ASTM D3953-06

(Specification)Standard Specification for Strapping, Flat Steel and Seal

Standard Specification for Strapping, Flat Steel and Seal

SCOPE

1.1 This specification covers flat steel strapping and seals intended for use in closing, reinforcing, bundling articles for shipment, unitizing, palletizing, and bracing for carloading and truckloading.

1.2 This specification includes strapping and seals made from carbon steel and applies only to the types and sizes as cataloged by strapping suppliers to be a standard, commercially available product. It does not include "specialty"-type strapping as developed for special applications or strapping produced from alloy metals.

1.3 The values stated in inch-pound units are to be regarded as standard.

The following safety hazards caveat applies only to the test method portion, Sections 11, 12, and 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3953 – 06

Standard Specification for

1

Strapping, Flat Steel and Seals

This standard is issued under the fixed designation D3953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D4332 Practice for Conditioning Containers, Packages, or

Packaging Components for Testing

1.1 This specification covers flat steel strapping and seals

D4675 Guide for Selection and Use of Flat Strapping

intended for use in closing, reinforcing, bundling articles for

Materials

shipment,unitizing,palletizing,andbracingforcarloadingand

E177 Practice for Use of the Terms Precision and Bias in

truckloading.

ASTM Test Methods

1.2 This specification includes strapping and seals made

E691 Practice for Conducting an Interlaboratory Study to

from carbon steel and applies only to the types and sizes as

Determine the Precision of a Test Method

cataloged by strapping suppliers to be a standard, commer-

2.2 Military Standard:

cially available product. It does not include “specialty”-type

MIL-STD-105 Sampling Procedures and Tables for Inspec-

strapping as developed for special applications or strapping

3

tion by Attributes

produced from alloy metals.

2.3 AAR Open Top Loading Rules Manual, Section No. 1,

1.3 The values stated in inch-pound units are to be regarded

General Rules for Loading All Commodities, Part 2, Rule 17

as standard.

AAR Rule Governing the Loading of Commodities on

1.4 The following safety hazards caveat applies only to the

4

Open Top Cars

test method portion, Sections 11, 12, and 13, of this specifica-

tion: This standard does not purport to address all of the safety

3. Terminology

concerns, if any, associated with its use. It is the responsibility

3.1 General definitions for packaging and distribution envi-

of the user of this standard to establish appropriate safety and

ronments are found in Terminology D996.

health practices and determine the applicability of regulatory

limitations prior to use.

4. Strapping Classifications

4.1 Strapping shall be of the following types, finish and

2. Referenced Documents

2 sizes:

2.1 ASTM Standards:

Type 1, Flat Strapping: Power Machine and Hand Applica-

A90/A90M Test Method for Weight [Mass] of Coating on

tion:

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

Regular-duty

A109/A109M Specification for Steel, Strip, Carbon (0.25

Regular-duty high-strength

Maximum Percent), Cold-Rolled

Heavy-duty

A239 Practice for Locating the Thinnest Spot in a Zinc

Type 2: Nail-On

(Galvanized) Coating on Iron or Steel Articles

4.1.1 Strapping Finish, Lubricated or Dry (see 8.3):

B504 Test Method for Measurement of Thickness of Me-

4.1.1.1 Finish A—Organic (Pigmented or Unpigmented

tallic Coatings by the Coulometric Method

Paint)

D996 TerminologyofPackagingandDistributionEnviron-

4.1.1.2 Finish B—Galvanized (Hot Dipped or Electro-

ments

Deposit Galvanized) (see 8.10):

D3951 Practice for Commercial Packaging

Grade 1—Heavy Coating

Grade 2—Moderate Coating

Grade 3—Commercial Coating

1

This specification is under the jurisdiction of ASTM Committee D10 on

4.1.1.3 Finish C—Organic Painted Metallic Filled (Alumi-

Packaging and is the direct responsibility of Subcommittee D10.25 on Palletizing

and Unitizing of Loads. num or Zinc)

Current edition approved Sept. 15, 2006. Published October 2006. Originally

approved in 1983. Last previous edition approved in 2005 as D3953–05.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4

Standards volume information, refer to the standard’s Document Summary page on Available from the Association of American Railroads (AAR), Safety and

the ASTM website. Operations, 50 F St., NW, Washington, DC 20001–1564.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3953–06

4.1.1.4 Finish D—Uncoated 7. Materials and Manufacture

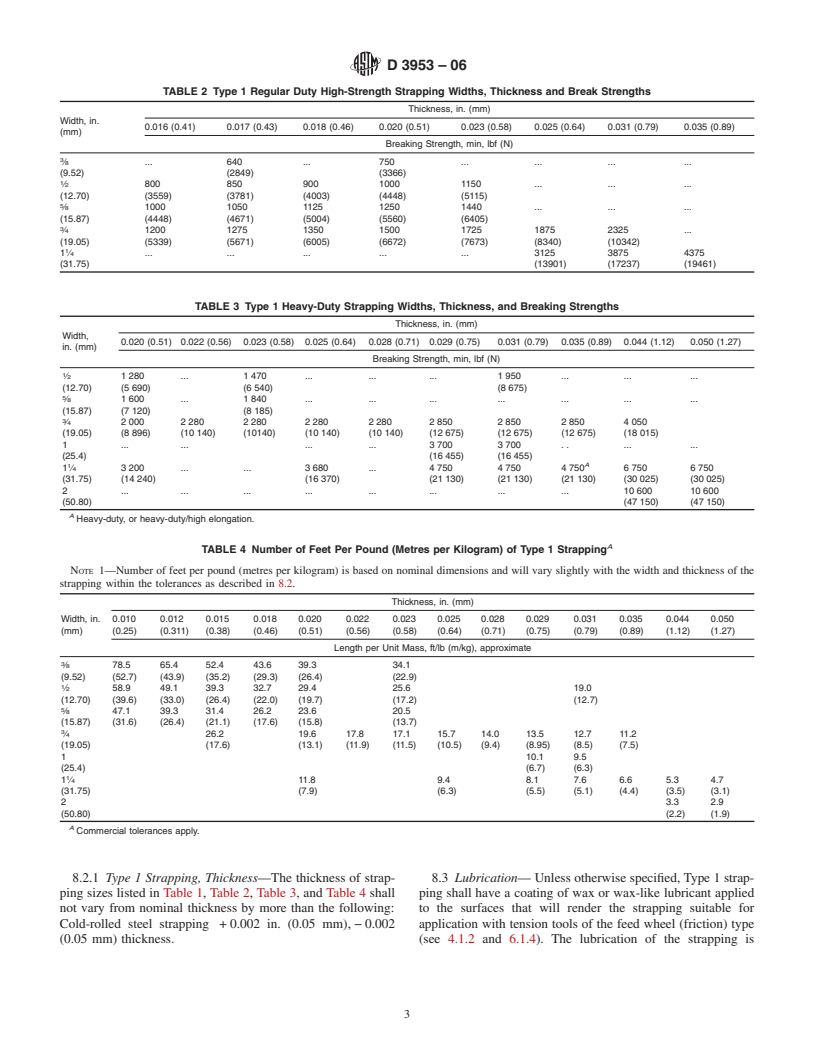

4.1.2 Strapping Sizes— Strapping shall have the widths and

7.1 Materials shall be cold-rolled carbon steel of the quality

thicknessesinaccordancewithsizesshowninTable1,Table2,

normally used for this purpose in commercial practice, and the

and Table 3.

physical mechanical property requirements, as determined by

tests, shall be within the allowable limits.

5. Seal Classifications

7.1.1 Type 1 Regular-Duty Strapping—Regular

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.