ASTM E9-09(2018)

(Test Method)Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

SIGNIFICANCE AND USE

5.1 Significance—The data obtained from a compression test may include the yield strength, the yield point, Young's modulus, the stress-strain curve, and the compressive strength (see Terminology E6). In the case of a material that does not fail in compression by a shattering fracture, compressive strength is a value that is dependent on total strain and specimen geometry.

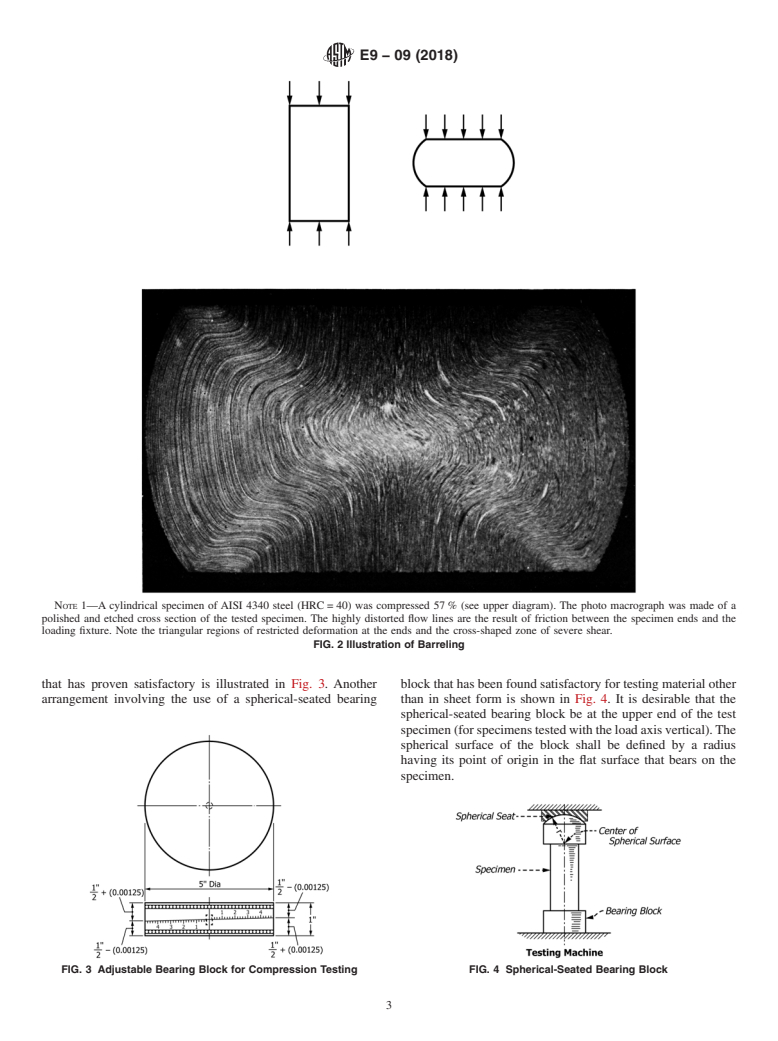

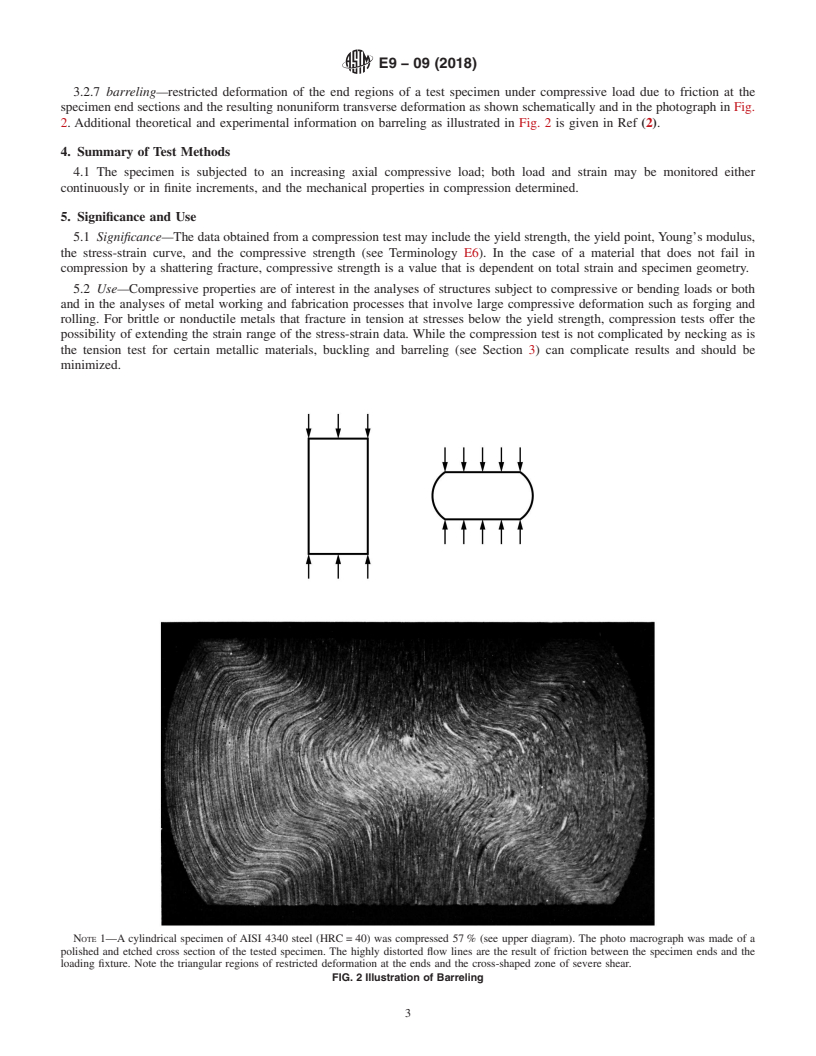

5.2 Use—Compressive properties are of interest in the analyses of structures subject to compressive or bending loads or both and in the analyses of metal working and fabrication processes that involve large compressive deformation such as forging and rolling. For brittle or nonductile metals that fracture in tension at stresses below the yield strength, compression tests offer the possibility of extending the strain range of the stress-strain data. While the compression test is not complicated by necking as is the tension test for certain metallic materials, buckling and barreling (see Section 3) can complicate results and should be minimized.

SCOPE

1.1 These test methods cover the apparatus, specimens, and procedure for axial-load compression testing of metallic materials at room temperature (Note 1). For additional requirements pertaining to cemented carbides, see Annex A1.

Note 1: For compression tests at elevated temperatures, see Practice E209.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E9 − 09 (Reapproved 2018)

Standard Test Methods of

Compression Testing of Metallic Materials at Room

1

Temperature

This standard is issued under the fixed designation E9; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E83Practice for Verification and Classification of Exten-

someter Systems

1.1 These test methods cover the apparatus, specimens, and

E111Test Method for Young’s Modulus, Tangent Modulus,

procedure for axial-load compression testing of metallic mate-

and Chord Modulus

rialsatroomtemperature(Note1).Foradditionalrequirements

E171/E171MPractice for Conditioning andTesting Flexible

pertaining to cemented carbides, see Annex A1.

Barrier Packaging

NOTE 1—For compression tests at elevated temperatures, see Practice

E177Practice for Use of the Terms Precision and Bias in

E209.

ASTM Test Methods

1.2 The values stated in inch-pound units are to be regarded

E209PracticeforCompressionTestsofMetallicMaterialsat

as standard. The values given in parentheses are mathematical

Elevated Temperatures with Conventional or Rapid Heat-

conversions to SI units that are provided for information only

ing Rates and Strain Rates

and are not considered standard.

E251Test Methods for Performance Characteristics of Me-

tallic Bonded Resistance Strain Gages

1.3 This standard does not purport to address all of the

E691Practice for Conducting an Interlaboratory Study to

safety concerns, if any, associated with its use. It is the

Determine the Precision of a Test Method

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental health practices and

3. Terminology

determine the applicability of regulatory limitations prior to

use.

3.1 Definitions: The definitions of terms relating to com-

1.4 This international standard was developed in accor-

pression testing and room temperature in Terminology E6 and

dance with internationally recognized principles on standard-

Practice E171/E171M, respectively, shall apply to these test

ization established in the Decision on Principles for the

methods.

Development of International Standards, Guides and Recom-

3.2 Definitions of Terms Specific to This Standard:

mendations issued by the World Trade Organization Technical

3.2.1 buckling—Inadditiontocompressivefailurebycrush-

Barriers to Trade (TBT) Committee.

ing of the material, compressive failure may occur by (1)

elastic instability over the length of a column specimen due to

2. Referenced Documents

nonaxiality of loading, (2) inelastic instability over the length

2

2.1 ASTM Standards:

of a column specimen, (3) a local instability, either elastic or

B557Test Methods for Tension Testing Wrought and Cast

inelastic, over a small portion of the gage length, or (4)a

Aluminum- and Magnesium-Alloy Products

twisting or torsional failure in which cross sections rotate over

E4Practices for Force Verification of Testing Machines

eachotheraboutthelongitudinalspecimenaxis.Thesetypesof

E6Terminology Relating to Methods of Mechanical Testing

failures are all termed buckling.

3.2.2 column—a compression member that is axially loaded

and that may fail by buckling.

1

These test methods are under the jurisdiction of ASTM Committee E28 on

3.2.3 radius of gyration—the square root of the ratio of the

Mechanical Testing and are the direct responsibility of Subcommittee E28.04 on

Uniaxial Testing.

momentofinertiaofthecrosssectionaboutthecentroidalaxis

Current edition approved Jan. 1, 2018. Published January 2018. Originally

to the cross-sectional area:

published in 1924. Last previous edition approved in 2009 as E9-09. DOI:

1/2

10.1520/E0009-09R18.

ρ 5 ~I/A! (1)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM where:

Standards volume information, refer to the standard’s Document Summary page on

ρ = radius of gyration,

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E9 − 09 (2018)

deformation as shown schematically and in the photograph in

I = moment of inertia of the cross section about centroidal

Fig. 2.Additional theoretical and experimental information on

axis (for specimens without lateral support, the smaller

barreling as illustrated in Fig. 2 is given in Ref (2).

value of I is the critical value), and

A = cross-sectional area.

4. Summary of Test Methods

3.2.4 critical stress—the axial uni

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E9 − 09 E9 − 09 (Reapproved 2018)

Standard Test Methods of

Compression Testing of Metallic Materials at Room

1

Temperature

This standard is issued under the fixed designation E9; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the apparatus, specimens, and procedure for axial-load compression testing of metallic materials

at room temperature (Note 1). For additional requirements pertaining to cemented carbides, see Annex A1.

NOTE 1—For compression tests at elevated temperatures, see Practice E209.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and environmental health practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

E4 Practices for Force Verification of Testing Machines

E6 Terminology Relating to Methods of Mechanical Testing

E83 Practice for Verification and Classification of Extensometer Systems

E111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

E171E171/E171M Practice for Conditioning and Testing Flexible Barrier Packaging

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E209 Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates

and Strain Rates

E251 Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions: The definitions of terms relating to compression testing and room temperature in Terminology E6 and

SpecificationPractice E171E171/E171M, respectively, shall apply to these test methods.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 buckling—In addition to compressive failure by crushing of the material, compressive failure may occur by (1) elastic

instability over the length of a column specimen due to nonaxiality of loading, (2) inelastic instability over the length of a column

1

These test methods are under the jurisdiction of ASTM Committee E28 on Mechanical Testing and are the direct responsibility of Subcommittee E28.04 on Uniaxial

Testing.

Current edition approved Nov. 1, 2009Jan. 1, 2018. Published December 2009January 2018. Originally published in 1924. Last previous edition approved in 2000 as E9

-89a(2000) which was withdrawn March 2009 and2009 as E9reinstated in November 2009. DOI: 10.1520/E0009-09. -09. DOI: 10.1520/E0009-09R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E9 − 09 (2018)

specimen, (3) a local instability, either elastic or inelastic, over a small portion of the gage length, or (4) a twisting or torsional

failure in which cross sections rotate over each other about the longitudinal specimen axis. These types of failures are all termed

buckling.

3.2.2 column—a compression member that is axially loaded and that may fail by buckling.

3.2.3 radius of gyration—the square root of the ratio of the moment of inertia of the cross section about the centroidal axi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.