ASTM D2274-14(2019)

(Test Method)Standard Test Method for Oxidation Stability of Distillate Fuel Oil (Accelerated Method)

Standard Test Method for Oxidation Stability of Distillate Fuel Oil (Accelerated Method)

SIGNIFICANCE AND USE

5.1 This test method provides a basis for the estimation of the oxidation stability of middle distillate fuels such as No. 2 fuel oil.

5.2 The test method may not provide a prediction of the quantity of insolubles that will form in field storage over any given period of time. The amount of insolubles formed in such field storage is subject to the specific conditions which are too variable for this test method to predict accurately.

5.3 Test Method D2274 yields results more rapidly than Test Method D4625, the 43 °C bottle test. However, as a result of the significantly elevated temperature and the pure oxygen atmosphere, the nature and amount of insolubles may deviate to a greater extent than Test Method D4625 from those formed in field storage.

SCOPE

1.1 This test method covers the measurement of the inherent stability of middle distillate petroleum fuels under specified oxidizing conditions at 95 °C.

Note 1: Fuels used in establishing the precision measures for this test method were described as gas oil, diesel fuel, No. 2 heating oil, and DFM, a Navy distillate fuel suitable for diesels, boilers, and gas turbines. (The term DFM is no longer used when referring to fuel meeting MIL-F-16884 requirements; rather it is called F76 as it conforms to NATO F76 requirements.) While the test method may be used for fuels outside the range of these fuels, the precision measures may not apply.

1.2 This test method is not applicable to fuels containing residual oil. This test method has not been validated for testing biodiesel, such as meeting Specification D6751 or blends of middle distillates and biodiesel, such as meeting Specification D7467, or both. Test Method D7462 has been determined to be suitable for testing B100 and all blends of middle distillates and biodiesel.

Note 2: No. 1 and No. 2 grades in Specifications D396 or D975 currently allow up to 5 % biodiesel meeting Specification D6751. Samples containing biodiesel can result in partial dissolution or compromise of the membrane filter and give erroneous results.

1.3 The values given in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2274 −14 (Reapproved 2019)

Designation: 388⁄97

Standard Test Method for

Oxidation Stability of Distillate Fuel Oil (Accelerated

Method)

This standard is issued under the fixed designation D2274; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 Thistestmethodcoversthemeasurementoftheinherent

stability of middle distillate petroleum fuels under specified

2. Referenced Documents

oxidizing conditions at 95 °C.

2.1 ASTM Standards:

NOTE 1—Fuels used in establishing the precision measures for this test

D381 Test Method for Gum Content in Fuels by Jet Evapo-

method were described as gas oil, diesel fuel, No. 2 heating oil, and DFM,

ration

a Navy distillate fuel suitable for diesels, boilers, and gas turbines. (The

term DFM is no longer used when referring to fuel meeting MIL-F-16884

D396 Specification for Fuel Oils

requirements; rather it is called F76 as it conforms to NATO F76

D943 Test Method for Oxidation Characteristics of Inhibited

requirements.) While the test method may be used for fuels outside the

Mineral Oils

range of these fuels, the precision measures may not apply.

D975 Specification for Diesel Fuel

1.2 This test method is not applicable to fuels containing

D1193 Specification for Reagent Water

residual oil. This test method has not been validated for testing

D4057 Practice for Manual Sampling of Petroleum and

biodiesel, such as meeting Specification D6751 or blends of

Petroleum Products

middle distillates and biodiesel, such as meeting Specification

D4177 Practice for Automatic Sampling of Petroleum and

D7467, or both.Test Method D7462 has been determined to be

Petroleum Products

suitable for testing B100 and all blends of middle distillates

D4625 Test Method for Middle Distillate Fuel Storage

and biodiesel.

Stability at 43 °C (110 °F)

NOTE 2—No. 1 and No. 2 grades in Specifications D396 or D975 D6751 Specification for Biodiesel Fuel Blend Stock (B100)

currentlyallowupto5 %biodieselmeetingSpecificationD6751.Samples

for Middle Distillate Fuels

containing biodiesel can result in partial dissolution or compromise of the

D7462 Test Method for Oxidation Stability of Biodiesel

membrane filter and give erroneous results.

(B100) and Blends of Biodiesel with Middle Distillate

1.3 The values given in SI units are to be regarded as the

Petroleum Fuel (Accelerated Method) (Withdrawn 2016)

standard. The values in parentheses are for information only.

D7467 Specification for Diesel Fuel Oil, Biodiesel Blend

1.4 This standard does not purport to address all of the (B6 to B20)

safety concerns, if any, associated with its use. It is the

2.2 Military Specification:

responsibility of the user of this standard to establish appro-

MIL-F-16884 Fuel, Navy Distillate

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3. Terminology

1.5 This international standard was developed in accor-

3.1 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of Committee D02 on Petroleum Standards volume information, refer to the standard’s Document Summary page on

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom- the ASTM website.

mittee D02.14 on Stability, Cleanliness and Compatibility of Liquid Fuels. The last approved version of this historical standard is referenced on

Current edition approved Dec. 1, 2019. Published December 2019. Originally www.astm.org.

approved in 1964. Last previous edition approved in 2014 as D2274 – 14. DOI: Available from Standardization Documents Order Desk, Bldg. 4, 700 Robbins

10.1520/D2274-14R19. Ave., Philadelphia, PA 19111-5098. Attn: NPODS

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2274 − 14 (2019)

3.1.1 adherent insolubles (formerly adherent gum), coils of copper and steel are used, it is important that any

n—material which is produced in the course of stressing residues that could contain these metals be eliminated from the

distillate fuel under the conditions of this test and which apparatus by thorough cleaning prior to use. Similarly, to

adheres to the glassware after fuel has been flushed from the preclude the presence of chromium ions, as well as to protect

system. laboratory personnel from potential harm, chromic acid shall

not be used for cleaning glassware in the practice of this

3.1.2 filterable insolubles, n—material, which is produced

method.

in the course of stressing distillate fuel under the conditions of

this test, which is capable of being removed from the fuel by

6.2 It has been found that commercial grades of acetone, if

filtration.This includes both material suspended in the fuel and

used in the trisolvent, can have impurities which cause an

material easily removed from the oxidation cell and oxygen

apparently greater level of adherent insolubles to be measured.

delivery tube with hydrocarbon solvent.

It is, therefore, critical that only reagent (or higher) grade

materials be used in preparing the trisolvent mixture.

3.1.3 inherent stability, n—the resistance to change when

the fuel is exposed to air, but in the absence of other

6.3 Ultraviolet light exposure has been found to increase the

environmental factors such as water, or reactive metals and

amount of total insolubles. Therefore, the fuel being tested

dirt.

shall be shielded from direct exposure to ultraviolet light

(sunlight or fluorescent). Conduct all sampling, measuring,

3.1.4 totalinsolubles,n—arithmeticsumoftheadherentand

filtration, and weighing away from direct sunlight and in as

filterable insolubles.

dark an area as would be compatible with other laboratory

3.1.5 zero time, n—the time the first of a batch of oxidation

operations. Storage before stress, the stress period and cool-

cells is placed in the heating bath.

down after stressing shall be in the dark.

3.1.5.1 Discussion—This is the time taken as the start of the

16 h of residence in the heating bath.

7. Apparatus

NOTE 3—It is suggested that all measuring equipment be calibrated

4. Summary of Test Method

according to manufacturer’s instructions on a periodic basis to assure

consistency of results.

4.1 A 350 mL volume of filtered middle distillate fuel is

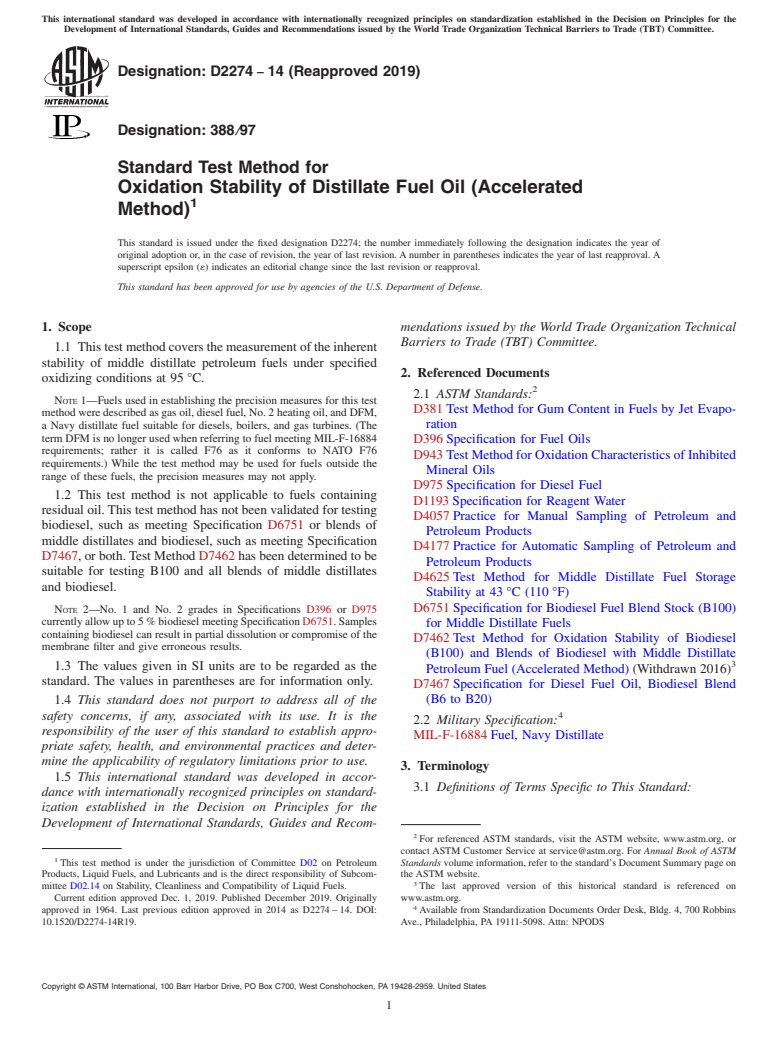

7.1 Oxidation Cell, of borosilicate glass, as shown in Fig. 1,

aged at 95 °C (203 °F) for 16 h while oxygen is bubbled

shall consist of a test tube, condenser, and oxygen delivery

through the sample at a rate of 3 L/h. After aging, the sample

tube. This cell is identical to that used in Test Method D943.

is cooled to approximately room temperature before filtering to

obtain the filterable insolubles quantity. Adherent insolubles

7.2 Heating Bath, with a thermostatically controlled liquid

are then removed from the oxidation cell and associated

medium, shall be capable of maintaining the bath temperature

glasswarewithtrisolvent.Thetrisolventisevaporatedtoobtain

at 95 °C 6 0.2 °C (203 °F 6 0.4 °F). It shall be fitted with a

the quantity of adherent insolubles. The sum of the filterable

suitable stirring device to provide a uniform temperature

and adherent insolubles, expressed as milligrams per 100 mL,

throughoutthebath.Itshallbelargeenoughtoholdthedesired

is reported as total insolubles.

number of oxidation cells immersed to a depth of approxi-

mately 350 mm. Further, the bath construction must permit

5. Significance and Use

shielding the fuel samples in the oxidation cells from light

while they are undergoing oxidation.

5.1 This test method provides a basis for the estimation of

the oxidation stability of middle distillate fuels such as No. 2

7.3 Flowmeters, shall have a capability of measuring 3 L⁄h

fuel oil.

60.3 L⁄hofoxygen.Oneflowmetershallbeprovidedforeach

oxidation cell.

5.2 The test method may not provide a prediction of the

quantity of insolubles that will form in field storage over any

7.4 Filter Drying Oven, shall be capable of safely evapo-

given period of time. The amount of insolubles formed in such

rating the solvent at 80 °C 6 2 °C (176 °F 6 4 °F) for the

field storage is subject to the specific conditions which are too

drying of filters.

variable for this test method to predict accurately.

7.5 Glassware Drying Oven, shall be capable of drying

5.3 TestMethodD2274yieldsresultsmorerapidlythanTest

glassware at 105 °C 6 5 °C (221 °F 6 9 °F).

Method D4625, the 43 °C bottle test. However, as a result of

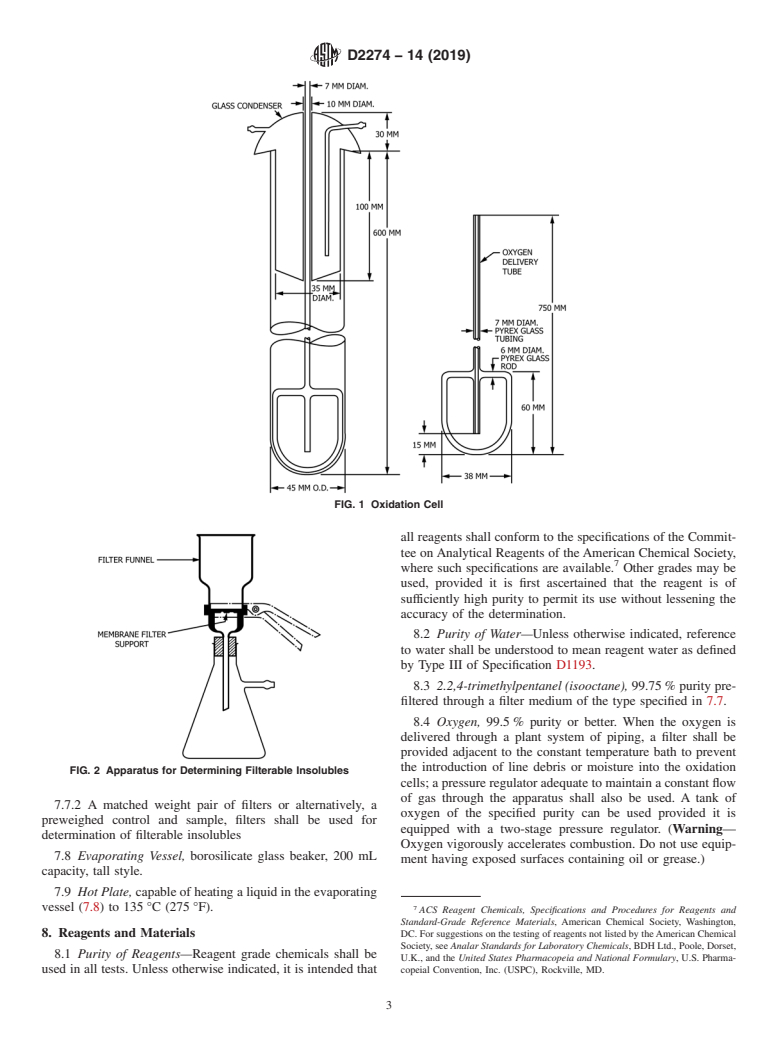

7.6 Filtration Assembly, see Fig. 2, shall be capable of

the significantly elevated temperature and the pure oxygen

holding the filters described in 7.7.

atmosphere, the nature and amount of insolubles may deviate

7.7 Filter Media , 47 mm diameter cellulose ester

to a greater extent than Test Method D4625 from those formed

surfactant-free membrane filters with a nominal pore size of

in field storage.

0.8 µm.

7.7.1 Single filters are to be used for prefiltration.

6. Interferences

6.1 Oxidation is a major chemical process causing adherent

This apparatus is available from suppliers of specialty petroleum testing

and filterable insolubles to form.Any substance such as copper

equipment.

or chromium that catalyzes oxidation reactions will cause

Supporting data have been filed at ASTM International Headquarters and may

greater quantities of insolubles to form. Since the apparatus

be obtained by requesting Research Report RR:D02-1012. Filters may be qualified

used in this test can also be used in Test Method D943, where using the procedure in this research report.

D2274 − 14 (2019)

FIG. 1 Oxidation Cell

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

accuracy of the determination.

8.2 Purity of Water—Unless otherwise indicated, reference

to water shall be understood to mean reagent water as defined

by Type III of Specification D1193.

8.3 2.2,4-trimethylpentanel (isooctane), 99.75 % purity pre-

filtered through a filter medium of the type specified in 7.7.

8.4 Oxygen, 99.5 % purity or better. When the oxygen is

delivered through a plant system of piping, a filter shall be

provided adjacent to the constant temperature bath to prevent

the introduction of line debris or moisture into the oxidation

FIG. 2 Apparatus for Determining Filterable Insolubles

cells; a pressure regulator adequate to maintain a constant flow

of gas through the apparatus shall also be used. A tank of

7.7.2 A matched weight pair of filters or alternatively, a

oxygen of the specified purity can be used provided it is

preweighed control and sample, filters shall be used for

equipped with a two-stage pressure regulator. (Warning—

determination of filterable insolubles

Oxygen vigorously accelerates combustion. Do not use equip-

7.8 Evaporating Vessel, borosilicate glass beaker, 200 mL

ment having exposed surfaces containing oil or grease.)

capacity, tall style.

7.9 Hot Plate, capable of heating a liquid in the evaporating

vessel (7.8) to 135 °C (275 °F).

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

8. Reagents and Materials DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

8.1 Purity of Reagents—Reagent grade chemicals shall be

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

used in all tests. Unless otherwise indicated, it is intended that copeial Convention, Inc. (USPC), Rockville, MD.

D2274 − 14 (2019)

8.5 Trisolvent, a mixture of equal volumes of acetone, 11. Procedure

methanol, and toluene. See 8.1.(Warning—It is particularly

11.1 Preparing the Sample—Place one filter (described in

important that technical, commercial, practical, or industrial

7.7) on the filter support and clamp the filter funnel to the

grades (however they are designated by the particular manu-

support as shown in Fig. 2. Apply suction (approximately

facturer) are not to be used, as their use may lead to apparently

80 kPa (12 psi)). Pour 400 mLof the fuel through the filter (see

increased levels of adherent insolubles.) (Warning—Fire

7.7) into a clean (10.1) 500 mL glass filtration flask. Repeat

hazard, toxic.)

preparation for each sample to be run. After filtration is

complete, discard the filter media. Never use the same filters

9. Samples and Sampling

for a second increment of fuel, because any material deposited

9.1 When obtaining samples for the laboratory, follow

on the filters by a previous increment of fuel can result in a

Practices D4057 or D4177, or other standard practice capable

greater removal of solids from the next increment.

of providing representative samples.

11.2 Assembling the Oxidation Apparatus:

9.2 Analyze fuel samples as soon as possible after receipt.

11.2.1 Place a clean oxygen delivery tube into a clean

When a fuel cannot be tested within one day, blanket it with an

oxidation cell (Section 10) and pour 350 mL 6 5 mL of the

inert gas such as oxygen-free nitrogen, argon, or helium and

filtered fuel into the cell.As soon thereafter as possible, but in

store at a temperature no higher than 10 °C (50 °F) but not

no case more than 1 h after measuring the fuel, immerse the

lower than the cloud point. (Warning—Plastic containers are

test cell in the 95 °C (203 °F) heating bath. During any interim

not acceptable for samples due to the potential for leaching of

period store the cell in the dark. The level of fuel in the

plasticizers. Samples should be taken preferably in metal cans

oxidation cell shall be below the level of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.