ASTM D2711-99

(Test Method)Standard Test Method for Demulsibility Characteristics of Lubricating Oils

Standard Test Method for Demulsibility Characteristics of Lubricating Oils

SCOPE

1.1 This test method covers the measurement of the ability of oil and water to separate from each other. It is intended for use in testing medium and high-viscosity lubricating oils.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2711 – 99 An American National Standard

Standard Test Method for

Demulsibility Characteristics of Lubricating Oils

This standard is issued under the fixed designation D 2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope bility characteristic of lubricating oils that are prone to water

contamination and may encounter the turbulence of pumping

1.1 This test method covers the measurement of the ability

and circulation capable of producing water-in-oil emulsions.

of oil and water to separate from each other. It is intended for

use in testing medium and high-viscosity lubricating oils.

5. Apparatus

1.2 The values stated in SI units are to be regarded as the

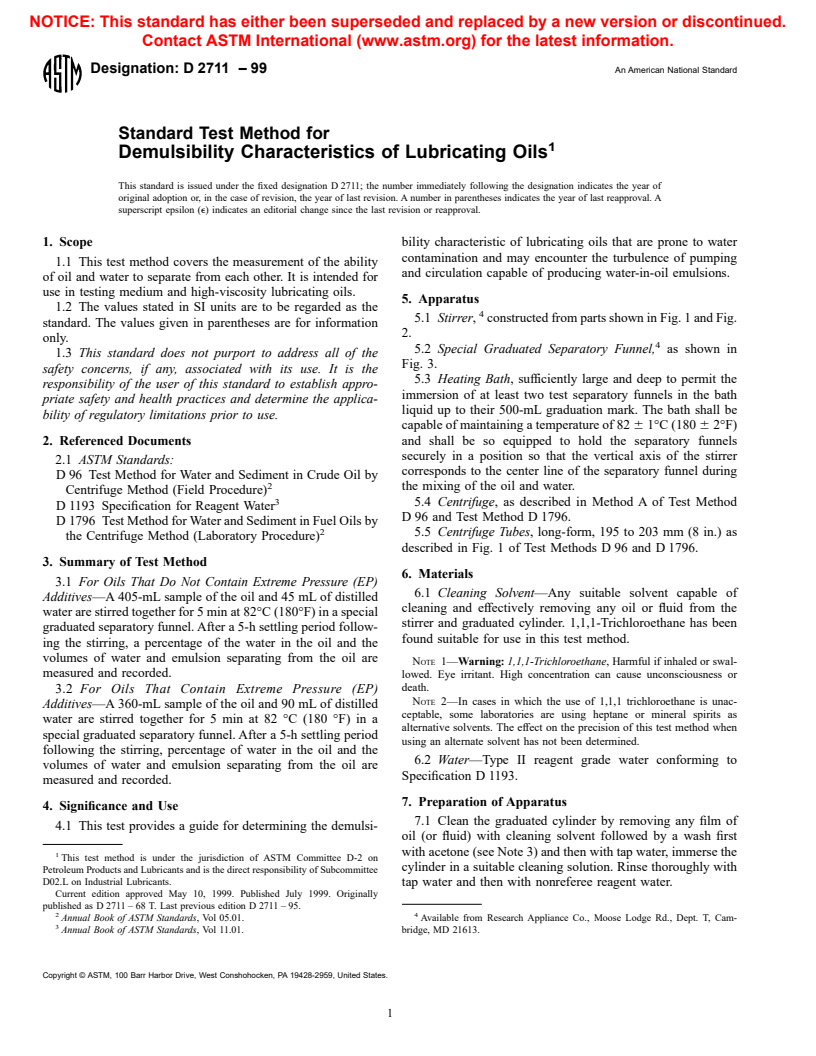

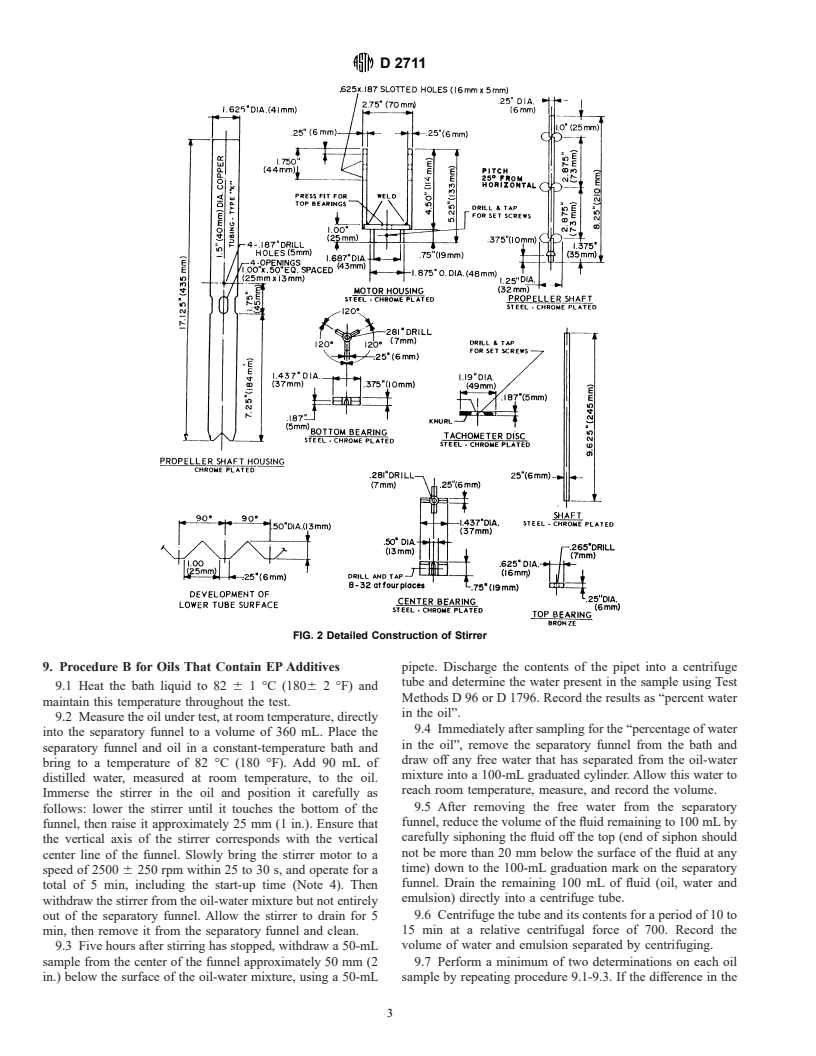

5.1 Stirrer, constructed from parts shown in Fig. 1 and Fig.

standard. The values given in parentheses are for information

2.

only.

5.2 Special Graduated Separatory Funnel, as shown in

1.3 This standard does not purport to address all of the

Fig. 3.

safety concerns, if any, associated with its use. It is the

5.3 Heating Bath, sufficiently large and deep to permit the

responsibility of the user of this standard to establish appro-

immersion of at least two test separatory funnels in the bath

priate safety and health practices and determine the applica-

liquid up to their 500-mL graduation mark. The bath shall be

bility of regulatory limitations prior to use.

capable of maintaining a temperature of 82 6 1°C (180 6 2°F)

2. Referenced Documents and shall be so equipped to hold the separatory funnels

securely in a position so that the vertical axis of the stirrer

2.1 ASTM Standards:

corresponds to the center line of the separatory funnel during

D 96 Test Method for Water and Sediment in Crude Oil by

2 the mixing of the oil and water.

Centrifuge Method (Field Procedure)

5.4 Centrifuge, as described in Method A of Test Method

D 1193 Specification for Reagent Water

D 96 and Test Method D 1796.

D 1796 Test Method for Water and Sediment in Fuel Oils by

5.5 Centrifuge Tubes, long-form, 195 to 203 mm (8 in.) as

the Centrifuge Method (Laboratory Procedure)

described in Fig. 1 of Test Methods D 96 and D 1796.

3. Summary of Test Method

6. Materials

3.1 For Oils That Do Not Contain Extreme Pressure (EP)

6.1 Cleaning Solvent—Any suitable solvent capable of

Additives—A 405-mL sample of the oil and 45 mL of distilled

cleaning and effectively removing any oil or fluid from the

water are stirred together for 5 min at 82°C (180°F) in a special

stirrer and graduated cylinder. 1,1,1-Trichloroethane has been

graduated separatory funnel. After a 5-h settling period follow-

found suitable for use in this test method.

ing the stirring, a percentage of the water in the oil and the

volumes of water and emulsion separating from the oil are

NOTE 1—Warning: 1,1,1-Trichloroethane, Harmful if inhaled or swal-

measured and recorded. lowed. Eye irritant. High concentration can cause unconsciousness or

death.

3.2 For Oils That Contain Extreme Pressure (EP)

NOTE 2—In cases in which the use of 1,1,1 trichloroethane is unac-

Additives—A 360-mL sample of the oil and 90 mL of distilled

ceptable, some laboratories are using heptane or mineral spirits as

water are stirred together for 5 min at 82 °C (180 °F) in a

alternative solvents. The effect on the precision of this test method when

special graduated separatory funnel. After a 5-h settling period

using an alternate solvent has not been determined.

following the stirring, percentage of water in the oil and the

6.2 Water—Type II reagent grade water conforming to

volumes of water and emulsion separating from the oil are

Specification D 1193.

measured and recorded.

7. Preparation of Apparatus

4. Significance and Use

7.1 Clean the graduated cylinder by removing any film of

4.1 This test provides a guide for determining the demulsi-

oil (or fluid) with cleaning solvent followed by a wash first

with acetone (see Note 3) and then with tap water, immerse the

This test method is under the jurisdiction of ASTM Committee D-2 on

cylinder in a suitable cleaning solution. Rinse thoroughly with

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.L on Industrial Lubricants. tap water and then with nonreferee reagent water.

Current edition approved May 10, 1999. Published July 1999. Originally

published as D 2711 – 68 T. Last previous edition D 2711 – 95.

2 4

Annual Book of ASTM Standards, Vol 05.01. Available from Research Appliance Co., Moose Lodge Rd., Dept. T, Cam-

Annual Book of ASTM Standards, Vol 11.01. bridge, MD 21613.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2711

FIG. 1 Stirrer

NOTE 3—Warning: Extremely flammable vapors may cause flash fires.

50-mL pipet. Discharge the contents of the pipet into a

centrifuge tube and determine the water present in the sample

7.2 Clean the stirrer by appropriate means, using the clean-

using Test Methods D 96 or D 1796. Record the results as

ing solvent (6.1). Allow the stirrer to air dry completely prior

“percent water in the oil.”

to use in the test.

8.4 With minimum delay, after sampling for the “percentage

8. Procedure

of water in the oil,” remove the separatory funnel from the bath

8.1 Heat the bath liquid to 82 6 1°C (1806 2°F) and

and draw off any free water that has separated from the

maintain this temperature throughout the test.

oil-water mixture into a 50-mL graduated cylinder. Allow this

8.2 Measure the oil under test, at room temperature, directly

water to reach room temperature, measure, and record the

into the separatory funnel to a volume of 405 mL. Place the

volume.

separatory funnel and oil in the constant-temperature bath and

8.5 After removing the free water from the separatory

bring it to a temperature of 82°C (180°F). Add 45 mL of

funnel, reduce the volume of the fluid remaining to 100 mL by

distilled water, measured at room temperature, to the oil.

carefully siphoning the fluid off the top (end of siphon should

Immerse the stirrer in the oil and position it carefully as

not be more than 20 mm below the surface of the fluid at any

follows: lower the stirrer until it touches the bottom of the

time) down to the 100-mL graduation mark on the separatory

funnel, then raise it approximately 25 mm (1 in.). Ensure that

funnel. Drain the remaining 100 mL of fluid (oil, water, and

the vertical axis of the stirrer corresponds with the vertical

emulsion) directly into a centrifuge tube.

center line of the funnel. Slowly bring the stirrer motor to a

8.6 Centrifuge the tube and its contents for a period of 10 to

speed of 4500 6 500 rpm within 25 to 30 s, and operate for a

15 min at a relative centrifugal force of 700. Record the

total of 5 min, including the start-up time. Then withdraw the

volume of water and emulsion separated by centrifuging.

stirrer from the oil-water mixture but not entirely out of the

8.7 Perform a minimum of two determinations on each oil

separatory funnel. Allow the stirrer to drain for 5 min, then

sample by repeating procedure 8.1-8.6. If the difference in the

remove from the separatory funnel and clean.

8.3 Five hours after stirring has stopped, withdraw a 50-mL two sets of results obtained is outside the repeatability limits of

Procedure A, discard them and obtain two additional sets of

sample from the center of the funnel and approximately 50 mm

(2 in.) below the surface of the oil-water mixture, using a results.

D 2711

FIG. 2 Detailed Construction of Stirrer

9. Procedure B for Oils That Contain EP Additives pipete. Discharge the contents of the pipet into a centrifuge

tube and determine the water present in the sample using Test

9.1 Heat the bath liquid to 82 6 1 °C (1806 2 °F) and

Methods D 96 or D 1796. Record the results as “percent water

maintain this temperature throughout the test.

in the oil”.

9.2 Measure the oil under test, at room temperature, directly

9.4 Immediately after sampling for the “percentage of water

into the separatory funnel to a volume of 360 mL. Place the

in the oil”, remove the separatory funnel from the bath and

separatory funnel and oil in a constant-temperature bath and

draw off any free water that has separated from the oil-water

bring to a temperature of 82 °C (180 °F). Add 90 mL of

mixture into

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.