ASTM D7196-16

(Test Method)Standard Test Method for Raveling Test of Cold Mixed Emulsified Asphalt Samples

Standard Test Method for Raveling Test of Cold Mixed Emulsified Asphalt Samples

SIGNIFICANCE AND USE

4.1 This test is useful for classifying the curing and formulation of cold mixed emulsified asphalt samples through ravel testing of compacted specimens. This performance test should be used to rank the mix conditions and approximate curing time for return to traffic and resistance to weather damage.

SCOPE

1.1 This test method measures the resistance to raveling characteristics of emulsified asphalt and field aggregates or Recycled Asphalt Pavement (RAP) mixtures by simulating an abrasion similar to early return to traffic.

1.2 A precision and bias statement for this standard has not been developed at this time. Therefore, this standard should not be used for acceptance or rejection of a material for purchasing purposes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7196 −16

Standard Test Method for

1

Raveling Test of Cold Mixed Emulsified Asphalt Samples

This standard is issued under the fixed designation D7196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of the Superpave Gyratory Compactor

2.2 ISSA Document:

1.1 This test method measures the resistance to raveling

ISSATechnical Bulletin No. 100 Test Method for Wet Track

characteristics of emulsified asphalt and field aggregates or

Abrasion of Slurry Surfaces

Recycled Asphalt Pavement (RAP) mixtures by simulating an

abrasion similar to early return to traffic.

3. Summary of Test Method

1.2 A precision and bias statement for this standard has not

3.1 An aggregate or RAP, or both, is mixed together with a

beendevelopedatthistime.Therefore,thisstandardshouldnot

preset amount of additives (if shown to be necessary), water (if

be used for acceptance or rejection of a material for purchasing

necessary) and emulsified asphalt. This may be a field blended

purposes.

mixture (Method A) or a laboratory blended mixture (Method

1.3 The values stated in SI units are to be regarded as

B). The mixture is compacted in a gyratory compactor and

standard. No other units of measurement are included in this

cured at the specified conditions for a designated period of

standard.

time. After the assigned curing time, a rotating rubber hose

1.4 This standard does not purport to address all of the exerts an abrasion force on the specimen for a preset time

safety concerns, if any, associated with its use. It is the period and the abraded loss of material is calculated.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4.1 This test is useful for classifying the curing and formu-

lation of cold mixed emulsified asphalt samples through ravel

2. Referenced Documents

testing of compacted specimens. This performance test should

2

2.1 ASTM Standards:

be used to rank the mix conditions and approximate curing

D75 Practice for Sampling Aggregates time for return to traffic and resistance to weather damage.

D977 Specification for Emulsified Asphalt

5. Apparatus

D979 Practice for Sampling Bituminous Paving Mixtures

D2397 Specification for Cationic Emulsified Asphalt 1

5.1 Hobart Mixer—The ⁄3 H.P. Fixed Speed Motor, model

D3910 Practices for Design, Testing, and Construction of

A 120 will be used to abrade the sample.

Slurry Seal

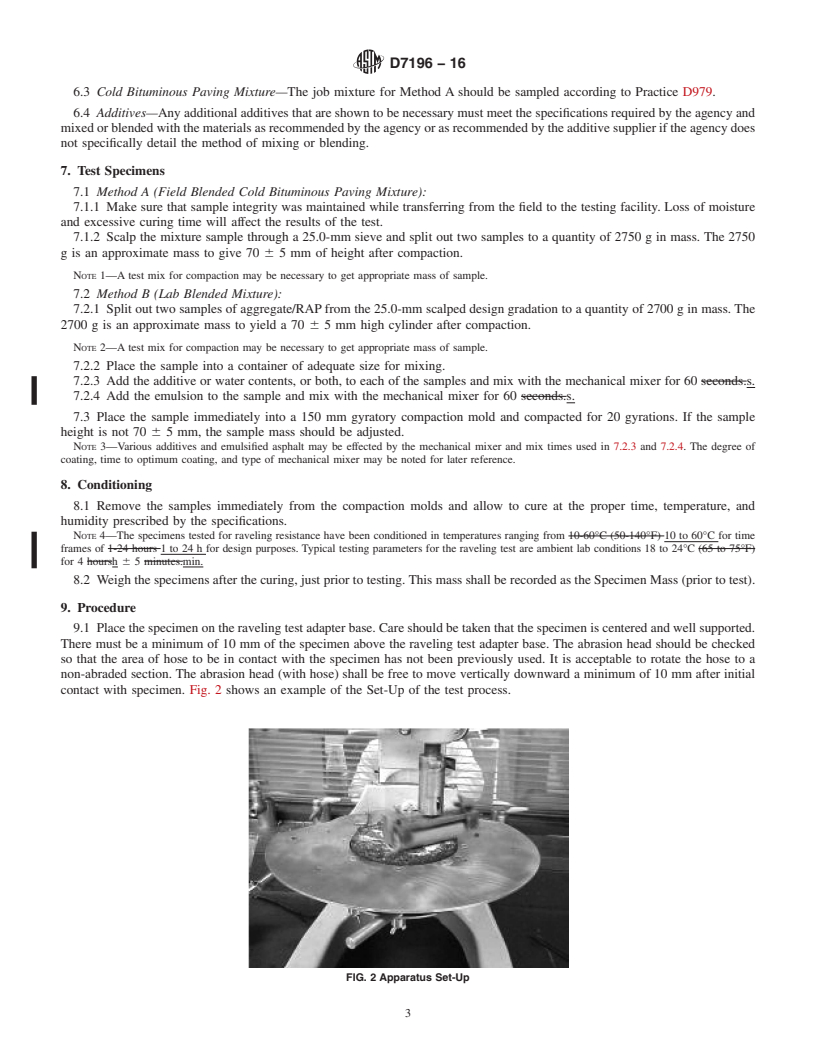

5.2 Raveling Test Adapter Base—This base must fit the

D4753 Guide for Evaluating, Selecting, and Specifying Bal-

Hobart mixer in 5.1 and be an adequate and level support for

ances and Standard Masses for Use in Soil, Rock, and

clamping the test specimen in place. The test specimen should

Construction Materials Testing

not move during abrasion.Apicture of the base can be seen in

D6372 Practice for Design, Testing, and Construction of

3

Fig. 1.

Microsurfacing

5.3 Raveling Test Abrasion Head with Hose—The abrasion

D6925 Test Method for Preparation and Determination of

head should be free floating over the sample and have a mass

the Relative Density ofAsphalt Mix Specimens by Means

of 600 6 15 g. This mass shall include the rubber hose. The

rubber hose shall be a Parker 290 Ozex General Purpose Hose

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

or equivalent. The hose shall be 19 mm ID by 6.25 mm wall

and Paving Materials and is the direct responsibility of Subcommittee D04.27 on

thickness and cut to 127 mm in length. The rubber hose shall

Cold Mix Asphalts.

Current edition approved Oct. 1, 2016. Published October 2016. Originally

approved in 2006. Last previous edition approved in 2012 as D7196 – 12. DOI:

3

10.1520/D7196-16. The sole source of supply of the Raveling Test Adapter Base known to the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or committee at this time is Precision Machine andWelding, Salina, Kansas. If you are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM aware of alternative suppliers, please provide this information to ASTM Interna-

Standards volume information, refer to the standard’s Document Summary page on tional Headquarters.Your comments will receive careful consideration at a meeting

1

the ASTM website. of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7196−16

6.2 Aggregates/RAP

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7196 − 12 D7196 − 16

Standard Test Method for

1

Raveling Test of Cold Mixed Emulsified Asphalt Samples

This standard is issued under the fixed designation D7196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method measures the resistance to raveling characteristics of emulsified asphalt and field aggregates or Recycled

Asphalt Pavement (RAP) mixtures by simulating an abrasion similar to early return to traffic.

1.2 The values stated in SI units are to be regarded as the standard unless otherwise indicated.

1.2 A precision and bias statement for this standard has not been developed at this time. Therefore, this standard should not be

used for acceptance or rejection of a material for purchasing purposes.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D75 Practice for Sampling Aggregates

D977 Specification for Emulsified Asphalt

D979 Practice for Sampling Bituminous Paving Mixtures

D2379D2397 Test Method for Acidity of Formaldehyde SolutionsSpecification for Cationic Emulsified Asphalt

D3910 Practices for Design, Testing, and Construction of Slurry Seal

D4753 Guide for Evaluating, Selecting, and Specifying Balances and Standard Masses for Use in Soil, Rock, and Construction

Materials Testing

D6372 Practice for Design, Testing, and Construction of Microsurfacing

D6925 Test Method for Preparation and Determination of the Relative Density of Asphalt Mix Specimens by Means of the

Superpave Gyratory Compactor

2.2 ISSA Document:

ISSA Technical Bulletin No. 100 Test Method for Wet Track Abrasion of Slurry Surfaces

3. Summary of Test Method

3.1 An aggregate and/or RAP or RAP, or both, is mixed together with a preset amount of additives (if shown to be necessary),

water (if necessary) and emulsified asphalt. This may be a field blended mixture (Method A) or a laboratory blended mixture

(Method B). The mixture is compacted in a gyratory compactor and cured at the specified conditions for a designated period of

time. After the assigned curing time, a rotating rubber hose exerts an abrasion force on the specimen for a preset time period and

the abraded loss of material is calculated.

4. Significance and Use

4.1 This test is useful for classifying the curing and formulation of cold mixed emulsified asphalt samples through ravel testing

of compacted specimens. This performance test should be used to rank the mix conditions and approximate curing time for return

to traffic and resistance to weather damage.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.27 on Cold Mix

Asphalts.

Current edition approved Dec. 1, 2012Oct. 1, 2016. Published December 2012October 2016. Originally approved in 2006. Last previous edition published 2006 approved

in 2012 as D7196D7196 – 12.–06. DOI: 10.1520/D7196-12.10.1520/D7196-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7196 − 16

5. Apparatus

1

5.1 Hobart Mixer—The ⁄3 H.P. Fixed Speed Motor, model A 120 will be used to abrade the sample.

5.2 Raveling Test Adapter Base—This base must fit the Hobart mixer in 5.1 and be an adequate and level support for clamping

3

the test specimen in place. The test specimen should not move during abrasion. A picture of the base can be seen in Fig. 1.

NOTE 1—A Raveling Test Adapter Base meeting the requirements can be purchased from Precision Machine and Welding, Salina, Kansas, (785)

823-8760.

5.3 Raveling Test Abrasion Head with Hose—The abrasion head should be free floating o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.