ASTM B584-00

(Specification)Standard Specification for Copper Alloy Sand Castings for General Applications

Standard Specification for Copper Alloy Sand Castings for General Applications

SCOPE

1.1 This specification establishes requirements for copper alloy sand castings for general applications. Nominal compositions of the alloys defined by this specification are shown in Table 1. This is a composite specification replacing former documents as shown in Table 1.

Note 1-Other copper alloy castings are included in the following ASTM specifications: B22, B61, B62, B66, B67, B148, B176, B271, B369, B427, B492, B505, B763, B770, and B806.

1.2 Component part castings produced to this specification may be manufactured in advance and supplied from stock. In such cases the manufacturer shall maintain a general quality certification of all castings without specific record or date of casting for a specific casting.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 584 – 00

Standard Specification for

Copper Alloy Sand Castings for General Applications

This standard is issued under the fixed designation B 584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Continuous Castings

B 271 Specification for Copper-Base Alloy Centrifugal

1.1 This specification covers requirements for copper alloy

Castings

sand castings for general applications. Nominal compositions

B 369 Specification for Copper-Nickel Alloy Castings

of the alloys defined by this specification are shown in Table

B 427 Specification for Gear Bronze Alloy Castings

1. This is a composite specification replacing former docu-

B 492 Specification for Cast Copper-Nickel Ship Tailshaft

ments as shown in Table 1.

Sleeves

NOTE 1—Other copper alloy castings are included in the following

B 505 Specification for Copper-Base Alloy Continuous

ASTM specifications: B 22, B 61, B 62, B 66, B 67, B 148, B 176, B 271,

Castings

B 369, B 427, B 492, B 505, B 763, B 770, and B 806.

B 763 Specification for Copper Alloy Sand Castings for

1.2 Component part castings produced to this specification

Valve Application

may be manufactured in advance and supplied from stock. In

B 770 Specification for Copper-Beryllium Alloy Sand Cast-

such cases the manufacturer shall maintain a general quality

ings for General Applications

certification of all castings without specific record or date of

B 806 Specification for Copper Alloy Permanent Mold

casting for a specific casting.

Castings for General Applications

1.3 The values stated in inch-pound units are to be regarded

B 824 Specification for General Requirements for Copper

as the standard. The values given in parentheses are provided

Alloy Castings

for information purposes only.

B 846 Terminology for Copper and Copper Alloys

E 527 Practice for Numbering Metals and Alloys (UNS)

2. Referenced Documents

2.2 ASME Code:

2.1 ASTM Standards: 6

ASME Boiler and Pressure Vessel Code

B 22 Specification for Bronze Castings for Bridges and

Turntables 3. Terminology

B 61 Specification for Steam or Valve Bronze Castings

3.1 Definitions of terms relating to copper alloys can be

B 62 Specification for Composition Bronze or Ounce Metal

found in Terminology B 846.

Castings

4. General Requirements

B 66 Specification for Bronze Castings for Steam Locomo-

tive Wearing Parts

4.1 The following sections of Specification B 824 form a

B 67 Specification for Car and Tender Journal Bearings,

part of this specification. In the event of a conflict between this

Lined

specification and Specification B 824, the requirements of this

B 148 Specification for Aluminum-Bronze Sand Castings

specification shall take precedence.

B 176 Specification for Copper-Alloy Die Castings

4.1.1 Terminology,

B 208 Practice for Preparing Tension Test Specimens for

4.1.2 Other Requirements,

Copper Alloy Sand, Permanent Mold, Centrifugal, and

4.1.3 Dimensions, Mass, and Permissible Variations,

4.1.4 Workmanship, Finish, and Appearance,

4.1.5 Sampling,

This practice is under the jurisdiction of ASTM Committee B05 on Copper and

4.1.6 Number of Tests and Retests,

Copper Alloys and is the direct responsibility of Subcommittee B05.05 on Castings

4.1.7 Specimen Preparation,

and Ingots for Remelting.

Current edition approved May 10, 2000. Published August 2000. Originally

published as B 584 - 73. Last previous edition B 584 - 98a.

The UNS system for copper and copper alloys (see Practice E 527) is a simple

expansion of the former standard designation system accomplished by the addition Discontinued—Annual Book of ASTM Standards, Vol 02.01.

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate Annual Book of ASTM Standards, Vol 01.01.

composition variations of the base alloy. Available from the American Society of Mechanical Engineers, United Engi-

Annual Book of ASTM Standards, Vol 02.01. neering Center, 345 E. 47th St., New York, NY 10017.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 584–00

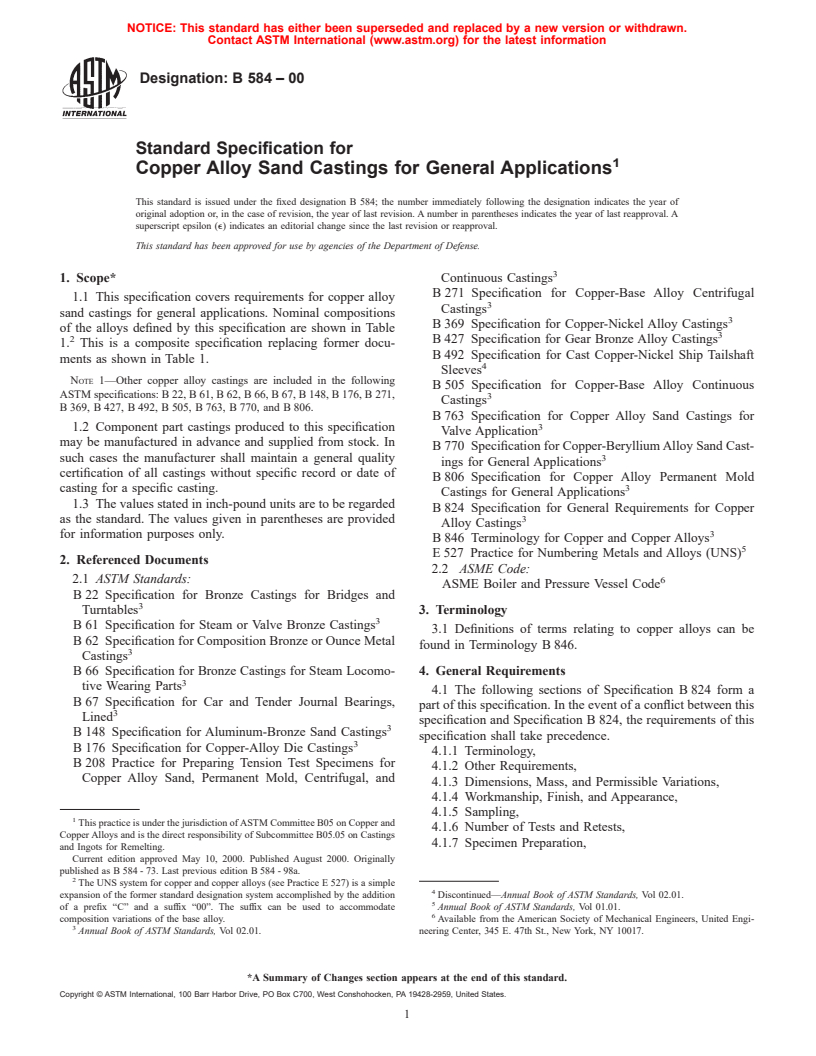

TABLE 1 Nominal Compositions

Copper

Alloy Previous Alum- Man- Sili- Nio- Bis-

Classification Commercial Designation Copper Tin Lead Zinc Nickel Iron

UNS Designation inum ganese con bium muth

No.

1 1

Leaded red brass C83450 . . . . . . 88 2 ⁄2 26 ⁄2 1 . . . . . .

C83600 B 145-4A 85-5-5-5 or No. 1 composition 85555 . . . . . . .

C83800 B 145-4B commercial red brass, 83-4-6-7 83467 . . . . . .

Leaded semi-red C84400 B 145-5A valve composition, 81-3-7-9 81379 . . . . . .

brass

1 1 1 1

C84800 B 145-5B semi-red brass, 76-2 ⁄2-6 ⁄2-15 76 2 ⁄2 6 ⁄2 15 . . . . . . .

Leaded yellow brass C85200 B 146-6A high-copper yellow brass 72 1 3 24 . . . . . . . . . . . . . . . . . . . . .

C85400 B 146-6B commercial No. 1 yellow brass 67 1 3 29 . . . . . . . . . . . . . . . . . . . . .

C85700 B 146-6C leaded naval brass 61 1 1 37 . . . . . . . . . . . . . . . . . . . . .

High-strength yellow C86200 B 147-8B high-strength manganese bronze 63 . . . . . . 27 . . . 3 4 3 . . . . . . . . .

brass

C86300 B 147-8C high-strength manganese bronze 61 . . . . . . 27 . . . 3 6 3 . . . . . . . . .

1 1

C86400 B 147-7A leaded manganese bronze 58 1 1 38 . . . 1 ⁄2 ⁄2 . . .

C86400 B 132-A

C86500 B 147-8A No. 1 manganese bronze 58 . . . . . . 39 . . . 1 1 1 . . . . . . . . .

C86700 B 132-B leaded manganese bronze 58 1 1 34 . . . 2 2 2 . . . . . . . . .

Silicon bronze + C87300 B 198-12A silicon bronze 95 . . . . . . . . . . . . . . . . . . 1 4 . . . . . .

silicon brass

1 1

C87400 B 198-13A silicon brass 82 . . . ⁄2 14 . . . . 3 ⁄2 . .

C87500 B 198-13B silicon brass 82 . . . . . . 14 . . . . . . . . . . . . 4 . . . . . .

C87600 B 198-13C silicon bronze 91 . . . . . . 5 . . . . . . . . . . . . 4 . . . . . .

C87610 B 198-12A silicon bronze 92 . . . . . . 4 . . . . . . . . . . . . 4 . . . . . .

A

Bismuth selenium C89510 . . . sebiloy I 87 5 . . . 5 . . . . . . . . . . . . . . . . . . 1.0

brass

B

C89520 . . . sebiloy II 86 5 ⁄2 . 5 . . . . . . 1.9

Bismuth semi-red C89844 . . . bismuth brass 84 ⁄2 4 . 8 . . . . . . 3

brass

Tin bronze + leaded C90300 B 143-1B modified “G” bronze, 88-8-0-4 88 8 . . . 4 . . . . . . . . . . . . . . . . . . . . .

tin bronze

C90500 B 143-1A “G” bronze, 88-10-0-2 88 10 . . . 2 . . . . . . . . . . . . . . . . . . . . .

1 1

C92200 B 143-2A steam or valve bronze-Navy “M” 88 6 1 ⁄2 4 ⁄2 . . . . . . .

C92210 . . . . . . 88524 1 . . . . .

C92300 B 143-2B 87-5-1-4, Navy PC 87814 . . . . . .

C92600 . . . 87-10-1-2 87 10 1 2 . . . . . . . . . . . . . . . . . . . . .

High-lead tin bronze C93200 B 144-3B 83-7-7-3 83773 . . . . . .

C93500 B 144-3C 85-5-9-1 85591 . . . . . .

C93700 B 144-3A 80-10-10 80 10 10 . . . . . . . . . . . . . . . . . . . . . . . .

C93800 B 144-3D 78-7-15 78 7 15 . . . . . . . . . . . . . . . . . . . . . . . .

C94300 B 144-3E 71-5-24 71 5 24 . . . . . . . . . . . . . . . . . . . . . . . .

Nickel-tin bronze + C94700 B 292-A nickel-tin bronze Grade “A” 88 5 . . . 2 5 . . . . . . . . . . . . . . . . . .

leaded nickel-tin

bronze

C94800 B 292-B leaded nickel-tin bronze Grade “B” 87512 5 . . . . .

C94900 . . . leaded nickel-tin bronze Grade “C” 80555 5 . . . . .

Spinodal alloy C96800 . . . . . . 82 8 . . . . . . 10 . . . . . . . . . . . . 0.2 . . .

Leaded nickel bronze C97300 B 149-10A 12 % leaded nickel silver 57 2 9 20 12 . . . . . . . . . . . . . . . . . .

C97600 B 149-11A 20 % leaded nickel silver 64448 20 . . . . .

C97800 B 149-11B 25 % leaded nickel silver 66522 25 . . . . .

A

Selenium 0.5.

B

Selenium 0.9.

4.1.8 Test Methods, 5.1.3 Copper alloy UNS Number (Table 1) and temper

4.1.9 Significance of Numerical Limits, (as-cast, heat treated, and so forth),

4.1.10 Inspection,

5.1.4 Pattern or drawing number, and condition (as-cast,

4.1.11 Rejection and Rehearing,

machined, etc.),

4.1.12 Certification,

5.1.5 ASME Boiler and Pressure Vessel Code—compliance

4.1.13 Test Report,

(Section 10),

4.1.14 Product Marking,

5.1.6 When material is purchased for agencies of the U.S.

4.1.15 Packaging and Package Marking, and

Government, the Supplementary Requirements of Specifica-

4.1.16 Supplementary Requirements.

tion B 824 may be specified.

5.2 The following options are available and should be

5. Ordering Information

specified in the purchase order when required:

5.1 Orders for castings under this specification should

5.2.1 Chemical analysis of residual elements (7.3),

include the following information:

5.1.1 Specification title, number, and year of issue, 5.2.2 Pressure test or soundness requirements (Specification

5.1.2 Quantity of castings, B 824),

B 584–00

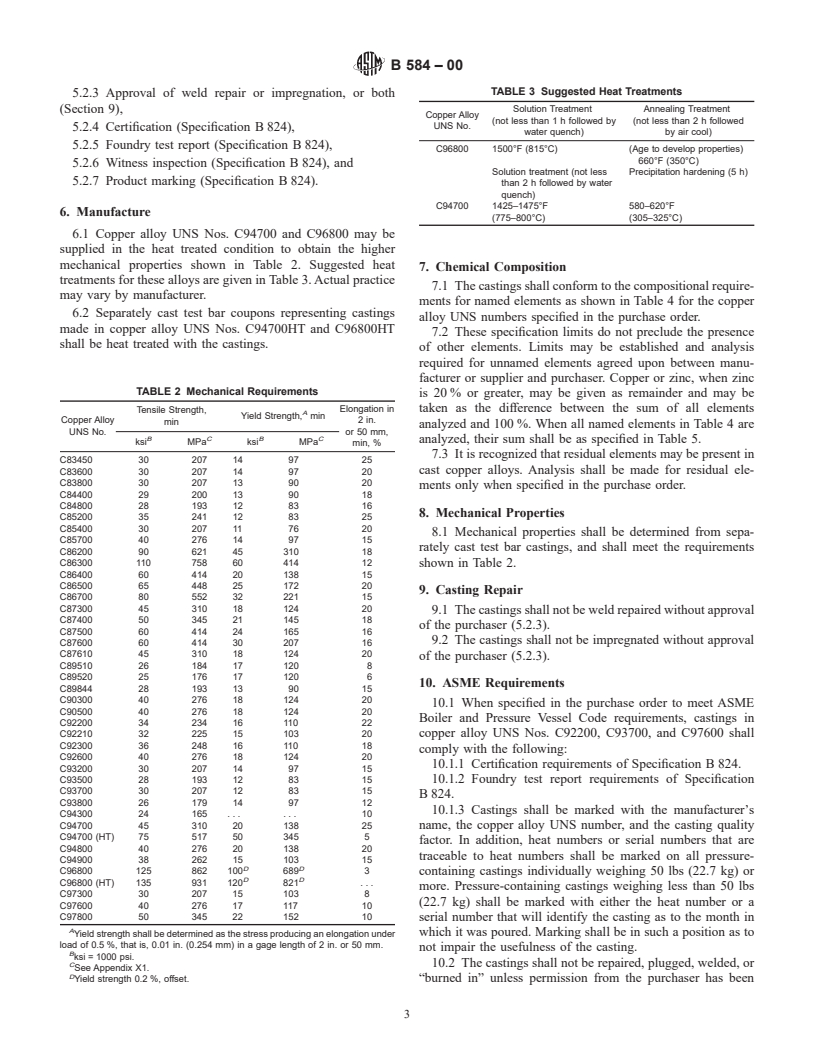

TABLE 3 Suggested Heat Treatments

5.2.3 Approval of weld repair or impregnation, or both

(Section 9), Solution Treatment Annealing Treatment

Copper Alloy

(not less than 1 h followed by (not less than 2 h followed

5.2.4 Certification (Specification B 824), UNS No.

water quench) by air cool)

5.2.5 Foundry test report (Specification B 824),

C96800 1500°F (815°C) (Age to develop properties)

660°F (350°C)

5.2.6 Witness inspection (Specification B 824), and

Solution treatment (not less Precipitation hardening (5 h)

5.2.7 Product marking (Specification B 824).

than 2 h followed by water

quench)

C94700 1425–1475°F 580–620°F

6. Manufacture

(775–800°C) (305–325°C)

6.1 Copper alloy UNS Nos. C94700 and C96800 may be

supplied in the heat treated condition to obtain the higher

mechanical properties shown in Table 2. Suggested heat

7. Chemical Composition

treatments for these alloys are given in Table 3. Actual practice

7.1 The castings shall conform to the compositional require-

may vary by manufacturer.

ments for named elements as shown in Table 4 for the copper

6.2 Separately cast test bar coupons representing castings

alloy UNS numbers specified in the purchase order.

made in copper alloy UNS Nos. C94700HT and C96800HT

7.2 These specification limits do not preclude the presence

shall be heat treated with the castings.

of other elements. Limits may be established and analysis

required for unnamed elements agreed upon between manu-

facturer or supplier and purchaser. Copper or zinc, when zinc

TABLE 2 Mechanical Requirements

is 20 % or greater, may be given as remainder and may be

Elongation in taken as the difference between the sum of all elements

Tensile Strength,

A

Yield Strength, min

Copper Alloy 2 in.

min

analyzed and 100 %. When all named elements in Table 4 are

UNS No. or 50 mm,

B C B C

analyzed, their sum shall be as specified in Table 5.

ksi MPa ksi MPa

min, %

7.3 It is recognized that residual elements may be present in

C83450 30 207 14 97 25

cast copper alloys. Analysis shall be made for residual ele-

C83600 30 207 14 97 20

C83800 30 207 13 90 20

ments only when specified in the purchase order.

C84400 29 200 13 90 18

C84800 28 193 12 83 16

8. Mechanical Properties

C85200 35 241 12 83 25

C85400 30 207 11 76 20

8.1 Mechanical properties shall be determined from sepa-

C85700 40 276 14 97 15

rately cast test bar castings, and shall meet the requirements

C86200 90 621 45 310 18

C86300 110 758 60 414 12 shown in Table 2.

C86400 60 414 20 138 15

C86500 65 448 25 172 20

9. Casting Repair

C86700 80 552 32 221 15

C87300 45 310 18 124 20

9.1 The castings shall not be weld repaired without approval

C87400 50 345 21 145 18

of the purchaser (5.2.3).

C87500 60 414 24 165 16

9.2 The castings shall not be impregnated without approval

C87600 60 414 30 207 16

C87610 45 310 18 124 20

of the purchaser (5.2.3).

C89510 26 184 17 120 8

C89520 25 176 17 120 6

10. ASME Requirements

C89844 28 193 13 90 15

C90300 40 276 18 124 20

10.1 When specified in the purchase order to meet ASME

C90500 40 276 18 124 20

Boiler and Pressure Vessel Code requirements, castings in

C92200 34 234 16 110 22

copper alloy UNS Nos. C92200, C93700, and C97600 shall

C92210 32 225 15 103 20

C92300 36 248 16 110 18

comply with the following:

C92600 40 276 18 124 20

10.1.1 Certification requirements of Specification B 824.

C93200 30 207 14 97 15

C93500 28 193 12 83 15 10.1.2 Foundry test report requirements of Specification

C93700 30 207 12 83 15

B 824.

C93800 26 179 14 97 12

10.1.3 Castings shall be marked with the manufacturer’s

C94300 24 165 . . . . . . 10

C94700 45 310 20 138 25 name, the copper alloy UNS number, and the casting quality

C94700 (HT) 75 517 50 345 5

factor. In addition, heat numbers or serial numbers that are

C94800 40 276 20 138 20

traceable to heat numbers shall be marked on all pressure-

C94900 38 262 15 103 15

D D

C96800 125 862 100 689 3

containing castings individually weighing 50 lbs (22.7 kg) or

D D

C96800 (HT) 135 931 120 821 .

more. Pressure-containing castings weighing less than 50 lbs

C97300 30 207 15 103 8

(22.7 kg) shall be marked with either the heat number or a

C97600 40 276 17 117 10

C97800 50 345 22 152 10

serial number that will identify the casting as to the month in

A

Yield strength shall be determined as the stress producing an elongation under which it was poured. Marking shall be in such a position as to

load of 0.5 %, that is, 0.01 in. (0.254 mm) in a gage length of 2 in. or 50 mm.

not impair the usefulness of the casting.

B

ksi = 1000 psi.

C 10.2 The castings shall not be repaired, plugged, welded, or

See Appendix X1.

D

Yield strength 0.2 %, offset. “burned in” unless permission from the purchaser has been

B 584–00

TABLE 4 Chemical Requirements

Composition, % Max Except as Indicated

Copper

Major Elements Residual Elements

Alloy

UNS

Nickel Nickel

Alumi- Manga- Sele- Anti- Phos- Alumi- Manga-

No. Copper Tin Lead Zinc Iron Incl. Silicon Bismuth Iron incl. Sulfur Silicon Lead

num nese nium mony phorus num nese

Cobalt Cobalt

C83450 87.0–89.0 2.0–3.5 1.5–3.0 5.5–7.5 . . . 0.75–2.0 . . . . . . . . . . . . . . . 0.30 0.25 . . . 0.08 0.05 0.005 . . . 0.005 . . .

A

C83600 84.0–86.0 4.0–6.0 4.0–6.0 4.0–6.0 . . . 1.0 . . . . . . . . . . . . . . . 0.30 0.25 . . . 0.08 0.05 0.005 . . . 0.005 . . .

A

C83800 82.0–83.8 3.3–4.2 5.0–7.0 5.0–8.0 . . . 1.0 . . . . . . . . . . . . . . . 0.30 0.25 . . . 0.08 0.03 0.005 . . . 0.005 . . .

A

C84400 78.0–82.0 2.3–3.5 6.0–8.0 7.0–10.0 . . . 1.0 . . . .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.