ASTM B894-99e1

(Specification)Standard Specification for Zinc-Copper-Aluminum Alloy Die Castings

Standard Specification for Zinc-Copper-Aluminum Alloy Die Castings

SCOPE

1.1 This specification covers zinc-copper-aluminum alloy die castings. (UNS Z46541).

1.2 The values stated in inch-pound units are standard. The SI values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: B 894 – 99

Standard Specification for

Zinc-Copper-Aluminum Alloy Die Castings

This standard is issued under the fixed designation B 894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—The caveat in section 1.3 and section 3. Terminology were added editorially in December 2000.

1. Scope E 536 Test Method for Chemical Analysis of Zinc and Zinc

Alloys

1.1 This specification covers zinc-copper-aluminum alloy

E 634 Practice for Sampling of Zinc and Zinc Alloys for

die castings. (UNS Z46541).

Optical Emission Spectrochemical Analysis

1.2 The values stated in inch-pound units are standard. The

2.3 Federal Standards:

SI values in parentheses are for information only.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.3 This standard does not purport to address all of the

2.4 Military Standard:

safety concerns, if any, associated with its use. It is the

MIL-P-116 Methods of Preservation

responsibility of the user of this standard to become familiar

MIL-STD-129 Marking for Shipment and Storage

with all hazards including those identified in the appropriate

2.5 NADCA Standard:

Material Data Sheet for this product/material as provided by

NADCA Product Specification Standards for Die Cast-

the manufacturer, to establish appropriate safety and health

ings

practices, and determine the applicability of regulatory limi-

tations prior to use.

3. Terminology

2. Referenced Documents 3.1 Terms shall be defined in accordance with Terminology

B 899.

2.1 The following documents of the issue in effect on date

3.2 Definitions of Terms Specific to This Standard:

of order acceptable form a part of this specification to the

3.2.1 die casting—a metal object produced by the introduc-

extent referenced herein:

tions of molten metal under pressure into a metal die.

2.2 ASTM Standards:

B 892 Specification for Zinc-Copper-Aluminum Alloys in

4. Ordering Information

Ingot Form for Die Castings

4.1 Orders for die castings shall include the following basic

B 899 Terminology Relating to Non-ferrous Metals and

4 information:

Alloys

4.1.1 This specification number and date,

E 10 Test Method for Brinell Hardness of Metallic Materi-

5 4.1.2 Quantity and delivery schedule, as required,

als

4.1.3 Part name and number,

E 29 Practice for Using Significant Digits in Test Date to

6 4.1.4 Alloy (Table 1), and

Determine Conformance with Specifications

4.1.5 Drawing of die casting, when required, giving all

E 47 Test Methods for Chemical Analysis of Zinc Die

7 necessary dimensions and showing latest revisions and allow-

Casting Alloys

ances for machining, if any. Location of ejector pin marks or

E 88 Practice for Sampling Nonferrous Metals and Alloys

7 parting lines shall be at the option of the producer, unless

in Cast Form for Determination of Chemical Composition

8 specifically designated on the drawing.

E 527 Practice for Numbering Metals and Alloys

4.2 Additional tests, options and special inspection require-

ments as provided below should be justified only on the basis

of need. These shall be specified in the contract or purchase

This specification is under the jurisdiction of ASTM Committee B-2 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.04 on Zinc and Cadmium.

Current edition approved Feb. 10, 1999. Published May 1999.

2 9

See Footnote B in Table 1. Annual Book of ASTM Standards, Vol 03.06.

3 10

Annual Book of ASTM Standards, Vol 02.02. Available from Superintendent of Documents, US Government Printing

Annual Book of ASTM Standards, Vol 02.04. Office, Washington, DC 20402.

5 11

Annual Book of ASTM Standards, Vol 03.01. Available from Standardized Documents Order Desk, Bldg. 4, Section D, 700

Annual Book of ASTM Standards, Vol 14.02. Robbins Ave., Philadelphia, PA 19111-5004, Attn: NPODS.

7 12

Annual Book of ASTM Standards, Vol 03.05. Available from North American Die Casting Association, 9701 West Higgins

Annual Book of ASTM Standards, Vol 01.01. Road, Suite 880, Rosemont, Il 60018–4721, USA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 894

order, as additional procedures and extended delivery time may 6.2.1.1 Unless otherwise specified in the contract, purchase

be involved. order, or part drawing, detailed dimensional conformance shall

4.2.1 Chemical analysis (7.1.1), normally be determined on one or more production samples.

4.2.2 Quality assurance (Section 6), 6.2.2 When specified in the contact, purchase order, or part

4.2.3 Special proof tests or mechanical properties (Section drawing, special inspection lot definitions may be established,

8), for a specific part.

4.2.4 General quality options for internal soundness or for

7. Chemical Requirements

finish (Section 10),

7.1 Limits—The die casting shall conform to the require-

4.2.5 Source inspection (Section 11),

ments as to chemical composition in Table 1. Conformance

4.2.6 Certification (Section 13),

shall be determined by the producer by analyzing samples

4.2.7 Marking for identification (Section 14), and

taken at the time castings are made. If the producer has

4.2.8 Special packaging (Section 15).

determined the chemical composition of the metal during the

5. Materials and Manufacture

course of manufacture, he shall not be required to sample and

5.1 The metal used in the manufacture of die castings shall

analyze the finished product.

be zinc alloy of a specified chemical composition conforming

7.1.1 When a detailed chemical analysis is required with a

to the requirements of Specification B 892.

shipment, is shall be called for in the contract or purchase

5.2 The material covered by this specification shall be of

order.

uniform quality and shall be free of harmful contamination.

7.1.2 If the producer’s or supplier’s method of composition

control is acceptable, sampling for chemical analysis may be

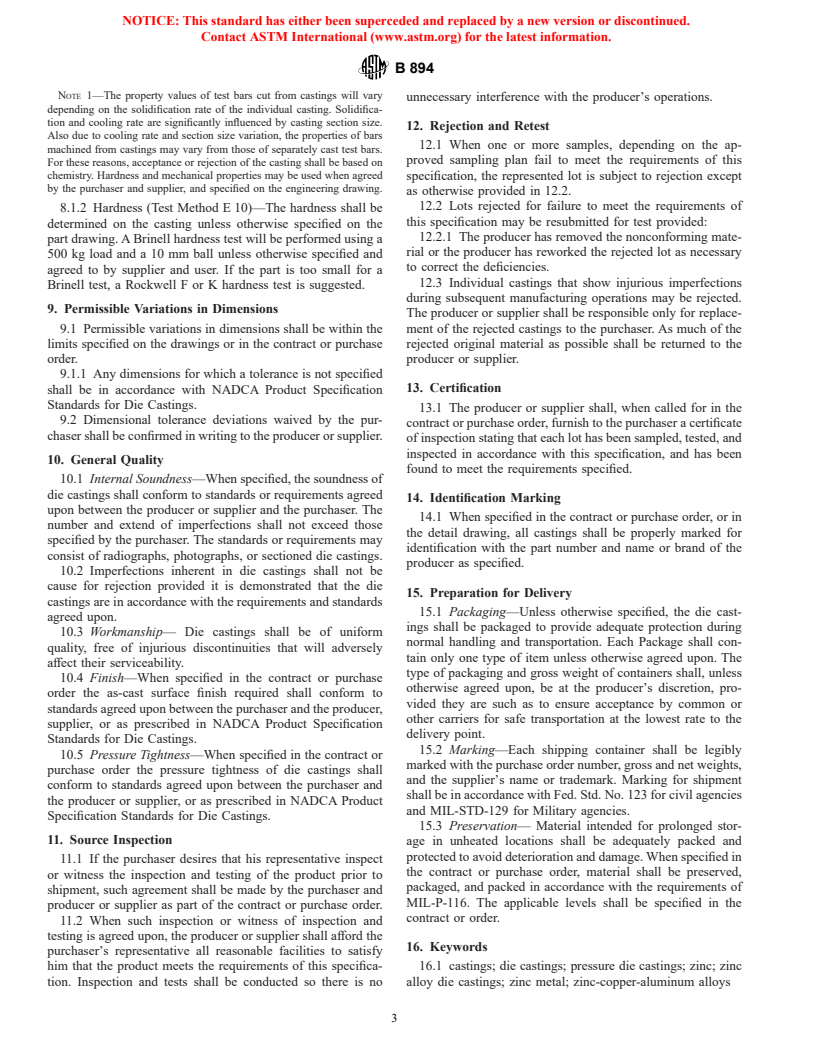

TABLE 1 Chemical Requirements, Composition, Zinc-Copper-

waived at the discretion of the purchaser.

A

Aluminum Die Castings

7.2 Number of Samples—When required, samples for deter-

Composition, %

mination of chemical composition shall be taken to represent

Elements

B

(Z46541)

the following:

Copper 5.0 to 6.0

7.2.1 A sample shall be taken from each of two representa-

Aluminum 2.5 to 3.3

tive castings selected from each lot defined in 6.2.

Magnesium 0.025 - 0.05

7.3 Methods of Sampling—Samples from die castings for

Iron 0.075 max

Lead 0.005 max

determination of chemical composition shall be taken in

Cadmium 0.004 max

accordance with one of the following methods:

Tin 0.003 max

C

7.3.1 Samples for chemical analysis shall be taken from the

Zinc Remainder

material by drilling, sawing, milling, turning or clipping a

A

The following applies to all specified limits in this table: For purposes of

determining conformance with this specification, the observed value or calculated representative piece or pieces to obtain a weight of prepared

value obtained from analysis shall be rounded off to the nearest unit in the last

sample not less than 100 g. Sampling shall be in accordance

right-hand place of figures used in expressing the specified limit, in accordance

with Practice E 88.

with the rounding method of Practice E 29.

B

UNS designations were established in accordance with Practice E 527. 7.3.2 By agreement, an appropriate spectrographic sample

C

Determined arithmetically by difference.

may be prepared at time of manufacture in accordance with

Practice E 634.

6. Quality Assurance

7.3.3 The method of sampling cast products for spectro-

6.1 Responsibility for Inspection—When specified in the

chemical and other methods of analysis shall be suitable for the

contract or purchase order, the producer or supplier is respon-

form of material being analyzed and the type of analytical

sible for the performance of all inspection and test require-

method used.

ments specified herein. Except as otherwise specified in the

7.4 Method of Analysis—The determination of chemical

contract or order, the producer or supplier may use his own or

composition shall be made in accordance with suitable chemi-

any other suitable facilities for the performance of the inspec-

cal (Test Methods E 47 for tin or Test Method E 536), or other

tion and test requirements specified herein, unless disapproved

methods. In case of dispute, the results secured by Test Method

by the purchaser. The purchaser shall have the right to perform

E 536 and Test Method E 47 for tin only, shall be the basis of

any of the inspections and tests set forth in this specification.

acceptance.

Quality assurance standards shall be agreed upon between the

8. Mechanical Properties and Tests

producer or supplier and purchaser at the time a contract or

order is placed. 8.1 Unless specified in the contract or purchase order, or

6.2 For normal inspection purposes, an inspection lot shall specified on the detail drawing, acceptance of die castings

consist of the production from each die during a single under this s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.