ASTM C557-03(2009)e1

(Specification)Standard Specification for Adhesives for Fastening Gypsum Wallboard to Wood Framing

Standard Specification for Adhesives for Fastening Gypsum Wallboard to Wood Framing

ABSTRACT

This specification covers the minimum performance standards for and properties of adhesives intended to bond the back surface paper of gypsum wallboard to wood framing members. Test requirements and test methods for the adhesive used for the application of all thicknesses of gypsum wallboard are also covered. The specification provides a basis for ensuring the quality of adhesives. Compression shear test, tensile test, gap filling or bridging characteristics test, freeze-thaw stability test, and accelerated adhesive aging shall be performed on the adhesive. The tests are suitable for products performance certification and quality control programs and can be useful the general public, adhesive manufacturers, distributors, specifiers, architects, contractors, testing laboratories and other businesses and professionals.

SCOPE

1.1 This specification includes properties and covers minimum performance standards for adhesives intended to bond the back surface paper of gypsum wallboard to wood framing members.

1.2 This specification also covers test requirements and test methods for the adhesive used for the application of all thicknesses of gypsum wallboard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C557 −03 (Reapproved 2009)

Standard Specification for

Adhesives for Fastening Gypsum Wallboard to Wood

Framing

This standard is issued under the fixed designation C557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorial changes were made throughout in November 2009.

1. Scope* 3. Terminology

3.1 Definitions—Many terms in this specification are de-

1.1 This specification includes properties and covers mini-

fined in Terminology D907.

mumperformancestandardsforadhesivesintendedtobondthe

back surface paper of gypsum wallboard to wood framing

4. Significance and Use

members.

4.1 The specification applies to adhesives for bonding the

1.2 This specification also covers test requirements and test

back surface paper of gypsum wallboard of any thickness to

methods for the adhesive used for the application of all

wood-framing members.

thicknesses of gypsum wallboard.

4.2 This specification provides a basis for ensuring the

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

quality of the adhesives.

as standard. The values given in parentheses are mathematical

4.3 Although the bonds rendered by these adhesives shall

conversions to SI units that are provided for information only

have enough strength by themselves to maintain the bond

and are not considered standard.

betweenadherends,theyarenotintendedasasubstituteforthe

1.4 This standard does not purport to address all of the

common practice of using mechanical fasteners to maximize

safety concerns, if any, associated with its use. It is the

integrity of drywall-wood-framing structures.

responsibility of the user of this standard to establish appro-

4.4 The tests are suitable for products performance certifi-

priate safety and health practices and determine the applica-

cation and quality control programs and can be useful to the

bility of regulatory limitations prior to use.

generalpublic,adhesivemanufacturers,distributors,specifiers,

architects,contractors,testinglaboratoriesandotherbusinesses

2. Referenced Documents

and professionals

2.1 ASTM Standards:

4.5 Theresultsdonotincludeallpossibleconditions,which

C1396/C1396MSpecification for Gypsum Board

may occur during final assembly, but indicate a set of perfor-

D905Test Method for Strength Properties of Adhesive

mance characteristics for laboratory controlled bonding vari-

Bonds in Shear by Compression Loading

ables.

D907Terminology of Adhesives

E4Practices for Force Verification of Testing Machines

5. Adhesive Physical Property Requirements

E177Practice for Use of the Terms Precision and Bias in

5.1 Adhesives—The adhesives shall be uniform, homoge-

ASTM Test Methods

neous mixtures of elastomeric polymers or viscoelastic resins,

or both, free of lumps or foreign matter.

5.1.1 Workability—When applied to the framing member

This specification is under the jurisdiction of ASTM Committee D14 on

with a caulking gun or notched trowel, or both, in accordance

Adhesives and is the direct responsibility of Subcommittee D14.70 on Construction

with the manufacturer’s instructions, the adhesive shall exhibit

Adhesives.

a consistency capable of ensuring non-sagging properties.

Current edition approved Nov. 1, 2009. Published December 2009. Originally

ε1

5.1.2 Open Time—The adhesive shall have an open assem-

approved in 1965. Last previous edition approved in 2003 as C557–03 . DOI:

10.1520/C0557-03R09E01.

bly time of between 10 to 20 min to give the user sufficient

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

time to apply and, if necessary, reposition the gypsum wall-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

board at ambient temperatures, ranging from 40 to 100°F (4 to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 38°C).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C557−03 (2009)

5.1.3 Storage Life—The adhesive shall remain serviceable 8.5 Spacers—No. 20 gauge (American Standard or B&S)

and meet all the requirements of this specification for not less bronze or brass wire ⁄32-in. (0.8-mm) diameter.

than six months after delivery, when stored in original un-

8.6 Trowels—Plastic or metal with ⁄16-in. (4.76-mm) deep

opened containers at temperatures ranging from 40 to 85°F (4

V-notches.

to 30°C).

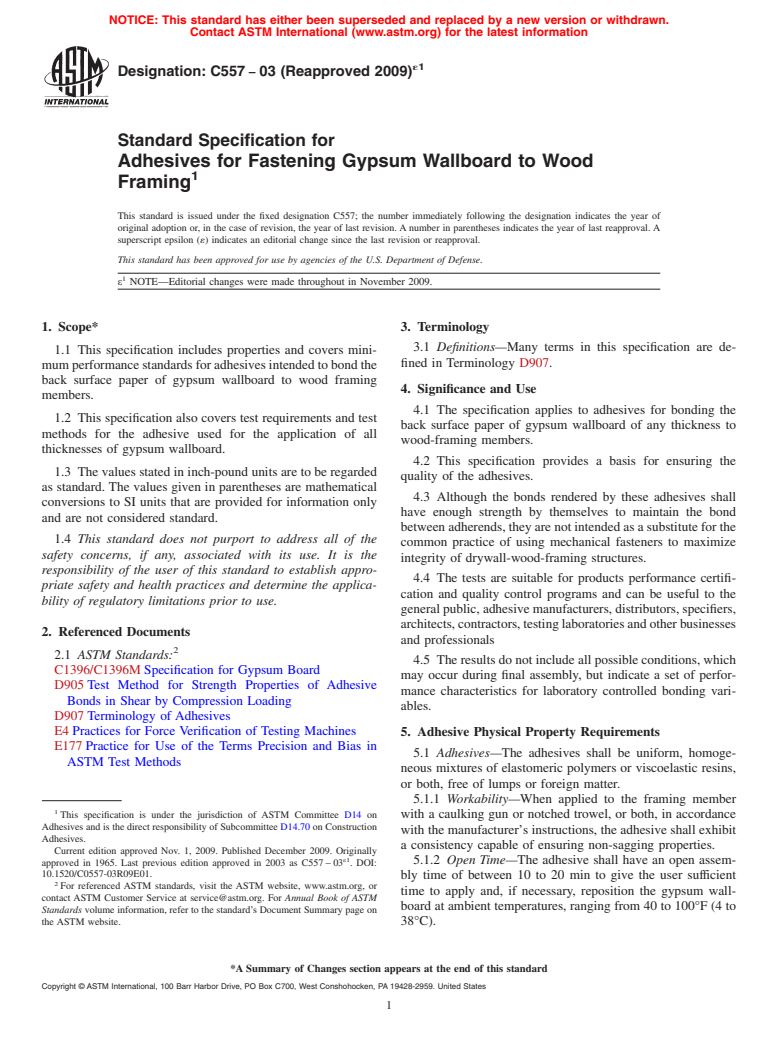

8.7 Compression Shear Test Fixture—A compression-shear

6. Adhesive Performance Property Requirements

apparatusthatissimilarto,butofalargerscalethanthefixture

recommendedinTestMethodD905.Asimilarfixtureisshown

6.1 The adhesives shall conform to the requirements sum-

in Fig. 1.

marized in Table 1.

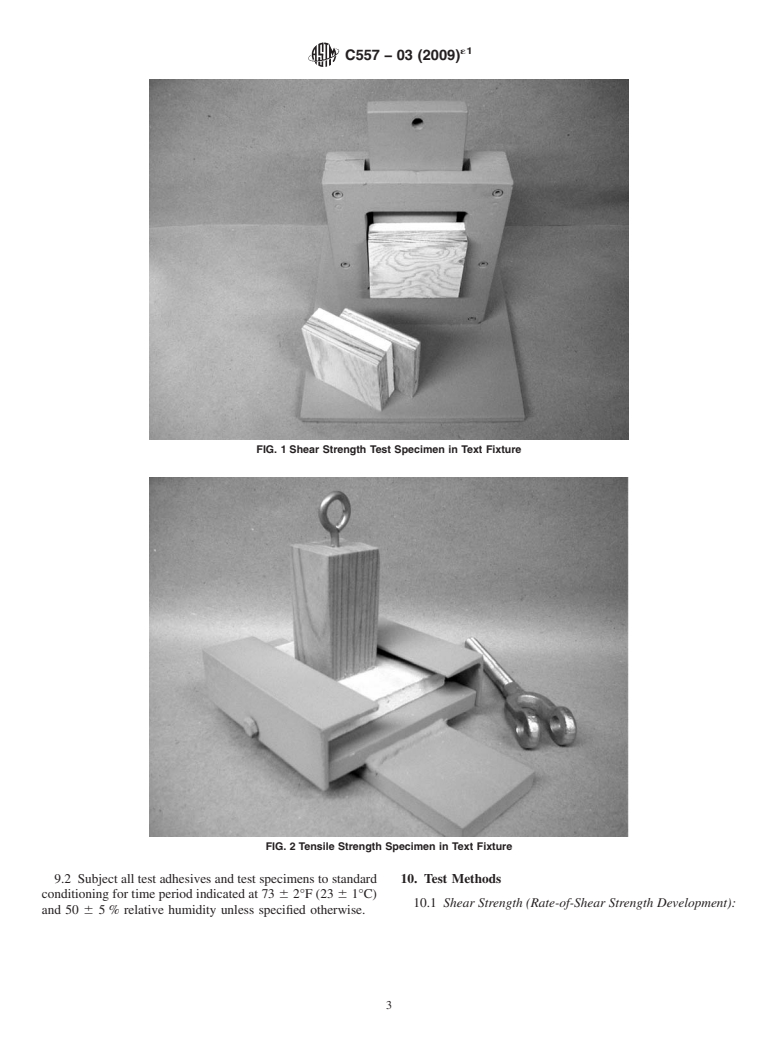

8.8 Tensile Test Fixture—An assembly of one 5 by 5 by

7. Sampling

1 1

⁄2-in. (127 by 127 by 12.7-mm) thick steel plate and two 1 ⁄2

1 1

7.1 The test adhesive sample size of 1 qt (approximately 1

by 1 ⁄2-in. by ⁄4-in. thick by 6-in. long (38.1 by 38.1 by

L) is a minimum amount to complete one full series of testing. 6.4-mmthickby152-mmlong)steelanglesections.SeeFig.2.

The sample is to be handled and stored according to the

8.9 Scaffold Nails—6d, common, double-head, smooth

manufacturers recommendations. For qualification testing, the

shaft, 0.113-in. (2.87-mm) diameter, 2 in. (51 mm) long.

sample is to be representative of the final product for which

8.10 Testing Machine—Any suitable testing machine that is

recognition is sought.

capable of operation at a constant rate of motion of the

8. Materials and Apparatus for Conducting Tests

moveableheadandhasaforcemeasurementaccuracyof 61%

when calibrated in accordance with Practices E4.

8.1 Gypsum Wallboard— ⁄2-in. (12.7-mm) thick, complying

with Specification C1396/C1396M; the dimensions are speci-

8.11 Wood Screw with Eyelet—#6 by 1 ⁄2-in. (38.1-mm)

fied in each test. 3

long, with a ⁄8-in. (9.5-mm) inside diameter eyelet.

5 19

8.2 Plywood— ⁄8-in. (15.9-mm) or ⁄32-in (15.1-mm) U.S.

5 19

8.12 Plywood Shim— ⁄8-in. (15.9-mm) or ⁄32-in. (15.1-

Product Standard PS-1-95 grade marked stamped commercial 1

mm) thick plywood with dimensions of 4 by 3 ⁄2 in. (101.6 by

plywood, Group 1 Species, exterior glue, or sanded exterior

88.9-mm) for shear test specimens and 4 by 4 in. (101.6 by

grade plywood, underlayment type, with A grade face ply for

101.6-mm) for tensile test specimens.

the adhesion surface.

9. Conditioning of Materials and Specimens (Standard

8.3 Douglas-fir Dimension Lumber—Nominal 2 by 4, 1 ⁄2

1 1

by 1 ⁄2 by 3 ⁄2-in. (38.0 by 38.0 by 89.0 mm); No. 1, Conditions)

straight-grained, and knot-free; the dimensions are specified in

9.1 Condition the gypsum wallboard, plywood, and

each test.

Douglas-fir, lumber to a constant weight at 73 6 2°F (23 6

8.4 Polyvinyl Acetate Adhesive—Any commercially avail- 1°C) and 50 6 5% relative humidity, unless specified other-

able product. wise.

TABLE 1 Adhesive Properties and Performance Requirements

Reference

Test Method Property Condition Requirements

Number

Rate of shear strength development 10.1.4 shear strength 24 h at Std. Cond. 10 psi (69 kPa) min

10.1.5 shear strength 14 days at Std. Cond. 40 psi (276 kPa) min

10.1.6 shear strength 14 days at Std. Cond., + cyclic 32 psi (220 kPa) min

lab exposure, + 2 days at

Std. Cond.

10.1.7 shear strength (a) 178 N (40 lbf) for 24 h at no bond separation

Std. Cond.

(b) 89 N (20 lbf) for 24 h at no bond separation

100°F

Rate of tensile strength development 10.2.3 tensile strength 24 h at Std. Cond. 15 psi (103 kPa) min

10.2.4 tensile strength 14 days at Std. Cond. 25 psi (172 kPa) min

Adhesive open-time determination 10.3 open-time 24 h at Std. Cond. 75 % paper transfer, min

Substrate wet-out by adhesive

1. Plywood 10.4.1 wet-out spatula applied good wetting property

2. Wallboard 10.4.2 wet-out spatula applied good wetting property

Bridging 10.5 gap filling 48 h at Std. Cond. adhesive bond line is maintained -

report paper failure %

Accelerated adhesive aging 10.6 accelerated aging 500 h at 70°C (158°F) no fracture into separate pieces

Freeze-thaw stability † 10.7 low-temperature storage 3 cycles of: no change in workability; 10 psi

24 h at -17°C (0°F) + 24 h at (69 kPa) shear strength, min

Std. Cond.

Suitability as a laminating adhesive for vinyl- 10.8.1 compatibility 24 h at 38°C (100°F) no blistering, vinyl-film discoloration,

covered wallboard or bond failure

10.8.2 staining 1 h at Std. Cond. no swelling or discoloration

† Corrected editorially.

´1

C557−03 (2009)

FIG. 1Shear Strength Test Specimen in Text Fixture

FIG. 2Tensile Strength Specimen in Text Fixture

9.2 Subjectalltestadhesivesandtestspecimenstostandard 10. Test Methods

conditioning for time period indicated at 73 6 2°F (23 6 1°C)

10.1 Shear Strength (Rate-of-Shear Strength Development):

and 50 6 5% relative humidity unless specified otherwise.

´1

C557−03 (2009)

10.1.1 Preparation of Gypsum Wallboard-Plywood 10.1.2.5 Immediately following assembly, compress each

Laminates—Eachlaminateisconstructedbybondingapieceof test specimen under a uniformly distributed load of 15 lb (67

1 1 1

4by3 ⁄2 by ⁄2-in. thick (102 by 89 by 12.7-mm) gypsum N) for a period of 3 to 3- ⁄2 min.

5 1

wallboard front paper surface paper to a ⁄8-in. (15.9 mm) or 10.1.2.6 After the 3 to 3- ⁄2 min period, remove the load,

⁄32-in.(15.1-mm)plywoodshimofthesamedimensionswith withdraw the spacers, wipe the excess adhesive from the

a commercially available PVA adhesive. The plywood rein- bonded edges with a square-edged spatula taking care not to

forces the gypsum wallboard to prevent fracture before the disturb the alignment of the bonded pieces.

ultimate shear load can be achieved. The grain of the gypsum 10.1.3 ShearStrengthDetermination—Aftercompletingthe

wallboard back surface paper is parallel with the 3 ⁄2-in. appropriate conditioning, test the specimen in shear using a

(89-mm) direction. compression-shear test fixture as shown in Fig. 1. The bottom

10.1.2 Preparation of Shear Strength Test Specimens— edge of the wallboard-plywood laminate rests on self-aligning

Prepare the number of test specimens indicated in 10.1.4 – seat as the test loading is simultaneously applied to the top

10.1.7 by bondinga4by3 ⁄2 in. (102 by 89-mm) piece edge of the single plywood. The stress applied is parallel and

plywood to the previously prepared wallboard-plywood lami- uniformly distributed to the bond line shear plane and requires

nate as follows: careful orientation using shims and self-aligning apparatus as

10.1.2.1 Spread the test adhesive onto the plywood bonding necessary.Determinetheshearstrengthatacrossheadspeedof

surface with a trowel having ⁄16-in. (4.8-mm) deep V-notches 0.50-in/min (12.7-mm/min). Observations are made during

so that the adhesive ridges are parallel to the grain of wood. stress application to ensure the test assembly maintains proper

Duringapplicationholdthetrowelatanapproximate90°angle alignment and the fixture operates without binding or friction

to the receiving surface. throughout the test. Record the maximum shear strength and

10.1.2.2 Insert six wire spacers No. 20 gauge at least 2-in. theaverageshearstrengthforthe24h,14–day,cycleexposure,

(51.0-mm) long in the joint 1-in. 6 ⁄16-in. (25.4 6 1.6-mm). and static load test conditions.

Position the spacers so that one is on the centerline of the 10.1.4 Shear Strength After 24 h:

bonded area (perpendicular to the ridges), and the others are 10.1.4.1 Prepare five test assemblies using the procedure in

1-in.(25.4-mm)awayfromthecenterspacersandparalleltoit. 10.1.1 and 10.1.2.

10.1.2.3 Allow an open time of 30 s 6 5 s upon completion 10.1.4.2 After aging the assemblies 24 h 6 1 h at standard

of spreading. condition (9.1), determine the shear strength in accordance

10.1.2.4 Squarely position the gypsum wallboard-plywood with 10.1.3.

laminate back surface paper onto the adhesive coated plywood 10.1.5 Shear Strength After 14 Days:

1 1

with the overlapping 2 ⁄2 6 ⁄16-in. (63.5 6 1.6-mm), thus 10.1.5.1 Preparefivetestassembliessusingtheprocedurein

2 2

forming the 10-in. (64.5-cm ) bonded area. See Fig. 3. 10.1.1 to 10.1.2.

FIG. 3Shear Strength Test Specimen Assembly

´1

C557−03 (2009)

10.1.5.2 After aging the assemblies 14 days at standard all sides when the bond area is compressed to a line thickness

condition (9.1), determine the shear strength in accordance of approximately ⁄32 in. (0.8 mm).

with 10.1.3. 10.2.1.3 Insertandpositiontwowirespacers,No.20gauge,

10.1.6 Shear Strength After Cyclic Exposure: at least 3 in. (76 mm) long into the bonded area with the

10.1.6.1 Prepare five test assemblies using the procedure in spacerspositioned ⁄4in.(6.3mm)fromeachedgeofthewood

10.1.1 and 10.1.2. block.

10.1.6.2 After aging the assemblies 14 days at standard 10.2.1.4 Compress the bonded area of each tensile test

condition (9.1), process the assemblies through four complete specimen immediately under a load of 5 lb 6 0.1 lb (22 N) for

cycles (see Table 2). Store the assemblies at standard condi- 3 min.

tions (9.1) for 24 h after each cycle. 10.2.1.5 Removetheweightandnextthespacers.Scrapeall

10.1.6.3 At the end of the cycling, condition the test excess adhesive away from edges using a square-tipped

specimens for 2 days in standard conditions and determine the spatula, taking care to avoid disturbing the alignment. See Fig.

shear strength in accordance with 10.1.3. 4.

10.1.7 Shear Strength for Static Load: 10.2.2 Tensile-Strength Determination—Determine the ten-

10.1.7.1 Prepare ten assemblies using the procedure in sile strength of the adhesive on a testing machine capable of

10.1.1 and 10.1.2.

providing loading at a rate of 60 lbf (267 N)/min. Position the

10.1.7.2 Condition the shear test specimens 14 days at tensiletestspecimenwiththeDouglas-firwoodblockcentered

standard conditions.

between the angles. Refer to Fig. 2. The tensile test fixture is

10.1.7.3 Subject five shear test specimens to a static load of mounted to a permanent base and includes self-alignment

40 lbf (178 N) at 73 6 2°F (23 6 1°C) and five shear test

features to ensure the stress application is perpendicular to the

specimens to 20 lbf (89 N) at 100.2 6 2.0°F (38 6 1°C) for a joint until failure. Connect the tensile test specimen to the test

period of 24 h. When testing, the wallboard/plyw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.