ASTM D3345-08

(Test Method)Standard Test Method for Laboratory Evaluation of Wood and Other Cellulosic Materials for Resistance to Termites

Standard Test Method for Laboratory Evaluation of Wood and Other Cellulosic Materials for Resistance to Termites

ABSTRACT

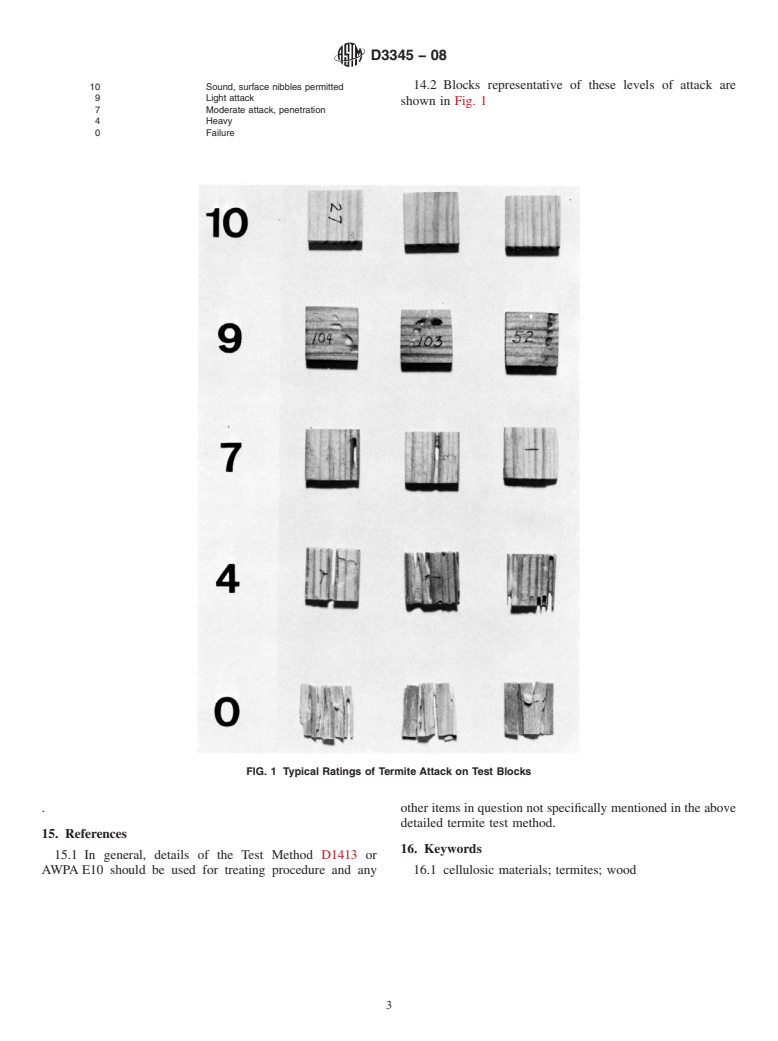

This test method covers the laboratory evaluation of treated or untreated cellulosic material for its resistance to subterranean termites. This test should be considered as a screening test for treated material and further evaluation by field methods is required. Different kinds of equipment and materials to be used in the evaluation of the cellulosic material include containers, glass or clean plastic, tray, enamel, stainless steel, paper towels, and volatile chemicals. Southern yellow pine (SYP) sapwood with no visible defects and smoothed surfaces shall be evaluated by using reagents like benzalkonium chloride solution and distilled water. Other wood species may be used, but in each separate test using other species as the major test wood, five SYP sapwood blocks should be used as additional controls to permit the correlation of test results among laboratories. A block evaluation with corresponding rating system shall be performed by visualization method.

SCOPE

1.1 This test method covers the laboratory evaluation of treated or untreated cellulosic material for its resistance to subterranean termites. This test should be considered as a screening test for treated material and further evaluation by field methods is required.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—See 6.1.4.)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3345 − 08

Standard Test Method for

Laboratory Evaluation of Wood and Other Cellulosic

1

Materials for Resistance to Termites

This standard is issued under the fixed designation D3345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Tray, enamel, stainless steel, or plastic, 0.25 m by 0.51

m (10 by 20 in.) and bucket.

1.1 This test method covers the laboratory evaluation of

treated or untreated cellulosic material for its resistance to 3.3 Paper Towels.

subterranean termites. This test should be considered as a

screening test for treated material and further evaluation by

4. Reagents and Materials

field methods is required.

4.1 Benzalkonium Chloride Solution (1+750)—Add 1 part

1.2 The values stated in SI units are to be regarded as the

benzalkonium chloride to 750 parts water. A comparable

standard. The values given in parentheses are for information

surface antiseptic is satisfactory.

only.

4.2 Distilled Water.

1.3 This standard does not purport to address all of the

4.3 Sand, brown or white, screened, washed, and heat-

safety concerns, if any, associated with its use. It is the

sterilized.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.4 SouthernYellowPine(SYP)(Pinusspp.)measuring25.4

bility of regulatory limitations prior to use. (Warning—See mm (1.00 in.) square by 6.4 mm (0.25 in.) in the tangential

6.1.4.) direction. Sapwood, no visible defects, smoothed surfaces

equivalent to planed or sanded, 2 to 3 rings/cm (4 to 6

rings/in.). All test samples should come from same parent

2. Referenced Documents

2 board.

2.1 ASTM Standards:

4.4.1 Other wood species may be used, but in each separate

D1413 Test Method for Wood Preservatives by Laboratory

test using other species as the major test wood, five SYP

Soil-Block Cultures

sapwood blocks should be used as additional controls to permit

3

2.2 Other Documents:

the correlation of test results among laboratories.

AWPA E10 Testing Wood Preservatives by Laboratory Soil-

4.5 Subterranean Termites—Use a major common species

Block Cultures

of the region being studied.

4.5.1 Specific identification of any termites used shall be

3. Apparatus

obtained and reported with the test data.

3.1 Containers, Glass or Clean Plastic, with loosely fitting

3

tops with liners removed, 220 to 450 cm (8 to 16 oz).

5. Determination of Sand Water-Holding Capacity

3.1.1 Ifvolatilechemicalsaretobetested,a4.8mm(No.12

3 5.1 Determine the quantity of distilled water to be added to

or approximately ⁄16 in.) hole is drilled in the center of the top.

the sand during the test as follows:

5.1.1 Place 100 g of oven-dry sand in a beaker and

determine the volume of water required to saturate the sand.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

The saturation point is defined as the point when the addition

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

Products. of more water will result in free water on the surface of the

Current edition approved March 1, 2008. Published April 2008. Originally

sand.

approved in 1974. Last previous edition approved in 1999 as D3345 – 74 (1999).

5.1.2 Calculate the percent saturation as follows:

DOI: 10.1520/D3345-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

% Saturation 5 ~weight of water/oven dry weight of sand! 3100 (1)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.1.3 Add water to the sand as follows:

the ASTM website.

3

% water to add 5 saturation 2 7.0 (2)

Available from the American Wood Protection Association (AWPA), PO Box

361784, Birmingham, AL 35236-1784, http://www.awpa.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3345 − 08

5.1.4 For example, the saturation point was reached at 20 9.4 Identify all blocks with a number in a suitable manner.

mL of water:

10. Assembling Containers

Saturation 5 20/100 3100 5 20.0% (3)

~ !

10.1 Prior to using, wash all containers rinsed in the surface

%Water to add 5 20.0 2 7.0 5 13.0%

antiseptic solution, and dry.

10.2 Place the test block in the bottom of the container with

6. Collection of Termites

one edge of the block up against the side of the container.

6.1 Subterranean Termites, for example, (Reticulitermes,

10.3 Add 200 g of sand to each container.

Coptotermes, spp.)—Collect f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3345–74 (Reapproved 1999) Designation:D3345–08

Standard Test Method for

Laboratory Evaluation of Wood and Other Cellulosic

1

Materials for Resistance to Termites

This standard is issued under the fixed designation D 3345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the laboratory evaluation of treated or untreated cellulosic material for its resistance to subterranean

termites. This test should be considered as a screening test for treated material and further evaluation by field methods is required.

1.2This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautions, see 6.1.5.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (Warning—See 6.1.4.)

2. Referenced Documents

2

2.1 ASTM Standards:

D 1413Test Method for Wood Preservatives by Laboratory Soil-Block Cultures Test Method for Wood Preservatives by

Laboratory Soil-Block Cultures

3

2.2 Other Documents:

AWPA E10 Testing Wood Preservatives by Laboratory Soil-Block Cultures

3. Apparatus

3

3.1 Containers, Glass or Clean Plastic, with loosely fitting tops with liners removed, 220 to 450 cm (8 to 16 oz).

3

3.1.1 If volatile chemicals are to be tested, a 4.8 mm (No. 12 or approximately ⁄16 in.) hole is drilled in the center of the top.

3.2 Tray, enamel, stainless steel, or plastic, 0.25 m by 0.51 m (10 by 20 in.) and bucket.

3.3 Paper Towels.

4. Reagents and Materials

4.1 Benzalkonium Chloride Solution (1+750)—Add 1 part benzalkonium chloride to 750 parts water. A comparable surface

antiseptic is satisfactory.

4.2 Distilled Water.

4.3 Sand, brown or white, screened, washed, and heat-sterilized.

4.4 Southern Yellow Pine (SYP) (Pinus spp.) measuring 25.4 mm (1.00 in.) square by 6.4 mm (0.25 in.) in the tangential

direction. Sapwood, no visible defects, smoothed surfaces equivalent to planed or sanded, 2 to 3 rings/cm (4 to 6 rings/in.). All

test samples should come from same parent board.

4.4.1 Other wood species may be used, but in each separate test using other species as the major test wood, five southern yellow

pineSYP sapwood blocks should be used as additional controls to permit the correlation of test results among laboratories.

4.5 Subterranean Termites—Use a major common species of the region being studied.

4.5.1 Specific identification of any termites used shall be obtained and reported with the test data.

1

This test method is under the jurisdiction ofASTM Committee D-7 on Wood and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood Products.

Current edition approved Aug. 30, 1974. Published October 1974.

1

This test method is under the jurisdiction ofASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood Products.

Current edition approved March 1, 2008. Published April 2008. Originally approved in 1974. Last previous edition approved in 1999 as D 3345 – 74 (1999).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 04.10.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the American Wood Protection Association (AWPA), PO Box 361784, Birmingham, AL 35236-1784, http://www.awpa.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3345–08

5. Determination of Sand Water-Holding Capacity

5.1 Determine the quantity of distilled water to be added to the sand during the test as follows:

5.1.1 Place 100 g of oven-dry sand in a beaker and determine the volume of water required

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.