ASTM D5671-95(2001)

(Practice)Standard Practice for Polishing and Etching Coal Samples for Microscopical Analysis by Reflected Light

Standard Practice for Polishing and Etching Coal Samples for Microscopical Analysis by Reflected Light

SCOPE

1.1 This practice covers laboratory procedures for preparing an etched, polished surface of granular and block samples of coal for examination with a microscope using reflected light illumination.

1.2 The values stated in SI units shall be considered as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5671 – 95 (Reapproved 2001)

Standard Practice for

Polishing and Etching Coal Samples for Microscopical

1

Analysis by Reflected Light

This standard is issued under the fixed designation D 5671; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Practice D 2797 or a block of coal obtained in accordance with

Practice D 5192 is polished to a flat, scratch-free surface, the

1.1 This practice covers laboratory procedures for preparing

reflectance of vitrinite is determined on a subsplit in accor-

an etched, polished surface of granular and block samples of

dance with Test Method D 2798, and then other subsplits are

coal for examination with a microscope using reflected light

chemically etched using an acidified potassium permanganate

illumination.

solution.

1.2 The values stated in SI units shall be considered as

standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

5.1 Components observable in surfaces of coal samples

safety concerns, if any, associated with its use. It is the

prepared in accordance with the laboratory procedures of this

responsibility of the user of this standard to establish appro-

practice will have differential relief that will aid in their

priate safety and health practices and determine the applica-

maceral identification by visual classification and enables

bility of regulatory limitations prior to use.

identification of plant parts or tissues that formed the coal.

2. Referenced Documents 5.2 Samples prepared by this practice can be used for

microscopical determination of the volume percent of physical

2.1 ASTM Standards:

2

components of coal in accordance with Test Method D 2799.

D 121 Terminology of Coal and Coke

D 2797 Practice for Preparing Coal Samples for Micro-

6. Apparatus

2

scopical Analysis by Reflected Light

6.1 Ultrasonic Cleaner—large enough for sample holder

D 2798 Test Method for Microscopical Determination of

and sample preparations to be immersed in cleaning solution.

the Reflectance of the Vitrinite in a Polished Specimen of

2 6.2 Beakers—glass beakers, 50, 100, and 500 ml capacity,

Coal

one each for each etching setup.

D 2799 Test Method for Microscopical Determination of

2 6.3 Stirring Rods—glass, approximately 20 cm long.

Volume Percent of Physical Components of Coal

6.4 Hot Plate—electric or gas-heated with capability for

D 4596 Practice for Collection of Channel Samples of Coal

2 temperature control and rotating stirring magnets.

in a Mine

2 6.5 Watch Glasses—glass, 100–200 mm in diameter de-

D 5192 Practice for Collection of Coal Samples from Core

pending on size of specimen blocks to be etched.

3. Terminology 6.6 Graduated Cylinders—glass, 25 and 100 ml.

6.7 Grinding and Polishing Equipment—one or several laps

3.1 Terminology used in this standard can be found in

on which the coal briquets or blocks can be ground and

Terminology D 121.

polished to a flat, scratch-free surface. Laps may be made of

4. Summary of Practice

aluminum, iron, brass, or bronze.

4.1 Asubsplit of a representative sample obtained in accor-

7. Reagents

dance with Practice D 4596 and prepared in accordance with

7.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

1

This practice is under the jurisdiction of ASTM Committee D05 on Coal and

all reagents conform to the specifications of the Committee on

Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic

Analytical Reagents of the American Chemical Society where

Analysis of Coal and Coke.

Current edition approved July 15, 1995. Published September 1995.

2

Annual Book of ASTM Standards, Vol 05.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5671 – 95 (2001)

3

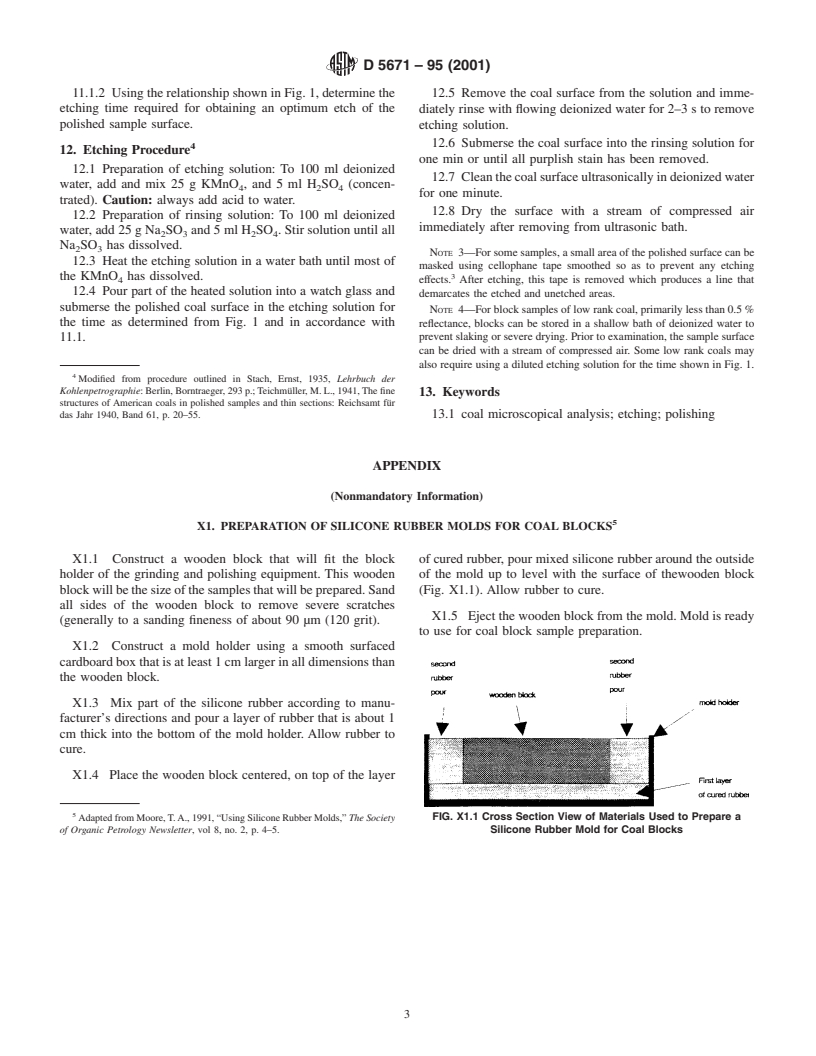

NOTE 1—Molds prepared from silicone rubber as described in Appen-

such specifications are available. Other grades may be used,

dix X1 do not require release agent.

provided it is first ascertained that the reagent is of sufficiently

highpuritytopermititsusewithoutlesseningthequalityofthe

9. Sample Preparation

etch.

9.1 Coal Briquets:

7.2 Potassium Permanganate (KMnO ), crystals.

4

9.1.1 Prepare granular samples as briquets in accordance

7.3 Sodium Sulfite (Na SO ), anhydrous, granular.

2 3

with Practice D 2797.

7.4 Sulfuric Acid (H SO ), 47 % H SO .

2 4 2 4

9.2 Coal Blocks:

7.5 Sodium Hydroxide solution, dissolve 10 g NaOH crys-

9.2.1 Obtain specimens from core or as blocks of coal from

tals in 90 g deionized water at

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.