitted 7.2.13 Drill, cordless, ⁄2 in., spare power pack, and carbide

documentation, however, would accurately represent the

drill bits.

sample tested.

7.2.14 Butane Torch.

7.2.15 Hacksaw, two HSS blades.

6. Sampling, Test Specimens, and Test Units

7.2.16 Sledgehammer, 16 in., 6 lb.

7.2.17 Rope, 20-ft length of ⁄2-in. diameter manila rope,

6.1 Sample Size—In order to facilitate test standardization

(4-lb).

all test samples will conform to the sizes specified in 6.1.1.

7.2.18 Fireman’s Axe, 36 in., 6 lb.

6.1.1 A minimum lateral area of 96 in. high and 30 ft in

7.2.19 Pipe Cutter, 4 in. O.D.

length. The requirements of this section and the procedures of

7.2.20 Bolt Cutter.12in.

the test method are intended to minimize test costs by

7.2.21 Fence Pliers,10in.

conducting as much testing on single test segments, if possible.

7.2.22 Cable Ratchet, 2000 lb capacity.

6.1.2 Test Environment—The location of the test shall be in

7.3 Medium Threat Severity Category Additional Tools:

a natural environment where the temperature minimum is not

7.3.1 Bolt Cutter,20in.

less than 40°F and the maximum is 95°F during the perfor-

7.3.2 Disc Grinder, 12 V with spare power pack and three

mance of the test. All tested materials and tools will be

cutting discs.

temperature conditioned in this environment for a minimum of

7.3.3 Drill Bits, 5.5 in., carbide.

24 h immediately prior to initiation of any test. The area

7.3.4 Axe, 36 in., 6 lb.

immediately adjacent to the test sample extending 6 ft to the

7.3.5 Hole Saw, 2 in.

left and right of either vertical edge of the sample, 10 ft from

the assault face of the sample, and 10 ft above the horizontal 7.3.6 Steel Pry Bar.

7.3.7 Jigsaw, cordless, 12 V, and three carbide blades.

surface supporting the test (attack) personnel, shall be free of

any and all obstructions and appurtenances. 7.3.8 Plate Shears,12in.

F2781 – 09

7.3.9 Sledgehammer, 30 in., 12 lb. 10. Testing Guidelines

7.3.10 Pipe, 1.660 in. O.D. by 20-ft long.

10.1 General Test Sequence—All samples submitted for

7.3.11 Steel Wedges, 6-in. long.

testing shall be in compliance with 6.1.1. The forced entry

7.3.12 Circular Saw, cordless, 18 V, 8-in. diameter, and

testing of all samples shall begin with a structured portion of

three blades.

testing as outlined in Tables 1 and 3 and continue through the

7.3.13 Disc Grinder, 18 V with spare power pack and three

discretionary

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.