ASTM E547-00(2009)

(Test Method)Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Cyclic Static Air Pressure Difference

Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Cyclic Static Air Pressure Difference

SIGNIFICANCE AND USE

This test method is a standard procedure for determining the resistance to water penetration under cyclic static air pressure differences. The air-pressure differences acting across a building envelope vary greatly. These factors should be fully considered prior to specifying the test pressure difference to be used.

Note 1—In applying the results of tests by this test method, note that the performance of a wall or its components, or both, may be a function of proper installation and adjustment. In service, the performance will also depend on the rigidity of supporting construction and on the resistance of components to deterioration by various causes, vibration, thermal expansion and contraction, etc. It is difficult to simulate the identical complex wetting conditions that can be encountered in service, with large wind-blown water drops, increasing water drop impact pressures with increasing wind velocity, and lateral or upward moving air and water. Some designs are more sensitive than others to this upward moving water.

Note 2—This test method does not identify unobservable liquid water which may penetrate into the test specimen.

SCOPE

1.1 This test method covers the determination of the resistance of exterior windows, curtain walls, skylights, and doors to water penetration when water is applied to the outdoor face and exposed edges simultaneously with a cyclic static air pressure at the outdoor face higher than the pressure at the indoor face.

1.2 This test method is applicable to any curtain-wall area or to windows, skylights, or doors alone.

1.3 This test method addresses water penetration through a manufactured assembly. Water that penetrates the assembly, but does not result in a failure as defined herein, may have adverse effects on the performance of contained materials such as sealants and insulating or laminated glass. This test method does not address these issues.

1.4 The proper use of this test method requires a knowledge of the principles of pressure measurement.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 7.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E547 − 00(Reapproved 2009)

Standard Test Method for

Water Penetration of Exterior Windows, Skylights, Doors,

and Curtain Walls by Cyclic Static Air Pressure Difference

This standard is issued under the fixed designation E547; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the resis- 3.1 Definitions—For definitions of general terms relating to

tance of exterior windows, curtain walls, skylights, and doors buildingconstructionusedinthistestmethod,seeTerminology

to water penetration when water is applied to the outdoor face E631.

and exposed edges simultaneously with a cyclic static air 3.2 Definitions of Terms Specific to This Standard:

pressure at the outdoor face higher than the pressure at the

3.2.1 specimen, n—the entire assembled unit submitted for

indoor face.

test as described in Section 8.

1.2 Thistestmethodisapplicabletoanycurtain-wallareaor

3.2.2 test pressure difference, n—the specified difference in

to windows, skylights, or doors alone.

static air pressure across the closed and locked or fixed

specimen expressed as pascals (lbf/ft ).

1.3 This test method addresses water penetration through a

manufactured assembly. Water that penetrates the assembly,

3.2.3 water penetration, n—penetration of water beyond a

but does not result in a failure as defined herein, may have

plane parallel to the glazing (the vertical plane) intersecting the

adverse effects on the performance of contained materials such

innermost projection of the test specimen, not including

as sealants and insulating or laminated glass. This test method

interiortrimandhardware,underthespecifiedconditionsofair

does not address these issues.

pressure difference across the specimen. For products with

non-planer glazing surfaces (domes, vaults, pyramids, etc.), the

1.4 The proper use of this test method requires a knowledge

plane defining water penetration is the plane defined by the

of the principles of pressure measurement.

innermost edges of the unit frame.

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are mathematical

4. Summary of Test Method

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard. 4.1 This test method consists of sealing the test specimen

into or against one face of a test chamber, and supplying air to

1.6 This standard does not purport to address all of the

or exhausting air from the chamber at the rate required to

safety concerns, if any, associated with its use. It is the

maintain the test pressure difference across the specimen for

responsibility of the user of this standard to establish appro-

the time cycle specified, while spraying water onto the outdoor

priate safety and health practices and determine the applica-

face of the specimen at the required rate and observing any

bility of regulatory limitations prior to use. For specific hazard

water penetration.

statements, see 7.1.

2. Referenced Documents 5. Significance and Use

2.1 ASTM Standards:

5.1 Thistestmethodisastandardprocedurefordetermining

E631 Terminology of Building Constructions

the resistance to water penetration under cyclic static air

pressure differences. The air-pressure differences acting across

a building envelope vary greatly. These factors should be fully

This test method is under the jurisdiction of ASTM Committee E06 on

considered prior to specifying the test pressure difference to be

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

used.

on Performance of Windows, Doors, Skylights and Curtain Walls.

Current edition approved Feb. 1, 2009. Published March 2009. Originally

NOTE 1—In applying the results of tests by this test method, note that

approved in 1975. Last previous edition approved in 2000 as E547 – 00. DOI:

the performance of a wall or its components, or both, may be a function

10.1520/E0547-00R09.

ofproperinstallationandadjustment.Inservice,theperformancewillalso

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

depend on the rigidity of supporting construction and on the resistance of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on components to deterioration by various causes, vibration, thermal expan-

the ASTM website. sion and contraction, etc. It is difficult to simulate the identical complex

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E547 − 00 (2009)

wetting conditions that can be encountered in service, with large wind-

velocity.Ameans of access into the chamber may be provided

blown water drops, increasing water drop impact pressures with increas-

to facilitate adjustments and observations after the specimen

ing wind velocity, and lateral or upward moving air and water. Some

has been installed.

designs are more sensitive than others to this upward moving water.

6.2.2 Air System—A controllable blower, compressed air

NOTE 2—This test method does not identify unobservable liquid water

which may penetrate into the test specimen.

supply, exhaust system, or reversible blower designed to

provide the required maximum air-pressure difference across

6. Apparatus

the specimen. The system must provide essentially constant air

flow at a fixed pressure for the required test period.

6.1 The description of apparatus in this section is general in

nature, and any arrangement of equipment capable of perform- 6.2.3 Pressure-Measuring Apparatus—A device to measure

the test pressure difference within a tolerance of 62% or

ing the test procedure within the allowable tolerances is

permitted. 62.5 Pa (60.01 in. of water column), whichever is greater.

6.2.4 Water-Spray System:

6.2 Major Components (Fig. 1):

6.2.4.1 The water-spray system shall deliver water uni-

6.2.1 Test Chamber or box with an opening, a removable

formly against the exterior surface of the test specimen at a

mounting panel, or one open side in which or against which the

2 2

minimum rate of 3.4 L⁄m · min (5.0 U.S. gal⁄ft · h).

specimenisinstalledandsealed.Atleastonestaticpressuretap

shall be provided to measure the chamber pressure, and shall 6.2.4.2 The water-spray system shall have nozzles spaced

be so located that the reading is unaffected by the velocity of on a uniform grid, located at a uniform distance from the test

the air supply to or from the chamber. The air supply opening specimen, and shall be adjustable to provide the specified

into the chamber shall be arranged so that the air does not quantity of water in such a manner as to wet all of the test

impinge directly on the test specimen with any significant specimen uniformly and to wet those areas vulnerable to water

NOTE 1—For a negative pressure system, the water-spray grid would be located outside the chamber and the air supply would be replaced by an

air-exhaust system.

FIG. 1 General Arrangement of the Water Leakage Apparatus Positive Chamber System

E547 − 00 (2009)

select specimens covering the range of sizes to be used in a building. In

penetration. If additional nozzles are required to provide

general, the largest size of a particular design, type, construction, and

uniformity of water spray at the edge of the test specimen, they

configuration to be used should be tested.

shall be equally spaced around the entire spray grid.

9. Calibration

7. Hazards

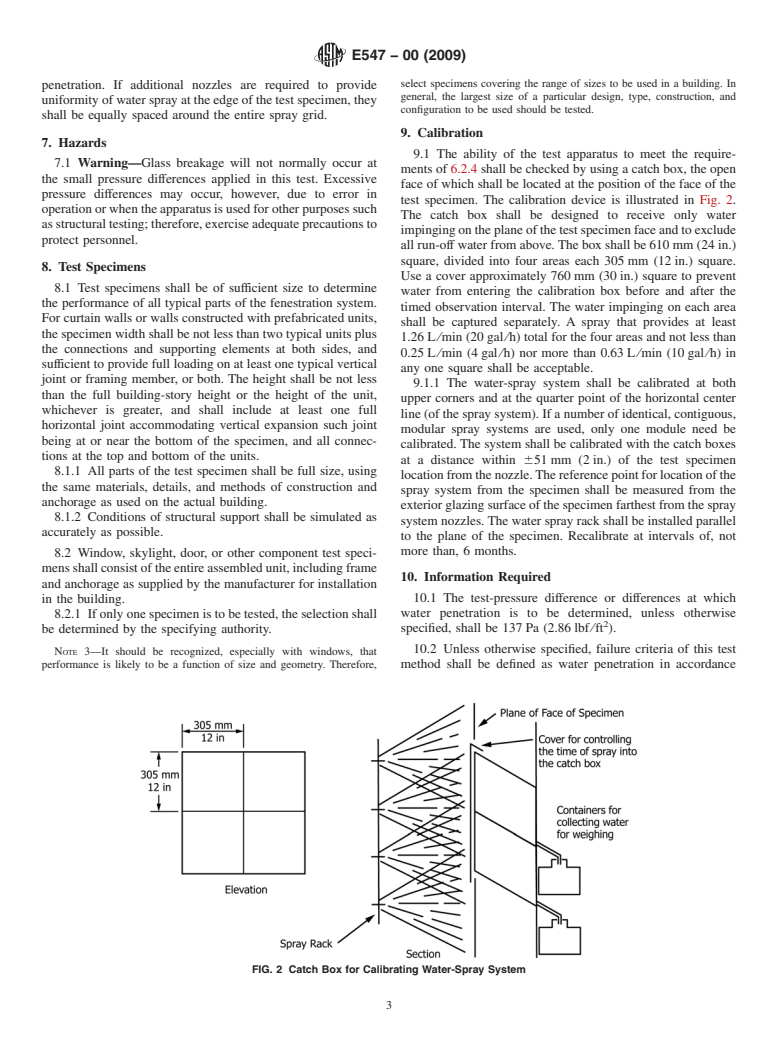

9.1 The ability of the test apparatus to meet the require-

7.1 Warning—Glass breakage will not normally occur at

ments of 6.2.4 shall be checked by using a catch box, the open

the small pressure differences applied in this test. Excessive

face of which shall be located at the position of the face of the

pressure differences may occur, however, due to error in

test specimen. The calibration device is illustrated in Fig. 2.

operationorwhentheapparatusisusedforotherpurposessuch

The catch box shall be designed to receive only water

asstructuraltesting;therefore,exerciseadequateprecautionsto

impingingontheplaneofthetestspecimenfaceandtoexclude

protect personnel.

all run-off water from above. The box shall be 610 mm (24 in.)

square, divided into four areas each 305 mm (12 in.) square.

8. Test Specimens

Use a cover approximately 760 mm (30 in.) square to prevent

8.1 Test specimens shall be of sufficient size to determine

water from entering the calibration box before and after the

the performance of all typical parts of the fenestration system.

timed observation interval. The water impinging on each area

For curtain walls or walls constructed with pre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: E 547 – 00 (Reapproved 2009)

Designation:E547–96

Standard Test Method for

Water Penetration of Exterior Windows, Curtain Walls, and

Doors by Cyclic Static Air Pressure DifferentialWater

Penetration of Exterior Windows, Skylights, Doors, and

Curtain Walls by Cyclic Static Air Pressure Difference

This standard is issued under the fixed designation E 547; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the resistance of exterior windows, curtain walls, skylights, and doors to water

penetration when water is applied to the outdoor face and exposed edges simultaneously with a cyclic static air pressure at the

outdoor face higher than the pressure at the indoor face.

1.2 This test method is applicable to any curtain-wall area or to windows, skylights, or doors alone.

1.3 Thistestmethodaddresseswaterpenetrationthroughamanufacturedassembly.Waterthatpenetratestheassembly,butdoes

not result in a failure as defined herein, may have adverse effects on the performance of contained materials such as sealants and

insulating or laminated glass. This test method does not address these issues.

1.4 The proper use of this test method requires a knowledge of the principles of pressure measurement.

1.5The values stated in SI units are to be regarded as the standard. The inch-pound equivalents of SI units may be approximate.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see 7.1.

2. Referenced Documents

2.1 ASTM Standards:

E 631 Terminology of Building Constructions

3. Terminology

3.1 Definitions—For definitions of general terms relating to building construction used in this test method, see Terminology

E 631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 specimen, n—the entire assembled unit submitted for test as described in Section 8.

3.2.2 test pressure difference, n—the specified difference in static air pressure across the closed and locked or fixed specimen

expressed as pounds-force per square foot (or pascals). pascals (lbf/ft ).

3.2.3 water penetration, n—penetration of water beyond the vertical plane intersecting the innermost projection of the test

specimen, not including interior trim and hardware, under the specified conditions of air pressure difference across the specimen.

—penetration of water beyond a plane parallel to the glazing (the vertical plane) intersecting the innermost projection of the test

specimen, not including interior trim and hardware, under the specified conditions of air pressure difference across the specimen.

For products with non-planer glazing surfaces (domes, vaults, pyramids, etc.), the plane defining water penetration is the plane

defined by the innermost edges of the unit frame.

This test method is under the jurisdiction ofASTM Committee E-6 on Performance of Buildings and is the direct responsibility of Subcommittee E06.51 on Component

Performance of Windows, Curtain Walls, and Doors.

Current edition approved Sept. 10, 1996. Published November 1996. Originally published as E547–75. Last previous edition E547–93.

This test method is under the jurisdiction ofASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.51 on Performance

of Windows, Doors, Skylights, and Curtain Walls.

Current edition approved Feb. 1, 2009. Published March 2009. Originally approved in 1975. Last previous edition approved in 2000 as E 547 – 00.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 04.11.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E547–00 (2009)

4. Summary of Test Method

4.1 This test method consists of sealing the test specimen into or against one face of a test chamber, and supplying air to or

exhausting air from the chamber at the rate required to maintain the test pressure difference across the specimen for the time cycle

specified, while spraying water onto the outdoor face of the specimen at the required rate and observing any water penetration.

5. Significance and Use

5.1 This test method is a standard procedure for determining the resistance to water penetration under cyclic static air pressure

differences. The air-pressure differences acting across a building envelope vary greatly. These factors should be fully considered

prior to specifying the test pressure difference to be used.

NOTE 1—In applying the results of tests by this test method, note that the performance of a wall or its components, or both, may be a function of proper

installation and adjustment. In service, the performance will also depend on the rigidity of supporting construction and on the resistance of components

to deterioration by various causes, vibration, thermal expansion and contraction, etc. It is difficult to simulate the identical complex wetting conditions

that can be encountered in service, with large wind-blown water drops, increasing water drop impact pressures with increasing wind velocity, and lateral

or upward moving air and water. Some designs are more sensitive than others to this upward moving water.

NOTE 2—This test method does not identify invisibleunobservable liquid water which may penetrate into the test specimen.

6. Apparatus

6.1 The description of apparatus in this section is general in nature, and any arrangement of equipment capable of performing

the test procedure within the allowable tolerances is permitted.

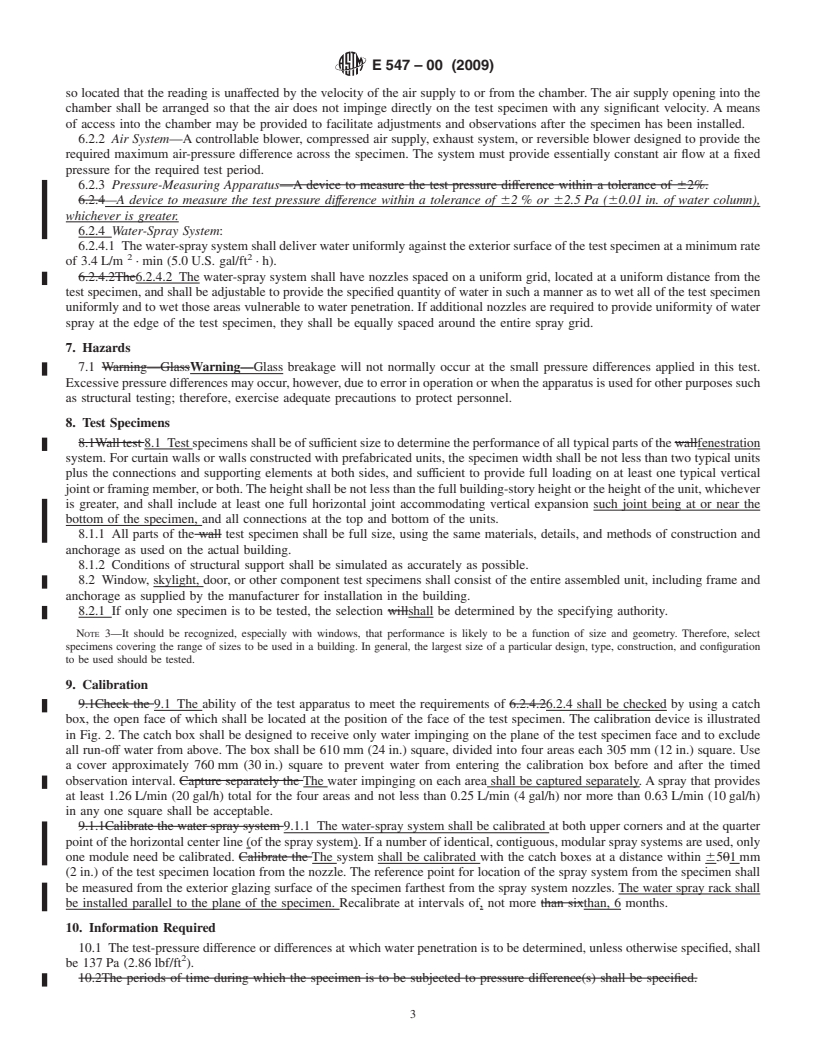

6.2 Major Components (Fig. 1):

6.2.1 Test Chamber or box with an opening, a removable mounting panel, or one open side in which or against which the

specimen is installed and sealed. At least one static pressure tap shall be provided to measure the chamber pressure, and shall be

NOTE 1—For a negative pressure system, the water-spray grid would be located outside the chamber and the air supply would be replaced by an

air-exhaust system.

FIG. 1 General Arrangement of the Water Leakage Apparatus Positive Chamber System

E547–00 (2009)

so located that the reading is unaffected by the velocity of the air supply to or from the chamber. The air supply opening into the

chamber shall be arranged so that the air does not impinge directly on the test specimen with any significant velocity. A means

of access into the chamber may be provided to facilitate adjustments and observations after the specimen has been installed.

6.2.2 Air System—A controllable blower, compressed air supply, exhaust system, or reversible blower designed to provide the

required maximum air-pressure difference across the specimen. The system must provide essentially constant air flow at a fixed

pressure for the required test period.

6.2.3 Pressure-Measuring Apparatus—A device to measure the test pressure difference within a tolerance of 62%.

6.2.4—A device to measure the test pressure difference within a tolerance of 62% or 62.5 Pa (60.01 in. of water column),

whichever is greater.

6.2.4 Water-Spray System:

6.2.4.1 The water-spray system shall deliver water uniformly against the exterior surface of the test specimen at a minimum rate

2 2

of 3.4 L/m · min (5.0 U.S. gal/ft · h).

6.2.4.2The6.2.4.2 The water-spray system shall have nozzles spaced on a uniform grid, located at a uniform distance from the

test specimen, and shall be adjustable to provide the specified quantity of water in such a manner as to wet all of the test specimen

uniformly and to wet those areas vulnerable to water penetration. If additional nozzles are required to provide uniformity of water

spray at the edge of the test specimen, they shall be equally spaced around the entire spray grid.

7. Hazards

7.1 Warning—GlassWarning—Glass breakage will not normally occur at the small pressure differences applied in this test.

Excessive pressure differences may occur, however, due to error in operation or when the apparatus is used for other purposes such

as structural testing; therefore, exercise adequate precautions to protect personnel.

8. Test Specimens

8.1Walltest8.1 Testspecimensshallbeofsufficientsizetodeterminetheperformanceofalltypicalpartsofthewallfenestration

system. For curtain walls or walls constructed with prefabricated units, the specimen width shall be not less than two typical units

plus the connections and supporting elements at both sides, and sufficient to provide full loading on at least one typical vertical

jointorframingmember,orboth.Theheightshallbenotlessthanthefullbuilding-storyheightortheheightoftheunit,whichever

is greater, and shall include at least one full horizontal joint accommodating vertical expansion such joint being at or near the

bottom of the specimen, and all connections at the top and bottom of the units.

8.1.1 All parts of the wall test specimen shall be full size, using the same materials, details, and methods of construction and

anchorage as used on the actual building.

8.1.2 Conditions of s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.