ASTM D1631-99(2004)

(Test Method)Standard Test Method for Water in Phenol and Related Materials by the Iodine Reagent Method

Standard Test Method for Water in Phenol and Related Materials by the Iodine Reagent Method

SIGNIFICANCE AND USE

This test method is particularly useful for determining small amounts of water in hygroscopic materials. This test method is suitable for setting specifications on materials referenced in the scope. It may also be used as an internal quality control tool and in development or research work.

SCOPE

1.1 This test method covers the determination of water in phenol and related materials such as cresols, xylenols, naphthalene, pyridine, and quinoline.

1.2 This test method has been found applicable to a variety of materials varying in water content from 100 mg/kg to solutions containing a relatively high percent of water.

1.3 The following applies to all specified limits in this standard: for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D1631–99(Reapproved2004)

Standard Test Method for

Water in Phenol and Related Materials by the Iodine

Reagent Method

This standard is issued under the fixed designation D1631; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This test method covers the determination of water in

2.2 Other Document:

phenol and related materials such as cresols, xylenols, naph-

OSHA Regulations,29 CFR, Paragraphs 1910.1000 and

thalene, pyridine, and quinoline.

1910.1200

1.2 This test method has been found applicable to a variety

of materials varying in water content from 100 mg/kg to

3. Terminology

solutions containing a relatively high percent of water.

3.1 See Terminology D4790 for definition of terms used in

1.3 The following applies to all specified limits in this

this test method.

standard: for purposes of determining conformance with this

standard, an observed value or a calculated value shall be

4. Summary of Test Method

rounded off “to the nearest unit” in the last right-hand digit

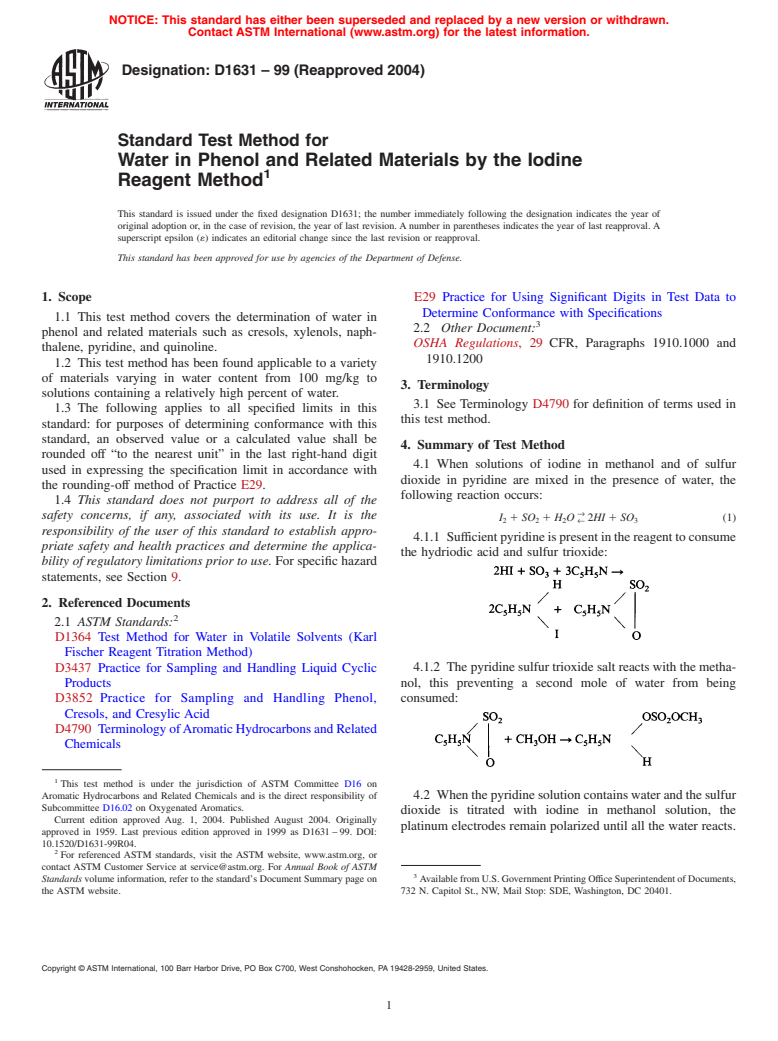

4.1 When solutions of iodine in methanol and of sulfur

used in expressing the specification limit in accordance with

dioxide in pyridine are mixed in the presence of water, the

the rounding-off method of Practice E29.

following reaction occurs:

1.4 This standard does not purport to address all of the

→

safety concerns, if any, associated with its use. It is the I 1 SO 1 H O 2HI 1 SO (1)

2 2 2 ← 3

responsibility of the user of this standard to establish appro-

4.1.1 Sufficientpyridineispresentinthereagenttoconsume

priate safety and health practices and determine the applica-

the hydriodic acid and sulfur trioxide:

bility of regulatory limitations prior to use. For specific hazard

statements, see Section 9.

2. Referenced Documents

2.1 ASTM Standards:

D1364 Test Method for Water in Volatile Solvents (Karl

Fischer Reagent Titration Method)

D3437 Practice for Sampling and Handling Liquid Cyclic 4.1.2 The pyridine sulfur trioxide salt reacts with the metha-

Products nol, this preventing a second mole of water from being

D3852 Practice for Sampling and Handling Phenol, consumed:

Cresols, and Cresylic Acid

D4790 TerminologyofAromaticHydrocarbonsandRelated

Chemicals

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of 4.2 Whenthepyridinesolutioncontainswaterandthesulfur

Subcommittee D16.02 on Oxygenated Aromatics.

dioxide is titrated with iodine in methanol solution, the

Current edition approved Aug. 1, 2004. Published August 2004. Originally

platinum electrodes remain polarized until all the water reacts.

approved in 1959. Last previous edition approved in 1999 as D1631 – 99. DOI:

10.1520/D1631-99R04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the ASTM website. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1631–99 (2004)

A slight excess of iodine depolarizes the electrodes, allowing specifications are available. Other grades may be used, pro-

current to flow through the microammeter which indicates the vided it is first ascertained that the reagent is of sufficiently

end point. high purity to permit its use without lessening the accuracy of

the determination.

8.2 Iodine Solution—Dissolve 150 g of iodine (I ) crystals

5. Significance and Use

in 3 Lof anhydrous methanol. Place the solution in the reagent

5.1 This test method is particularly useful for determining

bottle connected to the buret as shown in Fig. 1.

small amounts of water in hygroscopic materials. This test

8.3 Methanol, anhydrous, containing less than 0.05 % wa-

method is suitable for setting specifications on materials

ter.

referenced in the scope. It may also be used as an internal

8.4 Pyridine Solution—Place 4000 mL of refined grade

quality control tool and in development or research work.

pyridine in a 5000-mL distilling flask. Distill over and discard

400 mLof forecut at atmospheric pressure. Distill off 3400 mL

6. Interferences

of center cut and transfer to a suitable glass bottle fitted with a

two-hole stopper. Through one hole of the stopper insert a

6.1 This test method is not applicable in the presence of

piece of glass tubing that extends almost to the bottom of the

mercaptans, peroxides, or appreciable quantities of aldehydes

bottle; through the other hole insert a short piece of glass

or amines.

tubing to serve as a vent. Through the long tube add 400 g of

6.2 If ketones are present in the sample, interference from

refrigerant-grade sulfur dioxide (SO ) dried through concen-

them can be avoided by employing the glycol-pyridine sample

trated sulfuric acid (H SO sp gr 1.84), and allow the solution

2 4

solvent specified in Test Method D1364.

to cool. Fit the vent tube with a drying tube and an aspirator

bulb; connect the long tube with an adapter suitable for

7. Apparatus

introducing the reagent into the titration flask. For convenience

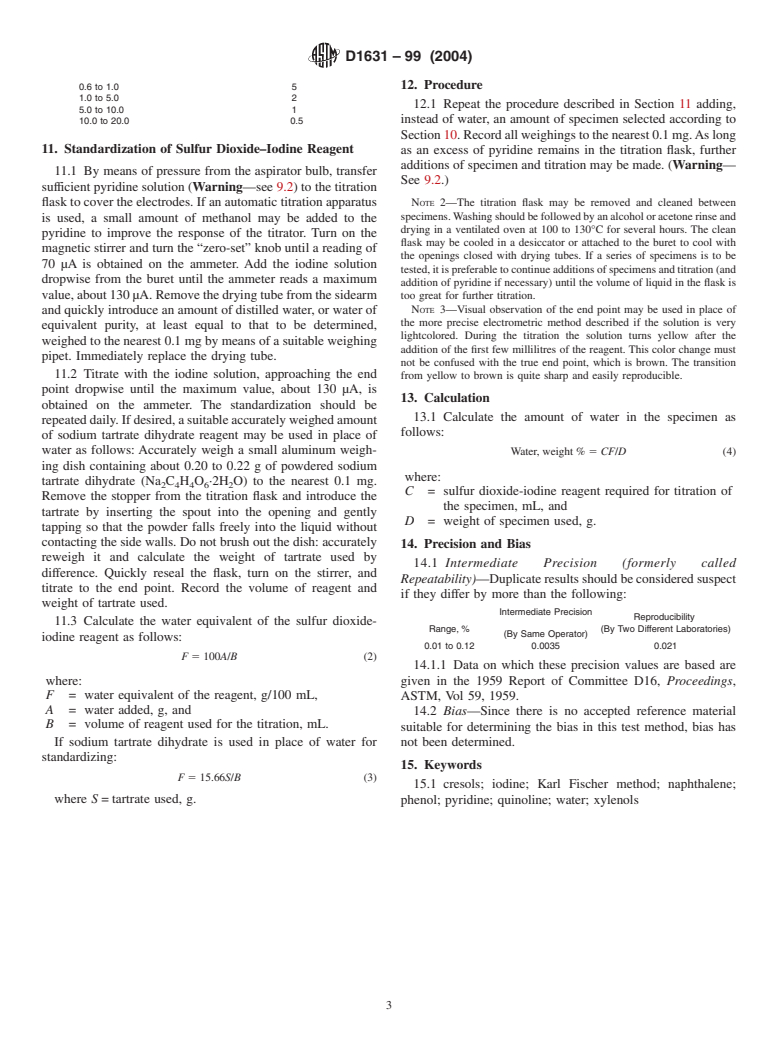

7.1 The apparatus shall be assembled as shown in Fig. 1.

in measuring, a suitable reservoir may be placed in the system.

Any suitable modification permitting equal facility and accu-

NOTE 1—In place of the divided reagents described in 8.2, 8.3, and 8.4

racy may be used. Automatic titration equipment is commer-

it is permissible to employ the single solution reagent specified in Test

cially available and may be used.

Method D1364 or commercial Karl Fischer reagents. Pyridine-free re-

agents are available from various laboratory suppliers and may be used if

suitable for the material being tested.

8. Reagents

8.5 When handling Karl Fischer reagent refer to Practice

8.1 Reagent grade chemicals shall be used in all tests.

D3437.

Unless otherwise indicated, it is intended that all reagents shall

conform to the specifications of the Committee on Analytical

9. Hazards

Reagents of the American Chemical Society, where such

9.1 Consult current OSHA regulations supplier’s Material

Safety Data Sheets and local regulations for all mater

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.