ASTM B372-11

(Specification)Standard Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

Standard Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

ABSTRACT

This specification covers seamless copper and copper-alloy rectangular waveguide tube intended for use as transmission lines in electronic equipment. Four types of material are specified having the following nominal compositions: C10200, C10300, C12000, and C22000. The copper and copper-alloy tubes shall be finished by such cold-working and annealing operations as are necessary to meet the required properties. The material shall conform to the chemical requirements specified. The material shall conform to the Rockwell hardness requirements prescribed. The test specimens of copper UNS nos. C10200, C10300, and C12000 shall be free of cuprous oxide. It is to be expected that samples of Copper UNS Nos. C10200, C10300, and C12000 shall be capable of passing the embrittlement test. It is to be expected that samples of copper UNS nos. C10200, C10300, and C12000 will conform to the prescribed electrical resistivity requirements. Samples for chemical analysis shall be taken accordingly.

SIGNIFICANCE AND USE

For purposes of determining compliance with the specified limits for requirements of chemical composition, hardness, and electrical resistivity, an observed value or a calculated value shall be rounded to the nearest unit in the last right-hand place of the figures of the specified limit in accordance with the rounding method of Practice E29.

SCOPE

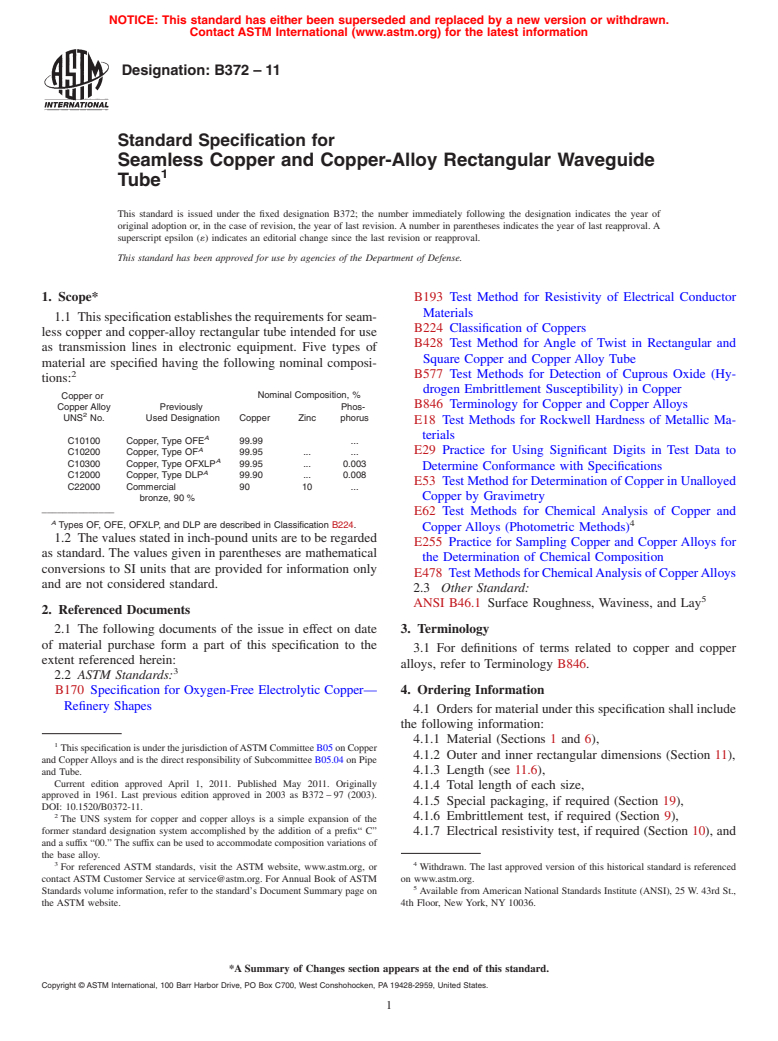

1.1 This specification establishes the requirements for seamless copper and copper-alloy rectangular tube intended for use as transmission lines in electronic equipment. Five types of material are specified having the following nominal compositions:

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B372 – 11

Standard Specification for

Seamless Copper and Copper-Alloy Rectangular Waveguide

1

Tube

This standard is issued under the fixed designation B372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B193 Test Method for Resistivity of Electrical Conductor

Materials

1.1 Thisspecificationestablishestherequirementsforseam-

B224 Classification of Coppers

less copper and copper-alloy rectangular tube intended for use

B428 Test Method for Angle of Twist in Rectangular and

as transmission lines in electronic equipment. Five types of

Square Copper and Copper Alloy Tube

material are specified having the following nominal composi-

2 B577 Test Methods for Detection of Cuprous Oxide (Hy-

tions:

drogen Embrittlement Susceptibility) in Copper

Copper or Nominal Composition, %

B846 Terminology for Copper and Copper Alloys

Copper Alloy Previously Phos-

2

UNS No. Used Designation Copper Zinc phorus

E18 Test Methods for Rockwell Hardness of Metallic Ma-

terials

A

C10100 Copper, Type OFE 99.99 .

A

E29 Practice for Using Significant Digits in Test Data to

C10200 Copper, Type OF 99.95 . .

A

C10300 Copper, Type OFXLP 99.95 . 0.003

Determine Conformance with Specifications

A

C12000 Copper, Type DLP 99.90 . 0.008

E53 Test Method for Determination of Copper in Unalloyed

C22000 Commercial 90 10 .

Copper by Gravimetry

bronze, 90 %

______________

E62 Test Methods for Chemical Analysis of Copper and

A

4

Types OF, OFE, OFXLP, and DLP are described in Classification B224.

Copper Alloys (Photometric Methods)

1.2 The values stated in inch-pound units are to be regarded

E255 Practice for Sampling Copper and Copper Alloys for

as standard. The values given in parentheses are mathematical

the Determination of Chemical Composition

conversions to SI units that are provided for information only

E478 TestMethodsforChemicalAnalysisofCopperAlloys

and are not considered standard.

2.3 Other Standard:

5

ANSI B46.1 Surface Roughness, Waviness, and Lay

2. Referenced Documents

2.1 The following documents of the issue in effect on date 3. Terminology

of material purchase form a part of this specification to the

3.1 For definitions of terms related to copper and copper

extent referenced herein:

alloys, refer to Terminology B846.

3

2.2 ASTM Standards:

4. Ordering Information

B170 Specification for Oxygen-Free Electrolytic Copper—

Refinery Shapes

4.1 Orders for material under this specification shall include

the following information:

4.1.1 Material (Sections 1 and 6),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1.2 Outer and inner rectangular dimensions (Section 11),

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

and Tube. 4.1.3 Length (see 11.6),

Current edition approved April 1, 2011. Published May 2011. Originally

4.1.4 Total length of each size,

approved in 1961. Last previous edition approved in 2003 as B372 – 97 (2003).

4.1.5 Special packaging, if required (Section 19),

DOI: 10.1520/B0372-11.

2

4.1.6 Embrittlement test, if required (Section 9),

The UNS system for copper and copper alloys is a simple expansion of the

former standard designation system accomplished by the addition of a prefix“ C”

4.1.7 Electrical resistivity test, if required (Section 10), and

and a suffix “00.” The suffix can be used to accommodate composition variations of

the base alloy.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Withdrawn. The last approved version of this historical standard is referenced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM on www.astm.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

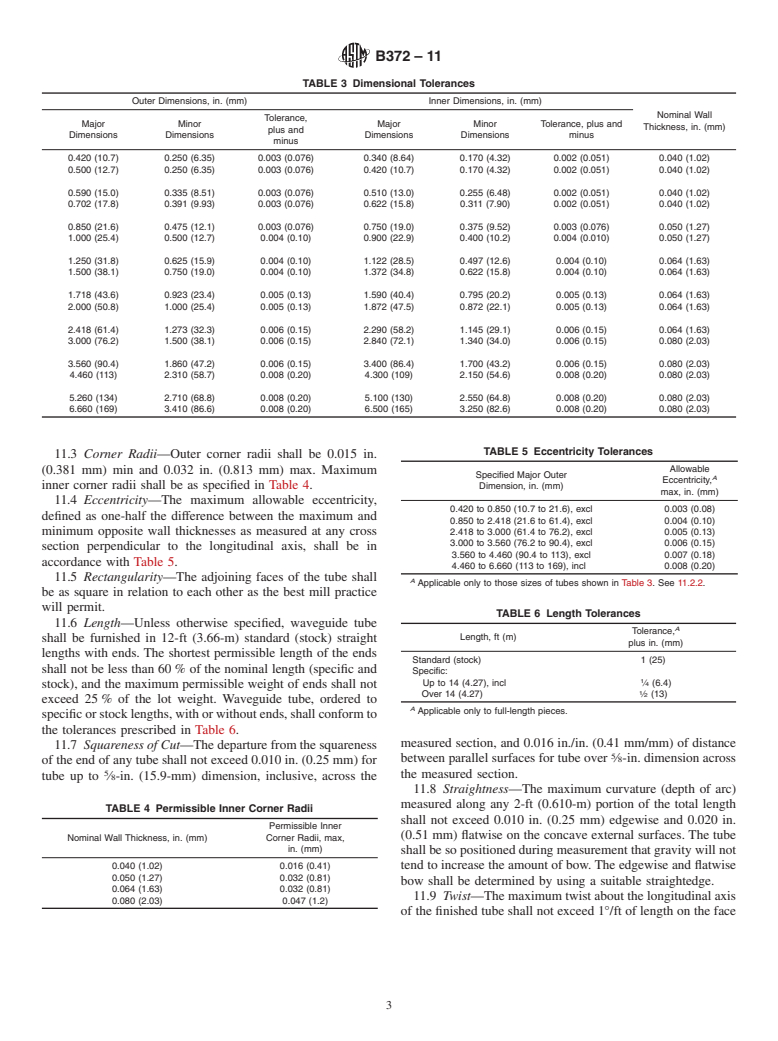

B372 – 11

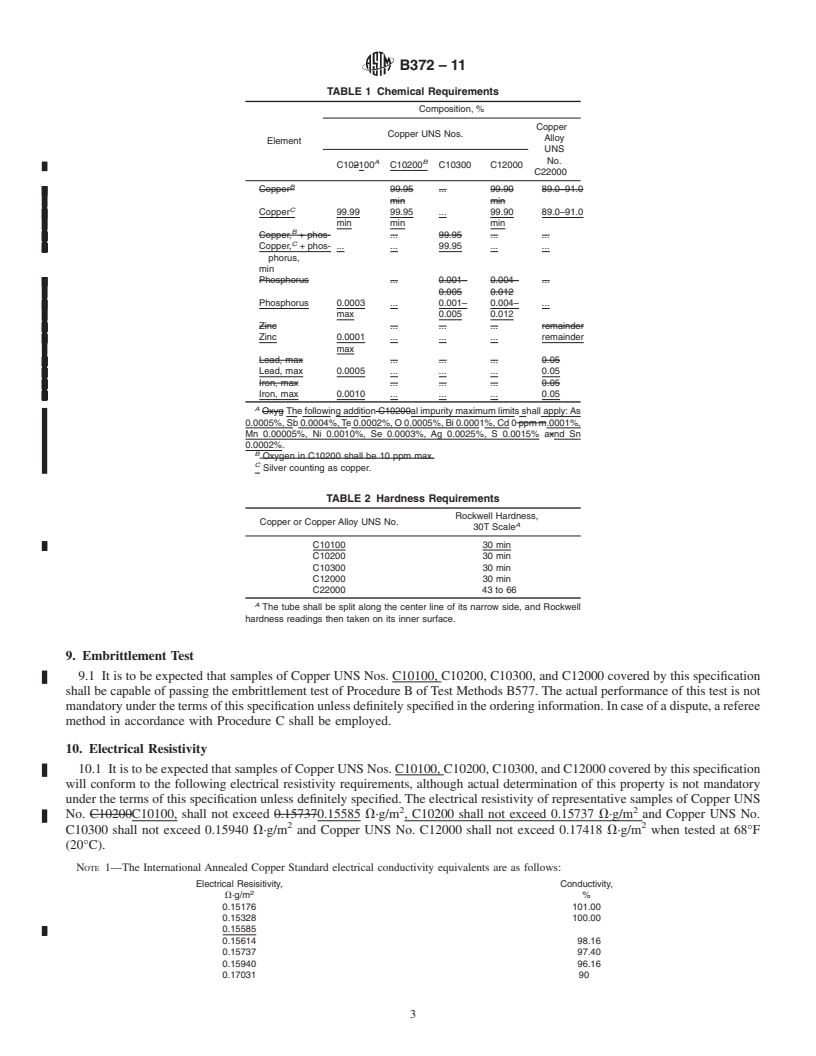

TABLE 2 Hardness Requirements

4.1.8 Special finish, if required (see 12.2).

Rockwell Hardness,

Copper or Copper Alloy UNS No.

A

5. Materials and Manufacture

30T Scale

5.1 The material shall be of such quality and purity that the C10100 30 min

C10200 30 min

finished product shall have the properties and characteristics

C10300 30 min

prescribed in this specification, and shall be cold drawn to size.

C12000 30 min

5.2 The copper will normal

...

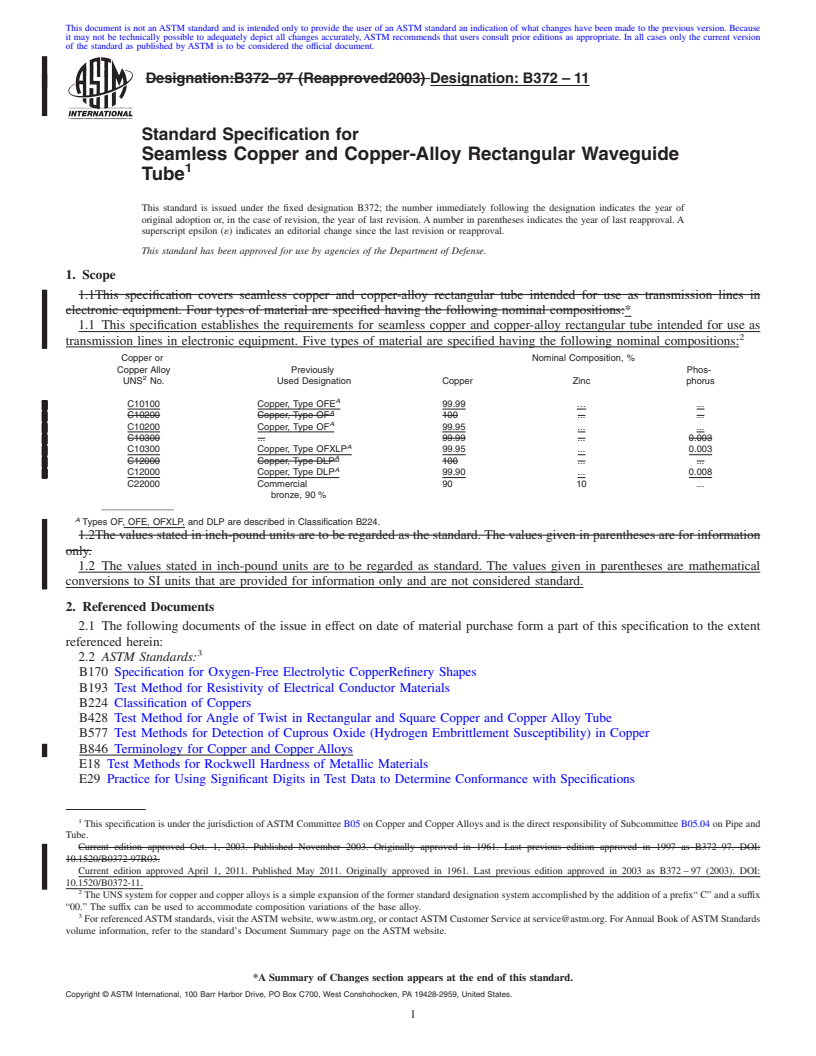

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B372–97 (Reapproved2003) Designation: B372 – 11

Standard Specification for

Seamless Copper and Copper-Alloy Rectangular Waveguide

1

Tube

This standard is issued under the fixed designation B372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1This specification covers seamless copper and copper-alloy rectangular tube intended for use as transmission lines in

electronic equipment. Four types of material are specified having the following nominal compositions:*

1.1 This specification establishes the requirements for seamless copper and copper-alloy rectangular tube intended for use as

2

transmission lines in electronic equipment. Five types of material are specified having the following nominal compositions:

Copper or Nominal Composition, %

Copper Alloy Previously Phos-

2

UNS No. Used Designation Copper Zinc phorus

A

C10100 Copper, Type OFE 99.99 … .

A

C10200 Copper, Type OF 100 . .

A

C10200 Copper, Type OF 99.95 . .

C10300 . 99.99 . 0.003

A

C10300 Copper, Type OFXLP 99.95 . 0.003

A

C12000 Copper, Type DLP 100 . .

A

C12000 Copper, Type DLP 99.90 . 0.008

C22000 Commercial 90 10 .

bronze, 90 %

______________

A

Types OF, OFE, OFXLP, and DLP are described in Classification B224.

1.2The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B170 Specification for Oxygen-Free Electrolytic CopperRefinery Shapes

B193 Test Method for Resistivity of Electrical Conductor Materials

B224 Classification of Coppers

B428 Test Method for Angle of Twist in Rectangular and Square Copper and Copper Alloy Tube

B577 Test Methods for Detection of Cuprous Oxide (Hydrogen Embrittlement Susceptibility) in Copper

B846 Terminology for Copper and Copper Alloys

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2003. Published November 2003. Originally approved in 1961. Last previous edition approved in 1997 as B372–97. DOI:

10.1520/B0372-97R03.

Current edition approved April 1, 2011. Published May 2011. Originally approved in 1961. Last previous edition approved in 2003 as B372 – 97 (2003). DOI:

10.1520/B0372-11.

2

The UNS system for copper and copper alloys is a simple expansion of the former standard designation system accomplished by the addition of a prefix“ C” and a suffix

“00.” The suffix can be used to accommodate composition variations of the base alloy.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B372 – 11

E53 Test Method for Determination of Copper in Unalloyed Copper by Gravimetry

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

2.3 Other Standard:

4

ANSI B46.1 Surface Roughness, Waviness, and Lay

3. Terminology

3.1Definitions:

3.1.1lengths—straight pieces of the product.

3.1.1.1ends—straight pieces, shorter than the nominal length, left over after cutting the product into mill lengths, stock lengths

or specific lengths. They are subject to mi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.