ASTM D2096-00

(Test Method)Standard Test Method for Colorfastness and Transfer of Color in the Washing of Leather

Standard Test Method for Colorfastness and Transfer of Color in the Washing of Leather

SCOPE

1.1 This test method covers the determination of the colorfastness of colored leathers, with or without a surface coating. The leathers to be tested are of the type normally expected to withstand frequent laundering. This test method also covers the simultaneous staining of adjacent textile materials when the leather specimens are washed. This test method does not apply to wet blue. Two procedures are covered depending on the apparatus used:

1.1.1 Procedure A , using the Launder-Ometer and

1.1.2 Procedure B , using an alternative washing machine.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2096–00

Standard Test Method for

Colorfastness and Transfer of Color in the Washing of

Leather

This standard is issued under the fixed designation D 2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the determination of the color- 3.1 Three leather specimens 50 by 80 mm (approximately 2

fastness of colored leathers, with or without a surface coating. by 3 in.), and one piece of multifiber test fabric of nearly equal

The leathers to be tested are of the type normally expected to size are washed together in soapy water at 120°F (49°C).After

withstandfrequentlaundering.Thistestmethodalsocoversthe ⁄2 h of washing, the leather specimens and cloth are removed

simultaneous staining of adjacent textile materials when the and rinsed carefully in running water at about 95°F (35°C).

leather specimens are washed. This test method does not apply One leather specimen and the test cloth are removed and

to wet blue. Two procedures are covered depending on the air-dried. A new piece of test cloth is added to the remaining

apparatus used: two leather specimens and these are washed, as above, for ⁄2h.

1.1.1 Procedure A, using the Launder-Ometer, and The rinsing is repeated; again one leather specimen and the test

1.1.2 Procedure B, using an alternative washing machine. cloth are removed for drying. The remaining leather specimen,

1.2 The values stated in inch-pound units are to be regarded with a new piece of test cloth, is washed again for ⁄2h. This

as the standard. The values stated in parentheses are provided final leather specimen and test cloth are then rinsed and dried

for information only. as above. When dry, the color of the washed leather specimens

1.3 This standard does not purport to address all of the is rated by comparing it with an unwashed piece of leather.

safety concerns, if any, associated with its use. It is the Transfer of color to the test fabric is rated by comparison with

responsibility of the user of this standard to establish appro- an unwashed piece of test fabric. These comparisons are made

priate safety and health practices and determine the applica- with the aid of the proper Gray Scale. All ratings are made on

bility of regulatory limitations prior to use. dry test specimens.

2. Referenced Documents 4. Significance and Use

2.1 ASTM Standards: 4.1 The procedure is intended, primarily to evaluate the

D 499 Specification for White Floating Toilet Soap ability of a leather specimen to withstand fixed, and rather

2.2 ISO Standard: strenuous, laundering conditions. This test is not intended as a

ISO R105/I, Part 2 Gray Scale for Evaluating Change in recommended washing procedure, neither household nor com-

Color mercial. Although this test concerns itself with colorfastness

ISO R105/I, Part 3 Gray Scale for Evaluating Staining and transfer of color during washing, the washed leather

specimens are available also for comparing other properties

(that is, tensile strength, area change, change in outline, etc.)

This test method is under the jurisdiction ofASTM Committee D31 on Leather with those of unwashed samples.

and is the direct responsibility of Subcommittee D31.04 onApparel and Upholstery.

This test method was developed in cooperation with theAmerican Leather Chemists

5. Apparatus

Assn.

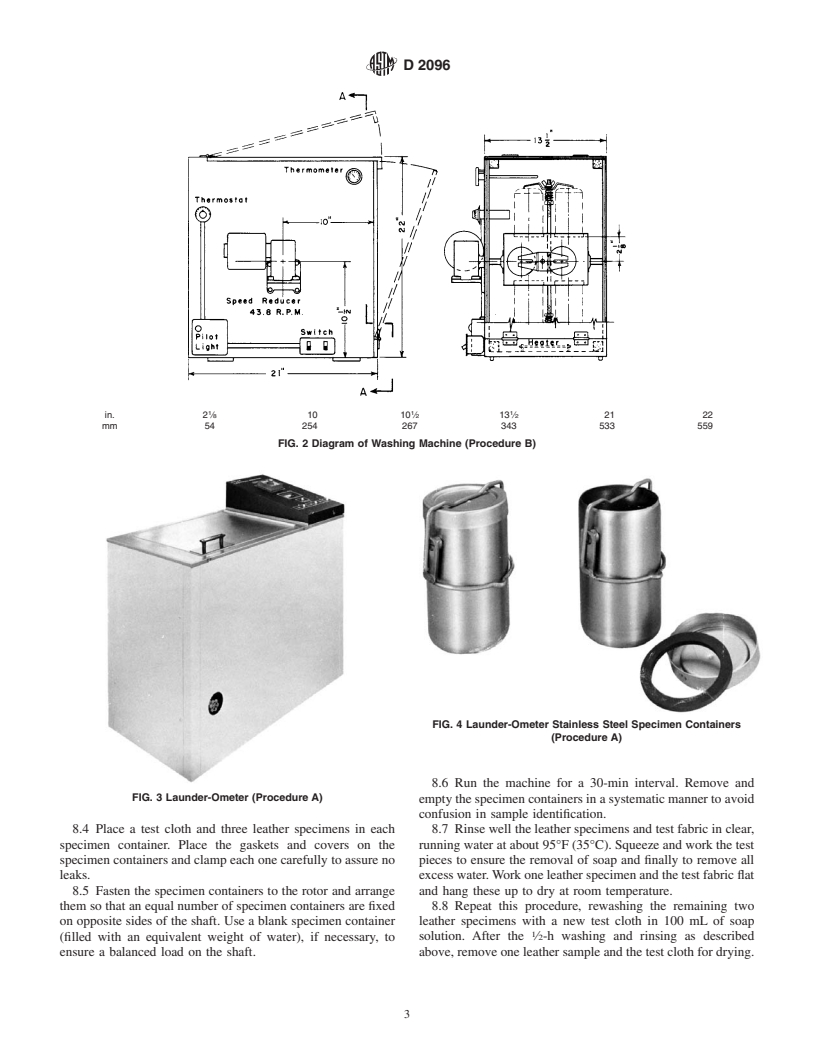

5.1 Washing Machine—A Launder-Ometer, or an assembly

Current edition approved Sept. 10, 2000. Published October 2000. Originally

e1

published as D 2096 – 62T. Last previous edition D 2096 – 93 (1998) .

of apparatus capable of similar test conditions (Note 1). In

The Launder-Ometer and its development are described in the American

either machine, 1-pt (500-mL) specimen containers are held

DyestuffReporter, Oct. 29, 1928, p. 679. It is described also in the currentTechnical

with their bases toward a horizontal shaft and 2-in. (50 mm)

Manual of the American Association of Textile Chemists and Colorists. The

out from its center of rotation. Speed of rotation shall be 40 to

Launder-Ometer is manufactured by Atlas Electric Devices Co., 4114 N. Raven-

swood Ave., Chicago, IL 60613; telephone: (773) 327-4520; fax: (773) 327-5787.

45 rpm. Provision shall be made for maintaining the initial

Such an apparatus is illustrated in Figs. 3, 4, and 5.

temperature of the specimen containers throughout the test.

Annual Book of ASTM Standards, Vol 15.04.

4 Additional agitation shall be provided by ⁄4-in. (6.4 mm)

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036; telephone: (212) 642-4900; fax: (212) 302-1286. stainless steel balls in the specimen containers.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2096

FIG. 1 Washing Machine, Heated Air Bath (Procedure B)

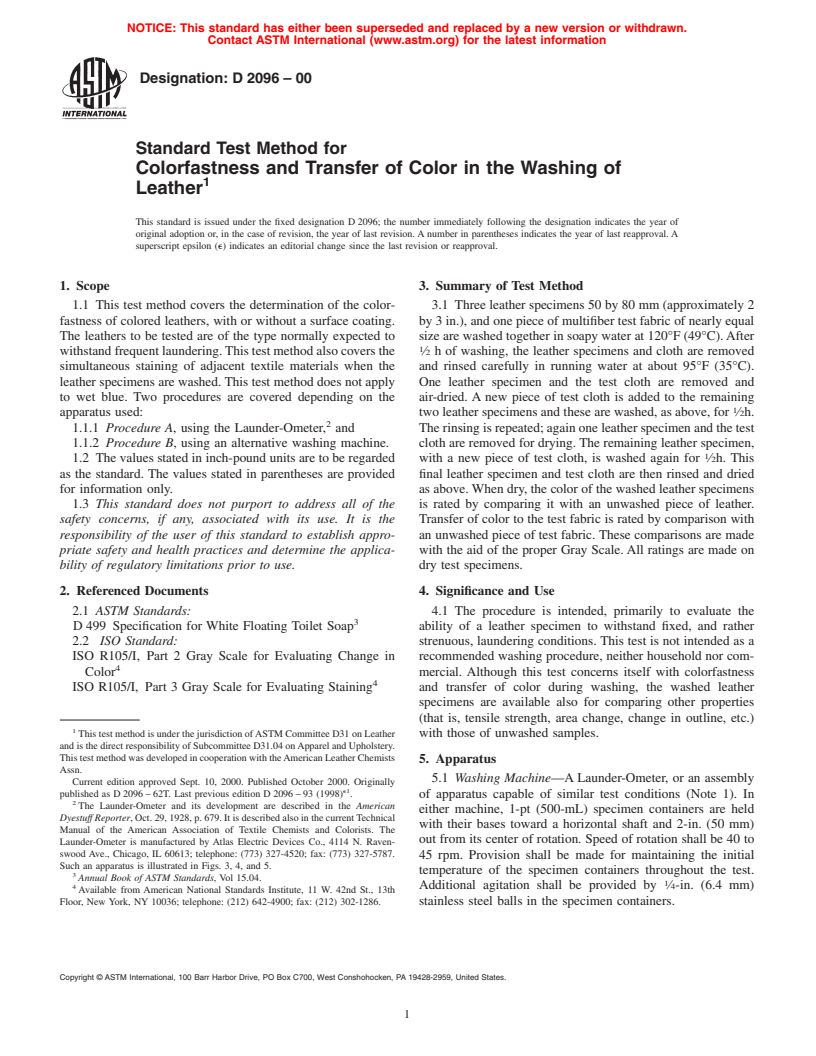

NOTE 1—A motor-driven assembly, designed to hold 1-pt (500-mL)

5.5.1 ISO R105/I, Part 2, British, for assessing the effect in

specimen containers so that they are relative to the axis of the motor shaft

fastness testing, and

in the same way as in the Launder-Ometer, can be used. The entire

5.5.2 ISO R105/I, Part 3, British, for determining the degree

assembly, fitted with specimen containers, shall be turned at 40 to 45 rpm

of staining in fastness testing.

inside a simple boxlike container which is heated at 120°F (49°C) with

thermostatic control. Thus, heat loss from the preheated contents of the

specimen containers is held at a minimum during the 30-min washing 6. Reagent

periods. Such an apparatus is illustrated in Figs. 1 and 2.

6.1 Mild Soap Solution, 0.5 %, such as made from a white,

5.2 Specimen Containers, glass or stainless steel, 1-pt (500-

floating,toiletsoap(SpecificationD 499).Thesolutionshallbe

mL), washer, and cap.

made with distilled water; 300 mL are required for a complete

5.3 Balls, type 316 stainless steel, ⁄4-in. (6.4-mm) diameter,

three-wash test for each specimen container.

20 per specimen container.

5.4 Test Cloth, multifiber, 50 by 80 mm, three pieces per

7. Test Specimen

test.

7.1 The specimen shall be a piece of leather 2 by 3 in.

NOTE 2—Multifibertestfabricsareavailablein6-fibercloth,containing

(approximately 50 by 80 mm). Three specimens are required

7 7

filling strips of wool, Orlon, Dacron, nylon-66, bleached cotton, and

for each complete wash test. A fourth piece, unwashed, is

acetate, assembled in 2-in. (50-mm) repeats. Tests may be run with any

required for purposes of comparison.

test fabric of special interest and reported accordingly.

5.5 Gray Scales, consisting of the following:

8. Procedure A—Using Launder-Ometer

8.1 Adjust the Launder-Ometer to maintain the temperature

at 120°F (49°C).

Detailed drawings for such an apparatus are available at a nominal cost from

the ASTM Headquarters, 100 Barr Harbor Drive, W. Conshohocken, PA 19428-

8.2 Preheat the soap solution to 120°F (49°C) and add 150

2959. Request Adjunct ADJD2096.

mL to each specimen container.

The sole source of supply of the test cloth known to the committee at this time

is Testfabrics, Inc., 200 Blackford Ave., P.O. Box 420, Middlesex, NJ 08846-0420; 8.3 Add twenty stainless steel balls to each specimen

telephone: (201) 469-6446; fa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.