ASTM B372-97(2003)

(Specification)Standard Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

Standard Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

ABSTRACT

This specification covers seamless copper and copper-alloy rectangular waveguide tube intended for use as transmission lines in electronic equipment. Four types of material are specified having the following nominal compositions: C10200, C10300, C12000, and C22000. The copper and copper-alloy tubes shall be finished by such cold-working and annealing operations as are necessary to meet the required properties. The material shall conform to the chemical requirements specified. The material shall conform to the Rockwell hardness requirements prescribed. The test specimens of copper UNS nos. C10200, C10300, and C12000 shall be free of cuprous oxide. It is to be expected that samples of Copper UNS Nos. C10200, C10300, and C12000 shall be capable of passing the embrittlement test. It is to be expected that samples of copper UNS nos. C10200, C10300, and C12000 will conform to the prescribed electrical resistivity requirements. Samples for chemical analysis shall be taken accordingly.

SCOPE

1.1 This specification covers seamless copper and copper-alloy rectangular tube intended for use as transmission lines in electronic equipment. Four types of material are specified having the following nominal compositions:Copper or Copper Alloy UNS No. Previously Used DesignationNominal Composition, % Copper ZincPhos- phorusC10200Copper, Type OF100......C10300...99.99...0.003C12000Copper, Type DLP100......C22000Commercial bronze, 90 %9010... Types OF and DLP are described in Classification B 224.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B372 – 97 (Reapproved 2003)

Standard Specification for

Seamless Copper and Copper-Alloy Rectangular Waveguide

Tube

This standard is issued under the fixed designation B372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Square Copper and Copper Alloy Tube

B577 Test Methods for Detection of Cuprous Oxide (Hy-

1.1 This specification covers seamless copper and copper-

drogen Embrittlement Susceptibility) in Copper

alloy rectangular tube intended for use as transmission lines in

E18 Test Methods for Rockwell Hardness of Metallic Ma-

electronic equipment. Four types of material are specified

terials

having the following nominal compositions:

E29 Practice for Using Significant Digits in Test Data to

Copper or Nominal Composition, %

Determine Conformance with Specifications

Copper Alloy Previously Phos-

UNS No. Used Designation Copper Zinc phorus

E53 Test Method for Determination of Copper in Unalloyed

Copper by Gravimetry

A

C10200 Copper, Type OF 100 . .

E62 Test Methods for Chemical Analysis of Copper and

C10300 . 99.99 . 0.003

A

C12000 Copper, Type DLP 100 . .

Copper Alloys (Photometric Methods)

C22000 Commercial 90 10 .

E255 Practice for Sampling Copper and Copper Alloys for

bronze, 90 %

______________ the Determination of Chemical Composition

A

E478 TestMethodsforChemicalAnalysisofCopperAlloys

Types OF and DLP are described in Classification B224.

2.3 Other Standard:

1.2 The values stated in inch-pound units are to be regarded

ANSI B46.1 Surface Roughness, Waviness, and Lay

as the standard. The values given in parentheses are for

information only.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2.1 The following documents of the issue in effect on date 3.1.1 lengths—straight pieces of the product.

3.1.1.1 ends—straight pieces, shorter than the nominal

of material purchase form a part of this specification to the

length, left over after cutting the product into mill lengths,

extent referenced herein:

stock lengths or specific lengths. They are subject to minimum

2.2 ASTM Standards:

length and maximum weight requirements.

B170 Specification for Oxygen-Free Electrolytic Copper—

3.1.1.2 specific—straight lengths that are uniform in length,

Refinery Shapes

as specified, and subject to established length tolerances.

B193 Test Method for Resistivity of Electrical Conductor

3.1.1.3 specific with ends—specific lengths, including ends.

Materials

3.1.1.4 stock—straightlengthsthataremillcutandstoredin

B224 Classification of Coppers

advance of orders. They are usually 12 ft (3.66 m) and subject

B428 Test Method for Angle of Twist in Rectangular and

to established length tolerances.

3.1.1.5 stock with ends—stock lengths, including ends.

3.1.2 tube—a hollow product of round or any other cross

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

section having a continuous periphery.

and Tube.

3.1.2.1 tube, waveguide—atubeusedastransmissionlineto

Current edition approved Oct. 1, 2003. Published November 2003. Originally

electronic equipment.

approved in 1961. Last previous edition approved in 1997 as B372 – 97. DOI:

10.1520/B0372-97R03.

4. Ordering Information

The UNS system for copper and copper alloys is a simple expansion of the

former standard designation system accomplished by the addition of a prefix“ C”

4.1 Orders for material under this specification shall include

and a suffix “00.” The suffix can be used to accommodate composition variations of

the following information:

the base alloy.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B372 – 97 (2003)

TABLE 2 Hardness Requirements

4.1.1 Material (Sections 1 and 6),

4.1.2 Outer and inner rectangular dimensions (Section 11), Rockwell Hardness,

Copper or Copper Alloy UNS No.

A

30T Scale

4.1.3 Length (see 11.6),

C10200 30 min

4.1.4 Total length of each size,

C10300 30 min

4.1.5 Special packaging, if required (Section 19),

C12000 30 min

4.1.6 Embrittlement test, if required (Section 9),

C22000 43 to 66

4.1.7 Electrical resistivity test, if required (Section 10), and A

The tube shall be split along the center line of its narrow side, and Rockwell

hardness readings then taken on its inner surface.

4.1.8 Special finish, if required (see 12.2).

5. Materials and Manufacture

9. Embrittlement Test

5.1 The material shall be of such quality and purity that the

finished product shall have the properties and characteristics 9.1 It is to be expected that samples of Copper UNS Nos.

prescribed in this specification, and shall be cold drawn to size. C10200, C10300, and C12000 covered by this specification

5.2 The copper will normally be of the types given in Table shall be capable of passing the embrittlement test of Procedure

1, but may be of such other types as may be agreed upon B of Test Methods B577. The actual performance of this test is

between the manufacturer or supplier, and the purchaser. not mandatory under the terms of this specification unless

definitely specified in the ordering information. In case of a

5.3 The copper and copper-alloy tubes shall be finished by

suchcold-workingandannealingoperationsasarenecessaryto dispute, a referee method in accordance with Procedure C shall

be employed.

meet the required properties.

6. Chemical Composition 10. Electrical Resistivity

6.1 Thematerialshallconformtothechemicalrequirements 10.1 It is to be expected that samples of Copper UNS Nos.

specified in Table 1. C10200, C10300, and C12000 covered by this specification

will conform to the following electrical resistivity require-

6.2 These specification limits do not preclude the presence

of other elements. Limits for unnamed elements may be ments, although actual determination of this property is not

mandatory under the terms of this specification unless defi-

established by agreement between manufacturer or supplier

and purchaser. nitely specified. The electrical resistivity of representative

samples of Copper UNS No. C10200 shall not exceed 0.15737

6.3 For copper alloys in which zinc is specified as the

remainder, either copper or zinc may be taken as the difference V·g/m andCopperUNSNo.C10300shallnotexceed0.15940

V·g/m andCopperUNSNo.C12000shallnotexceed0.17418

between the sum of all the elements analyzed and 100 %.

6.3.1 Alloy C22000—When all the elements in Table 1 are V·g/m when tested at 68°F (20°C).

analyzed, their sum shall be 99.8 % minimum.

NOTE 1—The International Annealed Copper Standard electrical con-

ductivity equivalents are as follows:

7. Rockwell Hardness

Electrical Resisitivity, Conductivity,

V·g/m %

7.1 The material shall conform to the Rockwell hardness

0.15176 101.00

requirements prescribed in Table 2.

0.15328 100.00

0.15614 98.16

0.15737 97.40

8. Microscopical Examination

0.15940 96.16

8.1 The test specimens of Copper UNS Nos. C10200, 0.17031 90

0.17418 88

C10300, and C12000 shall be free of cuprous oxide as

determined by Procedure A of Test Methods B577. In case of

11. Dimensions and Permissible Variations

a dispute, a referee method in accordance with Procedure C

11.1 General:

shall be employed.

11.1.1 The standard method of specifying, ordering, and

measuring rectangular waveguide tube shall be major by minor

outer dimension and major by minor inner dimension.

TABLE 1 Chemical Requirements

11.1.2 All cross-sectional measurements shall be made at

Composition, %

the corners at a point at least ⁄2 in. (12.7 mm) from the ends.

Copper

Copper UNS Nos.

Element

11.1.3 Forthepurposeofdeterminingconformancewiththe

Alloy

UNS No.

dimensional requirements prescribed in this specification, any

A

C10200 C10300 C12000

C22000

measured value outside the specified limiting values for any

B

Copper 99.95 min . 99.90 min 89.0–91.0

dimension may be cause for rejection.

B

Copper, + phos- . 99.95 . .

11.2 Dimensional Tolerances:

phorus, min

Phosphorus . 0.001–0.005 0.004–0.012 .

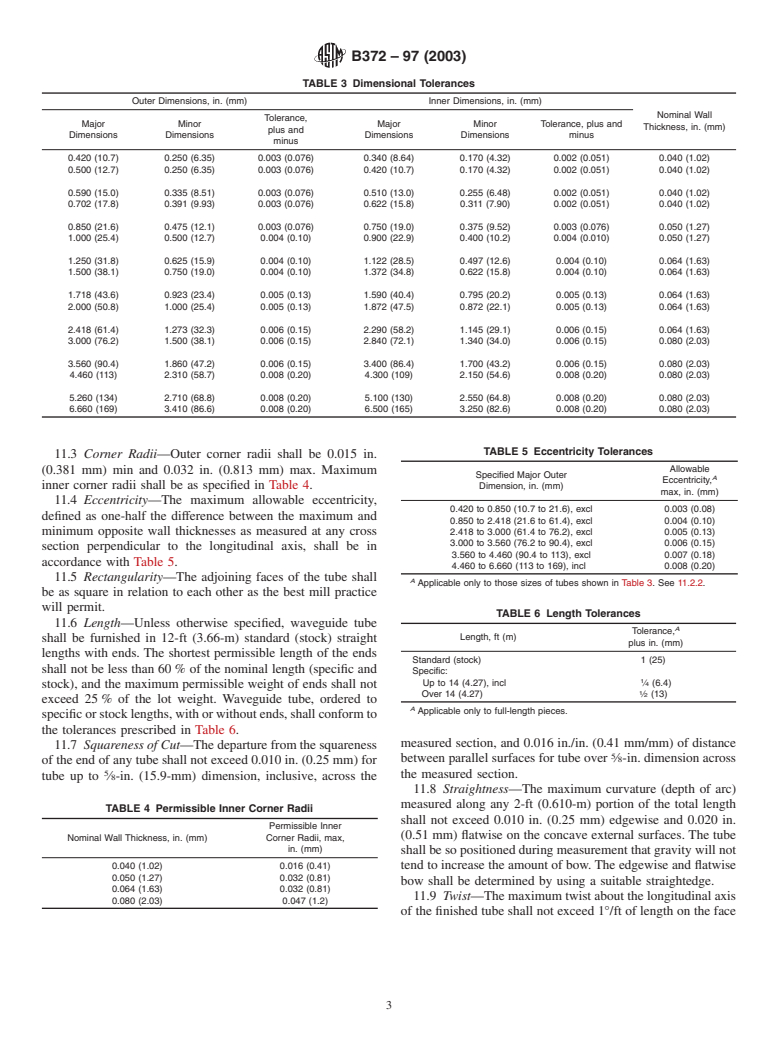

11.2.1 Standard dimensions and tolerances of waveguide

Zinc . . . remainder

tube shall be as specified in Table 3.

Lead, max . . . 0.05

11.2.2 Other dimensions and tolerances shall be subject to

Iron, max . . . 0.05

A agreement between the manufacturer or supplier and the

Oxygen in C10200 shall be 10 ppm max.

B

Silver counting as copper. purchaser.

B372 – 97 (2003)

TABLE 3 Dimensional Tolerances

Outer Dimensions, in. (mm) Inner Dimensions, in. (mm)

Nominal Wall

Tolerance,

Major Minor Major Minor Tolerance, plus and

Thickness, in. (mm)

plus and

Dimensions Dimensions Dimensions Dimensions minus

minus

0.420 (10.7) 0.250 (6.35) 0.003 (0.076) 0.340 (8.64) 0.170 (4.32) 0.002 (0.051) 0.040 (1.02)

0.500 (12.7) 0.250 (6.35) 0.003 (0.076) 0.420 (10.7) 0.170 (4.32) 0.002 (0.051) 0.040 (1.02)

0.590 (15.0) 0.335 (8.51) 0.003 (0.076) 0.510 (13.0) 0.255 (6.48) 0.002 (0.051) 0.040 (1.02)

0.702 (17.8) 0.391 (9.93) 0.003 (0.076) 0.622 (15.8) 0.311 (7.90) 0.002 (0.051) 0.040 (1.02)

0.850 (21.6) 0.475 (12.1) 0.003 (0.076) 0.750 (19.0) 0.375 (9.52) 0.003 (0.076) 0.050 (1.27)

1.000 (25.4) 0.500 (12.7) 0.004 (0.10) 0.900 (22.9) 0.400 (10.2) 0.004 (0.010) 0.050 (1.27)

1.250 (31.8) 0.625 (15.9) 0.004 (0.10) 1.122 (28.5) 0.497 (12.6) 0.004 (0.10) 0.064 (1.63)

1.500 (38.1) 0.750 (19.0) 0.004 (0.10) 1.372 (34.8) 0.622 (15.8) 0.004 (0.10) 0.064 (1.63)

1.718 (43.6) 0.923 (23.4) 0.005 (0.13) 1.590 (40.4) 0.795 (20.2) 0.005 (0.13) 0.064 (1.63)

2.000 (50.8) 1.000 (25.4) 0.005 (0.13) 1.872 (47.5) 0.872 (22.1) 0.005 (0.13) 0.064 (1.63)

2.418 (61.4) 1.273 (32.3) 0.006 (0.15) 2.290 (58.2) 1.145 (29.1) 0.006 (0.15) 0.064 (1.63)

3.000 (76.2) 1.500 (38.1) 0.006 (0.15) 2.840 (72.1) 1.340 (34.0) 0.006 (0.15) 0.080 (2.03)

3.560 (90.4) 1.860 (47.2) 0.006 (0.15) 3.400 (86.4) 1.700 (43.2) 0.006 (0.15) 0.080 (2.03)

4.460 (113) 2.310 (58.7) 0.008 (0.20) 4.300 (109) 2.150 (54.6) 0.008 (0.20) 0.080 (2.03)

5.260 (134) 2.710 (68.8) 0.008 (0.20) 5.100 (130) 2.550 (64.8) 0.008 (0.20) 0.080 (2.03)

6.660 (169) 3.410 (86.6) 0.008 (0.20) 6.500 (165) 3.250 (82.6) 0.008 (0.20) 0.080 (2.03)

TABLE 5 Eccentricity Tolerances

11.3 Corner Radii—Outer corner radii shall be 0.015 in.

Allowable

(0.381 mm) min and 0.032 in. (0.813 mm) max. Maximum

Specified Major Outer

A

Eccentricity,

inner corner radii shall be as specified in Table 4. Dimension, in. (mm)

max, in. (mm)

11.4 Eccentricity—The maximum allowable eccentricity,

0.420 to 0.850 (10.7 to 21.6), excl 0.003 (0.08)

defined as one-half the difference between the maximum and

0.850 to 2.418 (21.6 to 61.4), excl 0.004 (0.10)

minimum opposite wall thicknesses as measured at any cross 2.418 to 3.000 (61.4 to 76.2), excl 0.005 (0.13)

3.000 to 3.560 (76.2 to 90.4), excl 0.006 (0.15)

section perpendicular to the longitudinal axis, shall be in

3.560 to 4.460 (90.4 to 113), excl 0.007 (0.18)

accordance with Table 5.

4.460 to 6.660 (113 to 169), incl 0.008 (0.20)

11.5 Rectangularity—The adjoining faces of the tube shall

A

Applicable only to those sizes of tubes shown in Table 3. See 11.2.2.

be as square in relation to each other as the best mill practice

will permit.

TABLE 6 Length Tolerances

11.6 Length—Unless otherwise specified, waveguide tube

A

Tolerance,

Length, ft (m)

shall be furnished in 12-ft (3.66-m) standard (stock) straight

plus in. (mm)

lengths with ends. The shortest permissible length of the ends

Standard (stock) 1 (25)

shall not be less than 60 % of the nominal length (specific and

Specific:

Up to 14 (4.27), incl ⁄4 (6.4)

stock), and the maximum permissible weight of ends shall not

Over 14 (4.27) ⁄2 (13)

exceed 25 % of the lot weight. Waveguide tube, ordered to

A

Applicable only to full-length pieces.

specificorstocklengths,withorwithoutends,shallconformto

the tolerances prescribed in Table 6.

measured section, and 0.016 in./in. (0.41 mm/mm) of distance

11.7 Squareness of Cut—The departure from the squareness

between parallel surfaces for tube over ⁄8-in. dimension across

of the end of any tube shall not exceed 0.010 in. (0.25 mm) for

the measured section.

tube up to ⁄8-in. (15.9-mm) dimension, inclusive, across the

11.8 Straightness—The maximum curvature (depth of arc)

measured along any 2-ft (0.610-m) portion of the total length

TABLE 4 Permissible Inner Corner Radii

shall not exceed 0.010 in. (0.25 mm) edgewise and 0.020 in.

Permissible Inner

(0.51 mm) flatwise on the concave external surfaces. The tube

Nominal Wall Thickness, in. (mm) Corner Radii, max,

in. (mm)

shall be so positioned during measurement that gravity will not

0.040 (1.02) 0.016 (0.41) tend to increase the amount of bow. The edgewise and flatwise

0.050 (1.27) 0.032 (0.81)

bow shall be determined by using a suitable straightedge.

0.064 (1.63) 0.032 (0.81)

11.9 Twist—The maximum twist about the longitudinal axis

0.080 (2.03) 0.047 (1.2)

of the finished tube shall not exceed 1°/ft of length on the face

B372 – 97 (2003)

of any surface, inside or outside. Determination of twist shall conformance to chemical composition as follows: Conform-

be in accordance with Test Method B428. ance shall be determined by the manufacturer by analyzing

11.10 Surface Roughness—The average interior surface samples taken at the time the castings are poured or samples

roughness of the finished tube, in accordance with AN- taken from the semi-finished product. If the manufacturer

SI B46.1, shall not exceed 32 µin. A.A. for tube up to 4 in. determinesthechemicalcompositionofthematerialduringthe

(102 mm) major ID and 64 µin.A.A. for tube whose major ID course of manufacture, he shall not be required to sample and

is 4 in. or over. analyze the finished product. The number of samples taken for

determination of chemical composition shall be as follows:

12. Workmanship, Finish, and Appearance

14.1.1.1 Whensamplesaretakenatthetimethecastingsare

12.1 The material shall be free of defects of a nature that

poured, at least one sample shall be taken for each group of

interfere with normal commercial applications. The finished

castings poured simultaneously

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.