ASTM E330/E330M-14(2021)

(Test Method)Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference

Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference

SIGNIFICANCE AND USE

5.1 This test method is a standard procedure for determining structural performance under uniform static air pressure difference. This typically is intended to represent the effects of a wind load on exterior building surface elements. The actual loading on building surfaces is quite complex, varying with wind direction, time, height above ground, building shape, terrain, surrounding structures, and other factors. The resistance of many windows, curtain walls, and door assemblies to wind loading is also complex and depends on the complete history of load, magnitude, duration, and repetition. These factors are discussed in ASCE/SEI 7 and in the literature (1-8).5

5.2 Design wind velocities are selected for particular geographic locations and probabilities of occurrence based on data from wind velocity maps such as are provided in ASCE/SEI 7. These wind velocities are translated into uniform static air pressure differences and durations acting inward and outward. Complexities of wind pressures, as related to building design, wind intensity versus duration, frequency of occurrence, and other factors must be considered. Superimposed on sustained winds are gusting winds which, for short periods of time from a fraction of a second to a few seconds, are capable of moving at considerably higher velocities than the sustained winds. The analytical procedures in ASCE/SEI 7, wind tunnel studies, computer simulations, and model analyses are helpful in determining the appropriate design wind loads on exterior surface elements of buildings. Generally, wind load durations obtained from ASCE/SEI 7 are 2 s to 10 s and are dependent upon the specific time reference employed in determining the pressure coefficients.

5.3 Some materials have strength or deflection characteristics that are time dependent. Therefore, the duration of the applied test load may have a significant impact on the performance of materials used in the test specimen. The most common examples of materials with...

SCOPE

1.1 This test method describes the determination of the structural performance of exterior windows, doors, skylights, and curtain walls under uniform static air pressure differences, using a test chamber. This test method is applicable to curtain wall assemblies including, but not limited to, metal, glass, masonry, and stone components.2

1.2 This test method is intended only for evaluating the structural performance associated with the specified test specimen and not the structural performance of adjacent construction.

1.3 The proper use of this test method requires a knowledge of the principles of pressure and deflection measurement.

1.4 This test method describes the apparatus and the procedure to be used for applying uniformly distributed test loads to a specimen.

1.4.1 Procedure A (see 11.2) shall be used when a load-deflection curve is not required.

1.4.2 Procedure B (see 11.3) shall be used when a load-deflection curve is required.

1.5 The text of this standard references notes and footnotes which provide explanatory materials. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

1.8 This international standard was developed in accordance with int...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E330/E330M − 14 (Reapproved 2021)

Standard Test Method for

Structural Performance of Exterior Windows, Doors,

Skylights and Curtain Walls by Uniform Static Air Pressure

Difference

This standard is issued under the fixed designation E330/E330M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope used independently of the other, and values from the two

systems shall not be combined.

1.1 This test method describes the determination of the

1.7 This standard does not purport to address all of the

structural performance of exterior windows, doors, skylights,

safety concerns, if any, associated with its use. It is the

and curtain walls under uniform static air pressure differences,

responsibility of the user of this standard to establish appro-

using a test chamber. This test method is applicable to curtain

priate safety, health, and environmental practices and deter-

wall assemblies including, but not limited to, metal, glass,

mine the applicability of regulatory limitations prior to use.

masonry, and stone components.

For specific hazard statements, see Section 7.

1.2 This test method is intended only for evaluating the

1.8 This international standard was developed in accor-

structural performance associated with the specified test speci-

dance with internationally recognized principles on standard-

men and not the structural performance of adjacent construc-

ization established in the Decision on Principles for the

tion.

Development of International Standards, Guides and Recom-

1.3 The proper use of this test method requires a knowledge

mendations issued by the World Trade Organization Technical

of the principles of pressure and deflection measurement. Barriers to Trade (TBT) Committee.

1.4 This test method describes the apparatus and the proce-

2. Referenced Documents

dure to be used for applying uniformly distributed test loads to

2.1 ASTM Standards:

a specimen.

E631 Terminology of Building Constructions

1.4.1 Procedure A (see 11.2) shall be used when a load-

E997 Test Method for Evaluating Glass Breakage Probabil-

deflection curve is not required.

ity Under the Influence of Uniform Static Loads by Proof

1.4.2 Procedure B (see 11.3) shall be used when a load-

Load Testing

deflection curve is required.

E998 Test Method for Structural Performance of Architec-

1.5 The text of this standard references notes and footnotes

tural Glass Products Under the Influence of Uniform

which provide explanatory materials. These notes and foot-

Static Loads

notes (excluding those in tables and figures) shall not be

E1233/E1233M Test Method for Structural Performance of

considered as requirements of the standard.

ExteriorWindows,Doors,Skylights,andCurtainWallsby

Cyclic Air Pressure Differential

1.6 The values stated in either SI units or inch-pound units

E1300 Practice for Determining Load Resistance of Glass in

are to be regarded separately as standard. The values stated in

Buildings

each system are not necessarily exact equivalents; therefore, to

E1886 Test Method for Performance of Exterior Windows,

ensure conformance with the standard, each system shall be

Curtain Walls, Doors, and Impact Protective Systems

Impacted by Missile(s) and Exposed to Cyclic Pressure

Differentials

This test method is under the jurisdiction of ASTM Committee E06 on

E1996 Specification for Performance of Exterior Windows,

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

Curtain Walls, Doors, and Impact Protective Systems

on Performance of Windows, Doors, Skylights and Curtain Walls.

Current edition approved Oct. 15, 2021. Published October 2021. Originally

approved in 1967. Last previous edition approved in 2014 as E330/E330M – 14.

DOI: 10.1520/E0330_E0330M–14R21. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Additional information on curtain wall assemblies can be obtained from the contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fenestration & Glazing Industry Alliance (FGIA), 1900 E Golf Rd, Suite 1250 Standards volume information, refer to the standard’s Document Summary page on

Schaumburg, IL 60173, https://www.fgiaonline.org/. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E330/E330M − 14 (2021)

Impacted by Windborne Debris in Hurricanes wind load on exterior building surface elements. The actual

loading on building surfaces is quite complex, varying with

2.2 ASCE/SEI Standard:

wind direction, time, height above ground, building shape,

ASCE/SEI 7 Minimum Design Loads for Buildings and

terrain, surrounding structures, and other factors. The resis-

Other Structures

tance of many windows, curtain walls, and door assemblies to

3. Terminology

wind loading is also complex and depends on the complete

history of load, magnitude, duration, and repetition. These

3.1 Definitions—Definitions are in accordance with Termi-

factors are discussed in ASCE/SEI 7 and in the literature

nology E631, unless otherwise indicated.

(1-8).

3.2 Definitions of Terms Specific to This Standard:

3.2.1 design wind load—the uniform static air pressure

5.2 Design wind velocities are selected for particular geo-

differences, inward and outward, for which the specimen

graphic locations and probabilities of occurrence based on data

would be designed under service load conditions using con-

from wind velocity maps such as are provided inASCE/SEI 7.

ventional wind engineering specifications and concepts, ex-

These wind velocities are translated into uniform static air

pressed in pascals [or pounds-force per square foot]. This

pressure differences and durations acting inward and outward.

pressure is determined by either analytical or wind-tunnel

Complexities of wind pressures, as related to building design,

procedures (such as are specified in ASCE/SEI 7).

wind intensity versus duration, frequency of occurrence, and

other factors must be considered. Superimposed on sustained

3.2.2 permanent deformation, n—the displacement or

winds are gusting winds which, for short periods of time from

change in dimension of the specimen after the applied load has

a fraction of a second to a few seconds, are capable of moving

been removed and the specimen has relaxed for the specified

at considerably higher velocities than the sustained winds. The

period of time.

analytical procedures in ASCE/SEI 7, wind tunnel studies,

3.2.3 proof load—atestloadmultipliedbyafactorofsafety.

computer simulations, and model analyses are helpful in

3.2.4 stick system, n—a curtain wall assembly composed of

determining the appropriate design wind loads on exterior

individually framed continuous members, vertical mullions,

surface elements of buildings. Generally, wind load durations

and horizontal rails that are installed in a sequential, piece-by-

obtained from ASCE/SEI 7 are 2 s to 10 s and are dependent

piece process. The completed system is assembled entirely in

upon the specific time reference employed in determining the

the field.

pressure coefficients.

3.2.5 structural distress—achangeinconditionofthespeci-

5.3 Some materials have strength or deflection characteris-

men indicative of deterioration or incipient failure, such as

tics that are time dependent. Therefore, the duration of the

cracking, local yielding, fastener loosening, or loss of adhesive

applied test load may have a significant impact on the

bond.

performance of materials used in the test specimen. The most

3.2.6 test load—thespecifieddifferenceinstaticairpressure

common examples of materials with time-dependent response

(positive or negative) for which the specimen is to be tested,

characteristics that are used are glass, plastics, and composites

expressed in pascals [or pounds-force per square foot].

that employ plastics. For this reason, the strength of an

assembly is tested for the actual time duration to which it

3.2.7 test specimen, n—the entire assembled unit submitted

would be exposed to a sustained or a gust load, or both, as

for test (as described in Section 8).

discussed above. Generally, U.S. practice for wind load testing

3.2.8 unit/panel system, n—a curtain wall assembly com-

has been to require a minimum test period of 10 s for test loads

posedofpre-assembledgroupsofindividualframingmembers.

equal to the design wind load and proof loads equal to 1.5

The completed system is designed to be modular,

timesthedesignwindload.Thusasafetyfactorisincorporated

transportable, and installed as a finished assembly.

inthetesting.Ifthedesignwindloadisdeterminedthroughthe

analytical procedures of ASCE/SEI 7, the test load shall be

4. Summary of Test Method

basedonthenominalloadsderivedfromtheloadcombinations

4.1 This test method consists of sealing the test specimen

used in allowable stress design.With test loads for wind higher

into or against one face of a test chamber, supplying air to or

than those determined by ASCE/SEI 7 or of longer time

exhausting air from the chamber according to a specific test

duration than 10 s, the designer must consider what safety

loading program, at the rate required to maintain the test

factors are appropriate. For test loads that represent design

pressure difference across the specimen, and observing,

loads other than wind, such as snow load, consideration shall

measuring, and recording the deflection, deformations, and

be given to establish an appropriate test period for both design

nature of any distress or failures of the specimen.

and proof load testing.

5. Significance and Use 5.4 This standard is not intended to account for the effect of

windborne debris or cyclic loads. Consideration of cyclic air

5.1 Thistestmethodisastandardprocedurefordetermining

pressure differentials is addressed in Test Method E1233/

structural performance under uniform static air pressure differ-

E1233M. Consideration of windborne debris in combination

ence. This typically is intended to represent the effects of a

4 5

Available from American Society of Civil Engineers (ASCE), 1801 Alexander The boldface numbers in parentheses refer to a list of references at the end of

Bell Dr., Reston, VA 20191, http://www.asce.org. this standard.

E330/E330M − 14 (2021)

NOTE 2—It is convenient to use a reversible blower or a separate

with cyclic air pressure differential representing extreme wind

pressure and exhaust system to provide the required air-pressure differ-

events is addressed in Test Method E1886 and Specification

ence so that the test specimen can be tested for the effect of wind blowing

E1996.

against the wall (positive pressure) or for the effect of suction on the lee

side of the building (negative pressure) without removing, reversing, and

5.5 Thistestmethodisnotintendedforuseinevaluatingthe

reinstalling the test specimen. If an adequate air supply is available, a

structural adequacy of glass for a particular application. When

completely airtight seal need not be provided around the perimeter of the

the structural performance of glass is to be evaluated, the

test specimen and the mounting panel, although it is preferable. However,

procedure described in Test Method E997 or E998 shall be

substantial air leakage will require an air supply of much greater capacity

used. to maintain the required pressure differences.

NOTE 1—In applying the results of tests by this test method, note that

6.2.3 Pressure-Measuring Apparatus, to measure the test

the performance of a wall or its components, or both, may be a function

pressure difference within a tolerance of 62% or 62.5 Pa

of fabrication, installation, and adjustment. The specimen may or may not

[60.01 in.] of water column, whichever is greater.

truly represent every aspect of the actual structure. In service, the

performance will also depend on the rigidity of supporting construction,

6.2.4 Deflection-Measuring System, to measure deflections

temperature, and on the resistance of components to deterioration by

within a tolerance of 60.25 mm [60.01 in.].

various other causes, including vibration, thermal expansion and

6.2.4.1 For Procedure A, any locations at which deflections

contraction, etc.

are to be measured shall be stated by the specifier.

6. Apparatus

6.2.4.2 ForProcedureB,maximumandenddeflectionsofat

least one of each type of principal member not directly and

6.1 Thedescriptionoftheapparatusisgeneralinnature;any

continuously supported by surrounding construction shall be

equipment capable of performing the test procedure within the

measured.Additional locations for deflection measurements, if

allowable tolerances is permitted.

required, shall be stated by the specifier.

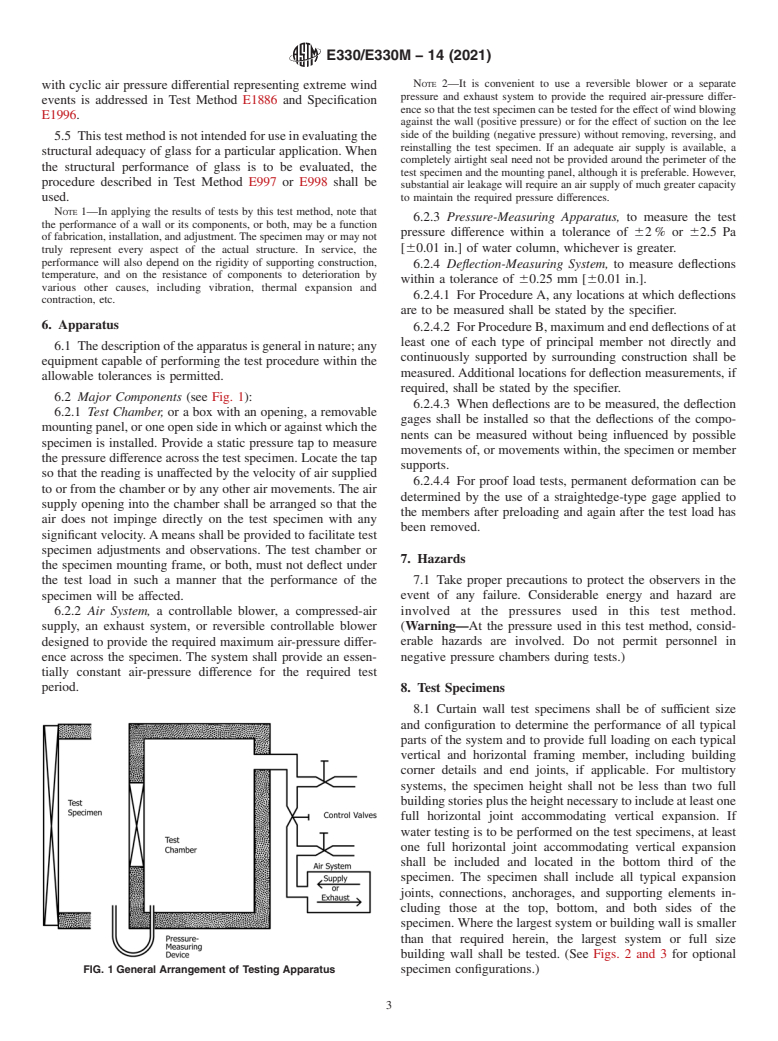

6.2 Major Components (see Fig. 1):

6.2.4.3 When deflections are to be measured, the deflection

6.2.1 Test Chamber, or a box with an opening, a removable

gages shall be installed so that the deflections of the compo-

mountingpanel,oroneopensideinwhichoragainstwhichthe

nents can be measured without being influenced by possible

specimen is installed. Provide a static pressure tap to measure

movements of, or movements within, the specimen or member

the pressure difference across the test specimen. Locate the tap

supports.

so that the reading is unaffected by the velocity of air supplied

6.2.4.4 For proof load tests, permanent deformation can be

to or from the chamber or by any other air movements. The air

determined by the use of a straightedge-type gage applied to

supply opening into the chamber shall be arranged so that the

the members after preloading and again after the test load has

air does not impinge directly on the test specimen with any

been removed.

significant velocity.Ameans shall be provided to facilitate test

specimen adjustments and observations. The test chamber or

7. Hazards

the specimen mounting frame, or both, must not deflect under

the test load in such a manner that the performance of the 7.1 Take proper precautions to protect the observers in the

specimen will be affected. event of any failure. Considerable energy and hazard are

6.2.2 Air System, a controllable blower, a compressed-air involved at the pressures used in this test method.

(Warning—At the pressure used in this test method, consid-

supply, an exhaust system, or reversible controllable blower

designed to provide the re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.