ASTM F2511-05(2022)

(Specification)Standard Specification for Rollers, Bearing, Needle, Ferrous, Solid

Standard Specification for Rollers, Bearing, Needle, Ferrous, Solid

ABSTRACT

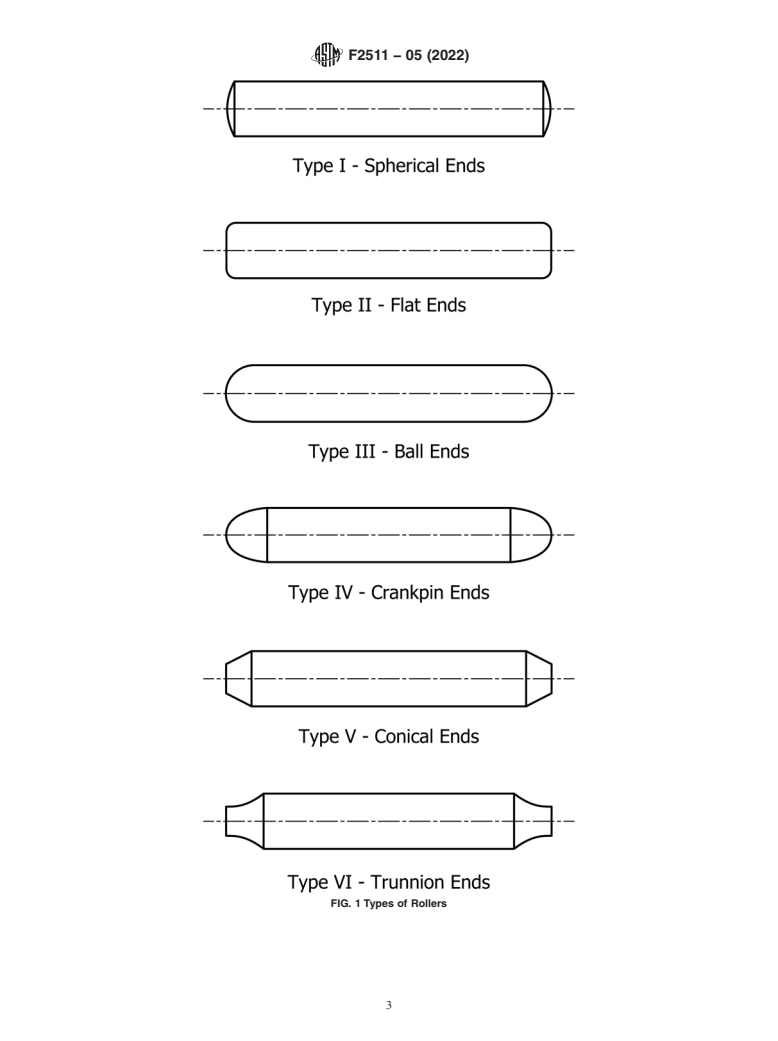

This specification covers the procurement requirements for solid ferrous needle rollers, including the MS19065 spherical ended solid ferrous needle rollers, intended for use in bearings and bearing applications. Rollers shall be made of chrome alloy steel E52100, and manufactured in any of the following types: Type I—spherical end; Type II—flat end; Type III—ball end; Type IV—crankpin end; Type V—conical end; and Type VI—trunnion end. Representative rollers shall be inspected by dimensional and visual examination, surface roughness examination, hot acid etch test, decarburization test, hardness test, chemical analysis, macro-examination, austenitic grain size test, and inclusion rating test.

SCOPE

1.1 This specification covers the procurement requirements for solid ferrous needle bearing rollers including the MS19065 spherical ended solid ferrous needle rollers as specified in Specification F2443.

1.2 Intended Use—The rollers covered in this specification are intended for use in bearings and bearing applications.

1.3 This specification contains many of the requirements of MIL-R-22440, which was originally developed by the Department of Defense and maintained by the Defense Supply Center in Richmond. The following government activity codes may be found in the Department of Defense, Standardization Directory SD-1.2

Preparing Activity

Custodians

Review Activities

DLA-GS4

Army-AT

Army-CR4

Navy-OS

Air Force-84

Air Force-99

DLA-GS4

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2511 −05 (Reapproved 2022)

Standard Specification for

Rollers, Bearing, Needle, Ferrous, Solid

This standard is issued under the fixed designation F2511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers the procurement requirements 2.1 ASTM Standards:

for solid ferrous needle bearing rollers including the MS19065 A295/A295M Specification for High-Carbon Anti-Friction

spherical ended solid ferrous needle rollers as specified in Bearing Steel

Specification F2443. A751 Test Methods and Practices for Chemical Analysis of

Steel Products

1.2 Intended Use—The rollers covered in this specification

D1974/D1974M Practice for Methods of Closing, Sealing,

are intended for use in bearings and bearing applications.

and Reinforcing Fiberboard Boxes

1.3 This specification contains many of the requirements of

D3951 Practice for Commercial Packaging

MIL-R-22440, which was originally developed by the Depart-

D3953 Specification for Strapping, Flat Steel and Seals

ment of Defense and maintained by the Defense Supply Center

D5118/D5118M PracticeforFabricationofFiberboardShip-

inRichmond.Thefollowinggovernmentactivitycodesmaybe

ping Boxes

found in the Department of Defense, Standardization Directory

D5168 Practice for Fabrication and Closure of Triple-Wall

SD-1.

Corrugated Fiberboard Containers

Preparing Activity Custodians Review Activities

D6251/D6251M Specification forWood-Cleated Panelboard

DLA-GS4 Army-AT Army-CR4

Shipping Boxes

Navy-OS Air Force-84

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Air Force-99

DLA-GS4

terials

1.4 The values stated in inch-pound units are to be regarded E140 Hardness Conversion Tables for Metals Relationship

Among Brinell Hardness, Vickers Hardness, Rockwell

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only Hardness, Superficial Hardness, Knoop Hardness, Sclero-

scope Hardness, and Leeb Hardness

and are not considered standard.

E381 Method of Macroetch Testing Steel Bars, Billets,

1.5 This standard does not purport to address all of the

Blooms, and Forgings

safety concerns, if any, associated with its use. It is the

E384 Test Method for Microindentation Hardness of Mate-

responsibility of the user of this standard to establish appro-

rials

priate safety, health, and environmental practices and deter-

F2443 Specification for Roller, Bearing, Needle, Ferrous,

mine the applicability of regulatory limitations prior to use.

Solid, Spherical End

1.6 This international standard was developed in accor-

2.2 ANSI Standards:

dance with internationally recognized principles on standard-

ASME B46.1 Surface Texture (Surface Roughness,

ization established in the Decision on Principles for the

Waviness, and Lay)

Development of International Standards, Guides and Recom-

ASME Y14.5 Dimensioning and Tolerancing

mendations issued by the World Trade Organization Technical

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

Barriers to Trade (TBT) Committee.

spection by Attributes

ThisspecificationisunderthejurisdictionofASTMCommitteeF34onRolling

Element Bearings and is the direct responsibility of Subcommittee F34.01 on

Rolling Element.

Current edition approved Jan. 1, 2022. Published January 2022. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 2005. Last previous edition approved in 2013 as F2511 – 05(2013). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/F2511-05R22. Standards volume information, refer to the standard’s Document Summary page on

The Military codes that are listed in SD-1 give the address and phone numbers the ASTM website.

of the DoD contacts. These are found in the DoD’s ASSIST website http:// Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

assist.daps.dla.mil/online/start/. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2511 − 05 (2022)

2.3 ISO Standards: 5. Ordering Information

ISO 5593 Rolling Bearings—Vocabulary

5.1 Procurement documents should specify the following:

ISO 10012–1 Quality Assurance Requirements for Measur-

5.1.1 Title, number, and date of this specification,

ing Equipment

5.1.2 Type of rollers required (see 4.1),

2.4 Military Standards:

5.1.3 Material required, if different than 6.1,

MIL-PRF-121 Barrier Materials, Greaseproof, Waterproof,

5.1.4 Diameter and length of rollers required (see 8.1),

Flexible, Heat-Sealable

5.1.5 Quantity required,

MIL-STD-129 Military Marking for Shipment and Storage

5.1.6 Dimensions and tolerances governing formulation of

MIL-PRF-131 Barrier Materials, Watervaporproof,

roller ends, if different than 8.1,

Greaseproof, Flexible, Heat-Sealable

5.1.7 Inspection records required (see 16.1.1),

MIL-STD-2073-1 DODStandardPracticeforMilitaryPack-

5.1.8 Required levels of packaging (see 15.1),

aging

5.1.9 Preservative required, if different than 15.2.1.2 and

MIL-PRF-22191 Barrier Materials, Transparent, Flexible,

15.2.1.3,

Heat-Sealable

5.1.10 Method of unit packaging required (see 15.2.1.3),

MIL-R-22440 Roller, Bearing, Needle, Ferrous, Solid

5.1.11 Number of rollers per unit package (see 15.2.1.3),

5.1.12 When case liner is not required (see 15.3.1.3), and

2.5 SAE Standards:

5.1.13 Special marking, if required (see 15.4).

SAEAMS-STD-66 Steel, Chemical Composition and Hard-

enability

6. Materials and Manufacture

SAE J418a Grain Size Determination of Steel

6.1 Material—Unless otherwise specified in the contract or

3. Terminology

order (see Section 5), the rollers shall be manufactured from

chrome alloy steel conforming to the chemical composition of

3.1 Definitions—For definitions of terms used in this

steel number AISI E52100 of SAE AMS-STD-66, AMS 6440

specification, refer to ISO 5593.

or AMS 6444. The steel shall be homogeneous in structure,

3.2 Definitions of Terms Specific to This Standard:

free from pipes, seams, laminations, bursts, flakes, excessive

3.2.1 heat of steel—batch of steel that was produced in a

segregation, and other detrimental defects (see 11.2.1). The

single furnace run. Steel from the same “heat” may be found in

steelshallhaveanaustenitegrainsizeof7orfiner(see11.3.3).

several different billets, bars, or coils of wire.

The rollers shall be free from surface decarburization (see

3.2.2 lot—lot shall consist of the finished rollers of the same

11.2.2).

type, diameter, length, and material, manufactured under the

6.1.1 Inclusion Rating—The chrome alloy steel shall not

same conditions, and submitted for acceptance at the same

exceed the inclusion rating specified for billets for wire and

time.This inspection lot shall be identified by a unique number

rods used in the manufacture of balls and rollers, as specified

(manufacturer’s lot control number) that will provide the

in Specification A295/A295M.

traceability of the rollers to be finished bearing assemblies.

7. Other Requirements

3.2.3 surface roughness (Ra)—the Ra, or roughness

average, surface roughness is the arithmetic average of the

7.1 Hardness—The rollers shall have a uniform hardness of

absolute value of the departure of the filtered roughness profile

60 to 64 Rockwell C or equivalent (see 11.2.3).

measured from the mean line. Ra values are normally specified

8. Dimensions and Permissible Variations

in microinches (micrometres). 1 µin. = 0.0254 µm (1 µm =

39.37 µin.). SeeASME B46.1 for more information on surface

8.1 Construction and Dimensions—The rollers shall be of

roughness.

the type, diameter, and length specified in the contract or order

(see Section 5) and shall be of solid construction. An illustra-

4. Classification

tion of the types of rollers covered herein is shown in Fig. 1.

Unless otherwise specified in the contract or order (see Section

4.1 The rollers shall be of the following types, as specified

in the contract or order (see Section 5 and Fig. 1): 5), dimensions and tolerances governing the formation of the

ends of the roller shall be in accordance with commercial

4.1.1 Type I—Spherical end.

4.1.2 Type II—Flat end. practice. Dimensions and tolerances shall be interpreted in

accordance was ASME Y14.5.

4.1.3 Type III—Ball end.

4.1.4 Type IV—Crankpin end. 8.1.1 Diameter—The diameter of the roller shall be within

+0.0000 in. (+0.000 mm) to –0.0002 in. (–0.005 mm) of the

4.1.5 Type V—Conical end.

4.1.6 Type VI—Trunnion end. value specified in the contract or order (see Section 5).

8.1.2 Length:

8.1.2.1 Types I, III, V, and VI—The length of the roller shall

be within +0.000 in. (+0.00 mm) to –0.020 in. (–0.51 mm) of

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland.

the value specified in the contract or order (see Section 5).

Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

8.1.2.2 Type II—The length of the roller shall be within

Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

+0.000 in. (+0.00 mm) to –0.006 in. (–0.15 mm) of the value

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001. specified in the contract or order (see Section 5).

F2511 − 05 (2022)

FIG. 1 Types of Rollers

F2511 − 05 (2022)

8.1.2.3 Type IV—The length of the roller shall be within The test procedures shall be in accordance with Test Methods

+0.000 in. (+0.00 mm) to –0.010 in. (–0.25 mm) of the value E18 Rockwell for superficial hardness tests and Test Method

specified in the contract or order (see Section 5). E384 for microhardness testing. Tables E140 shall be used for

hardness conversion to the C Rockwell scale. The rollers shall

9. Workmanship, Finish, and Appearance

be subjected to the test on flats of sufficient width, and material

9.1 Visual Appearance—Thecylindricalsurfaceoftheroller

of sufficient thickness, to give a true reading. For rollers less

shall be free from scratches, pits, rust, indications of soft spots,

than ⁄16 in. (1.6 mm) in diameter, an appropriate superficial

and other surface imperfections.

hardness or microhardness method shall be used. If any unit of

the sample does not comply with the requirements of 7.1, the

9.2 Surface Roughness—The surface roughness of the roller

lot shall be rejected. The manufacturer may have a standard

diameter shall not exceed 8 µin. Ra (0.20 µm Ra). Surface

repair procedure to retemper the rollers. The rollers would

roughness shall be interpreted in accordance with ASME

require reinspection after a retempering process.

B46.1.

11.3 Inspection of Material—The material used in the

10. Sampling

manufacture of the rollers furnished under this specification

10.1 For Examination—Asampleofrollersshallbeselected

shall have been inspected in accordance with and passed the

from each lot by the inspector in accordance with the proce-

following examination and tests.

dures of ANSI/ASQ Z1.4 with an AQL of 1.0%.

11.3.1 Chemical Analysis—A chemical analysis shall be

made on each heat of steel. The samples for analysis shall be

10.2 For Tests—A sample of rollers shall be selected from

selected from the billets, bars, or wire used in the manufacture

each lot by the inspector in accordance with the procedures of

of the rollers. The chemical analysis shall be conducted in

ANSI/ASQ Z1.4 with an AQL of 4.0%.

accordance with the test methods of the material specification

11. Inspection

or Test Methods, Practices, and Terminology A751. The

chemical composition determined by the above procedures

11.1 Examination:

shall be within the check analysis tolerances specified in SAE

11.1.1 Dimensional and Visual Examination— The sample

AMS-66 and standard industry practice.

rollers, selected in accordance with 10.1, shall be dimension-

11.3.2 Macro-Examination—A macro-examination shall be

ally and visually examined to determine compliance with 8.1

made on each heat of steel. The samples for examination shall

and 9.1 respectively.Any unit of the sample containing one or

be selected from the billets for the wire or rods used in the

more defects shall be rejected. If no defects are found in the

manufacture of the rollers. The samples shall be selected in

sample, the sample lot shall be accepted. If any defects are

accordance with Method E381. The macro-examination shall

found in the sample, the entire lot shall be inspected for the

be conducted in accordance with Method E381. The quality

defective characteristic and defective parts removed from the

and cleanliness of the steel as indicated by the results of the

lot.

macroexaminationshallbeequaltoorbetterthanmacrographs

11.1.2 Surface Roughness Examination— The sample

S2, R2, and C2 of Method E381 with defects Dl through D8

rollers, selected in accordance with 10.1, shall be examined to

unacceptable.

determine compliance with 9.2.Any unit of the sample, which

11.3.3 Austenitic Grain Size Test—An austenitic grain size

doesnotcomplywiththerequirementsspecifiedin9.2,shallbe

test shall be made on each heat of steel. The samples for test

rejected. Lot acceptance shall be in accordance with 10.1.Ifno

shall be selected from the billets for the wire or rods used in

defects are found in the sample, the sample lot shall be

accordance with SAE J418a. The austenitic grain size deter-

accepted. If any defects are found in the sample, the entire lot

mined by the above procedures shall be within the range

shall be inspected for the defective characteristic and defective

specified in 6.1.

parts removed from the lot.

11.3.4 Inclusion Rating Test—An inclusion rating test shall

11.2 Tests:

be made on each heat of steel. The samples for test shall be

11.2.1 Hot Acid Etch Test—The sample rollers, selected in

selected from the billets for the wire or rods used in the

accordance with 10.2, shall be etched for a minimum period of

manufacture of the rollers. The test shall be conducted in

15mininasolutionof50 %hydrochloricacidand50 %water.

accordance with the inclusion rating test specified in Specifi-

Thetemperatureofthesolutionshallbe160 °Fto180 °F.After

cation A295/A295M. The inclusion rating determined by the

etch

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.