ASTM A578/A578M-07(2012)

(Specification)Standard Specification for Straight-Beam Ultrasonic Examination of Rolled Steel Plates for Special Applications

Standard Specification for Straight-Beam Ultrasonic Examination of Rolled Steel Plates for Special Applications

ABSTRACT

This procedure covers the standard and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of rolled carbon and alloy steel plates. The amplitude linearity of the apparatus to be used shall be checked by positioning the transducer over the depth resolution notch in the IIW or similar block. The inspection shall be performed in an area free of operations that interfere with proper performance of the test. The test shall be performed either by direct contact, immersion, or liquid column coupling. Grid scanning shall be conducted along a continuous perpendicular line on the center. All discontinuities causing complete loss of reflection shall be recorded.

SCOPE

1.1 This specification covers the procedure and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of rolled carbon and alloy steel plates, 3/8 in. [10 mm] in thickness and over, for special applications. The method will detect internal discontinuities parallel to the rolled surfaces. Three levels of acceptance standards are provided. Supplementary requirements are provided for alternative procedures.

1.2 Individuals performing examinations in accordance with this specification shall be qualified and certified in accordance with the requirements of the latest edition of ASNT SNT-TC-1A or an equivalent accepted standard. An equivalent standard is one which covers the qualification and certification of ultrasonic nondestructive examination candidates and which is acceptable to the purchaser.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A578/A578M −07 (Reapproved 2012)

Standard Specification for

Straight-Beam Ultrasonic Examination of Rolled Steel Plates

for Special Applications

This standard is issued under the fixed designationA578/A578M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A264 Specification for Stainless Chromium-Nickel Steel-

2 Clad Plate

1.1 This specification covers the procedure and acceptance

A265 Specification for Nickel and Nickel-Base Alloy-Clad

standards for straight-beam, pulse-echo, ultrasonic examina-

Steel Plate

tion of rolled carbon and alloy steel plates, ⁄8 in. [10 mm] in

2.2 ANSI Standard:

thickness and over, for special applications. The method will

B 46.1 Surface Texture

detect internal discontinuities parallel to the rolled surfaces.

2.3 ASNT Standard:

Three levels of acceptance standards are provided. Supplemen-

SNT-TC-1A

tary requirements are provided for alternative procedures.

1.2 Individualsperformingexaminationsinaccordancewith

3. Ordering Information

this specification shall be qualified and certified in accordance

3.1 The inquiry and order shall indicate the following:

with the requirements of the latest edition of ASNT SNT-

3.1.1 Acceptance level requirements (Sections 7, 8, and 9).

TC-1A or an equivalent accepted standard. An equivalent

Acceptance Level B shall apply unless otherwise agreed to by

standard is one which covers the qualification and certification

purchaser and manufacturer.

of ultrasonic nondestructive examination candidates and which

3.1.2 Any additions to the provisions of this specification as

is acceptable to the purchaser.

prescribed in 5.2, 13.1, and Section 10.

1.3 The values stated in either SI units or inch-pound units

3.1.3 Supplementary requirements, if any.

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

4. Apparatus

system shall be used independently of the other. Combining

4.1 The amplitude linearity shall be checked by positioning

values from the two systems may result in non-conformance

the transducer over the depth resolution notch in the IIW or

with the standard.

similar block so that the signal from the notch is approximately

1.4 This standard does not purport to address all of the

30 % of the screen height, and the signal from one of the back

safety concerns, if any, associated with its use. It is the

surfaces is approximately 60 % of the screen height (two times

responsibility of the user of this standard to establish appro-

the height of the signal from the notch).Acurve is then plotted

priate safety and health practices and determine the applica-

showing the deviations from the above established 2:1 ratio

bility of regulatory limitations prior to use.

that occurs as the amplitude of the signal from the notch is

raised in increments of one scale division until the back

2. Referenced Documents

reflection signal reaches full scale, and then is lowered in

2.1 ASTM Standards:

increments of one scale division until the notch signal reaches

A263 Specification for Stainless Chromium Steel-Clad Plate

one scale division. At each increment the ratio of the two

signals is determined. The ratios are plotted on the graph at the

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

position corresponding to the larger signal. Between the limits

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.11 on Steel Plates for Boilers and Pressure Vessels. of 20 and 80 % of the screen height, the ratio shall be within

Current edition approved March 1, 2012. Published March 2012. Originally

10 % of 2:1. Instrument settings used during inspection shall

approved in 1967. Last previous edition approved in 2007 as A578/A578M – 07.

not cause variation outside the 10 % limits established above.

DOI: 10.1520/A0578_A0578M-07R12.

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SA-578/SA-578M in Section II of that Code.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

the ASTM website. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A578/A578M−07 (2012)

NOTE 1—Indications occurring midway between the initial pulse and

4.2 The transducer shall be 1 or 1 ⁄8 in. [25 or 30 mm] in

the first back reflection may cause a second reflection at the location of the

diameter or 1 in. [25 mm] square.

first back reflection. When this condition is observed it shall be investi-

4.3 Other search units may be used for evaluating and

gated additionally by use of multiple back reflections.

pinpointing indications.

6.3 Where grid scanning is performed and recordable con-

ditionsasin6.1and6.2aredetectedalongagivengridline,the

5. Procedure

entire surface area of the squares adjacent to this indication

5.1 Perform the inspection in an area free of operations that

shall be scanned. Where parallel path scanning is performed

interfere with proper performance of the test.

and recordable conditions as in 6.1 and 6.2 are detected, the

5.2 Unless otherwise specified, make the ultrasonic exami-

entire surface area ofa9by 9-in. [225 by 225-mm] square

nation on either major surface of the plate.

centered on this indication shall be scanned. The true bound-

5.3 The plate surface shall be sufficiently clean and smooth aries where these conditions exist shall be established in either

to maintain a first reflection from the opposite side of the plate

method by the following technique: Move the transducer away

at least 50 % of full scale during scanning. This may involve from the center of the discontinuity until the height of the back

suitable means of scale removal at the manufacturer’s option.

reflection and discontinuity indications are equal. Mark the

Condition local rough surfaces by grinding. Restore any plate at a point equivalent to the center of the transducer.

specified identification which is removed when grinding to

Repeat the operation to establish the boundary.

achieve proper surface smoothness.

7. Acceptance Standard—Level A

5.4 Perform the test by one of the following methods: direct

contact, immersion, or liquid column coupling. Use a suitable

7.1 Any area where one or more discontinuities produce a

couplant such as water, soluble oil, or glycerin. As a result of

continuous total loss of back reflection accompanied by con-

the test by this method, the surface of plates may be expected

tinuous indications on the same plane (within 5 % of plate

to have a residue of oil or rust or both.

thickness) that cannot be encompassed within a circle whose

diameter is 3 in. [75 mm] or ⁄2 of the plate thickness,

5.5 Anominal test frequency of 2 ⁄4 MHz is recommended.

whichever is greater, is unacceptable.

When testing plates less than ⁄4 in. [20 mm] thick a frequency

of 5 MHz may be necessary. Thickness, grain size or micro-

structureofthematerialandnatureoftheequipmentormethod 8. Acceptance Standards—Level B

may require a higher or lower test frequency. Use the trans-

8.1 Any area where one or more discontinuities produce a

ducers at their rated frequency.Aclean, easily interpreted trace

continuous total loss of back reflection accompanied by con-

pattern should be produced during the examination.

tinuous indications on the same plane (within 5 % of plate

5.6 Scanning:

thickness) that cannot be encompassed within a circle whose

5.6.1 Scanning shall be along continuous perpendicular grid

diameter is 3 in. [75 mm] or ⁄2 of the plate thickness,

lines on nominal 9-in. [225-mm] centers, or at the option of the

whichever is greater, is unacceptable.

manufacturer, shall be along continuous parallel paths, trans-

8.2 In addition, two or more discontinuities smaller than

verse to the major plate axis, on nominal 4-in. [100-mm]

described in 8.1 shall be unacceptable unless separated by a

centers, or shall be along continuous parallel paths parallel to

minimum distance equal to the greatest diameter of the larger

the major plate axis, on 3-in. [75-mm] or smaller centers.

discontinuity or unless they may be collectively encompassed

Measure the lines from the center or one corner of the plate

by the circle described in 8.1.

with an additional path within 2 in. [50 mm] of all edges of the

plate on the searching surface.

9. Acceptance Standard—Level C

5.6.2 Conduct the general scanning with an instrument

adjustment that will produce a first reflection from the opposite

9.1 Any area where one or more discontinuities produce a

side of a sound area of the plate from 50 to 90 % of full scale.

continuous total loss of back reflection accompanied by con-

Minor sensitivity adjustments may be made to accommodate

tinuous indications on the same plane (within 5 % of plate

for surface roughness.

thickness) that cannot be encompassed within a 1-in. [25-mm]

5.6.3 When a discontinuity condition is observed during

diameter circle is unacceptable.

general scanning adjust the instrument to produce a first

reflection from the opposite side of a sound area of the plate of

10. Report

75 6 5 % of full scale. Maintain this instrument setting during

10.1 Unless otherwise agreed to by the purchaser and the

evaluation of the discontinuity condition.

manufacturer, the manufacturer shall report the following data:

6. Recording

10.1.1 All recordable indications listed in Section 6 on a

6.1 Record all discontinuities causing complete loss of back sketch of the plate with sufficient data to relate the geometry

reflection. and identity of the sketch to those of the plate.

10.1.2 Test parameters including: Make and model of in-

6.2 For plates ⁄4 in. [20 mm] thick and over, record all

strument, test frequency, surface condition, transducer (type

indicationswithamplitudesequaltoorgreaterthan50 %ofthe

and frequency), and couplant.

initial back reflection and accompanied by a 50 % loss of back

reflection. 10.1.3 Date of test.

A578/A578M−07 (2012)

11. Inspection object of possible repair of the ultrasonically indicated defect

before rejection of the plate.

11.1 The inspector rep

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A578/A578M–07 Designation: A578/A578M – 07 (Reapproved 2012)

Standard Specification for

Straight-Beam Ultrasonic Examination of Rolled Steel Plates

for Special Applications

This standard is issued under the fixed designationA578/A578M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

1.1 This specification covers the procedure and acceptance standards for straight-beam, pulse-echo, ultrasonic examination of

rolled carbon and alloy steel plates, ⁄8 in. [10 mm] in thickness and over, for special applications. The method will detect internal

discontinuities parallel to the rolled surfaces. Three levels of acceptance standards are provided. Supplementary requirements are

provided for alternative procedures.

1.2 Individuals performing examinations in accordance with this specification shall be qualified and certified in accordance with

the requirements of the latest edition of ASNT SNT-TC-1A or an equivalent accepted standard. An equivalent standard is one

which covers the qualification and certification of ultrasonic nondestructive examination candidates and which is acceptable to the

purchaser.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.11

on Steel Plates for Boilers and Pressure Vessels.

Current edition approved Nov.March 1, 2007.2012. Published December 2007.March 2012. Originally approved in 1967. Last previous edition approved in 20012007 as

A578/A578M–96(2001).A578/A578M – 07. DOI: 10.1520/A0578_A0578M-07R12.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-578/SA-578M in Section II of that Code.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A578/A578M – 07 (2012)

2. Referenced Documents

2.1 ASTM Standards:

A263 Specification for Stainless Chromium Steel-Clad Plate

A264 Specification for Stainless Chromium-Nickel Steel-Clad Plate

A265 Specification for Nickel and Nickel-Base Alloy-Clad Steel Plate

2.2 ANSI Standard:

B 46.1 Surface Texture

2.3 ASNT Standard:

SNT-TC-1A

3. Ordering Information

3.1 The inquiry and order shall indicate the following:

3.1.1 Acceptance level requirements (Sections 7, 8, and 9). Acceptance Level B shall apply unless otherwise agreed to by

purchaser and manufacturer.

3.1.2 Any additions to the provisions of this specification as prescribed in 5.2, 13.1, and Section 10.

3.1.3 Supplementary requirements, if any.

4. Apparatus

4.1 The amplitude linearity shall be checked by positioning the transducer over the depth resolution notch in the IIW or similar

block so that the signal from the notch is approximately 30 % of the screen height, and the signal from one of the back surfaces

is approximately 60 % of the screen height (two times the height of the signal from the notch). A curve is then plotted showing

the deviations from the above established 2:1 ratio that occurs as the amplitude of the signal from the notch is raised in increments

of one scale division until the back reflection signal reaches full scale, and then is lowered in increments of one scale division until

the notch signal reaches one scale division.At each increment the ratio of the two signals is determined. The ratios are plotted on

the graph at the position corresponding to the larger signal. Between the limits of 20 and 80 % of the screen height, the ratio shall

be within 10 % of 2:1. Instrument settings used during inspection shall not cause variation outside the 10 % limits established

above.

4.2 The transducer shall be 1 or 1 ⁄8 in. [25 or 30 mm] in diameter or 1 in. [25 mm] square.

4.3 Other search units may be used for evaluating and pinpointing indications.

5. Procedure

5.1 Perform the inspection in an area free of operations that interfere with proper performance of the test.

5.2 Unless otherwise specified, make the ultrasonic examination on either major surface of the plate.

5.3 The plate surface shall be sufficiently clean and smooth to maintain a first reflection from the opposite side of the plate at

least 50 % of full scale during scanning.This may involve suitable means of scale removal at the manufacturer’s option. Condition

local rough surfaces by grinding. Restore any specified identification which is removed when grinding to achieve proper surface

smoothness.

5.4 Perform the test by one of the following methods: direct contact, immersion, or liquid column coupling. Use a suitable

couplant such as water, soluble oil, or glycerin. As a result of the test by this method, the surface of plates may be expected to

have a residue of oil or rust or both.

1 3

5.5 Anominal test frequency of 2 ⁄4 MHz is recommended. When testing plates less than ⁄4 in. [20 mm] thick a frequency of

5 MHz may be necessary. Thickness, grain size or microstructure of the material and nature of the equipment or method may

requireahigherorlowertestfrequency.Usethetransducersattheirratedfrequency.Aclean,easilyinterpretedtracepatternshould

be produced during the examination.

5.6 Scanning:

5.6.1 Scanning shall be along continuous perpendicular grid lines on nominal 9-in. [225-mm] centers, or at the option of the

manufacturer, shall be along continuous parallel paths, transverse to the major plate axis, on nominal 4-in. [100-mm] centers, or

shallbealongcontinuousparallelpathsparalleltothemajorplateaxis,on3-in.[75-mm]orsmallercenters.Measurethelinesfrom

the center or one corner of the plate with an additional path within 2 in. [50 mm] of all edges of the plate on the searching surface.

5.6.2 Conduct the general scanning with an instrument adjustment that will produce a first reflection from the opposite side of

a sound area of the plate from 50 to 90 % of full scale. Minor sensitivity adjustments may be made to accommodate for surface

roughness.

5.6.3 Whenadiscontinuityconditionisobservedduringgeneralscanningadjusttheinstrumenttoproduceafirstreflectionfrom

the opposite side of a sound area of the plate of 75 6 5 % of full scale. Maintain this instrument setting during evaluation of the

discontinuity condition.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

A578/A578M – 07 (2012)

6. Recording

6.1 Record all discontinuities causing complete loss of back reflection.

6.2 For plates ⁄4 in. [20 mm] thick and over, record all indications with amplitudes equal to or greater than 50 % of the initial

back reflection and accompanied by a 50 % loss of back reflection.

NOTE 1—Indications occurring midway between the initial pulse and the first back reflection may cause a second reflection at the location of the first

back reflection. When this condition is observed it shall be investigated additionally by use of multiple back reflections.

6.3 Where grid scanning is performed and recordable conditions as in 6.1 and 6.2 are detected along a given grid line, the entire

surface area of the squares adjacent to this indication shall be scanned. Where parallel path scanning is performed and recordable

conditions as in 6.1 and 6.2 are detected, the entire surface area ofa9by 9-in. [225 by 225-mm] square centered on this indication

shallbescanned.Thetrueboundarieswheretheseconditionsexistshallbeestablishedineithermethodbythefollowingtechnique:

Move the transducer away from the center of the discontinuity until the height of the back reflection and discontinuity indications

are equal. Mark the plate at a point equivalent to the center of the transducer. Repeat the operation to establish the boundary.

7. Acceptance Standard—Level A

7.1 Any area where one or more discontinuities produce a continuous total loss of back reflection accompanied by continuous

indications on the same plane (within 5 % of plate thickness) that cannot be encompassed within a circle whose diameter is 3 in.

[75 mm] or ⁄2 of the plate thickness, whichever is greater, is unacceptable.

8. Acceptance Standards—Level B

8.1 Any area where one or more discontinuities produce a continuous total loss of back reflection accompanied by continuous

indications on the same plane (within 5 % of plate thickness) that cannot be encompassed within a circle whose diameter is 3 in.

[75 mm] or ⁄2 of the plate thickness, whichever is greater, is unacceptable.

8.2 In addition, two or more discontinuities smaller than described in 8.1 shall be unacceptable unless separated by a minimum

distance equal to the greatest diameter of the larger discontinuity or unless they may be collectively encompassed by the circle

described in 8.1.

9. Acceptance Standard—Level C

9.1 Any area where one or more discontinuities produce a continuous total loss of back reflection accompanied by continuous

indications on the same plane (within 5 % of plate thickness) that cannot be encompassed within a 1-in. [25-mm] diameter circle

is unacceptable.

10. Report

10.1 Unless otherwise agreed to by the purchaser and the manufacturer, the manufacturer shall report the following data:

10.1.1 All recordable indications listed in Section 6 on a sketch of the plate with sufficient data to relate the geometry and

identity of the sketch to those of the plate.

10.1.2 Test parameters including: Make and model of instrument, test frequency, surface condition, transducer (type and

frequency), and couplant.

10.1.3 Date of test.

11. Inspection

11.1 The inspector representing the purchaser shall have access at all times, while work on the contract of the purchaser is being

performed, to all parts of the manufacturer’s works that concern the ultrasonic testing of the material ordered. The manufacturer

shall afford the inspector all reasonable facilities to satisfy him that the material is being furnished in accordance with this

specification.All tests and inspections shall be made at the place of manufacture prior to shipment, unless otherwise specified, and

shall be conducted without interfering unnecessarily with the manufacturer’s operations.

12. Rehearing

12.1 The manufacturer reserves the right to discuss rejectable ultrasonically tested plate with the purchaser with the object of

possible repair of the ultrasonically indicated defect before rejection of the plate.

13. Marking

13.1 Plates accepted according to this specification shall be identified by stenciling (stamping) “UT A578—A” on one corner

for Level A, “UT A578—B” for Level B, and “UT A578—C” for Level C. The supplement number shall be added for each

supplementary requirement ordered.

14. Keywords

14.1 nondestructive testing; pressure containing parts; pressure vessel steels; steel plate for pressure vessel applications; steel

plates; ultrasonic examinations

A578/A578M – 07 (2012)

SUPPLEMENTARY REQUIREMENTS

These supplementary requirements shall apply only when individually specified by the purchaser.

When details of these requirements are not covered herein, they are subject to agreement between the

manufacturer and the purchaser.

S1. Scanning

S1.1 Scanning shall be continuous over 100 % of the plate surface along parallel paths, transverse or parallel to the major plate

axis, with not less than 10 % overlap between each path.

S2. Acceptance Standard

S2.1 Any recordable condition listed in Section 6 that (1) is continuous, (2) is on the same plane (within 5 % of the plate

thickness), and (3) cannot be encompassed by a 3-in. [75-mm] diameter circle, is unacceptable.Two or more recordable conditions

(see Section 5), that (1) are on the same plane (within 5 % of plate thickness), (2) individually can be encompassed by a 3-in.

[75-mm] diameter circle, (3) are separated from each other by a distance less than the greatest dimension of the smaller indication,

and (4) collectively cannot be encompassed by a 3-in. [75-mm] diameter circle, are unacceptable.

S2.2 An acceptance level more restrictive than Section 7 or 8 shall be used by agreement between the manufacturer and

purchaser.

S3. Procedure

S3.1 The manufacturer shall provide a written procedure in accordance with this specification.

S4. Certification

S4.1 The manufacturer shall provide a written certification of the ultrasonic test operator’s qualifications.

S5. Surface Finish

S5.1 The surface finish of the plate shall be conditioned to a maximum 125 µin. [3 µm] AA (see ANSI B 46.1) prior to test.

S6. Withdrawn

See Specifications A263, A264, and A265 for equivalent descriptions for clad quality level.

S7. Withdrawn

See Specifications A263, A264, and A265 for equivalent descriptions for clad quality level.

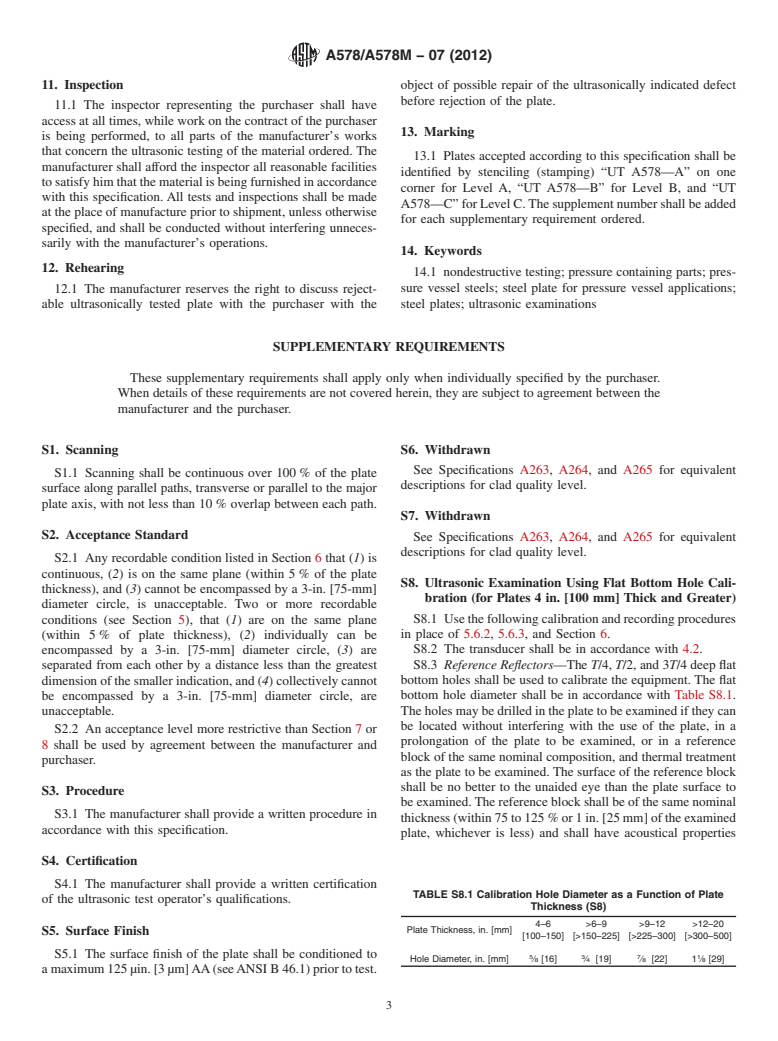

S8. Ultrasonic Examination Using Flat Bottom Hole Calibration (for Plates 4 in. [100 mm] Thick and Greater)

S8.1 Use the following calibration and recording procedures in place of 5.6.2, 5.6.3, and Section 6.

S8.2 The transducer shall be in accordance with 4.2.

S8.3 Reference Reflectors—The T/4, T/2, and 3T/4 deep flat bottom holes shall be used to calibrate the equipment. The flat

bottom hole diameter shall be in accordance with Table S8.1. The holes may be drilled in the plate to be examined if they can be

located without inte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.