ASTM G56-10

(Test Method)Standard Test Method for Abrasiveness of Ink-Impregnated Fabric Printer Ribbons and Other Web Materials

Standard Test Method for Abrasiveness of Ink-Impregnated Fabric Printer Ribbons and Other Web Materials

SIGNIFICANCE AND USE

This test method differentiates between web materials on the basis of their ability to cause wear on surfaces with which they come in contact. This test method can also be used to evaluate the wear resistance of different materials against such web materials.

SCOPE

1.1 This test method covers the determination of the abrasiveness of ink-impregnated fabric printer ribbons and other web materials by means of a sliding wear test.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G56 − 10

Standard Test Method for

Abrasiveness of Ink-Impregnated Fabric Printer Ribbons

1

and Other Web Materials

ThisstandardisissuedunderthefixeddesignationG56;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

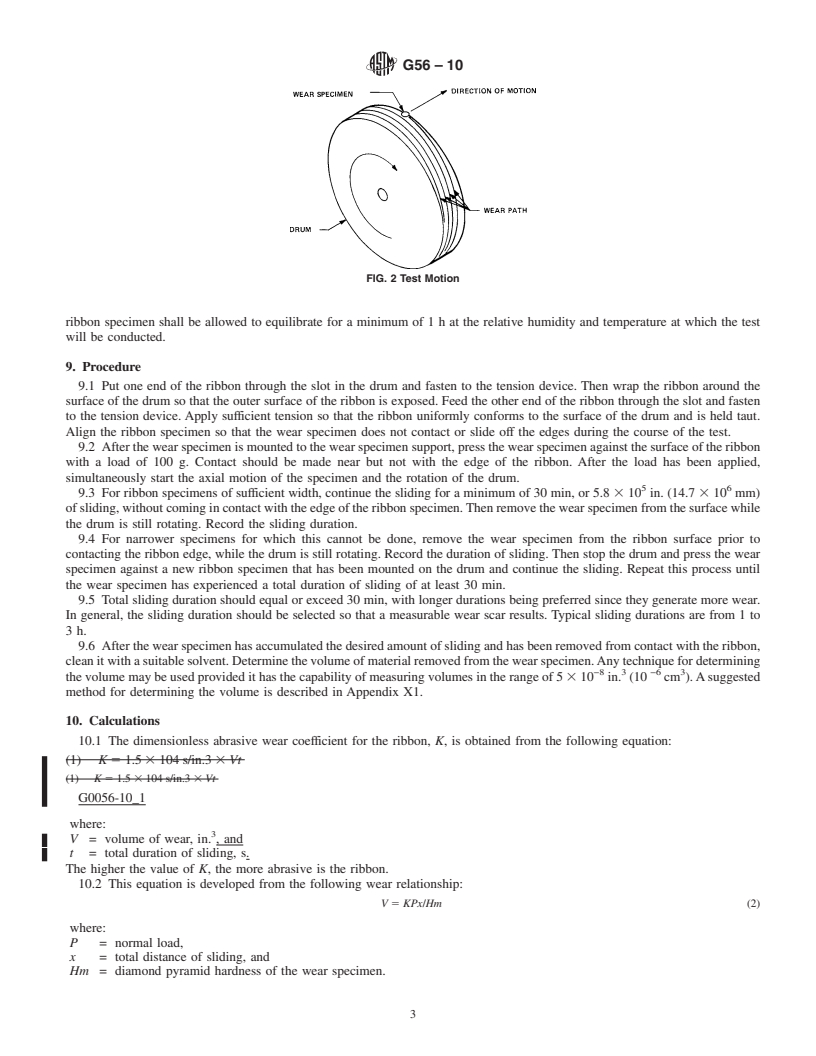

1. Scope the ribbon surface. While the drum rotates about its axis, the

steel sphere is slowly moved in an axial direction across the

1.1 This test method covers the determination of the abra-

surface of the ribbon (Note 1). After a specified amount of

siveness of ink-impregnated fabric printer ribbons and other

sliding has occurred, the test is stopped and the volume of

web materials by means of a sliding wear test.

material removed from the steel sphere is determined. This

1.2 The values stated in inch-pound units are to be regarded

volumeisthenusedtocomputeanabrasivewearcoefficientfor

as standard. The values given in parentheses are mathematical

the ribbon specimen.

conversions to SI units that are provided for information only

NOTE 1—These two motions ensure that the unused ribbon is continu-

and are not considered standard.

ally supplied to the contact area of the wear specimen; however, the

1.3 This standard does not purport to address all of the

contact region usually contains a mixture of unused and used ribbon

safety concerns, if any, associated with its use. It is the surface.

responsibility of the user of this standard to establish appro-

3

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 This test method differentiates between web materials

on the basis of their ability to cause wear on surfaces with

2. Referenced Documents

which they come in contact. This test method can also be used

2

2.1 ASTM Standards: to evaluate the wear resistance of different materials against

G40Terminology Relating to Wear and Erosion

such web materials.

4

3. Terminology

6. Apparatus

3.1 Definitions of Terms Specific to This Standard:

6.1 Ribbon Support Surface—The overall shape of this

3.1.1 abrasive wear coeffıcient (for a ribbon)—ameasureof

member is that of a cylindrical drum 48 6 1 in. (1220 6

the ability of the ribbon to wear surfaces with which it comes

25mm) in diameter, concentric to within 0.0005 in. (0.013

in contact.The larger the value, the greater the ability to cause

mm) total run-out, and 8.25 + 0.25−0in.(210+6−0mm)

wear.The abrasive wear coefficient determined by this method

wide(seeFig.1).Thesupportsurfaceisthecylindricalsurface.

isdirectlyproportionaltothevolumeofmaterialremovedfrom

This surface shall be rigid, made of metal (Note 2), and have

the steel sphere in the test.

a slot no greater than 0.020 in. (0.5 mm) in it so that the ends

of the ribbon may be fed through into the interior. The interior

3.2 For additional terms pertinent to this test method, see

shall contain a mechanism to uniformly provide tension to the

Terminology G40.

ribbon specimen. This member shall be able to rotate about its

4. Summary of Test Method

axis and provide a linear velocity at the surface of the ribbon

of 321 6 6 in./s (8150 6 150 mm/s).

4.1 A ribbon specimen is wrapped around the cylindrical

surface of a drum. A hardened steel sphere is pressed against

NOTE 2—2024 aluminum with a minimum thickness of 0.25 in.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

3

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive Adiscussionofthewearprocessandtheinfluenceofvariousparametersonthe

Wear. wear can be found in Bayer, R. G., “Wear by Paper and Ribbon,” Wear, Vol 49,

Current edition approved April 1, 2010. Published April 2010. Originally 1978, pp. 147–168 and Bayer, R. G., “ Mechanism of Wear by Ribbon and Paper,”

approved in 1977. Last previous edition approved in 2005 as G56–82(2005). DOI: IBM Journal of Research and Development, Vol 22, No. 6, November 1978, pp.

10.1520/G0056-10. 668–674.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Supporting data (implementation of the apparatus required is discussed in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM “Testing Machine for the Evaluation of Wear by Paper,”) have been filed atASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters and may be obtained by requesting Research Report

the ASTM website. RR:G02-1000.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G56−10

may be used, with similar dimensional and

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:G56–82 (Reapproved 2005) Designation:G56–10

Standard Test Method for

Abrasiveness of Ink-Impregnated Fabric Printer

RibbonsAbrasiveness of Ink-Impregnated Fabric Printer

1

Ribbons and Other Web Materials

ThisstandardisissuedunderthefixeddesignationG56;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the abrasiveness of ink-impregnated fabric printer ribbons and other web

materials by means of a sliding wear test.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

G40 Terminology Relating to Wear and Erosion

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 abrasive wear coeffıcient (for a ribbon)—a measure of the ability of the ribbon to wear surfaces with which it comes in

contact. The larger the value, the greater the ability to cause wear. The abrasive wear coefficient determined by this method is

directly proportional to the volume of material removed from the steel sphere in the test.

3.2 For additional terms pertinent to this test method, see Terminology G40.

4. Summary of Test Method

4.1 Aribbonspecimeniswrappedaroundthecylindricalsurfaceofadrum.Ahardenedsteelsphereispressedagainsttheribbon

surface.Whilethedrumrotatesaboutitsaxis,thesteelsphereisslowlymovedinanaxialdirectionacrossthesurfaceoftheribbon

(Note 1).After a specified amount of sliding has occurred, the test is stopped and the volume of material removed from the steel

sphere is determined. This volume is then used to compute an abrasive wear coefficient for the ribbon specimen.

NOTE 1—Thesetwomotionsensurethattheunusedribboniscontinuallysuppliedtothecontactareaofthewearspecimen;however,thecontactregion

usually contains a mixture of unused and used ribbon surface.

5. Significance and Use

5.1This test method differentiates between ribbons on the basis of their ability to cause wear on surfaces with which they come

3

in contact.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeG02onErosionWearandWear,ErosionandisthedirectresponsibilityofSubcommitteeG02.30onWear.

´1

Current edition approved Nov. 1, 2005. Published November 2005. Originally approved in 1977. Last previous edition approved in 2000 as G56–82(2000) . DOI:

10.1520/G0056-82R05.on Abrasive Wear.

Current edition approved April 1, 2010. Published April 2010. Originally approved in 1977. Last previous edition approved in 2005 as G56–82(2005). DOI:

10.1520/G0056-10.

2

Adiscussion of the wear process and the influence of various parameters on the wear can be found in Bayer, R. G., “Wear by Paper and Ribbon” Wear, Vol 49, 1978,

pp. 147–168 and Bayer, R. G., “ Mechanism of Wear by Ribbon and Paper,” IBM Journal of Research and Development, Vol 22, No. 6, November 1978, pp. 668–674

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

An implementation of the apparatus required is discussed in “Testing Machine for the Evaluation of Wear by Paper,” available from ASTM Headquarters as

RR:G02-1000.

3

Adiscussion of the wear process and the influence of various parameters on the wear can be found in Bayer, R. G., “Wear by Paper and Ribbon,” Wear, Vol 49, 1978,

pp. 147–168 and Bayer, R. G., “ Mechanism of Wear by Ribbon and Paper,” IBM Journal of Research and Development, Vol 22, No. 6, November 1978, pp. 668–674.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G56–10

5.1 Thistestmethoddifferentiatesbetweenwebmaterialsonthebasisoftheirabilitytocausewearonsurfaceswithwhichthey

comeincontact.Thistestmethodcanalsobeusedtoevaluatethewearresistanceofdifferentmaterialsagainst

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.