ASTM A747/A747M-04

(Specification)Standard Specification for Steel Castings, Stainless, Precipitation Hardening

Standard Specification for Steel Castings, Stainless, Precipitation Hardening

SCOPE

1.1 This specification covers iron-chromium-nickel-copper corrosion-resistant steel castings, capable of being strengthened by precipitation hardening heat treatment.

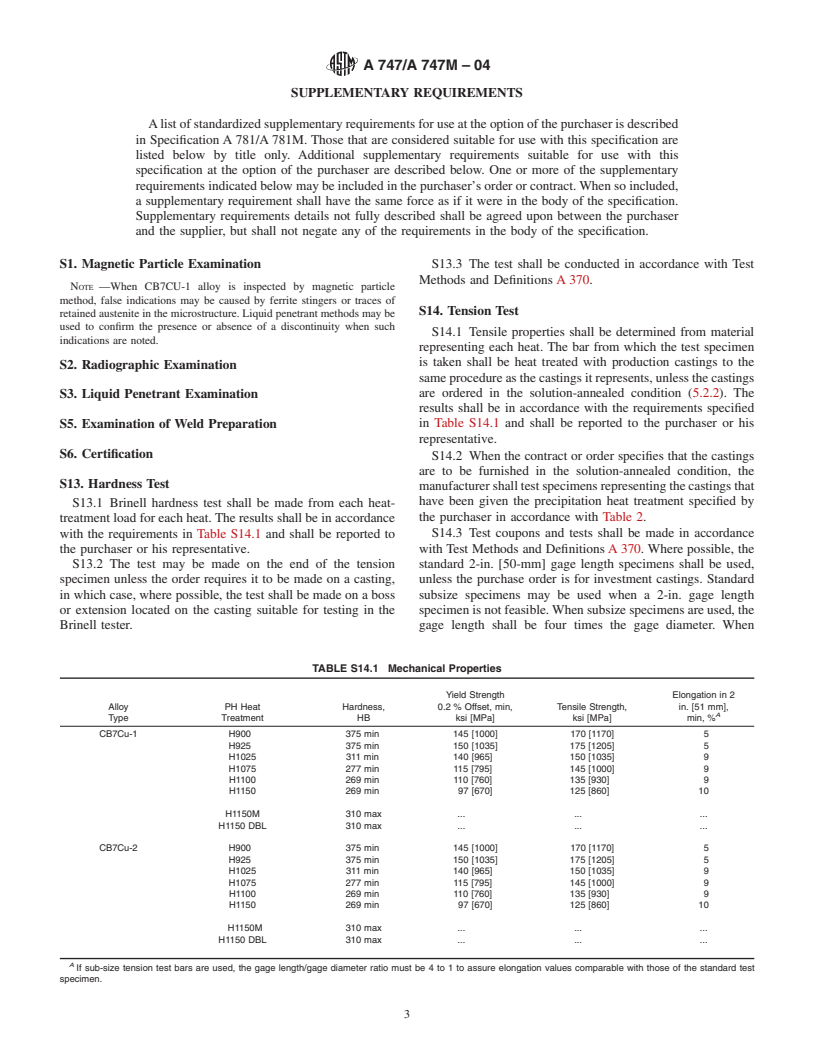

1.2 These castings may be used in services requiring corrosion resistance and high strengths at temperatures up to 600°F [315°C]. They may be machined in the solution-annealed condition and subsequently precipitation hardened to the desired high-strength mechanical properties specified in with little danger of cracking or distortion.

1.3 The material is not intended for use in the solution-annealed condition.

Note 1—If the service environment in which the material is to be used is considered conducive to stress-corrosion cracking, precipitation hardening should be performed at a temperature that will minimize the susceptibility of the material to this type of attack.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 747/A 747M – 04

Standard Specification for

1

Steel Castings, Stainless, Precipitation Hardening

This standard is issued under the fixed designationA 747/A 747M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E38 Methods for Chemical Analysis of Nickel-Chromium

3

and Nickel-Chromium-Iron Alloys

1.1 This specification covers iron-chromium-nickel-copper

E 353 Test Methods for Chemical Analysis of Stainless,

corrosion-resistant steel castings, capable of being strength-

Heat-Resisting, Maraging, and Other Similar Chromium-

ened by precipitation hardening heat treatment.

Nickel-Iron Alloys

1.2 These castings may be used in services requiring corro-

4

2.2 ASME Standard:

sion resistance and high strengths at temperatures up to 600°F

ASME Boiler and Pressure Vessel Code, Supplementary

[315°C]. They may be machined in the solution-annealed

Requirements S6, S14, and S27

condition and subsequently precipitation hardened to the de-

sired high-strength mechanical properties specified in Table

3. General Conditions for Delivery

S14.1 with little danger of cracking or distortion.

3.1 Material furnished to this specification shall be in

1.3 The material is not intended for use in the solution-

accordance with the requirements of Specification A 781/

annealed condition.

A 781M, including any supplementary requirements that are

NOTE 1—If the service environment in which the material is to be used

indicated in the purchase order. Failure to comply with the

is considered conducive to stress-corrosion cracking, precipitation hard-

general requirements of Specification A 781/A 781M consti-

ening should be performed at a temperature that will minimize the

tutes nonconformance with this specification. In case of con-

susceptibility of the material to this type of attack.

flict between the requirements of this specification and Speci-

1.4 The values stated in either inch-pound units or SI units

fication A 781/A 781M, this specification shall prevail.

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each 4. Ordering Information

system are not exact equivalents; therefore, each system must

4.1 Orders for material to this specification should include

be used independently of the other. Combining values from the

the following:

two systems may result in nonconformance with the specifi-

4.1.1 Specification number and grade (Table 1),

cation.

4.1.2 Heat treatment condition (SA, H900, and so forth),

Table 2,

2. Referenced Documents

4.1.3 Drawing or pattern,

2

2.1 ASTM Standards:

4.1.4 Options in the specification, if any, in accordance with

A 370 Test Methods and Definitions for MechanicalTesting

5.2, 6.3, and Section 7, and

of Steel Products

4.1.5 Supplementary requirements, if any, including the

A 732/A 732M Specification for Castings, Investment, Car-

standards of acceptance.

bon and Low Alloy Steel for General Application, and

4.1.6 Notice when the castings are to be used in equipment

Cobalt Alloy for High Strength at Elevated Temperatures

covered by the ASME Boiler and Pressure Vessel Code,

A 781/A 781M Specification for Castings, Steel and Alloy,

Supplementary Requirements S6, S14, and S27 are mandatory

Common Requirements, for General Industrial Use

and must be specified in the purchase order.

5. Materials and Manufacture

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

5.1 The steel shall be made by the electric furnace process

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

with or without separate refining such as argon-oxygen decar-

A01.18 on Castings.

Current edition approved Sept. 1, 2004. Published September 2004. Originally burization (AOD).

approved in 1977. Last previous edition approved in 1999 as A 747/A 747M – 99.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn.

4

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers (ASME), ASME

the ASTM website. International Headquarters, Three Park Ave., New York, NY 10016-5990.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 747/A 747M – 04

A

TABLE 1 Chemical Requirements

5.2.2 Solution annealing heat treatment shall consist of

heating the castings and test material to 1925°F 6 50°F

Grade CB7Cu-1 CB7Cu-2

[1050°C 6 30°C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.