ASTM C1676-08

(Specification)Standard Specification for Microporous Thermal Insulation

Standard Specification for Microporous Thermal Insulation

SCOPE

1.1 This specification covers the composition, physical properties, and product forms of microporous thermal insulation for use on surfaces at temperatures from 80 ˚°C (176 °F) up to 1150 ˚°C (2102 °F), unless otherwise agreed upon by the manufacturer and purchaser.

1.2 This specification only covers microporous thermal insulation comprising compacted powder, fibers and opacifiers.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound equivalents of SI units, given in parentheses, are given for information only and are only approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1676 −08

StandardSpecification for

Microporous Thermal Insulation

This standard is issued under the fixed designation C1676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C356 Test Method for Linear Shrinkage of Preformed High-

Temperature Thermal Insulation Subjected to Soaking

1.1 This specification covers the composition, physical

Heat

properties, and product forms of microporous thermal insula-

C390 Practice for Sampling and Acceptance of Thermal

tion for use on surfaces at temperatures from 80 °˚C (176 °F) up

Insulation Lots

to 1150 °˚C (2102 °F), unless otherwise agreed upon by the

C518 Test Method for Steady-State Thermal Transmission

manufacturer and purchaser.

Properties by Means of the Heat Flow Meter Apparatus

1.2 This specification only covers microporous thermal

C585 Practice for Inner and Outer Diameters of Thermal

insulation comprising compacted powder, fibers and opacifiers.

Insulation for Nominal Sizes of Pipe and Tubing

1.3 The values stated in SI units are to be regarded as the

C665 Specification for Mineral-Fiber Blanket Thermal Insu-

standard. The inch-pound equivalents of SI units, given in

lation for Light Frame Construction and Manufactured

parentheses, are given for information only and are only

Housing

approximate.

C795 Specification for Thermal Insulation for Use in Con-

tact with Austenitic Stainless Steel

1.4 This standard does not purport to address all of the

C1045 Practice for Calculating Thermal Transmission Prop-

safety concerns, if any, associated with its use. It is the

erties Under Steady-State Conditions

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- C1104/C1104M Test Method for Determining the Water

Vapor Sorption of Unfaced Mineral Fiber Insulation

bility of regulatory limitations prior to use.

E84 Test Method for Surface Burning Characteristics of

2. Referenced Documents Building Materials

2.1 ASTM Standards:

3. Terminology

C165 Test Method for Measuring Compressive Properties of

Thermal Insulations

3.1 Definitions—For definitions used in this specification,

C168 Terminology Relating to Thermal Insulation

see Terminology C168.

C177 Test Method for Steady-State Heat Flux Measure-

3.2 Definitions of Terms Specific to This Standard:

ments and Thermal Transmission Properties by Means of

3.2.1 flexible microporous insulation, n— insulation that is

the Guarded-Hot-Plate Apparatus

capable of conforming to a non planar surface being insulated

C201 Test Method for Thermal Conductivity of Refractories

without damage over a specified temperature range.

C302 Test Method for Density and Dimensions of Pre-

formed Pipe-Covering-Type Thermal Insulation

3.2.2 rigid microporous insulation , n— insulation that will

C303 Test Method for Dimensions and Density of Pre-

be damaged when forced to conform to a non-planar surface

formed Block and Board–Type Thermal Insulation

being insulated.

C335 Test Method for Steady-State Heat Transfer Properties

of Pipe Insulation

4. Classification

4.1 Microporous thermal insulation covered by this specifi-

cation shall be classified into three types as shown in Table 1.

This specification is under the jurisdiction of ASTM Committee C16 on

Type classification is based on the physical form in which the

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

Homogeneous Inorganic Thermal Insulations.

insulation is manufactured.

Current edition approved April 15, 2008. Published May 2008. DOI: 10.1520/

C1676-08.

4.2 Microporous thermal insulation covered by this specifi-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cation shall be classified into four grades as shown in Table 2.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Grade classification is based on the maximum recommended

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. use temperature of the insulation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

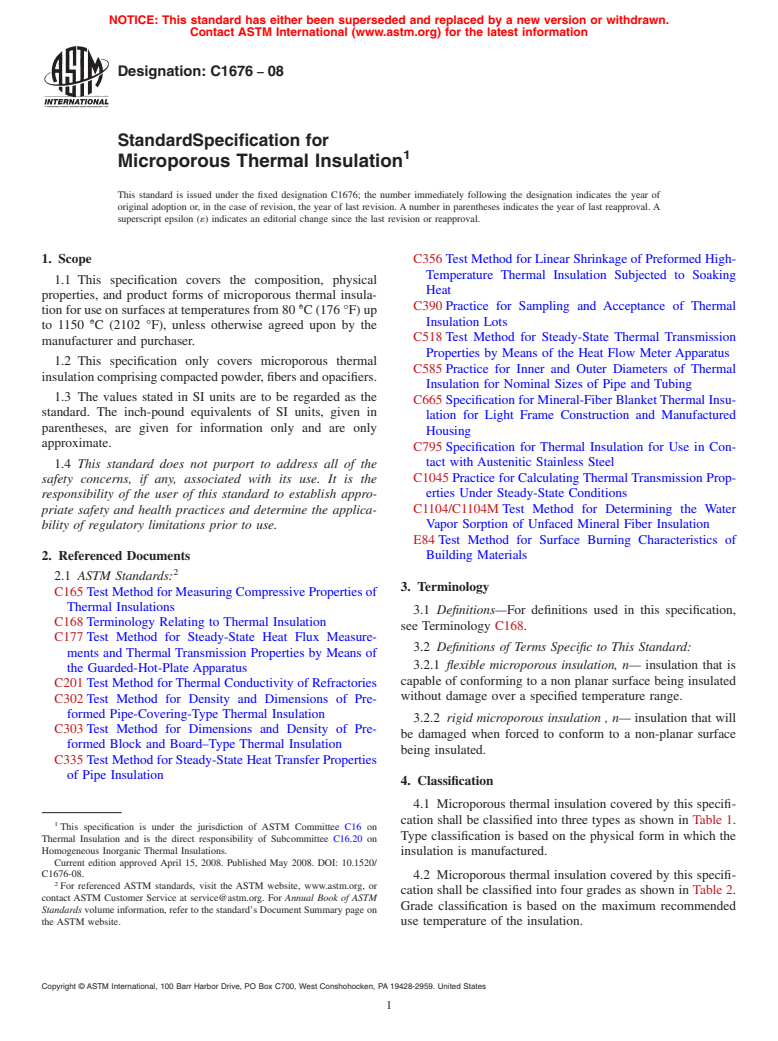

C1676−08

TABLE 1 Types of Microporous Insulation

Type Definition

Type I – Boards Boards are rigid pieces of microporous insulation of rectangular shape and cross-section in which the thickness is

uniform and substantially smaller than the other dimensions. The density of boards is in the range 200 to 450 kg/m

(12.5 to 28.1 lb/ft ). They are supplied either unfaced or faced. Facing materials often have maximum service

temperatures lower than that of the insulation and degrade without affecting the insulation properties in service.

Type II – Quilted Panels Quilted panels are flexible panels completely encased in woven glass cloth and stitched completely through parallel

or crosswise in distances from 25 to 100 mm (1 to 4 in.) in order to give flexibility in one or two dimensions. Thread

types used include glass, aramid, or stainless steel. The density of quilted panels is in the range 190 to 300 kg/m

(11.9 to 18.7 lb/ft ). The glass cloth is provided for handling purposes only and embrittles or melts at temperatures

below the maximum usage temperature of the insulation without affecting the insulation properties in service.

Type III – Molded Pipe Sections Molded Pipe sections are half-shells or segments of microporous insulation faced with woven glass cloth and high-

temperature adhesive for the insulation of cylindrical objects such as pipes. The density of pipe sections is in the

3 3

range 300 to 400 kg/m (18.7 to 25.0 lb/ft ). The glass cloth is provided for handling purposes only and embrittles or

melts at temperatures below the maximum usage temperature of the insulation without affecting the insulation

properties in service.

TABLE 2 Grades of Microporous Insulation

6. Materials and Manufacture

Grade Grade Temperature of use, °C (°F), max

6.1 Composition—Microporous insulation shall be com-

1 900 (1652)

2A 1000 (1832) prised of compacted inorganic metal oxide powders of surface

A

2B 250 (482)

area greater than 90 m /g (3,052 sq yd/oz), powdered inorganic

3 1150 (2102)

infra-red opacifiers and man-made or natural fibers or fila-

A

See 4.3 for a definition of the difference between Grades 2A and 2B.

ments. Asbestos shall not be used as an ingredient or compo-

nent of the product.

6.2 Typical facings are as follows:

6.2.1 Glass cloth, wrapped around or adhered to the surface

of the microporous insulation with an alkali silicate based

4.3 Grade 2B microporous insulation is hydrophobic and

has been chemically treated to make the material water- adhesive;

repellant.

6.2.2 For other facings, if available, contact the manufac-

4.3.1 Grade 2B, hydrophobic insulation, will retain its water turer.

repellency up to 250 °C (482 °F). At higher temperatures, the

treatment will degrade at a rate which depends on the tempera-

7. Physical Properties

ture applied. The user shall contact the manufacturer for

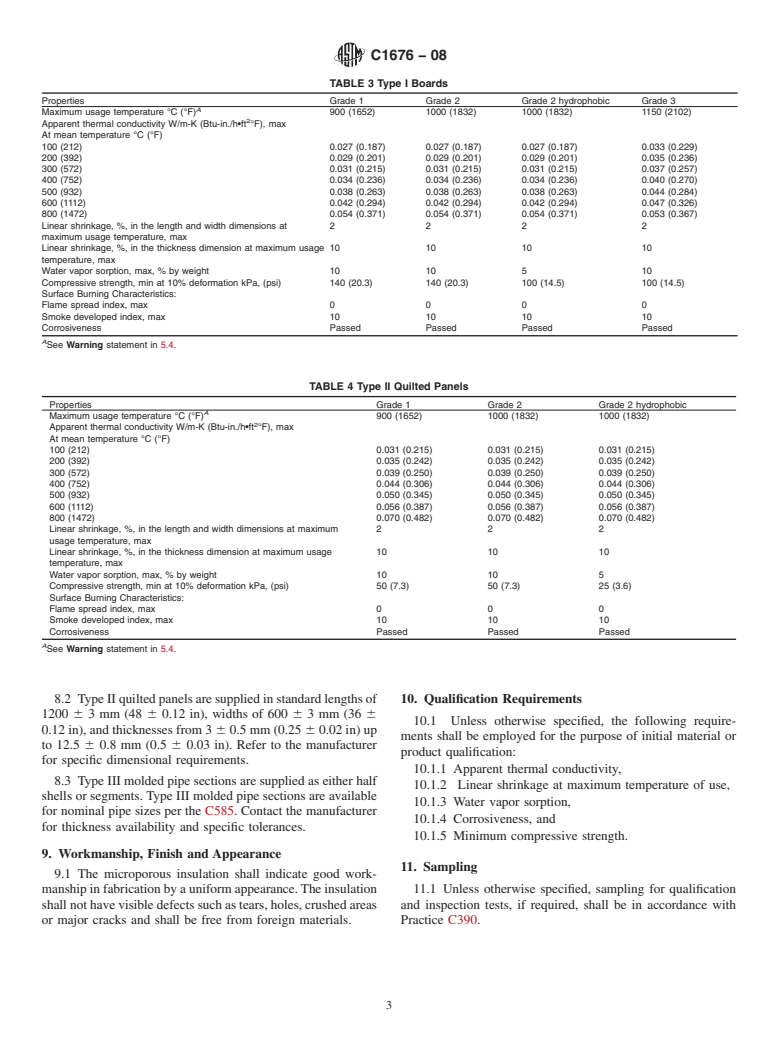

7.1 The microporous insulation shall conform to the physi-

specific information on the lifetime of the treatment at higher

cal requirements described in Tables 3-5, other than for

temperatures than 250 °C (482 °F).

maximum density which is provided for information only.

4.3.2 Grade 2B, hydrophobic insulation, which has been

Consult the manufacturer for specific design recommendations

heated to the point where the hydrophobic treatment is

for all material types, grades, and classes.

destroyed, performs as Grade 2 insulation with a use tempera-

7.2 The user is advised that some applications require

ture of 1000 ºC (1832 ºF).

knowledge of the thermal conductivity of the insulation mate-

rial at mean temperatures above those shown. Consult the

5. Ordering Information

manufacturer for data at mean temperatures exceeding those

5.1 The type, grade and dimensions shall be specified by the

listed.

purchaser.

7.3 Thephysicalrequirementsarebasedonthepropertiesof

5.2 The purchaser shall specify inspection of the material,

samples dried and conditioned, or both, as specified in the

where required.

referenced test methods. Microporous insulation, other than

grade 2 hydrophobic, tends to absorb moisture to varying

5.3 When a certification, test report, or both, are required, it

shall be specified by the purchaser. degrees depending on exposure conditions. It can absorb up to

4 times its dry weight if placed in direct contact with water

5.4 The purchaser and supplier shall agree whether the

through improper storage or application. Proper packaging and

insulation shall be supplied plain or with facings to facilitate

storage is required as defined in 15.1.

ease of handling, to minimize dust generation, or to resist the

ingressofwater.Iffaced,thepurchaserandsuppliershallagree

8. Dimensions and Tolerances

on the type and requirements. (Warning—The purchaser is

advised that the maximum use temperature of facings, 8.1 Type I boards are supplied in standard lengths up to

adhesives, and thread is usually lower than the maximum use 1000 63mm(40 6 0.12 in), widths up to 550 63mm(22

temperature of the insulation. The purchaser and supplier shall 6 0.12 in), and thicknesses from 10 6 0.5 mm (0.4 6 0.02 in)

agree whether the facings need to maintain their integrity on to 70 6 0.8 mm (2.8 6 0.02 in). Refer to the manufacturer for

heating or whether they are sacrificial ). specific dimensional requirements.

C1676−08

TA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.